Water tank welding device

A welding device and water tank technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor coaxiality of three sections, water leakage in the water tank, complicated operation, etc., so as to reduce the coaxiality error and save equipment. The effect of shortening the clamping time and simplifying the clamping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

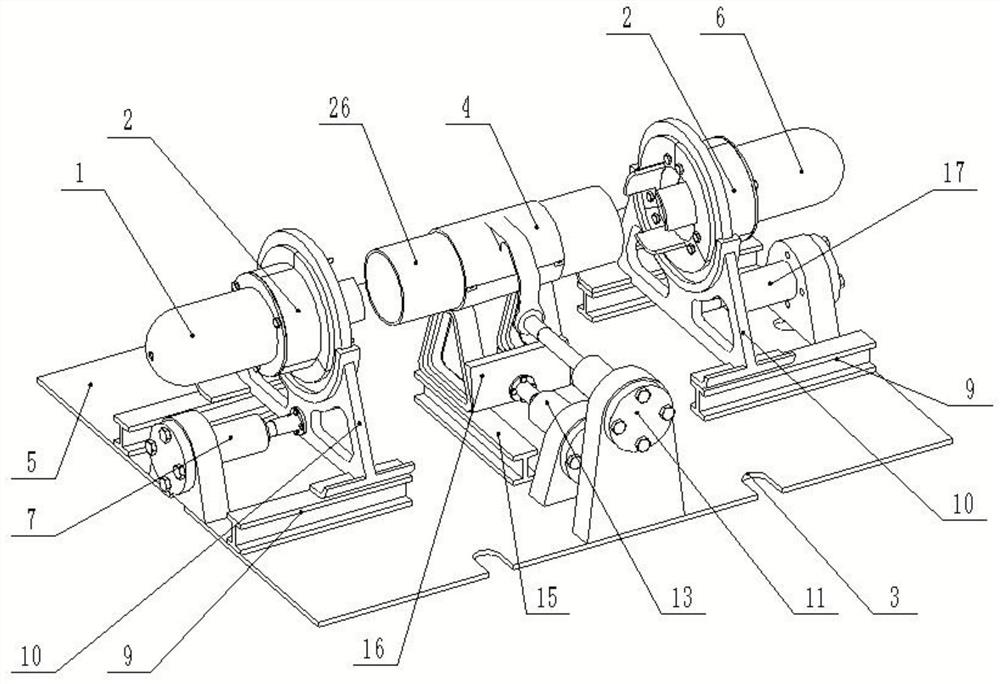

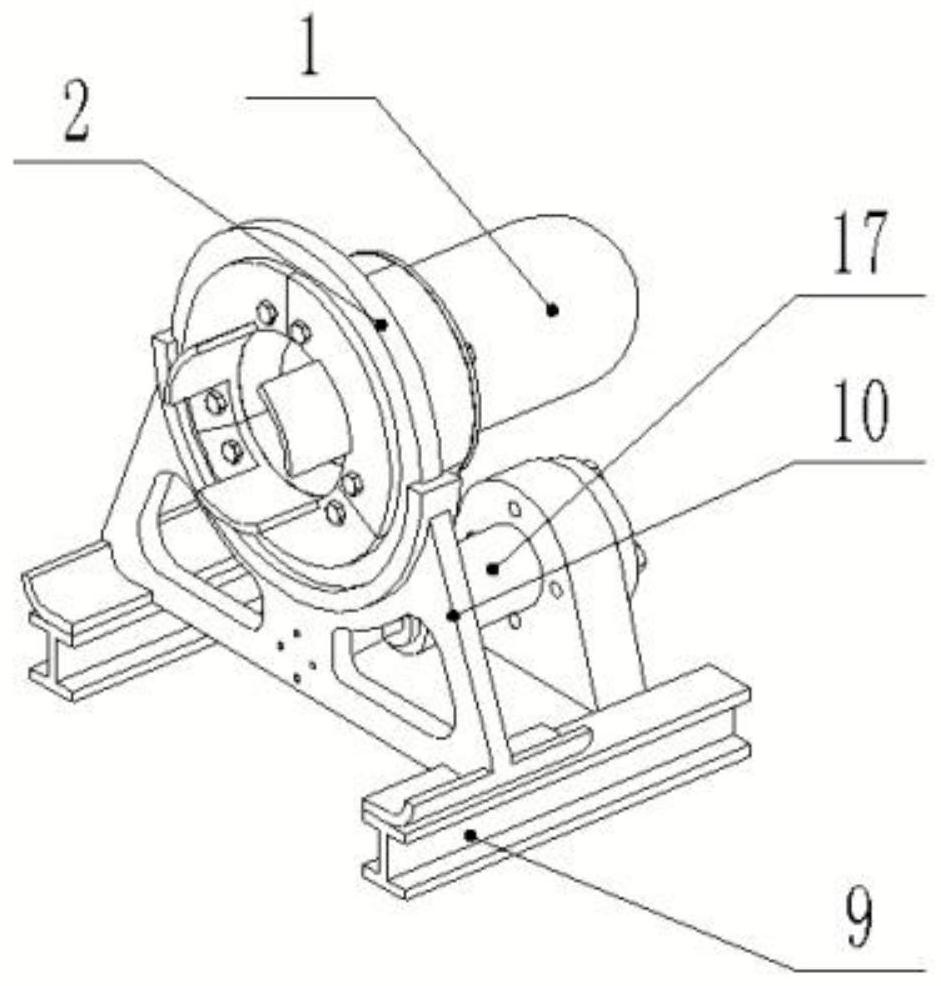

[0040] Now, the technical solutions in the embodiments of the present invention will be clearly and completely described in conjunction with the accompanying drawings. This figure is a simplified schematic diagram and only schematically illustrates the basic structure of the present invention.

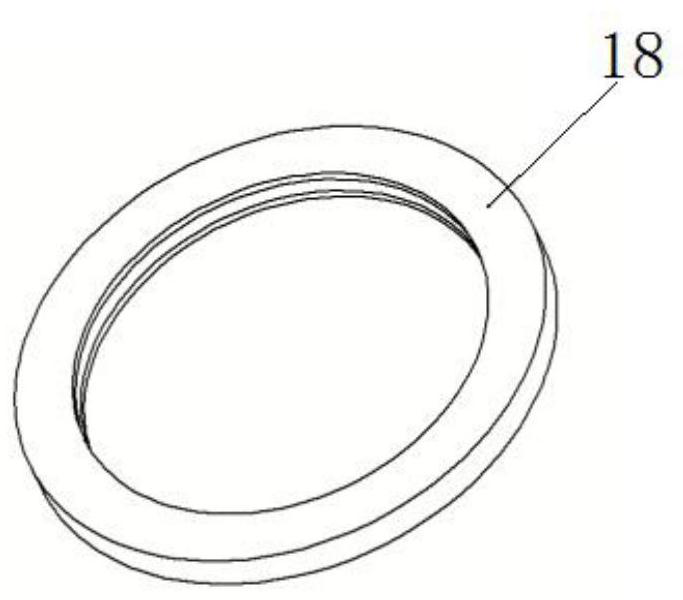

[0041] figure 1Among them, the present invention includes a central clamping mechanism and two side clamping mechanisms with the same structure; the two side clamping mechanisms are respectively used to clamp the upper half section 25 and the lower half section 27 of the water tank to be welded, and are symmetrically arranged on the bottom plate 5. On the left and right ends, each side clamping mechanism includes an outer ring 18 and a spring holder 2 that can move laterally with the propelling cylinder. The output shaft of the propulsion cylinder is connected; the spring holder 2 is horizontally sleeved in the outer ring 18; the spring holder 2 includes an airbag, and an annular disk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com