Fast fixture for two-sided flat shaft

A fixture and fast technology, applied in the direction of clamping, clamping devices, manufacturing tools, etc., can solve the problems of limiting the production efficiency of enterprises, manual fixation of bench vises, and large individual differences, and achieve flexible and variable fixation and assembly. The effect of improving the level of automation and simplifying the process of clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the drawings and embodiments. It should be noted that the embodiments in this application and the features in the embodiments can be modified in size without conflict. The dimensions and terms used here are only for describing specific embodiments, and are not intended to limit the exemplary embodiments of the present invention.

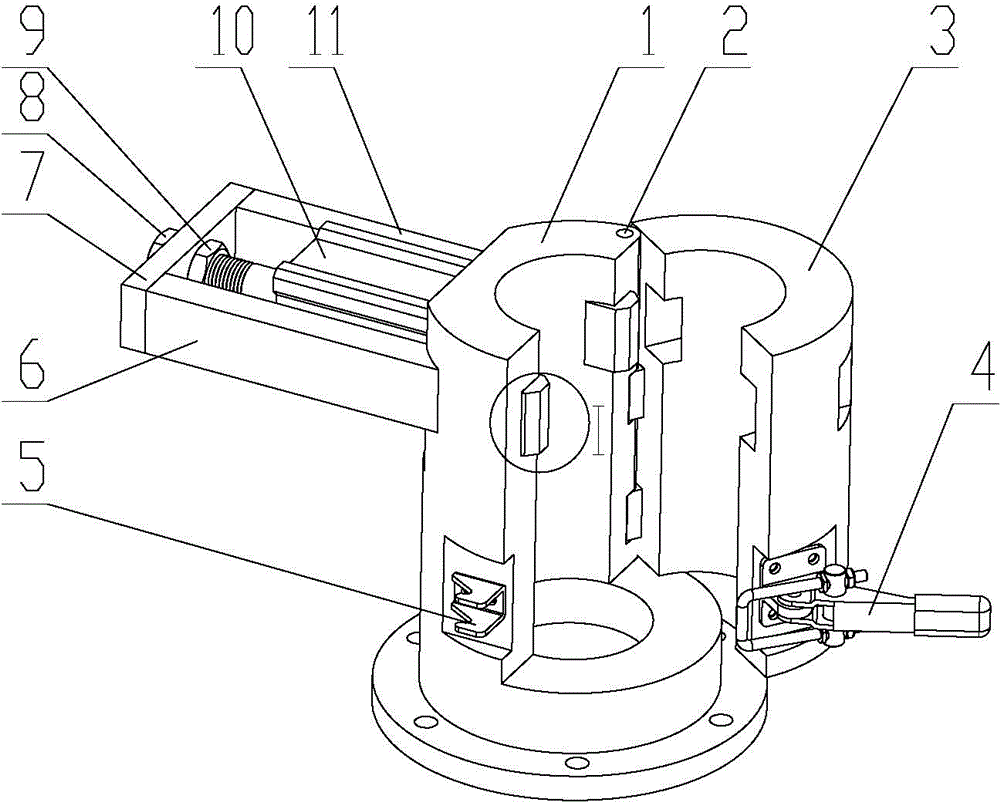

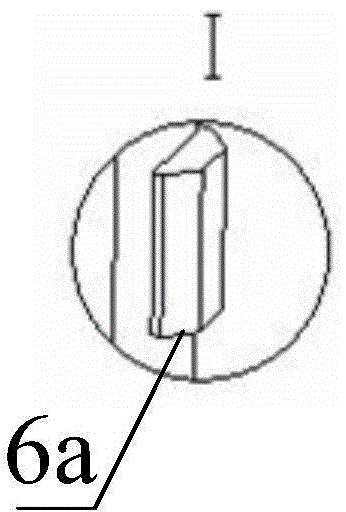

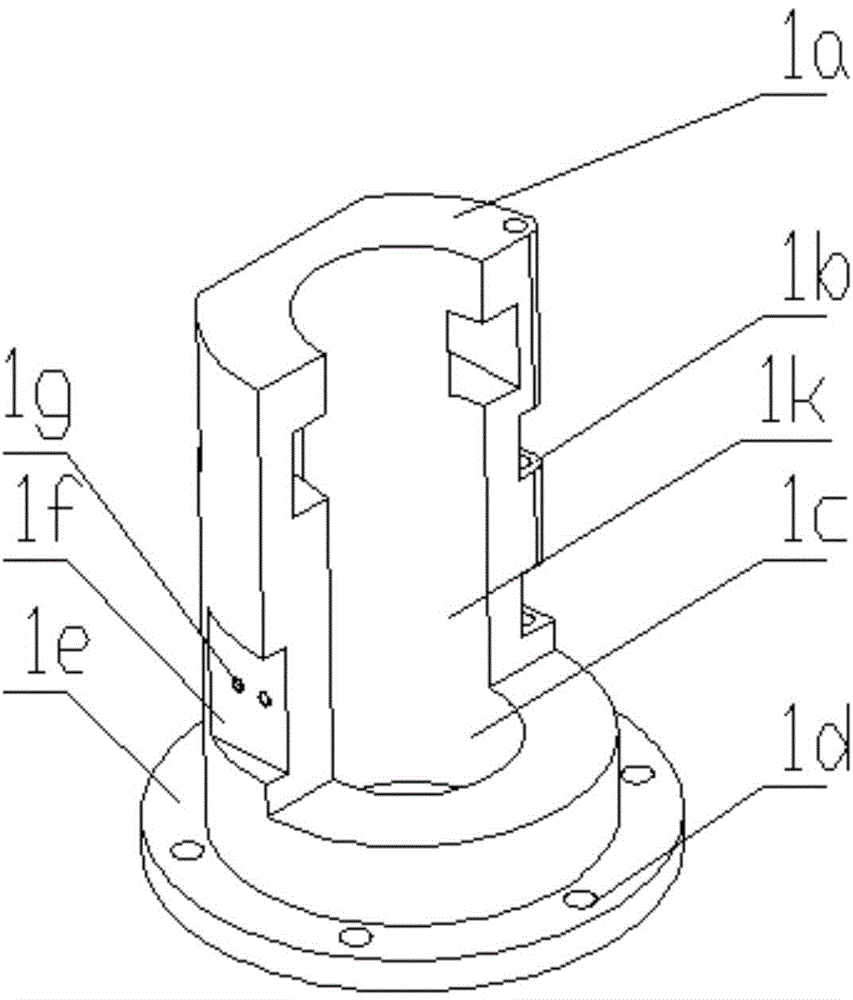

[0032] Such as Picture 1-1 , 2-1 As shown in 4-2, a double-sided flat shaft quick clamp, including a clamp body and a U-shaped limit mechanism; the clamp body includes a clamp fixing plate 1, a hinge pin 2, a clamp cover 3 and a quick clamp; a clamp fixing plate 1 It includes an integrated clamping block 1a and a flange 1e. The inner side of the clamping block 1a is provided with a semi-cylindrical first clamping groove 1k, and the flange 1e is provided with a cylindrical hole coaxial with and communicating with the clamping groove. 1c. The inside of the clamp cover 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com