Method and Apparatus for Flushing a Container with an Inert Gas

a technology of inert gas and container, applied in the field of potable fluid bottling, can solve the problems of adding more time to reducing the efficiency of the overall packaging cycle, and not being useful in the application of the method for non-pressurized containers such as milk and juice bottles, so as to improve the reduction of oxygen, reduce equipment and space, and improve the effect of oxygen reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A need remains for an effective method and apparatus for inerting a beverage container. Such a method preferably should work with established capping apparatuses and require a minimum of space for the inerting apparatus. In addition, a method and apparatus that can perform the inerting without adding additional time to the overall filling / sealing procedure would be considered advantageous.

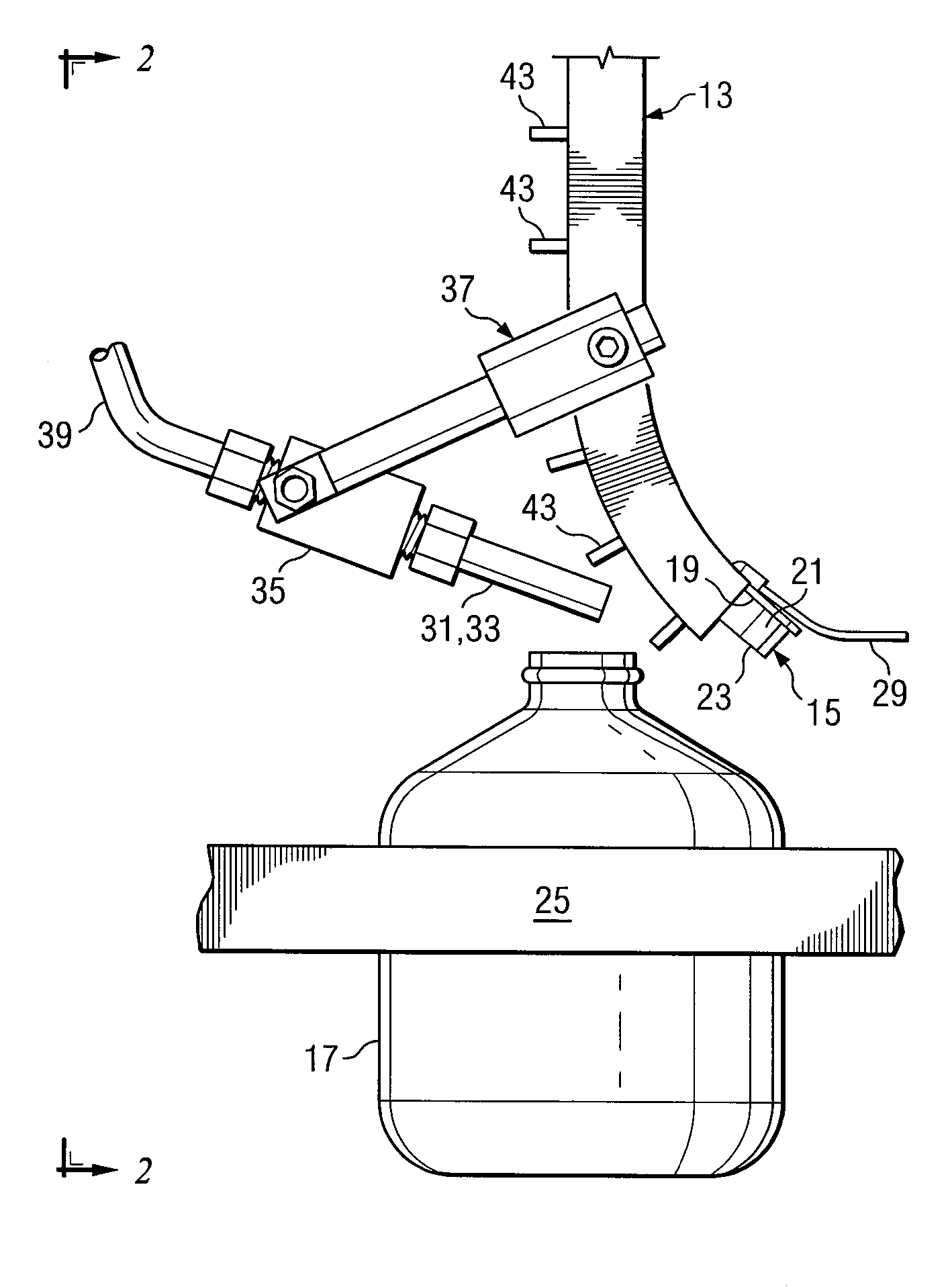

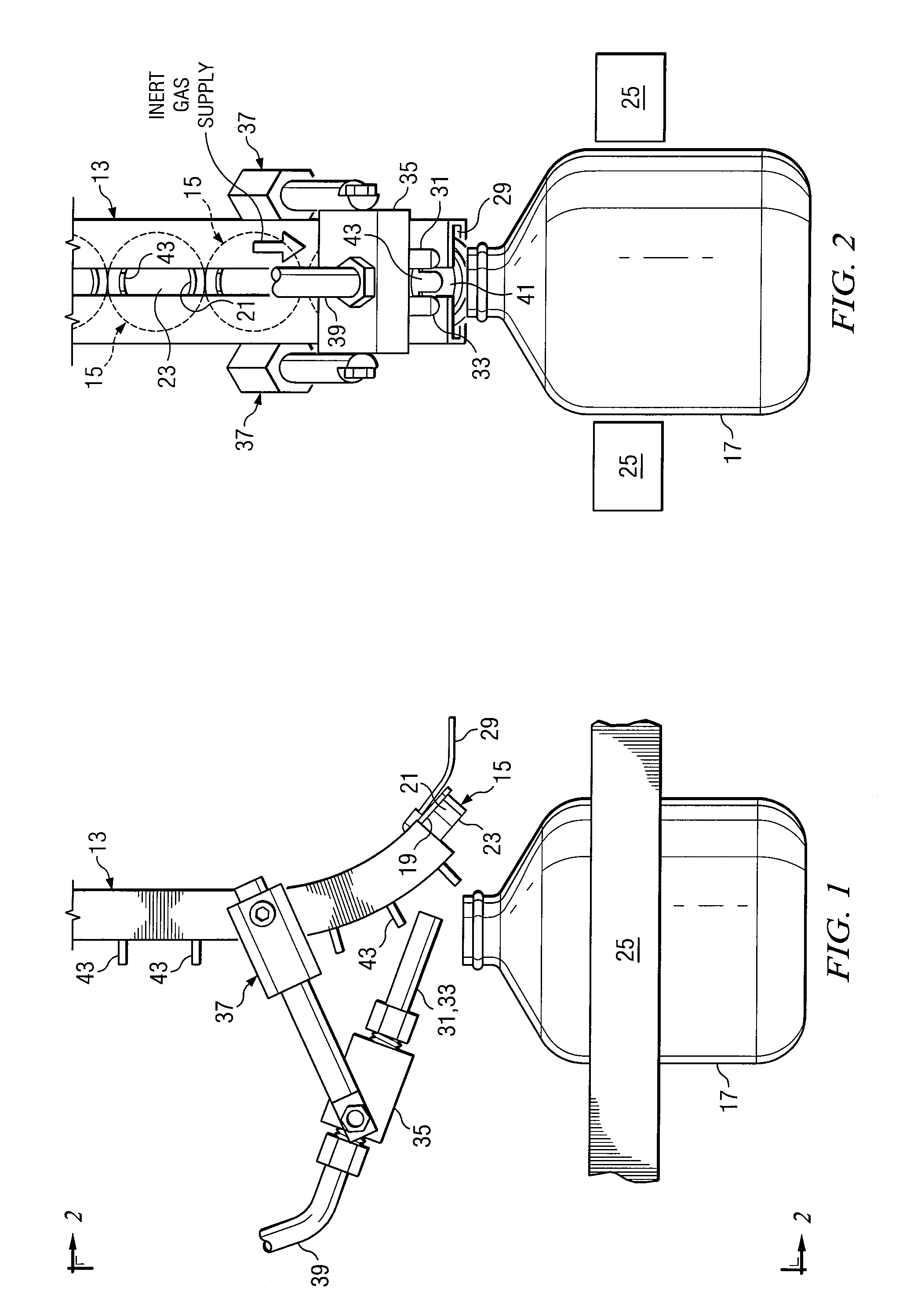

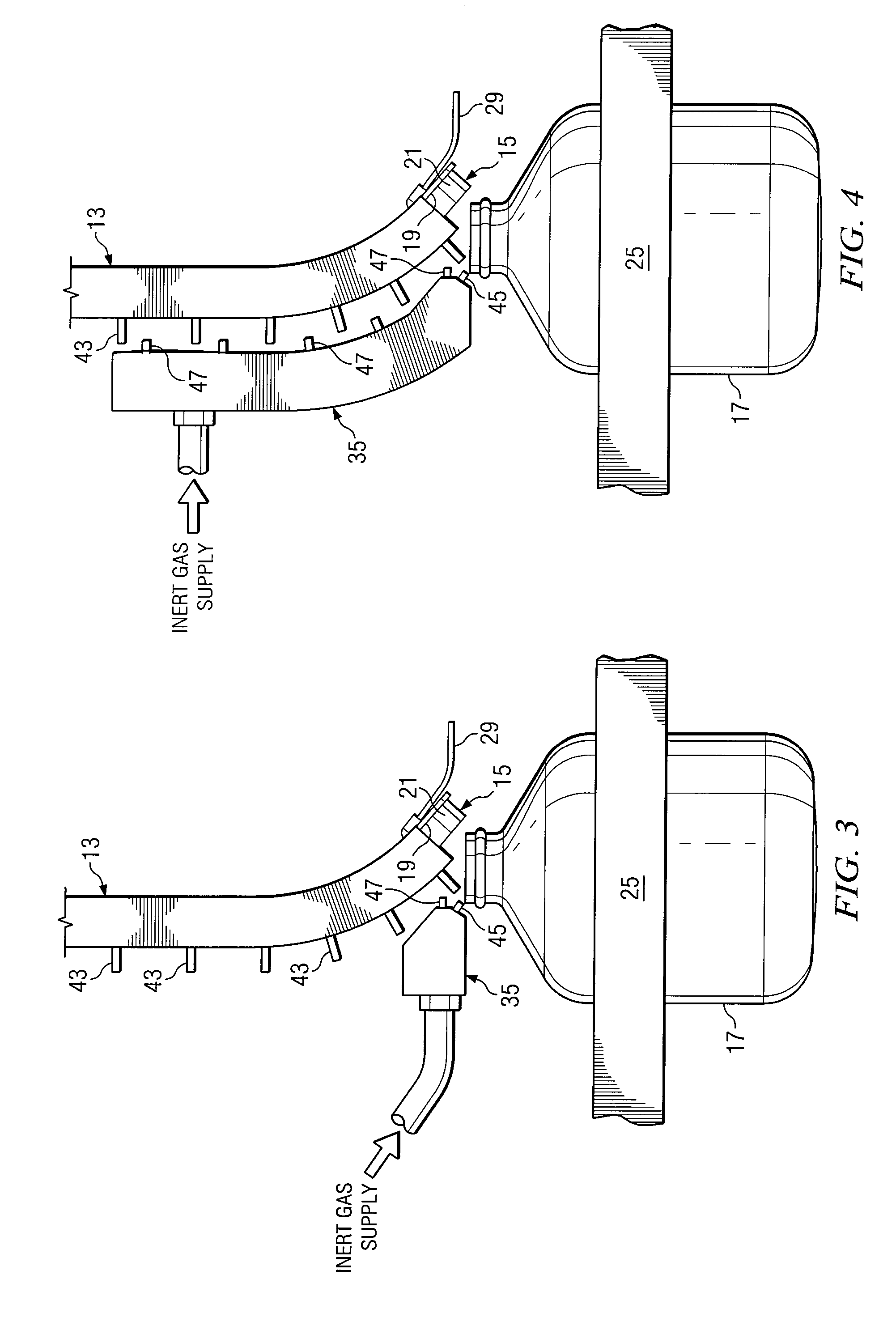

[0023]FIGS. 1 and 2 show a typical apparatus for capping one-gallon plastic milk bottles. The apparatus 11 is shown in schematic with nonessential equipment removed for visibility. Throughout the figures, which are not drawn to scale, equivalent elements are given identical reference numbers. While snap-on caps are shown, it is believed screw-on caps can also make use of the method of the invention for low pressure service, i.e. service in which the pressure in the sealed head space can range from slightly below to slightly above atmospheric pressure when capped, but not at high enough pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com