Swing bar type automatic glaze dipping device

An automatic and glaze-dipping technology, which is applied in the field of daily-use ceramic production equipment, can solve the problems of inconsistent glaze layer thickness, unqualified body glaze, insufficient automation, etc., to achieve no dead angle glaze, good glaze effect, Easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

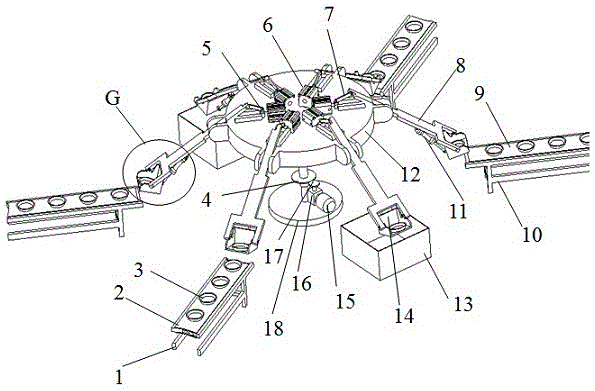

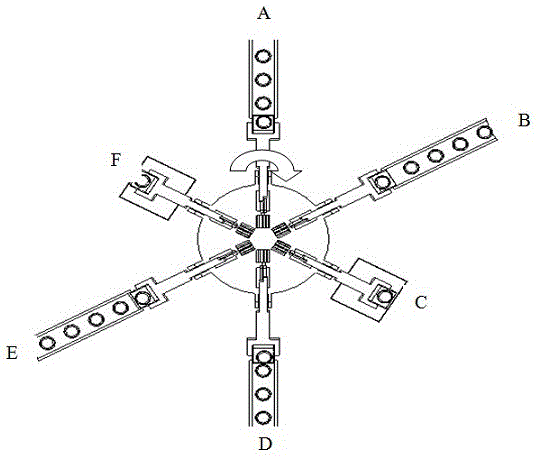

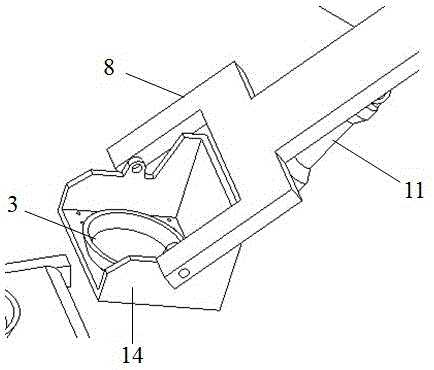

[0026] Such as Figure 1-3 As shown, the turntable motor 15 drives the sheave puller 17 to rotate through the reducer 16, and the sheave puller 17 moves the sheave 4 to rotate at intervals. At the same time, the swing angle cylinder 6 pulls the slider 5 along the radius of the turntable 12 Direction moves, and the tilting plate 8 elevation angle increases pallet 14 to the position equal to conveyor belt 2 9, at B, E station, the conveyor belt 2 9 that is installed on the transmission support 2 10 pushes the bowl base 3 into the tray 14 Bottom, then the tilting cylinder 11 pushes the tray 14 to rotate an angle around the hinge center with the tilting plate 8, and the bowl base 3 slides down to the inner right angle of the tray 14 to complete the preparatory work before glazing.

[0027] Then the turntable motor 15 drives the sheave puller 17 to rotate, the turntable 12 is indexed one-sixth of a week to the C and F stations, the tray 14 and the bowl blank 3 to be glazed move to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com