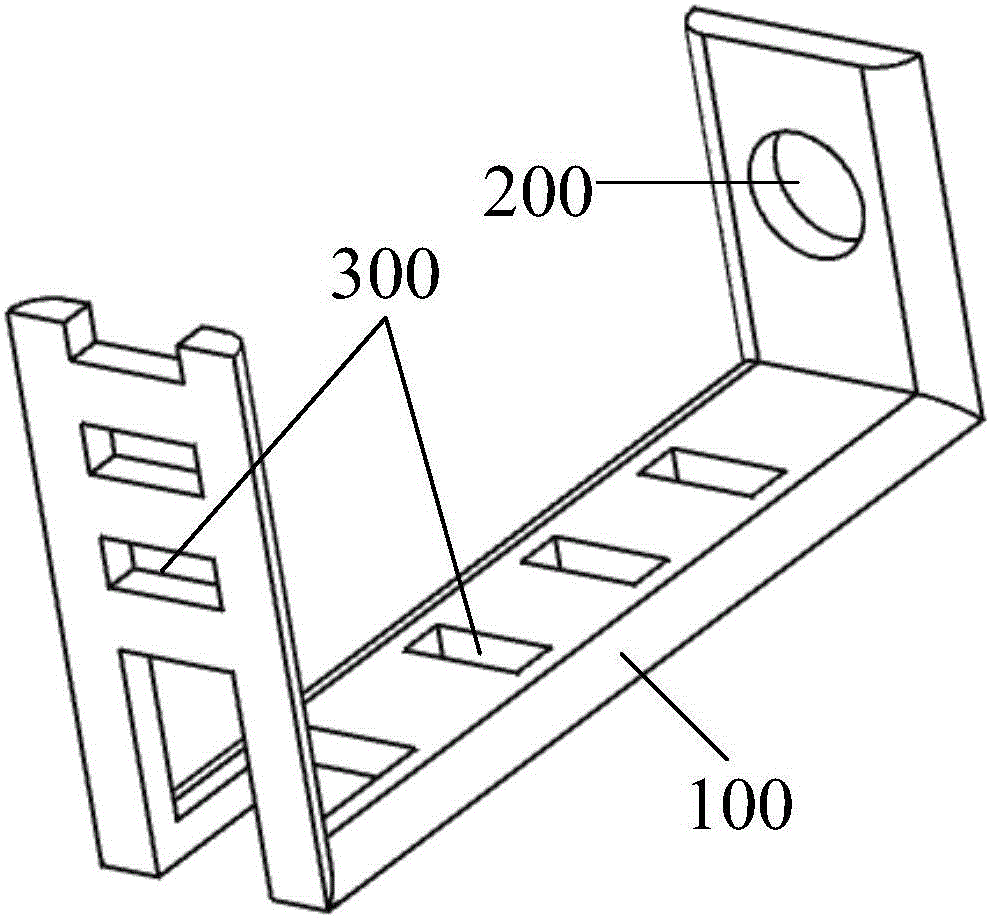

Clamping type fixed support

A fixed bracket and clamping type technology, applied in the field of clamping type fixed brackets, can solve the problems of weak strength at the opening, inconvenient installation of cable ties to fix the pipeline, and inability to move the fixed position of the pipeline, etc. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

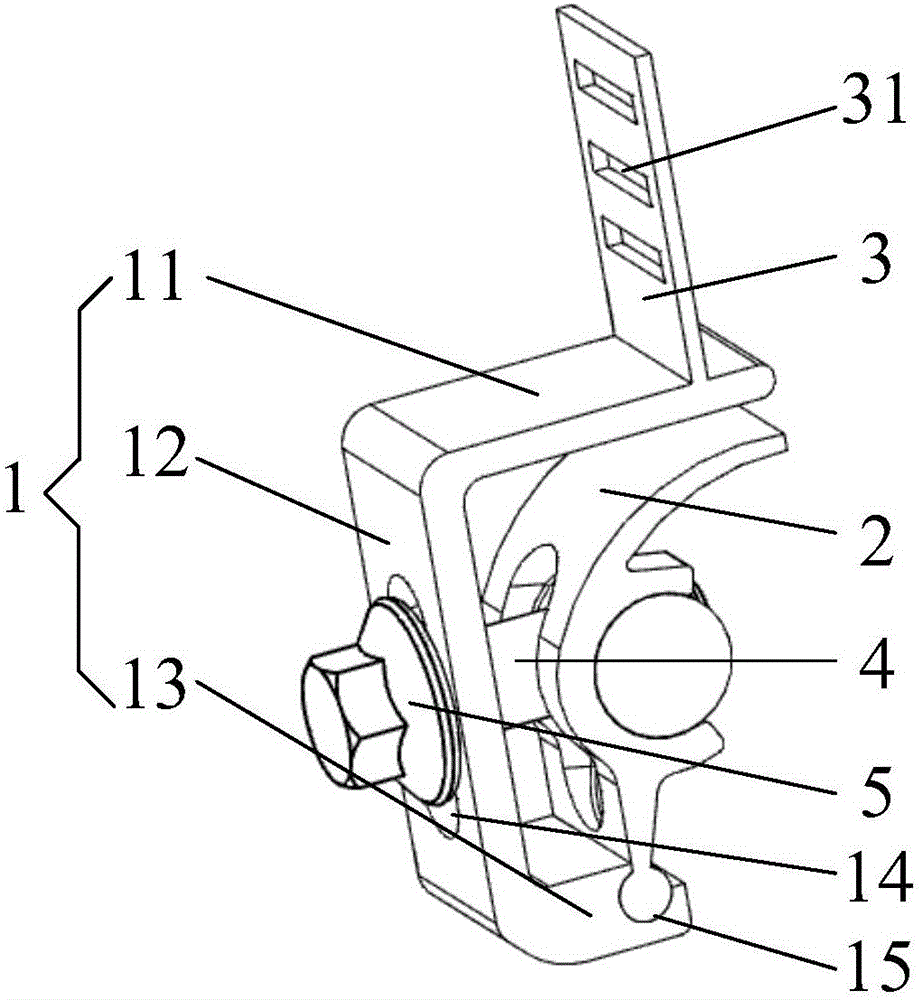

[0024] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

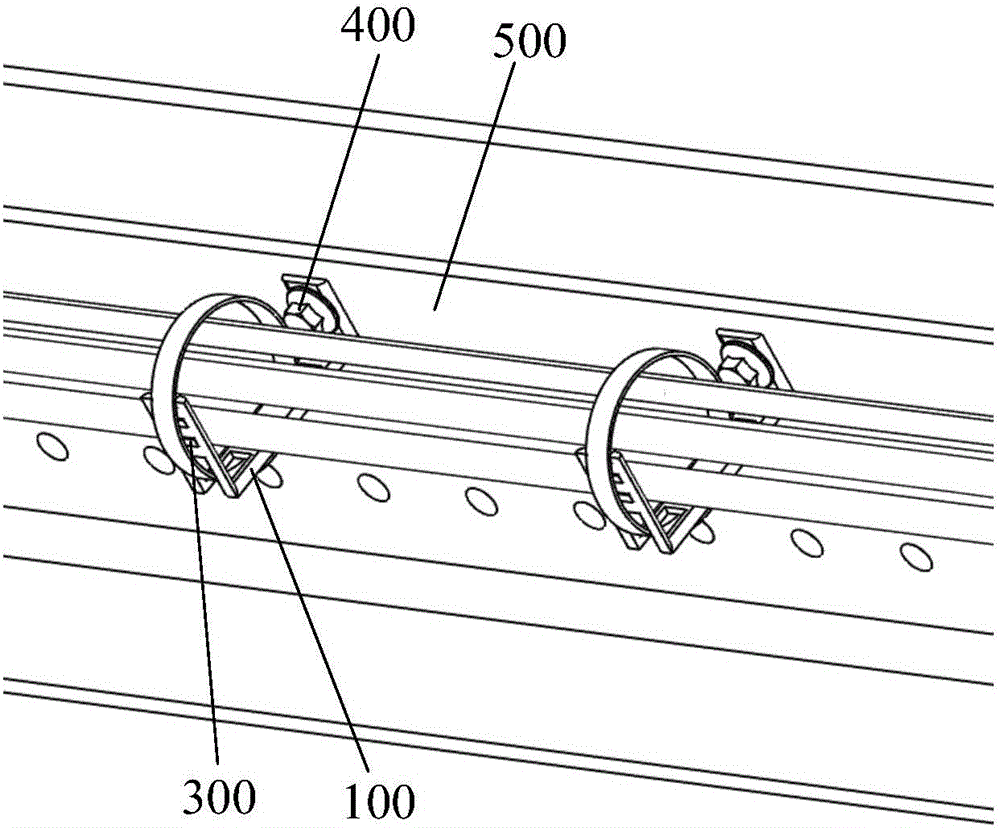

[0025] Embodiments of the present invention: as image 3 , a clamping fixed bracket, including a fixed bracket 1, a movable bracket 2, a cable tie mounting plate 3 and a connecting rod mechanism 4, the fixed bracket 1 includes a top plate 11, a vertical plate 12 and a bottom plate 13, the top plate 11 and The bottom boards 13 are arranged along the horizontal direction, and the vertical boards 12 are arranged along the vertical direction. For structural rationality, the length of the bottom boards 13 is less than the length of the top board 11, and the vertical boards 11 are provided with a second A waist-shaped hole 14, the bottom plate 13 is provided with a connection groove 15 with an opening; the cable tie installation plate 3 is arranged on the top of the top plate 11, and the cable tie ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com