Improved vertical lime kiln of mixed brick-concrete structure

An improved technology of brick-concrete structure, applied in the improvement field of lime shaft kiln with brick-concrete structure, can solve the problems of increasing the cost of lime per unit yield, affecting the safety of the kiln body structure, and damaging the outer wall of the kiln body, so as to achieve full combustion, Good heat insulation effect, safe and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

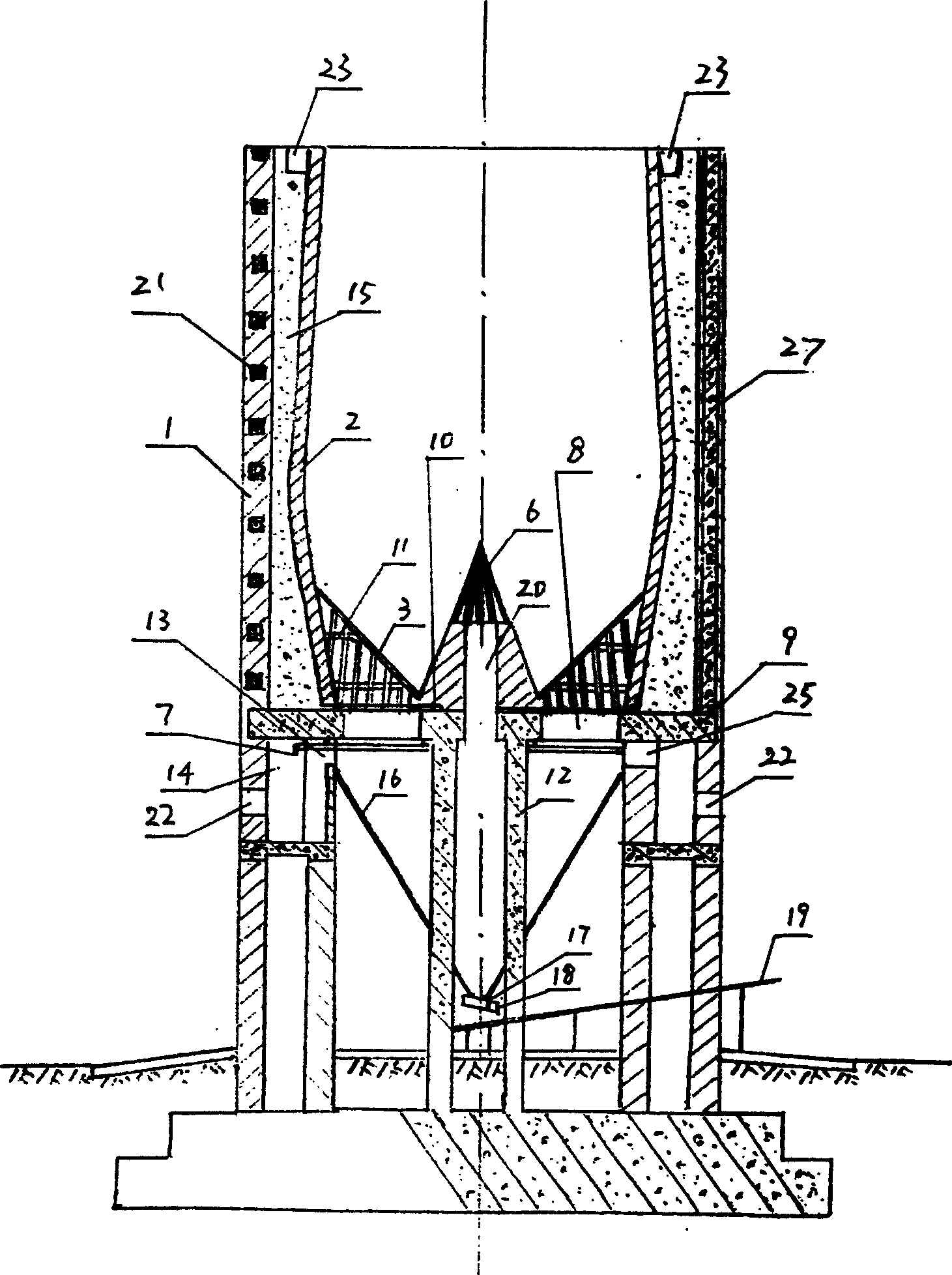

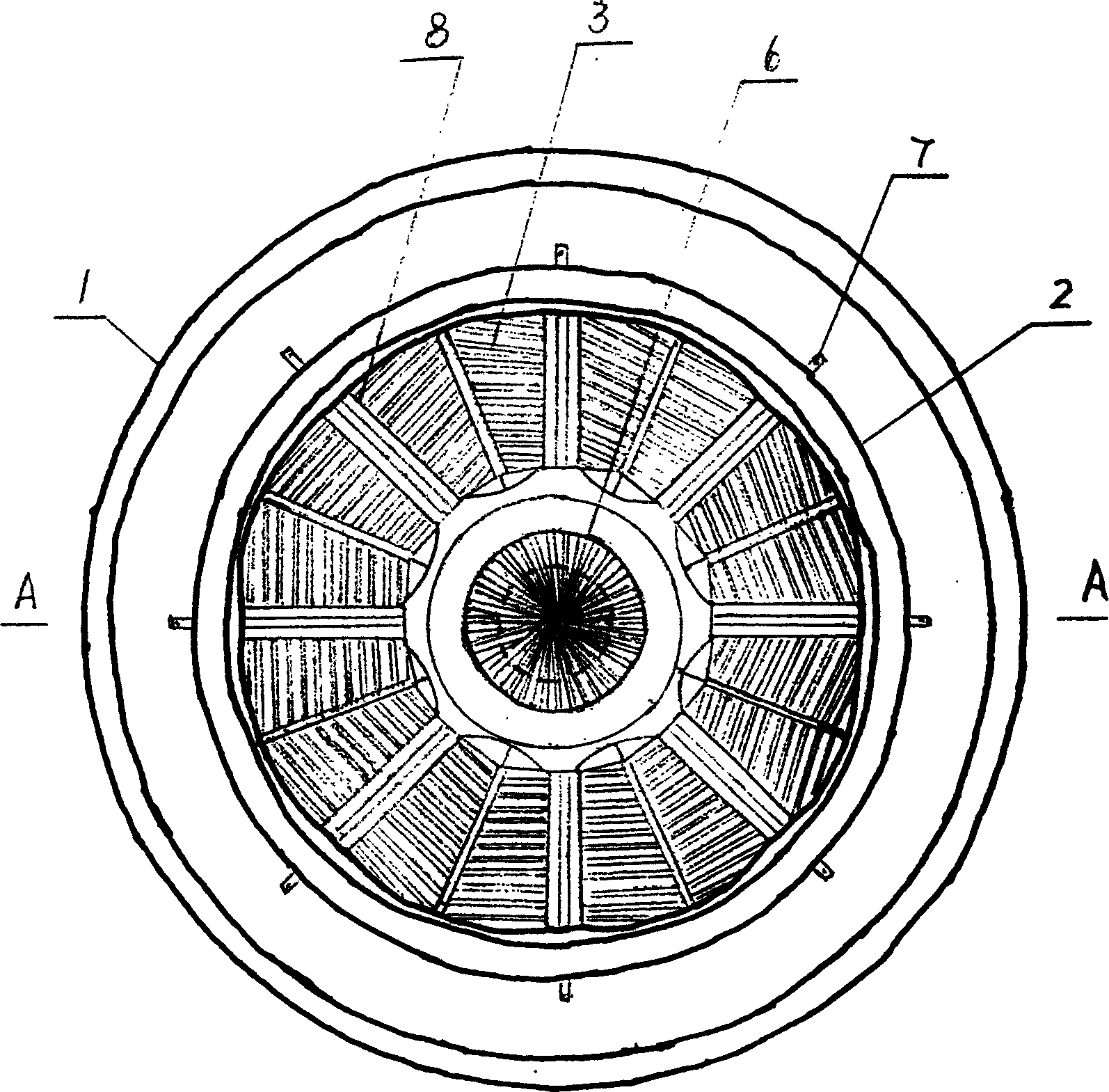

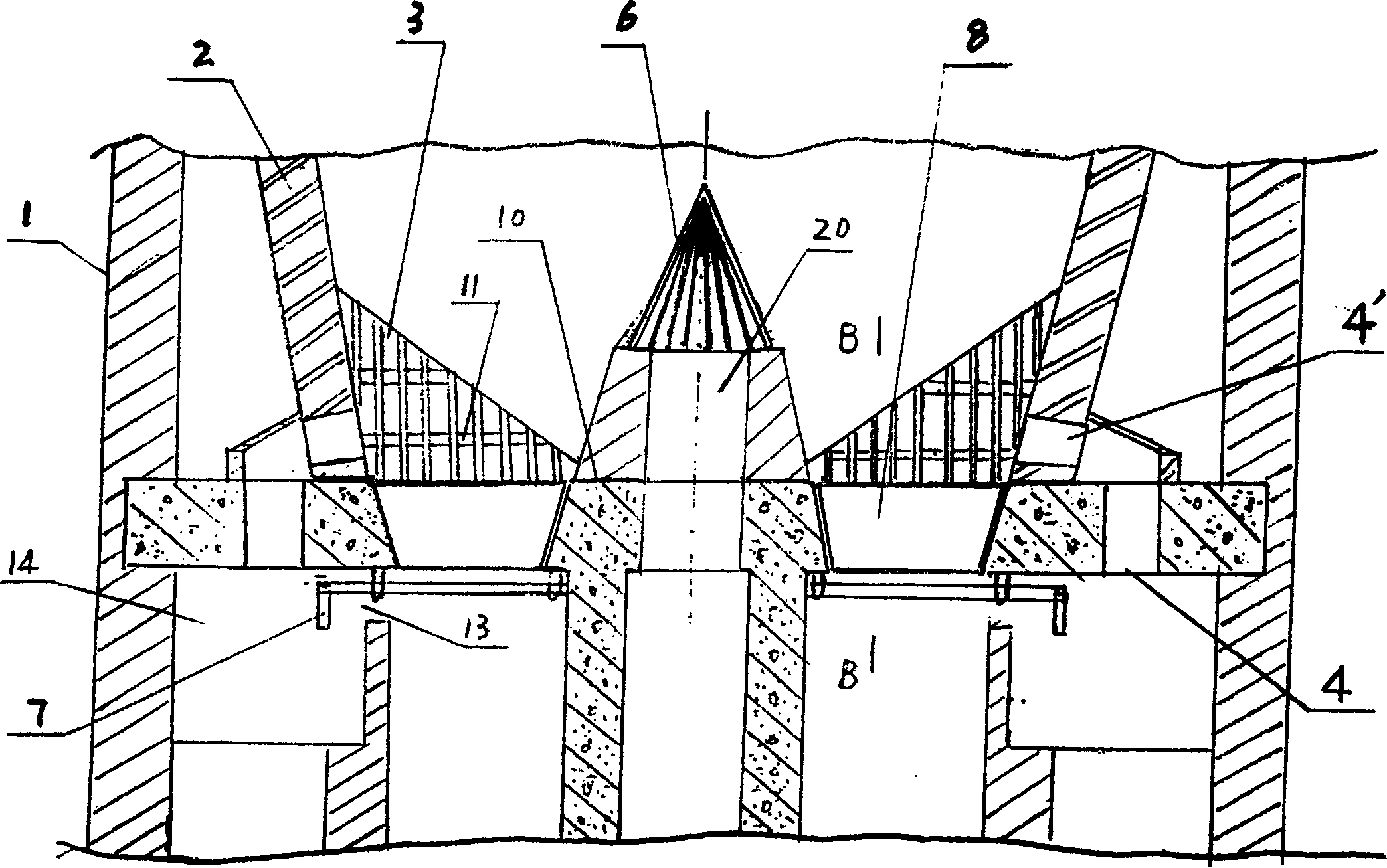

[0021] see figure 1 -- Figure 7 , the kiln outer wall 1 is made of 620mm thick M10 mixed mortar to build red bricks, with eleven reinforced concrete ring beams 21 and eight structural columns 27 inside. dense. Structural columns 27 are evenly distributed. The upper part (preheating zone) of the kiln body lining 2 is made into a circular platform, the diameter of the upper surface of the circular platform is φ7.0m, and the diameter of the bottom of the platform is φ7.6m. When the batch material falls, the surrounding material layer will be loose, and it will leak to the lower material layer. There will be more fuel in the kiln body; the lower part of the kiln body (cooling zone) is made into a circular table shape, the diameter of the upper opening of the circular table is φ7.5m, and the diameter of the lower opening is φ6.66m, which is conducive to the good distribution of air along the cross-section of the kiln body, and also Reduce the size of the discharge unit. The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com