Front structure for a motor vehicle

A body and automobile technology, applied in vehicle components, vehicle safety arrangements, superstructure sub-assemblies, etc., can solve the problem of not being able to ensure the accurate orientation of the bumper for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

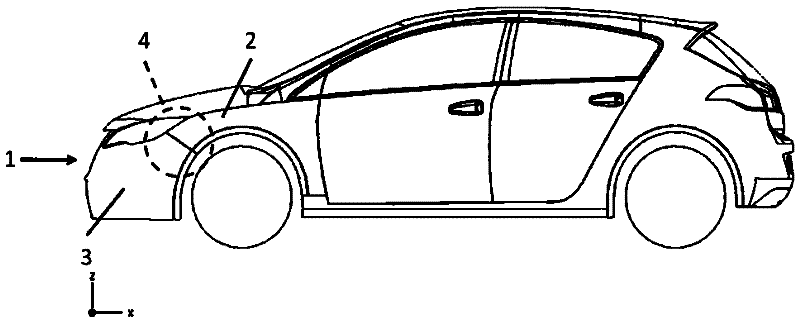

[0023] figure 1 A motor vehicle with a front end 1 is shown. The front body 1 has a fender 2 and a bumper 3 delimiting the front end 1 in the direction of travel. The bumper 3 is connected to the fender 2 via fastening means 4 . exist figure 1 , the fixing device 4 is covered by the fender 2 and the bumper 3 .

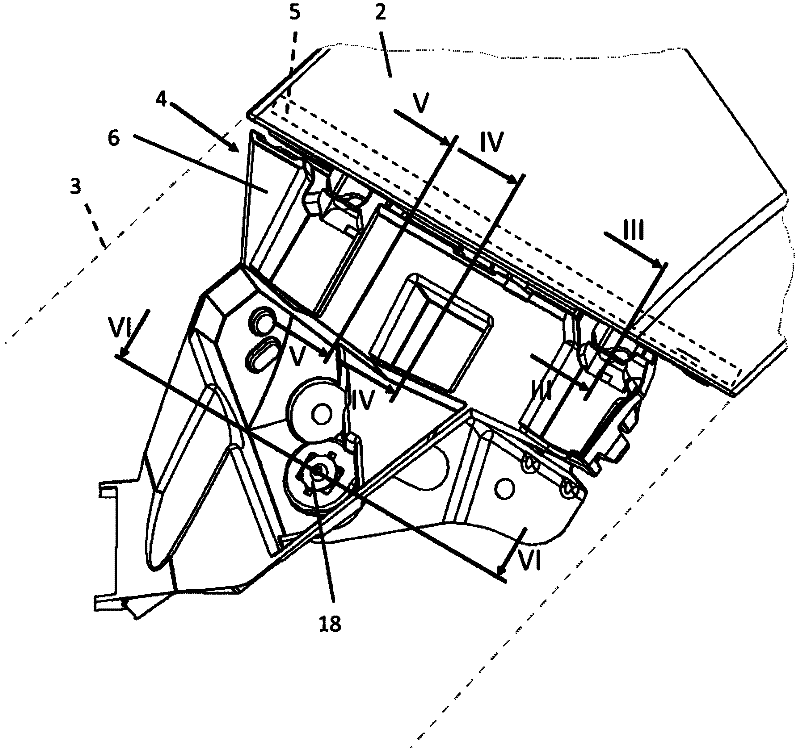

[0024] figure 2 show figure 1 Part of the front end 1 of the center body with the fender 2 and the fastening means 4 . In order to simplify the illustration, the outline of the bumper 3 is shown with dashed lines. The fastening device 4 has a fastening flange 5 fastened to the fender 2 and a guide rail 6 connected to the fastening flange 5 . Guide rail 6 is arranged below bumper 3, and in figure 2 The middle fixed edge plate 5 is mostly blocked by the fender 2 .

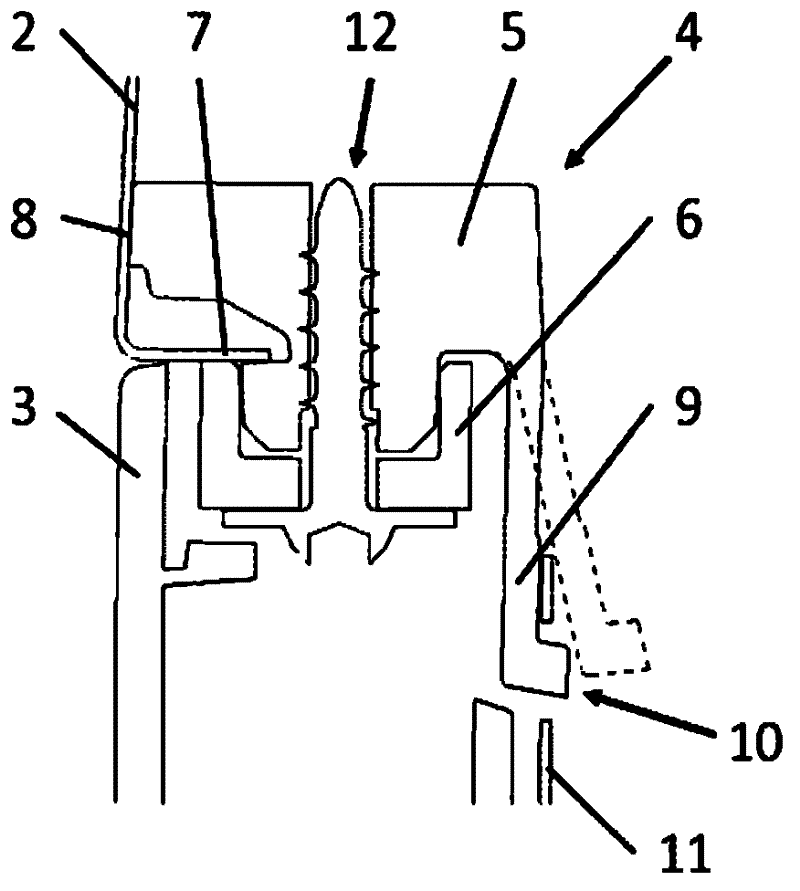

[0025] image 3 Shows sectioning along section line III-III figure 2 An enlarged cross-sectional view of the fixation device 4 in . It can be seen here that the fastening flange 5 bears against...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com