Toggle reversing ratchet wrench

A technology of ratchet wrench and ratchet parts, which is applied in the field of ratchet wrench, and can solve problems such as the inability to accurately move the brake block to change direction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

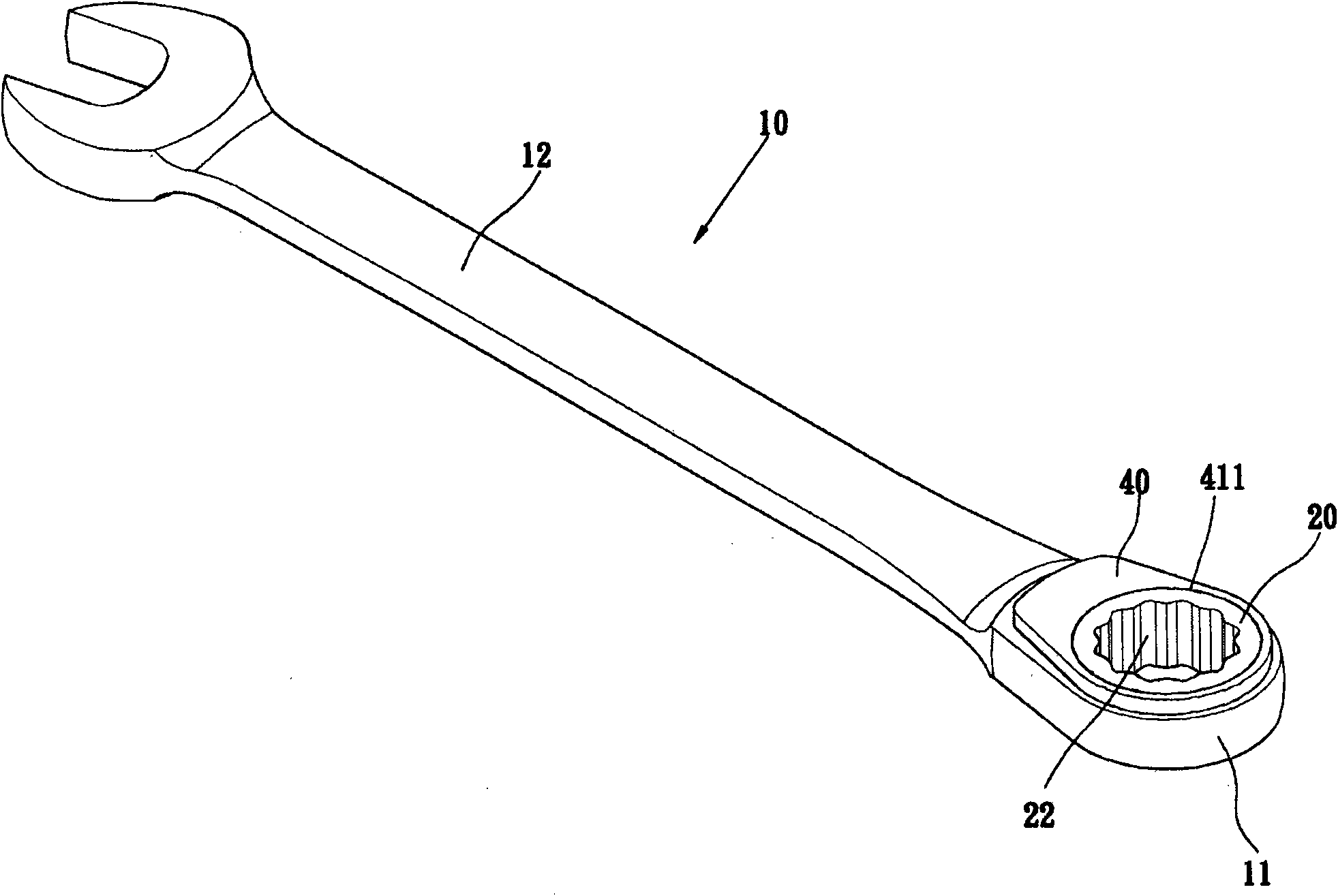

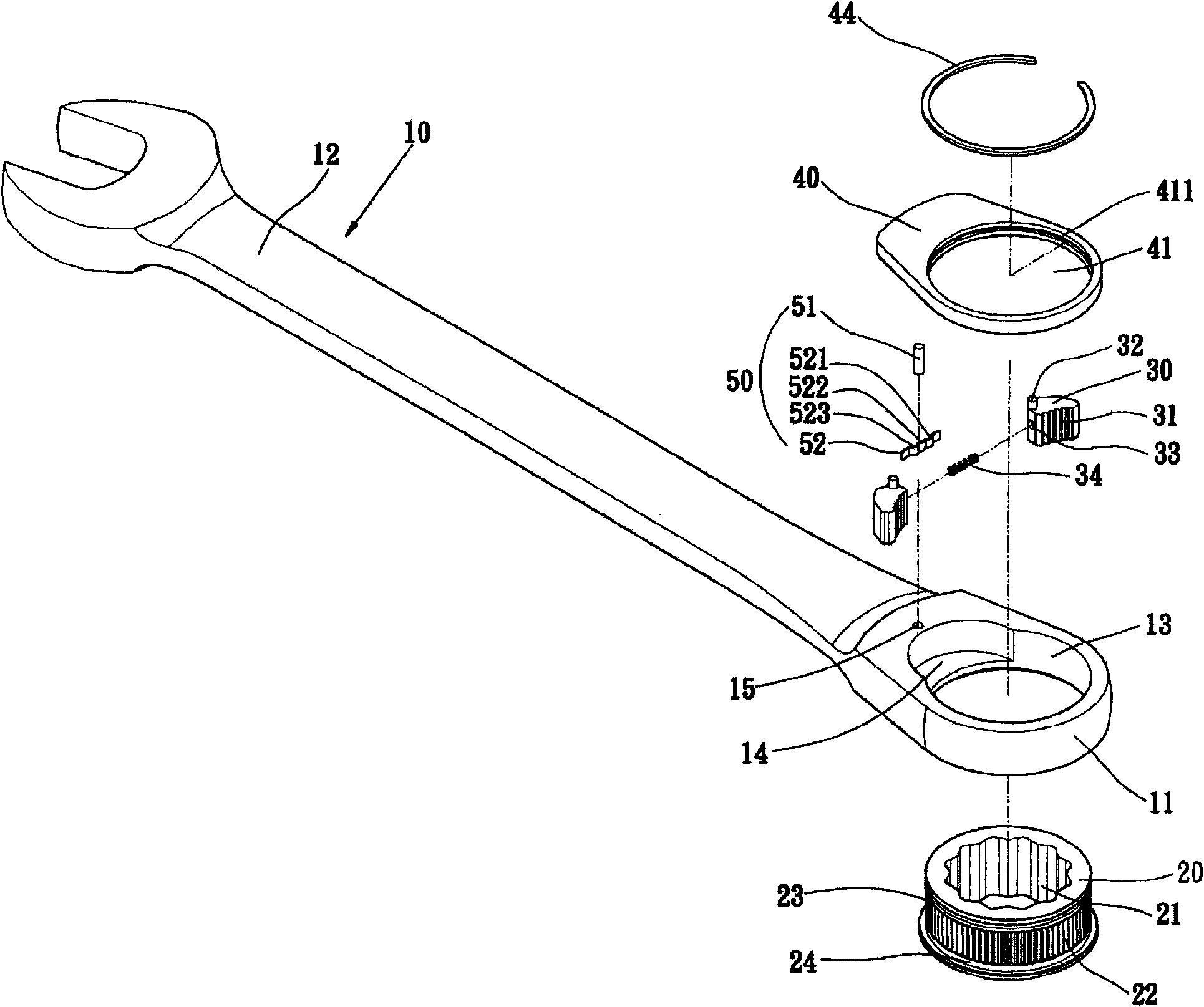

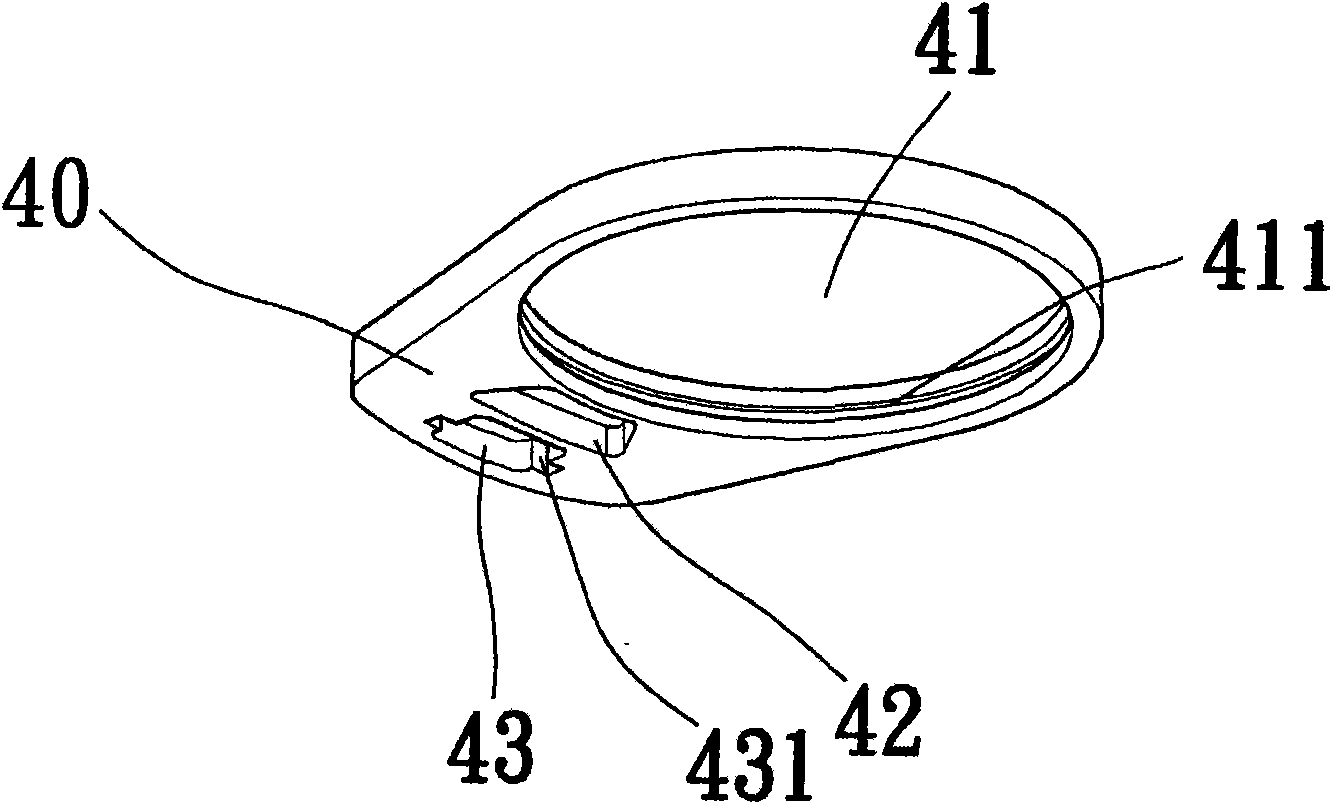

[0032] refer to figure 1 with figure 2 , the present invention provides a toggle type reversing ratchet wrench, in the first embodiment, it includes a body 10, a ratchet part 20, two latching parts 30, a reversing part 40 and a positioning device 50 .

[0033] One end of the main body 10 is provided with a driving part 11 , and the driving part 11 is connected with a gripping part 12 for a user to hold. The drive portion 11 is sequentially provided with a first accommodating portion 13 and a second accommodating portion 14 tangent to the first accommodating portion 13 towards the direction of the gripping portion 12, the first accommodating portion 13 generally has a The circular perforation is provided with a depression 131 at one end of the inner wall surface. The second accommodating portion 14 is generally an arc-shaped groove, and the top edge of the second accommodating portion 14 is hollow and open. A fixing hole 15 is defined behind the driving portion 11 relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com