Carbon dioxide beverage and beer pop can filling valve

A technology for cans and filling valves, which is applied in packaging, bottle filling, liquid bottling, etc. It can solve the problems of low single valve capacity, large liquid level deviation, high oxygenation of beverages or beer, and achieve high liquid level control accuracy , Eliminate liquid level fluctuations and high filling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

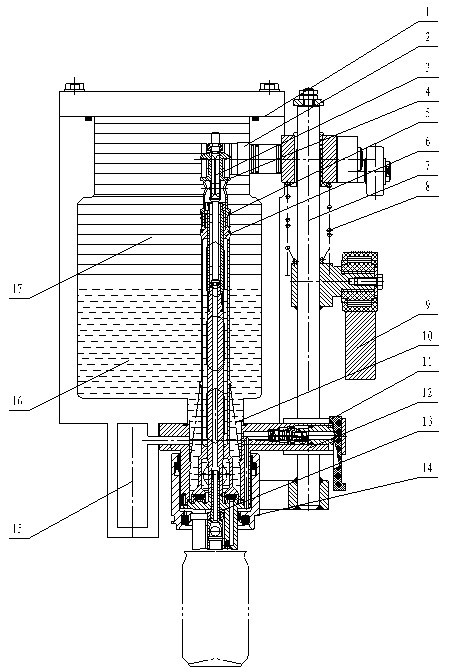

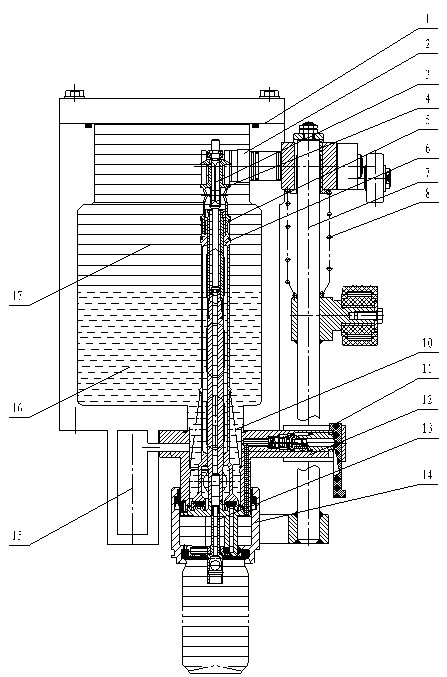

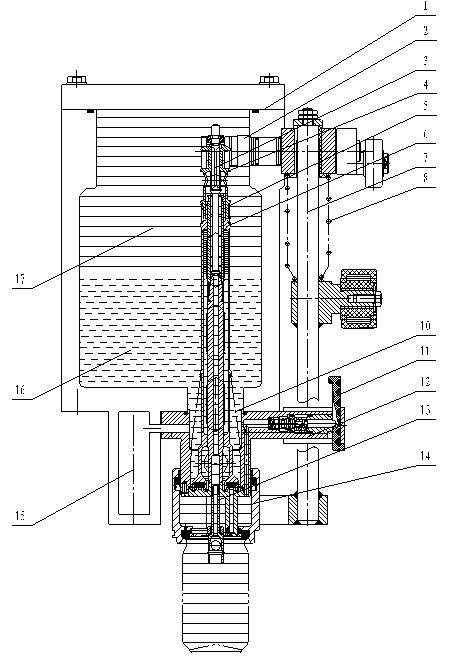

[0018] The filling valve of the present invention is installed on the rotary disc (not shown) of the filling machine, and rotates together with the rotary disc, as figure 1 As shown, the filling valve of the present invention mainly includes an annular material cylinder 1, a valve body 12 is provided at the bottom of the annular material cylinder 1, and a valve seat is installed at the bottom of the valve body 12. The lower space of the annular material cylinder 1 is used to house materials 16 , and the space above the materials is filled with back pressure gas 17 . The side wall of the annular material cylinder 1 is provided with a shift fork 2 that penetrates the material cylinder. One end of the shift fork 2 protruding from the material cylinder is connected to the eccentric wheel. The end of the shift fork 2 extending into the material cylinder is stuck on the sliding sleeve 4, and the sliding sleeve 4 is vertical In the annular material cylinder, there is a central tube c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com