Steel tube butt welding machine

A technology for butt welding machines and steel pipes, applied in the direction of tubular objects, welding equipment, auxiliary welding equipment, etc., which can solve the problems of low production efficiency and low welding pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

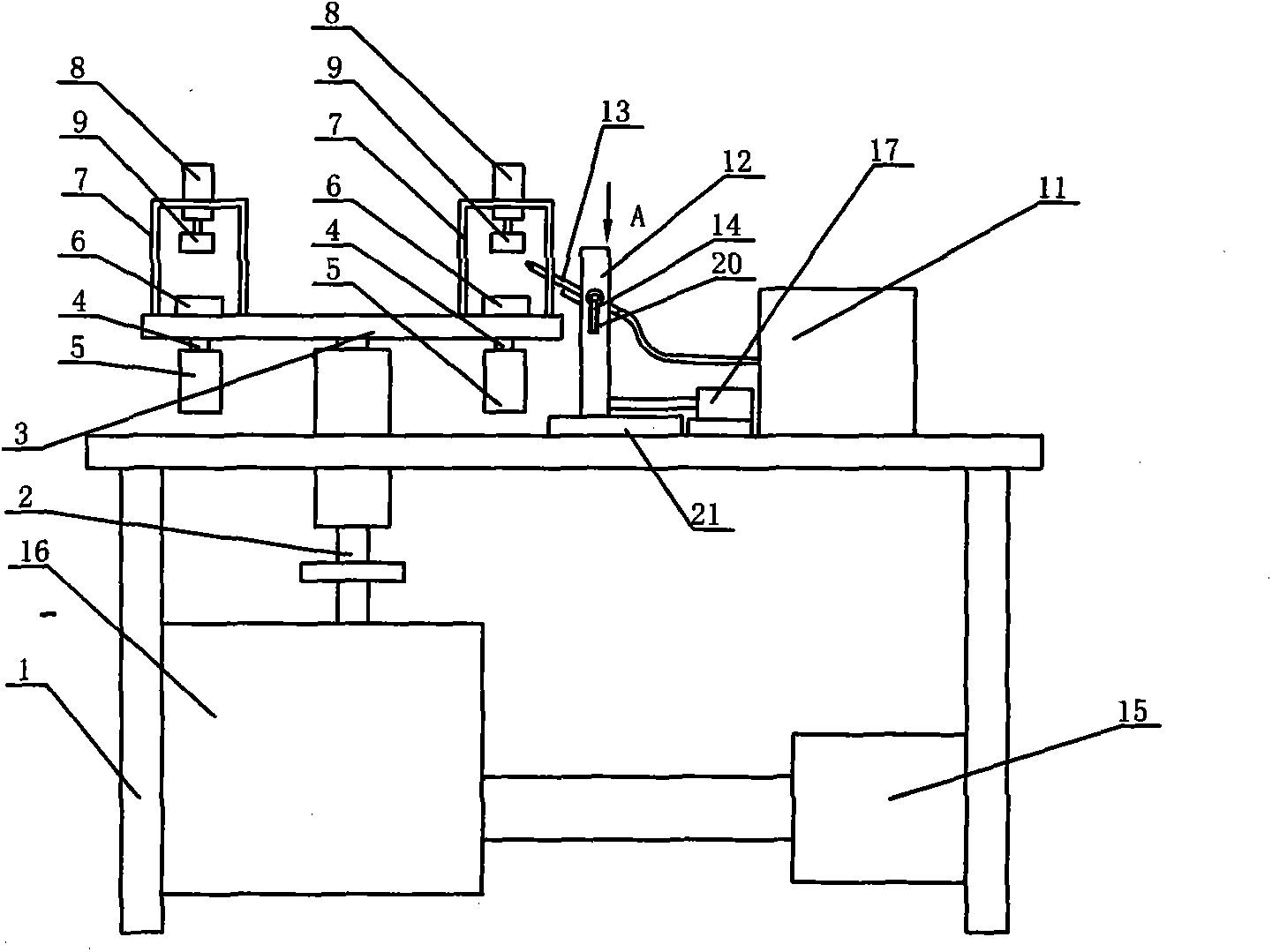

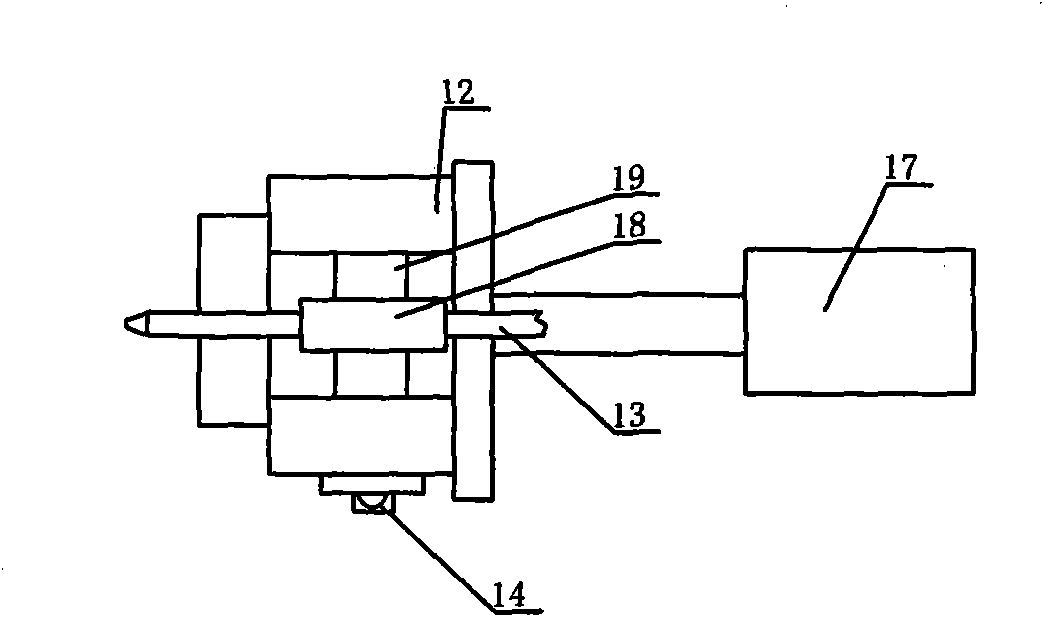

[0011] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0012] Such as figure 1 with figure 2 The shown steel pipe butt welding machine adopts a vertical structure to clamp the product to be processed (two sections of pipe fittings 10 to be welded that need to be butt welded), and it includes a frame 1, which is rotatably connected with a driving device that drives intermittent rotation and The main shaft 2 arranged vertically, the top of the main shaft 2 is equipped with a turntable 3, and the turntable 3 is rotated and connected with at least three rotating shafts 4 with spaced ring cloth, and the turntable 3 is also equipped with a driving motor 5 that drives the rotating shaft 4 to rotate respectively, and the rotating shaft 4 The top of the steel pipe fixture 6 is equipped with, and the support frame 7 corresponding to each rotating shaft 4 is also e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com