Multi-angle showerhead of washer

A multi-angle, washing machine technology, applied in the field of washing equipment and multi-angle nozzles of washing machines, can solve the problems of poor washing effect, small spraying range, slow cleaning speed, etc., achieve convenient operation, meet different pressures and cleaning areas, and apply wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

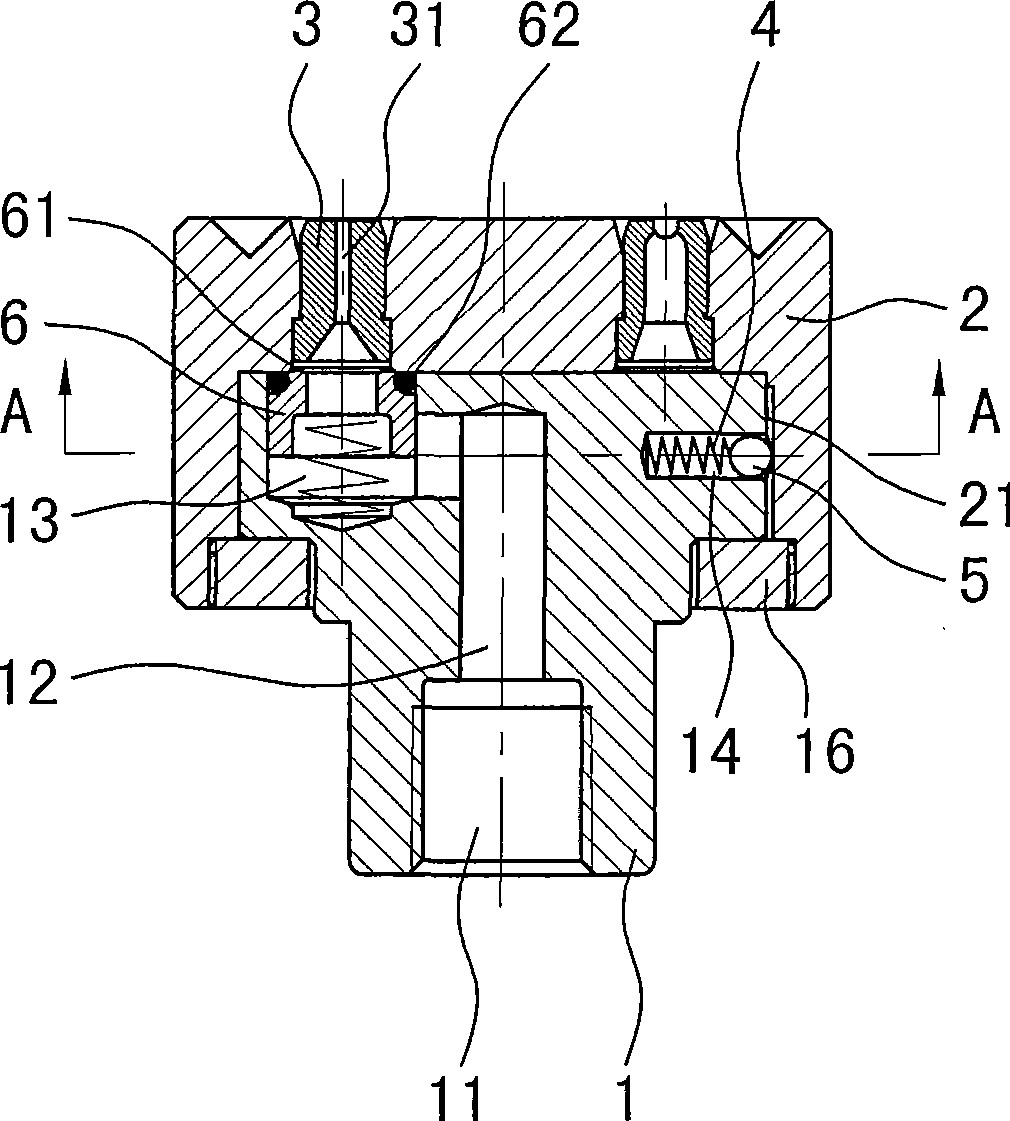

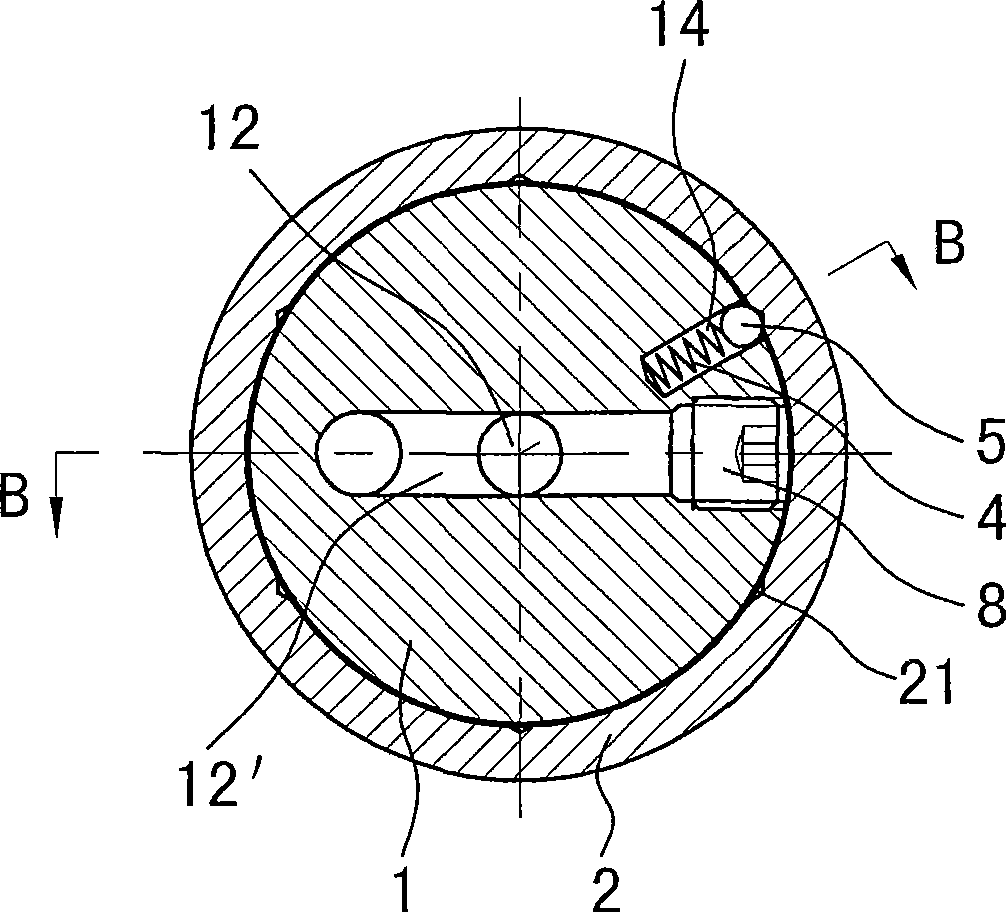

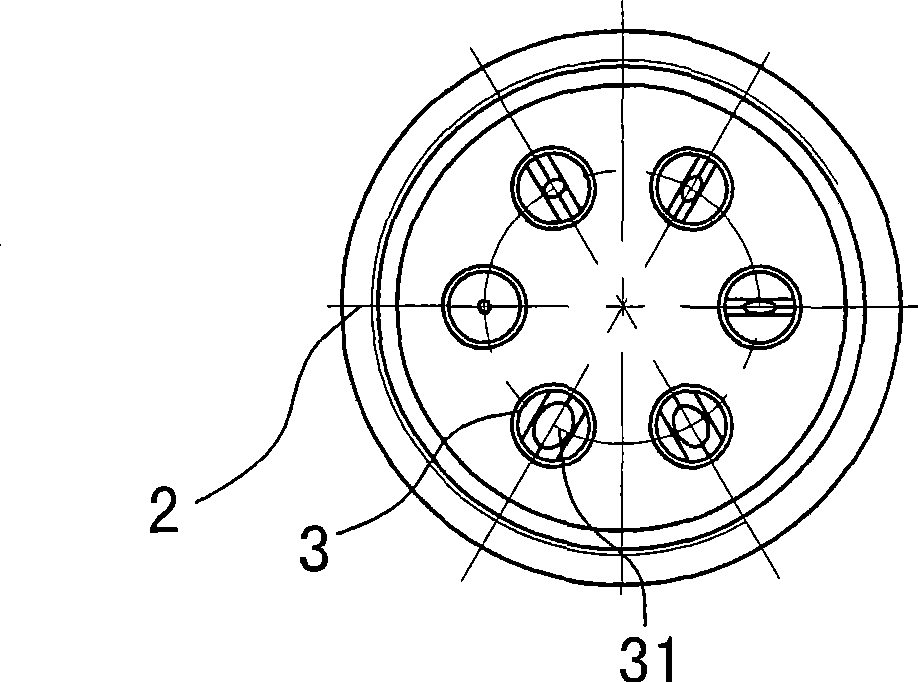

[0014] The invention discloses a cleaning machine multi-angle nozzle, such as figure 1 As shown, it includes the nozzle seat 1, the nozzle seat 1 is formed with a water inlet 11, a flow channel 12 and a water outlet 13, the water inlet 11 is connected to the spray rod, the flow channel 12 is connected to the water inlet 11 and the water outlet 13, and there are nozzles outside the nozzle seat 1 Set 2, the nozzle core 3 is installed in the nozzle cover, the nozzle core is formed with a water spray hole 31, the water spray hole 31 communicates with the water outlet 13, and it is characterized in that the nozzle seat 1 and the nozzle cover 2 are mutually rotatable and movable. One of the structural forms is: the nozzle cover 2 is made with a mounting hole, and the head of the mounting hole is made with an internal thread hole with a larger diameter than the mounting hole. First insert the nozzle seat 1 into the mounting hole, and then insert the locking ring 16 into the nozzle Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com