Automobile brake drum machining positioning structure and machining device thereof

A technology for automobile braking and processing devices, which is applied in the direction of grinding workpiece supports, etc., can solve the problems of inconvenient fixing and slow grinding efficiency, and achieve the effect of improving grinding efficiency and simple and quick positioning method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

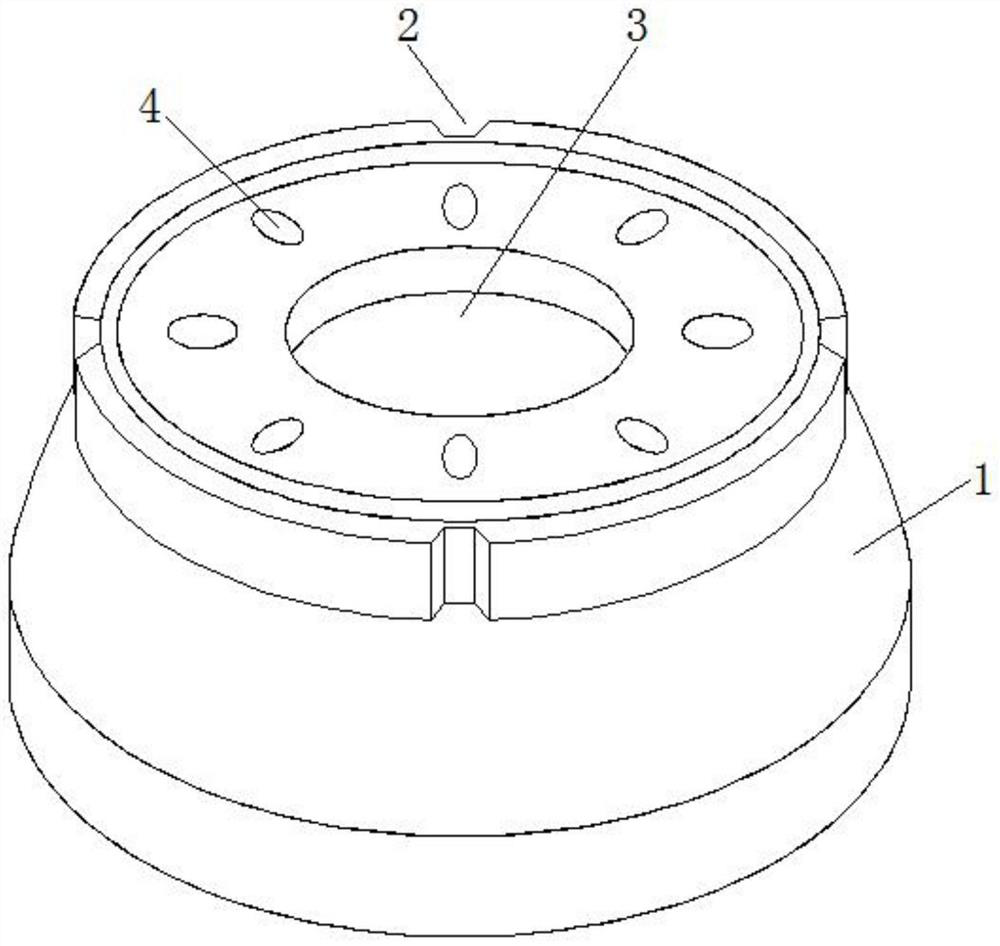

[0028] Example 1, refer to figure 1 , an automobile brake drum processing and positioning structure, including a drum body 1, an assembly hole 4 and a through groove 3 opened inside the drum body 1, and characterized in that it includes a positioning groove 2 opened on the outer ring of the drum body 1.

Embodiment 2

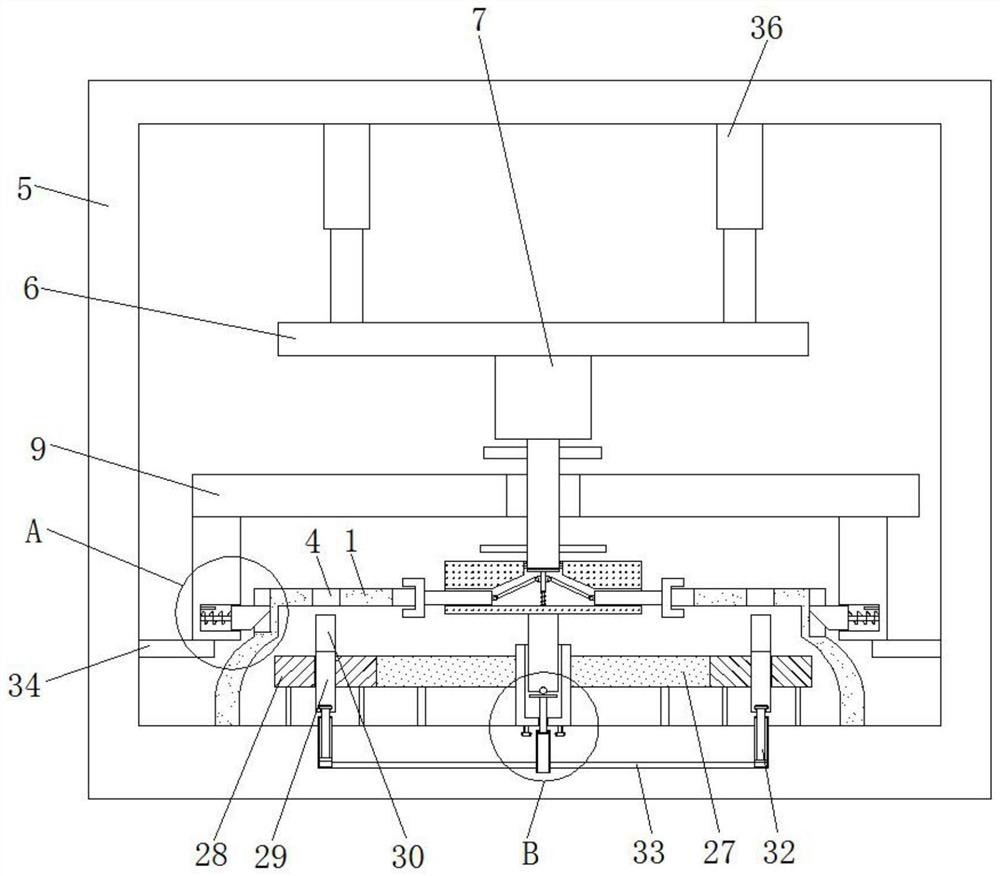

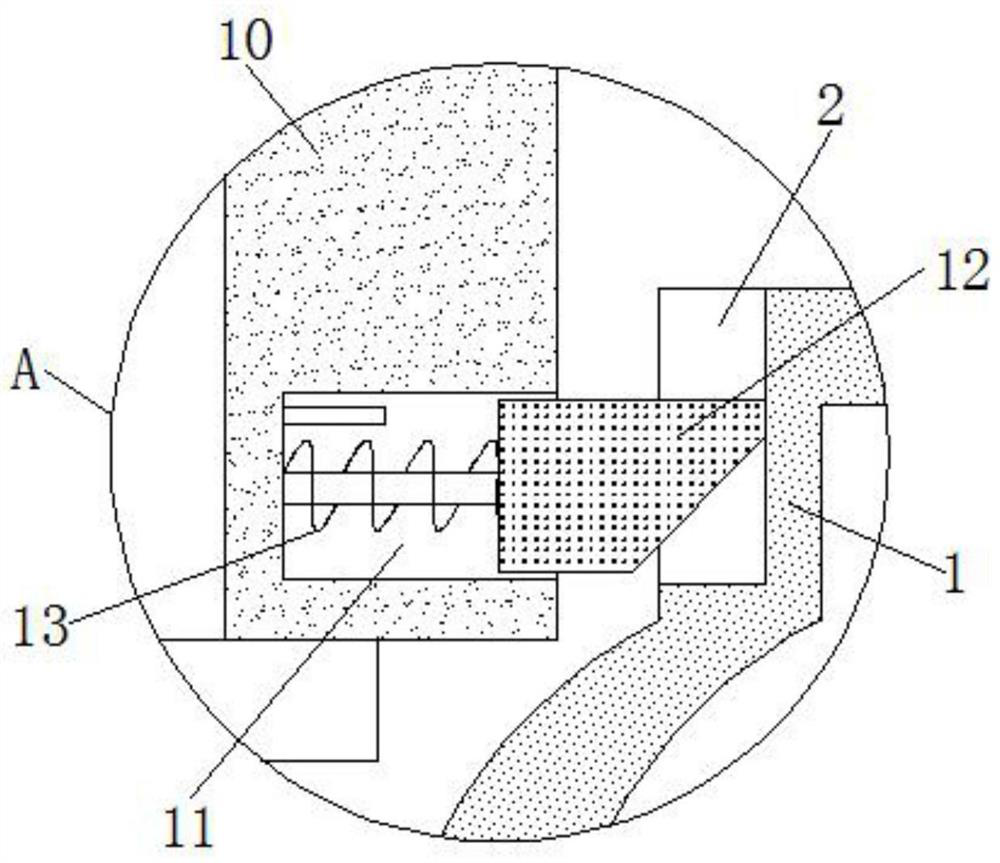

[0029] Example 2, refer to Figure 2-7 , an automobile brake drum processing device, comprising a housing 5 and a positioning mechanism for fixing the drum body 1, the positioning mechanism comprises a first fixed plate 9 that is slidably sleeved on the outside of the drive shaft 8, the bottom end of the first fixed plate 9 And the position relative to the positioning groove 2 is fixed with a second fixing plate 10 , a first installation groove 11 is opened inside the second fixing plate 10 , and the interior of the first installation groove 11 is horizontally slidably inserted with the matching positioning groove 2 to be snapped. The used clamping block 12, and a horizontally arranged first spring 13 is fixed between the first installation groove 11 and the clamping block 12, the inner bottom wall of the outer casing 5 is provided with a fixing groove for use with the drum body 1, and the inner bottom wall of the outer casing 5 is provided. The top wall is connected with a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com