a calibration tool

A tooling and calibration plate technology, applied in the manufacture of stator/rotor bodies, etc., can solve the problems of inability to guarantee assembly quality, high error, time-consuming, etc., to shorten the calibration time, solve the problem of unilateral suction, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

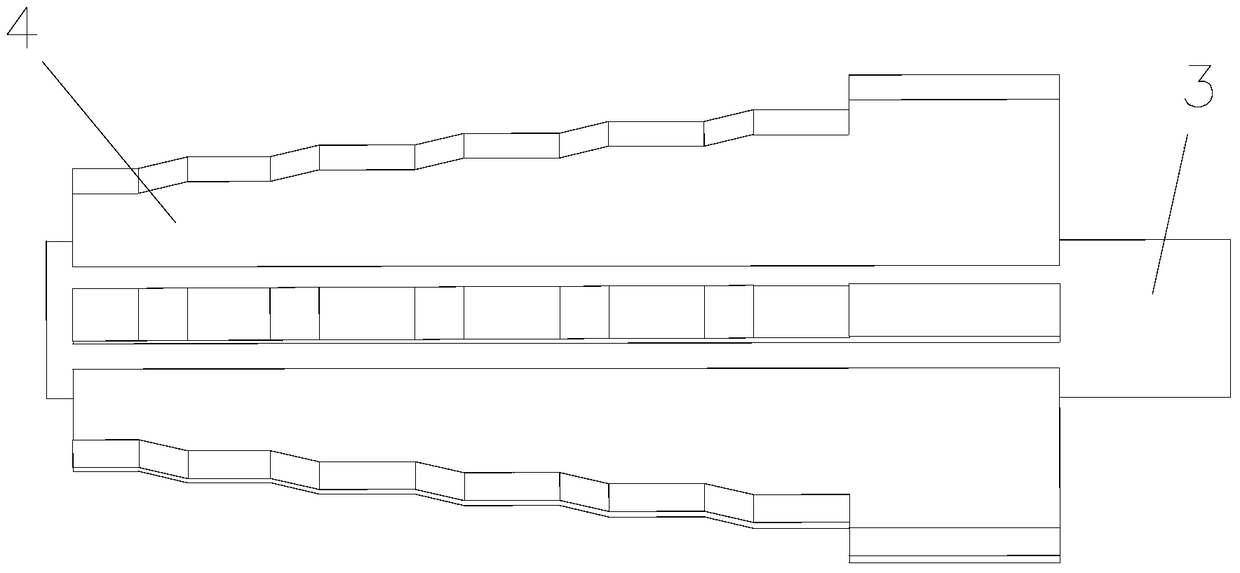

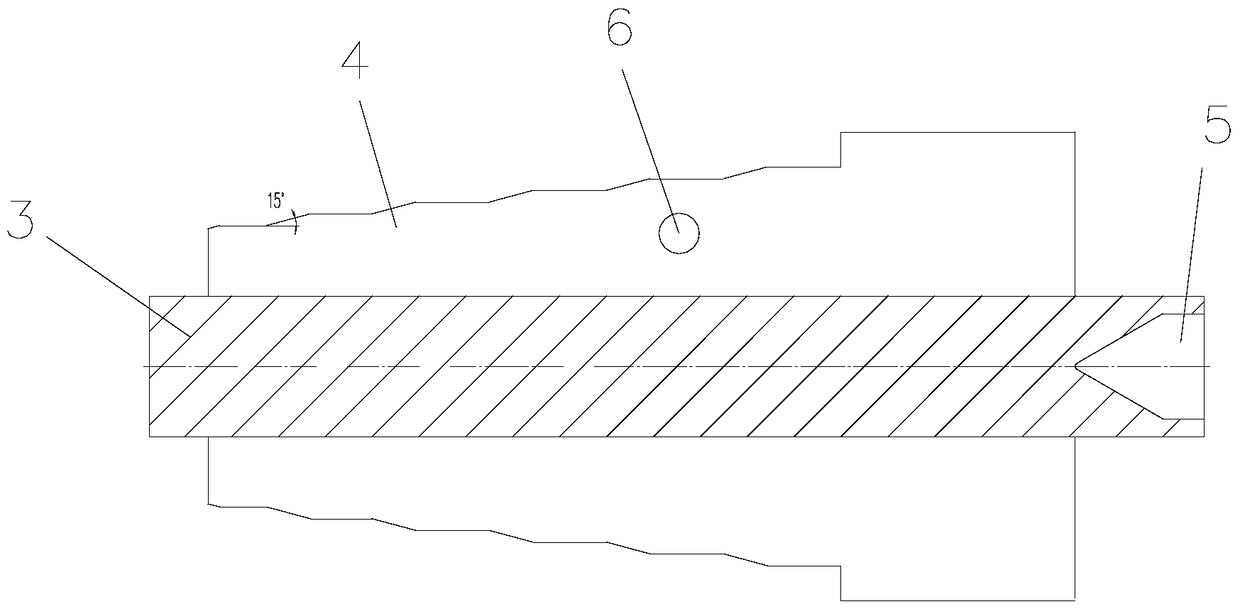

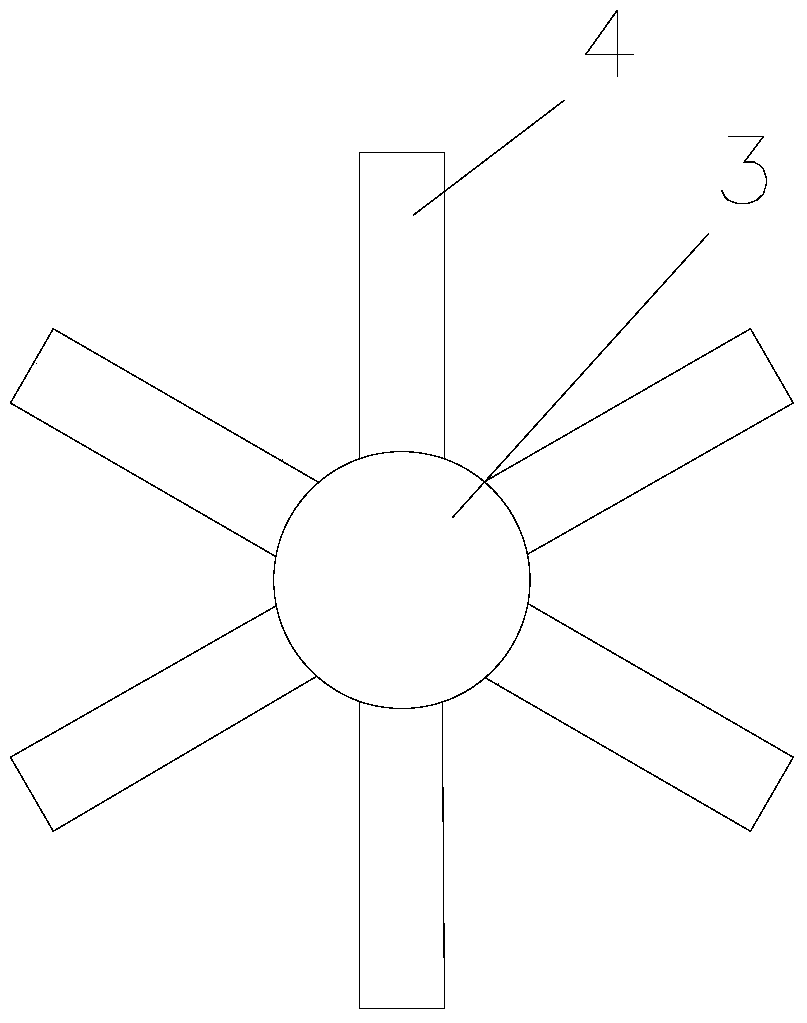

[0021] The invention discloses a calibration tool, which is installed on the thimble of a motor stator press-fitting machine 1, so that the calibration tool can extend into the bearing hole on the end cover of the stator 2 under the drive of the thimble to realize calibration. function, please refer to Figure 4 shown. Such as Figure 1-Figure 3 As shown, the correction tooling includes a main body part 3 and a correction part, specifically:

[0022] The main body 3 is a round rod coaxially arranged with the thimble.

[0023] The correction part includes a plurality of correction plates 4 arranged on the outer peripheral surface of the main body part 3 (the number of the correction plates 4 is not unique, but in order to ensure that it can realize the correction function of the axis of the stator 2, it should be at least on the main body Three correction plates 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com