Auto parts clamping device

A clamping device and accessory clamping technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve problems such as poor firmness and stability, and achieve the effects of simple operation, easy realization, firm and stable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

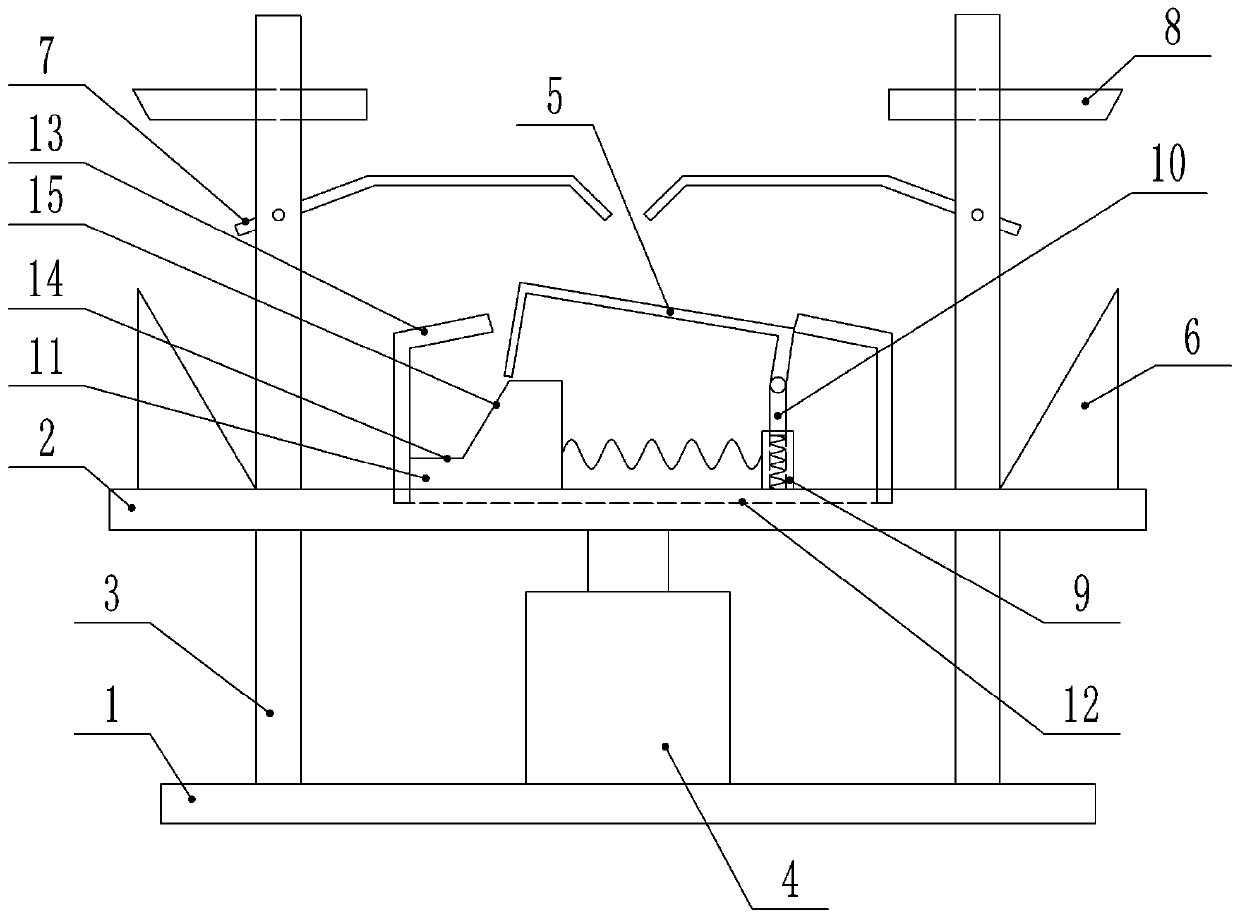

[0015] The reference signs in the accompanying drawings of the description include: base 1, lifting plate 2, guide rod 3, power unit 4, bearing seat 5, driving member 6, top clamping rod 7, wedge block 8, slide seat 9, slide block 10. A discharge block 11 , a second chute 12 , a side clamping rod 13 , a horizontal portion 14 , and an inclined portion 15 .

[0016] Such as figure 1 As shown, the auto parts clamping device includes a base 1 and a lifting plate 2, two guide rods 3 are welded symmetrically on both sides of the base 1, and the upper parts of the two guide rods 3 are provided with relative followers and position The opposite top clamping device, the top clamping device is under the follower; the lifting plate 2 is vertically slidably connected to the two guide rods 3, and the base 1 is provided with a power device 4 that drives the vertical sliding of the lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com