Universal fixture device and method for machining fan-shaped workpiece combinations

A fixture device and combined processing technology, applied in the field of mechanical processing, can solve the problems of long production preparation time, complex fixture design, poor versatility, etc., and achieve the effects of short production preparation time, shortened processing cycle and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

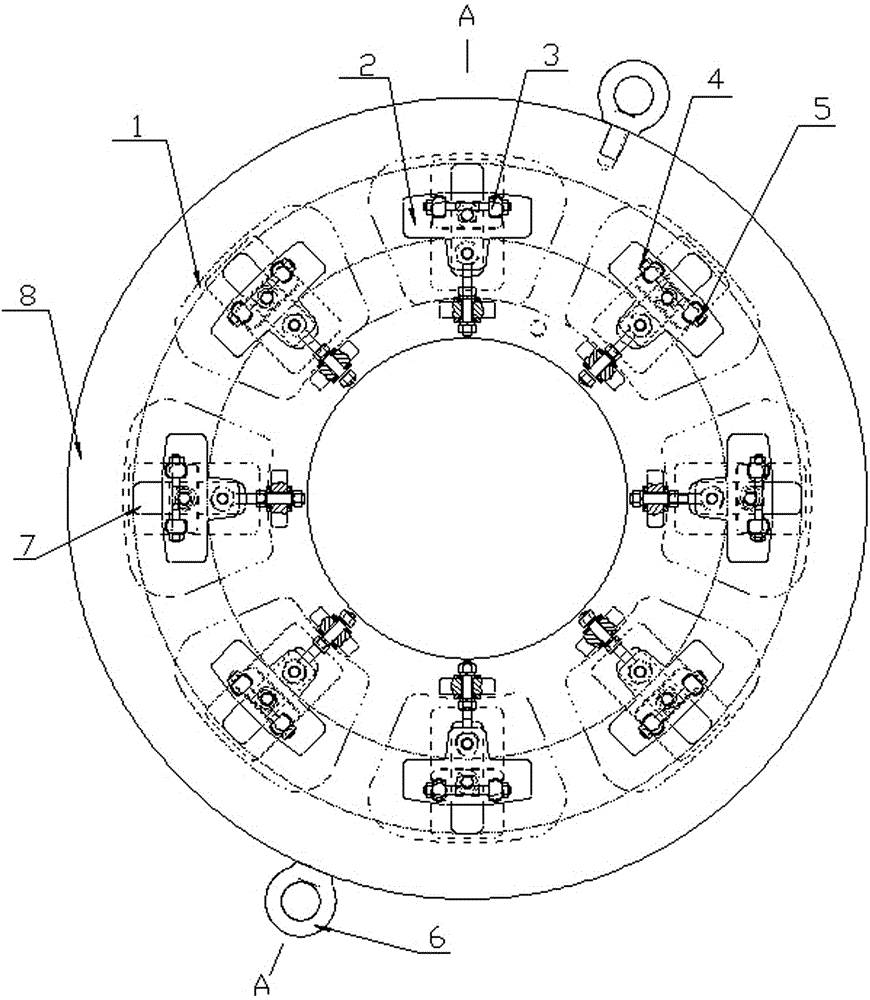

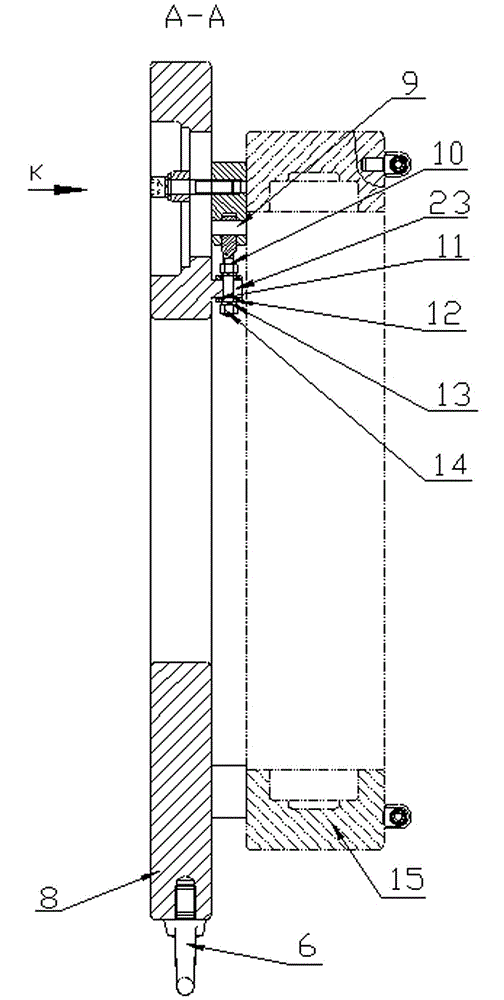

[0031] Example 1, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a universal fixture device for combined processing of fan-shaped workpieces has a base 8, and the base 8 is disc-shaped. In order to facilitate the hoisting of the universal fixture device, the outer periphery of the base 8 is fixedly connected with a lifting ring 6. In this embodiment, the lifting ring 6 is provided with 2, the centers of the two suspension rings 6 and the center of the base 8 are located on the same straight line.

[0032] The base 8 is provided with several groups of multi-equalized universal clamping bodies 1, and multiple groups of multi-equalized universal clamping bodies 1 are evenly distributed on the base 8 with the center of the base 8 as the center.

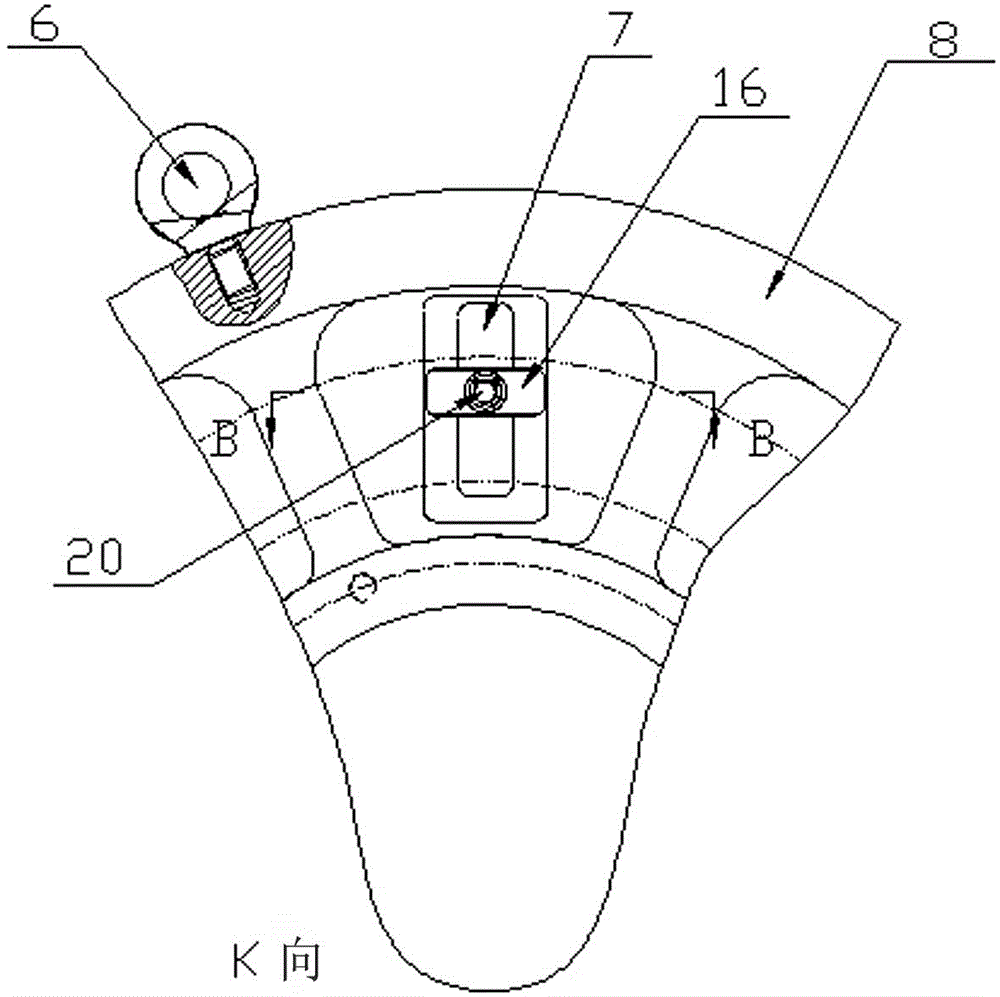

[0033] Multi-divided universal clip body 1 includes a chute 7, the chute 7 axially runs through the base 8, one side of the chute 7 is provided with a groove 21, the groove 21 is located on the side near the lower sur...

Embodiment 2

[0036] Embodiment 2, a clamping method for combined processing of sector-shaped workpieces. In this embodiment, a sector-shaped workpiece with an angle of 45 degrees is taken as an example for illustration.

[0037] step 1:

[0038] Combination of workpieces: Combine 8 fan-shaped workpieces into a full circle.

[0039] Step 2:

[0040] Machining the joint surface: process the joint surface according to the centripetal angle of each fan-shaped workpiece.

[0041] Step 3:

[0042] Drilling: on the upper and lower end surfaces of the fan-shaped workpiece, determine its radial position in its circumferential direction according to the size of the fan-shaped workpiece to be processed, and process the screw holes matched with the upper connecting screw 3 and the lower connecting screw 17.

[0043] Step 4:

[0044] Work piece axial height adjustment: Arrange each fan-shaped workpiece on the base 8 in order, determine its axial height according to the size of the fan-shaped workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com