Novel plastic bottle cap

A technology for plastics and bottle caps, applied in the directions of bottle/container cap, capping, bottle filling, etc., it can solve the problems of easy connection loose, error prone, and tightness not reaching the best state, and achieve the effect of ensuring product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

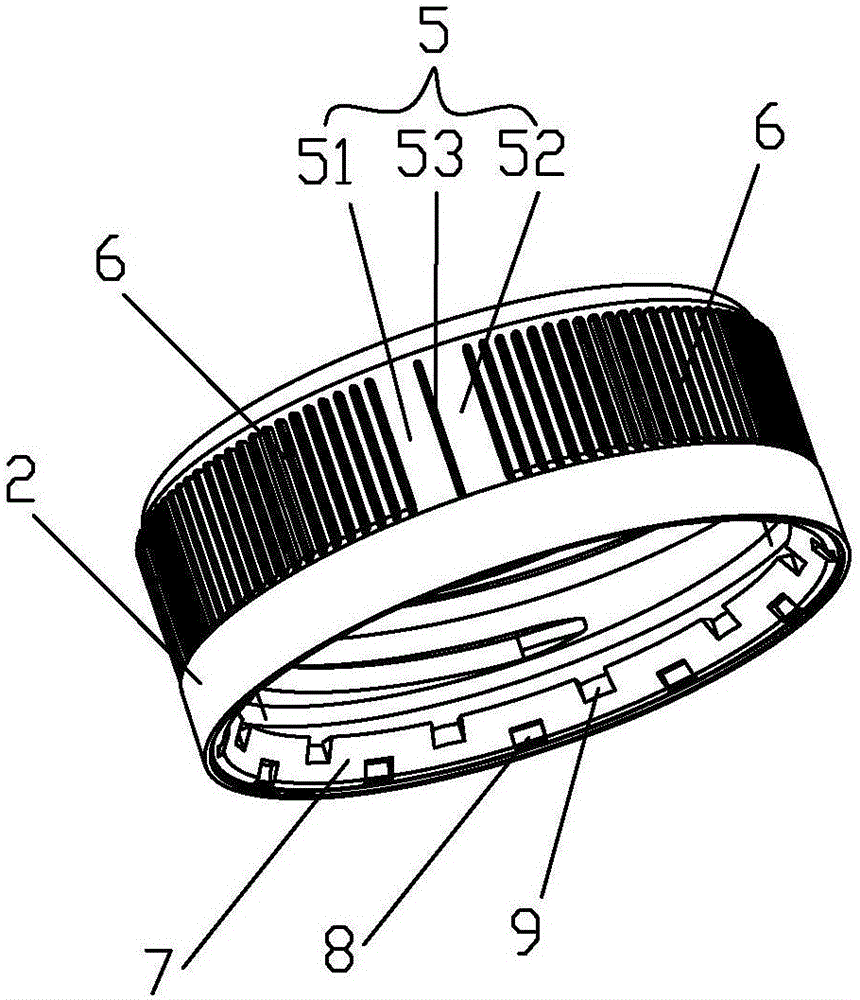

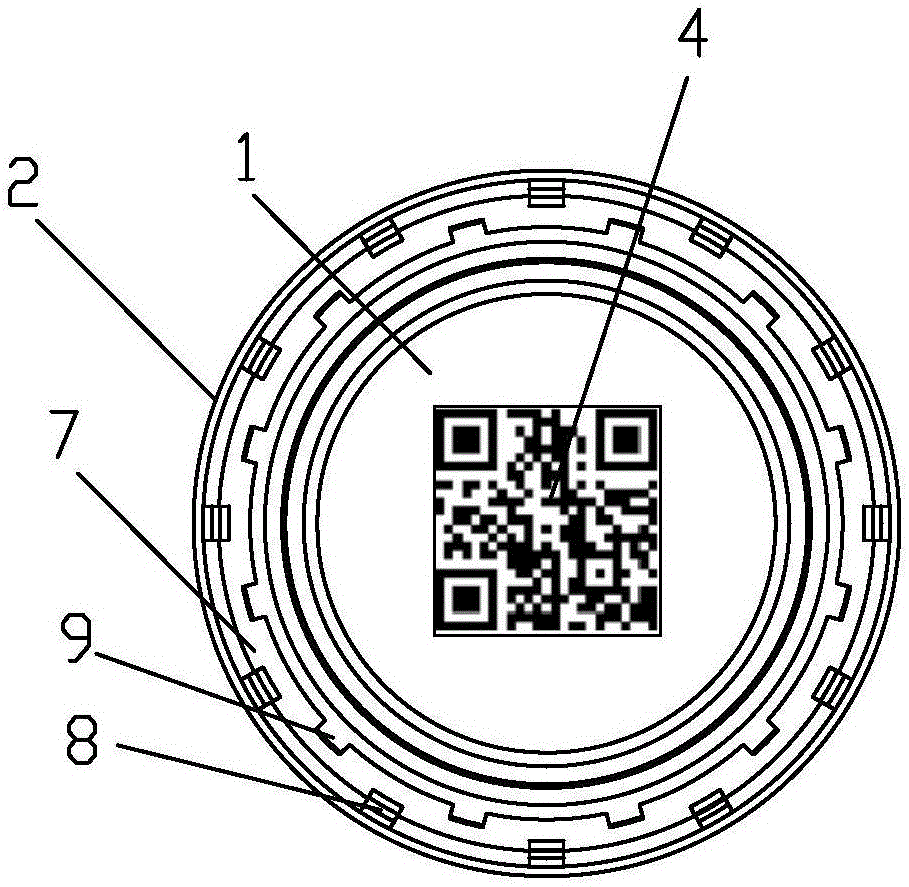

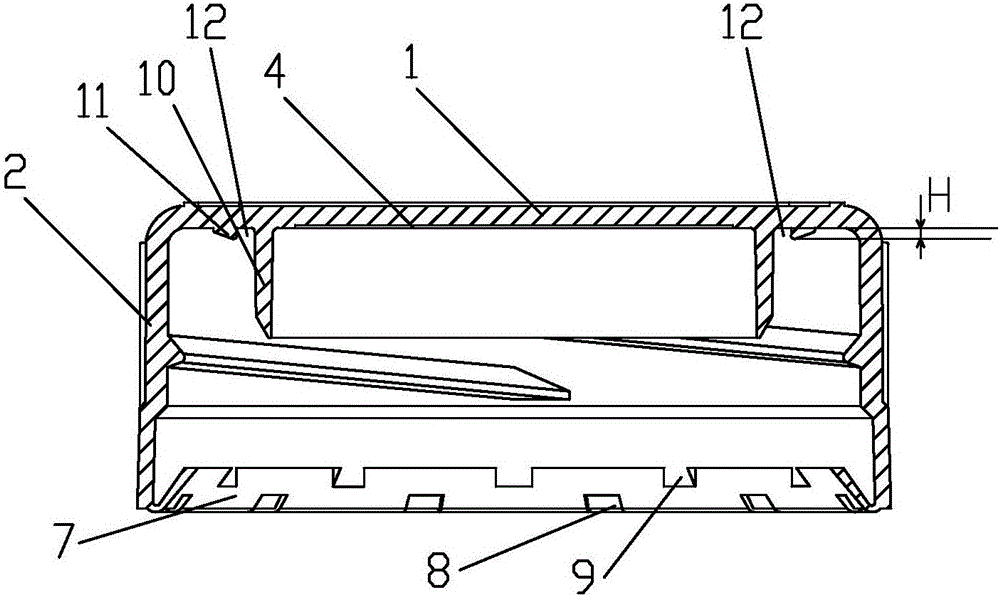

[0030] A plastic bottle cap comprises a top sheet 1, the outer edge of the top sheet 1 is provided with an annular side sheet 2 integrally formed with it and extends toward the top sheet 1 side, and the inner wall of the side sheet 2 is provided with a The threads of the bottle neck 3 match the threads, and the top sheet 1 is provided with an ultraviolet laser etching layer 4 formed by ultraviolet laser beam etching and capable of storing product information. The ultraviolet laser etching layer 4 is etched by ultraviolet laser beams. Information such as the production batch number of the product, whether it is a prize winner, and member points are stored in the ultraviolet laser etching layer 4. Since the ultraviolet laser beam is a cold light source, compared with laser infrared engraving In terms of thermal processing, the plastic material of the plastic bottle cap can ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com