System and method for testing dynamic characteristics of helical spring

A helical spring and dynamic characteristic technology, applied in the field of dynamic characteristic testing, can solve problems such as inability to obtain inherent characteristic parameters of the spring, inaccurate vibration characteristics of the air spring, and inability to reflect the vibration characteristics of the spring, etc., to achieve simple clamping process and wide application range Wide, easy to disassemble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

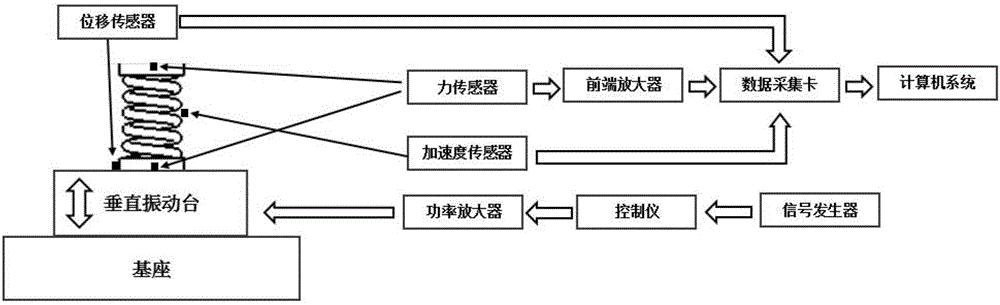

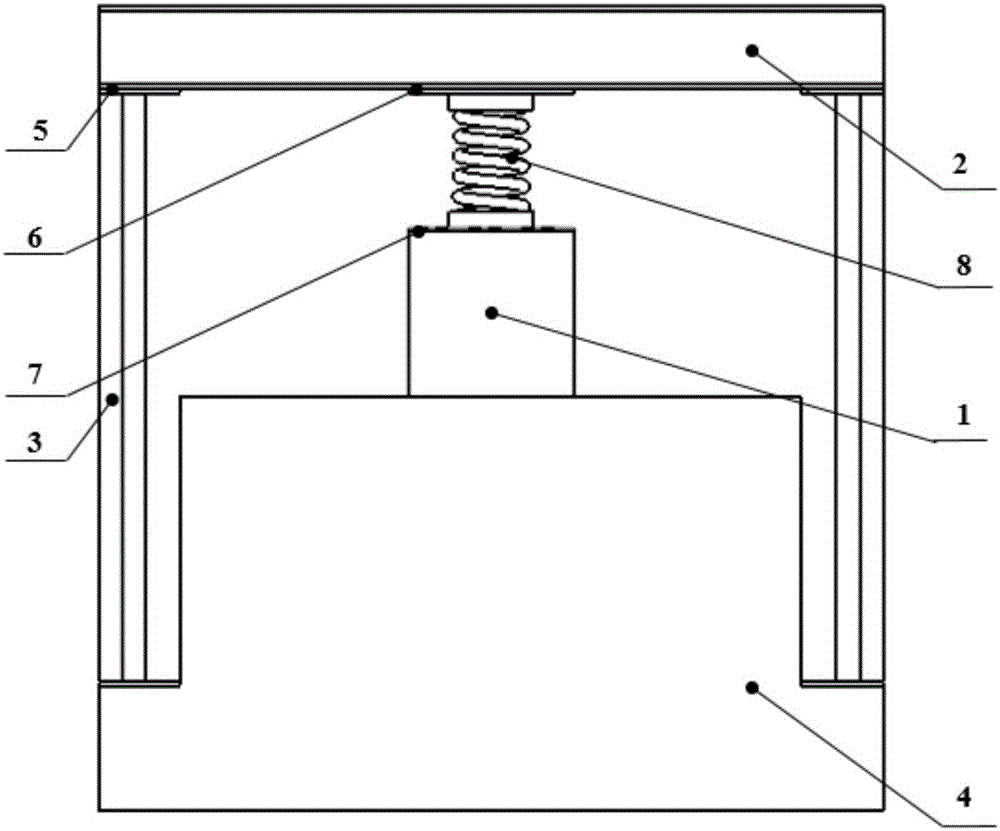

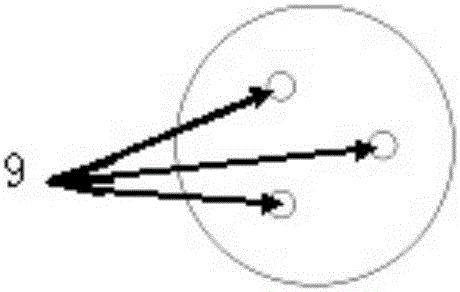

[0046] A helical spring dynamic characteristic testing system, used to test the dynamic performance of helical spring, the working principle diagram is as follows figure 1 As shown, the schematic diagram of the composition structure is shown in Figure 2-1 As shown, it includes a base 4, a vertical vibrating table 1, a displacement sensor, a special fixture, two sets of force sensors 9 for contacting the two ends of the coil spring 8 to be tested, and a spring fixed on each coil of the coil spring 8 to be tested. An acceleration sensor and a signal acquisition and processing device connected with each sensor. Among them, the vertical vibrating table 1 is fixed on the base 4, the exciting end of the vertical vibrating table 1 is fixed with the first bearing platform 7 by bolts, the special fixture includes the beam 2 and the side beam 3, and the beam 2 is welded by two H-shaped steel 21 in parallel Formed on it, the second load-bearing platform 6 is fixed by bolts, the first l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com