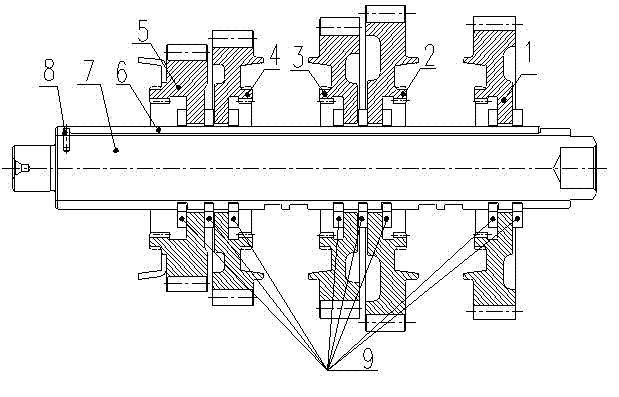

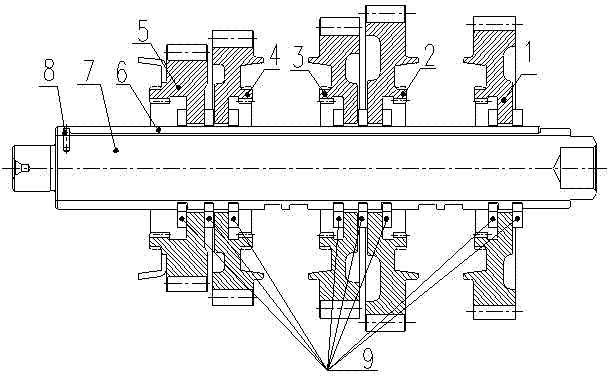

Spindle assembly for double-intermediate-shaft transmission

A technology of double intermediate shafts and transmissions, used in transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of high price, complicated assembly, and many parts, and achieve high durability, strong bearing capacity, and noise. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation manner.

[0012] As shown in the accompanying drawings, a main shaft assembly for a double countershaft transmission includes a main shaft, a number of gears mounted on the main shaft, etc., the main shaft is provided with a long keyway suitable for the size of the main shaft, and the long keyway A hexagonal key 6 is installed inside, and the hexagonal key 6 is axially positioned by the elastic cylindrical pin 8. The gear is installed on the main shaft through the hexagonal key 6, and the main shaft adjustment mated with the hexagonal key 6 is installed on both sides of the gear. The washer 9, the main shaft adjusting washer 9 axially locates the gear. Among them, the gear, the hexagonal key, the main shaft, the elastic cylindrical pin and the main shaft adjusting washer cooperate with each other to form a whole. Through the coope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com