Continuous casting argon blowing stopper rod and preparation method and application thereof

A stopper rod and continuous casting technology, which is applied in the field of continuous casting argon-blowing stopper rod and its preparation, can solve problems such as easy formation of large bubbles, slag roll-out, mold overflow, etc., so as to improve flow control accuracy and purify molten steel The effect of improving quality and improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

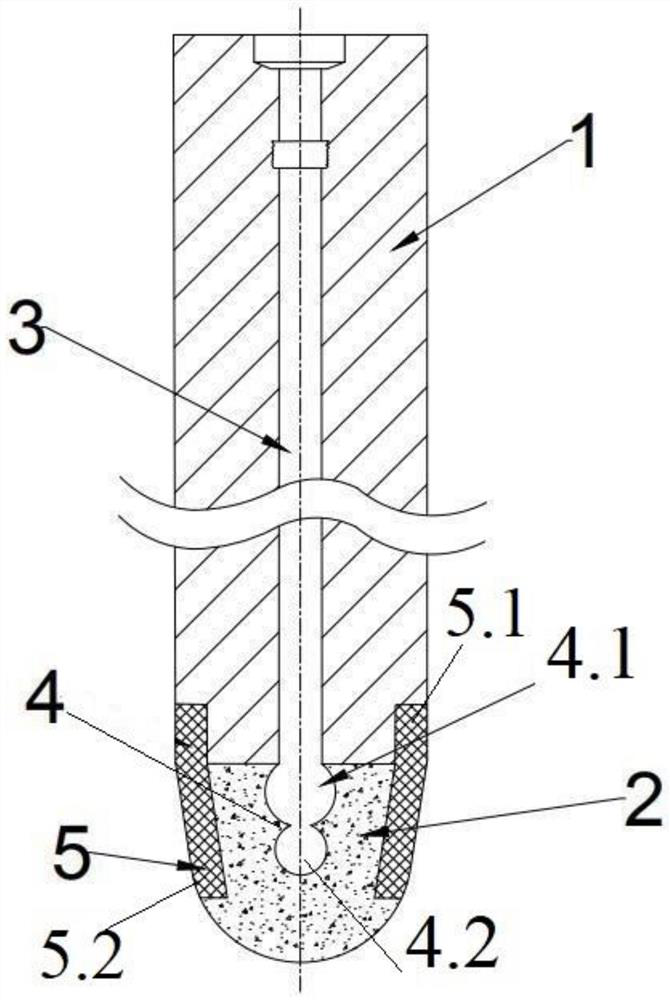

[0044] combine figure 1 It can be seen that the present invention discloses a continuous casting argon blowing plug rod, which combines figure 1 It can be seen that it includes a stopper rod body 1 and a stopper rod head 2 located at the front end of the stopper rod body 1. The stopper rod body 1 is provided with a tubular argon gas channel 3 leading to the stopper rod head 2. The stopper rod head 2 It is made of mesoporous material, the apparent porosity of the mesoporous material of the present invention is ≥18%, the median diameter of the pore diameter is ≤50 nm, and the apparent porosity of the mesoporous material is further preferably 18-30%, because the apparent porosity is When the rate is too large, the density of the plug head is too low and the structure is loose, which will affect the use effect; if the apparent porosity is too small, the air permeability will be low, which will affect the effect of argon blowing.

[0045] The inside of the stopper head 2 is provid...

Embodiment 2

[0050] The present invention discloses the preparation method of the stopper rod with the structure of the above-mentioned embodiment 1, which comprises the following steps:

[0051] 1) Ingredients: each part of the stopper is mixed with the raw materials by weight according to the ingredient list;

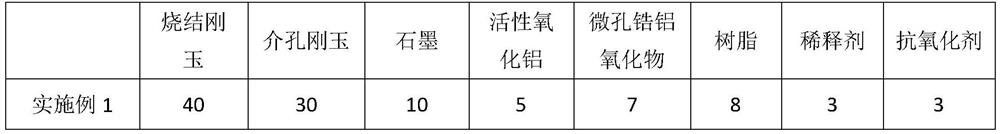

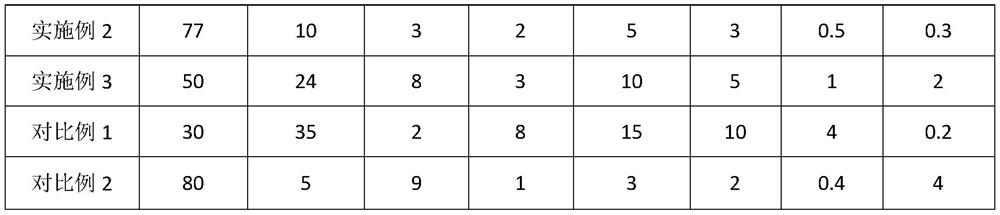

[0052] Wherein, the stopper head 2 is made of mesoporous material, wherein the mesoporous material is made from the following weight percentages of each raw material:

[0053] Sintered corundum 40%~77%, mesoporous corundum 10%~30%, graphite 3%~10%, activated alumina 2%~5%, microporous zirconium aluminum oxide 5%~10%, resin 3%~8 %, plus diluent 0.5%~3%, antioxidant 0.3%~3%;

[0054] The anti-scour layer contains the following weight percentages of each raw material:

[0055] Zirconium corundum 30%~65%, zircon sand 20%~40%, graphite 3%~10%, activated alumina 2%~5%, spinel 5%~10%, resin 3%~8%, Oxidant 0.3% to 3%.

[0056] The material of the stopper rod is a conventional material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com