Large corrugated pipe forming machine

A corrugated pipe and forming machine technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve problems such as high labor intensity, low production efficiency, and unguaranteed accuracy of tube blanks, so as to reduce labor intensity and improve work efficiency. The effect of improving efficiency and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

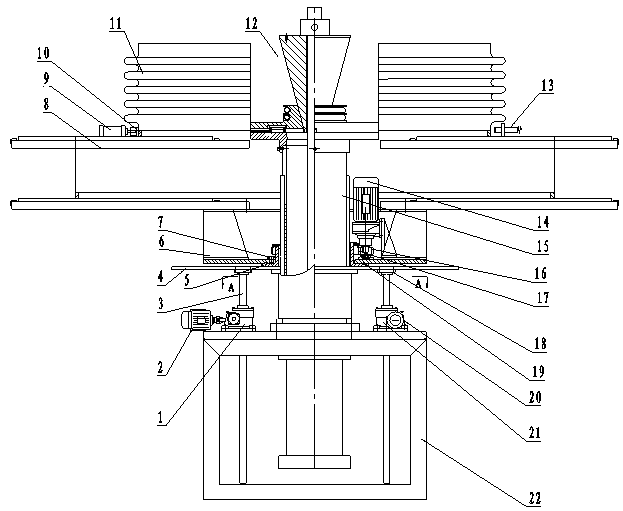

[0016] see figure 1 , The composition of the present invention includes a base 22, a central shaft 15, an expansion device 12, a tube blank tray 8, an indexing device, and a feeding device. The tube blank 11 to be processed is fixed on the tube blank tray 8, and each wave node is sequentially processed by the expansion device 12.

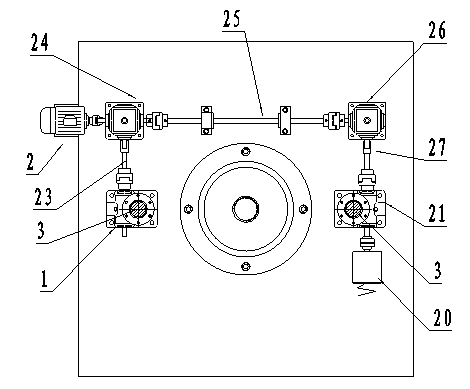

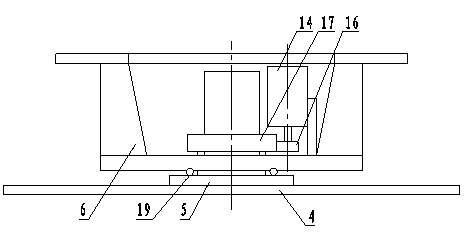

[0017] see figure 1 , image 3 , when the bulging device bulges, the tube blank will produce a non-round straight edge section, which needs to be rotated for multiple times to form the tube blank. The indexing device is a device used to replace manual rotation. The indexing device comprises an indexing motor 14, a transmission mechanism, and a chassis 4, a tray 5, and a rotating bracket 6 arranged in sequence from bottom to top. The tray 5 is set on the central shaft 14 of the molding machine and fixed with the chassis 4 . The top of the rotating bracket is fixed with the tube blank pallet 8, and the bottom is fixed with the pallet 5. The trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com