Method for aseptic filling with carbon dioxide-containing liquid contents

A carbon dioxide, filling method technology, applied in liquid filling, liquid processing, liquid bottling, etc., can solve problems such as taste deterioration, and achieve the effect of maintaining taste, reducing container cost, and maintaining high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

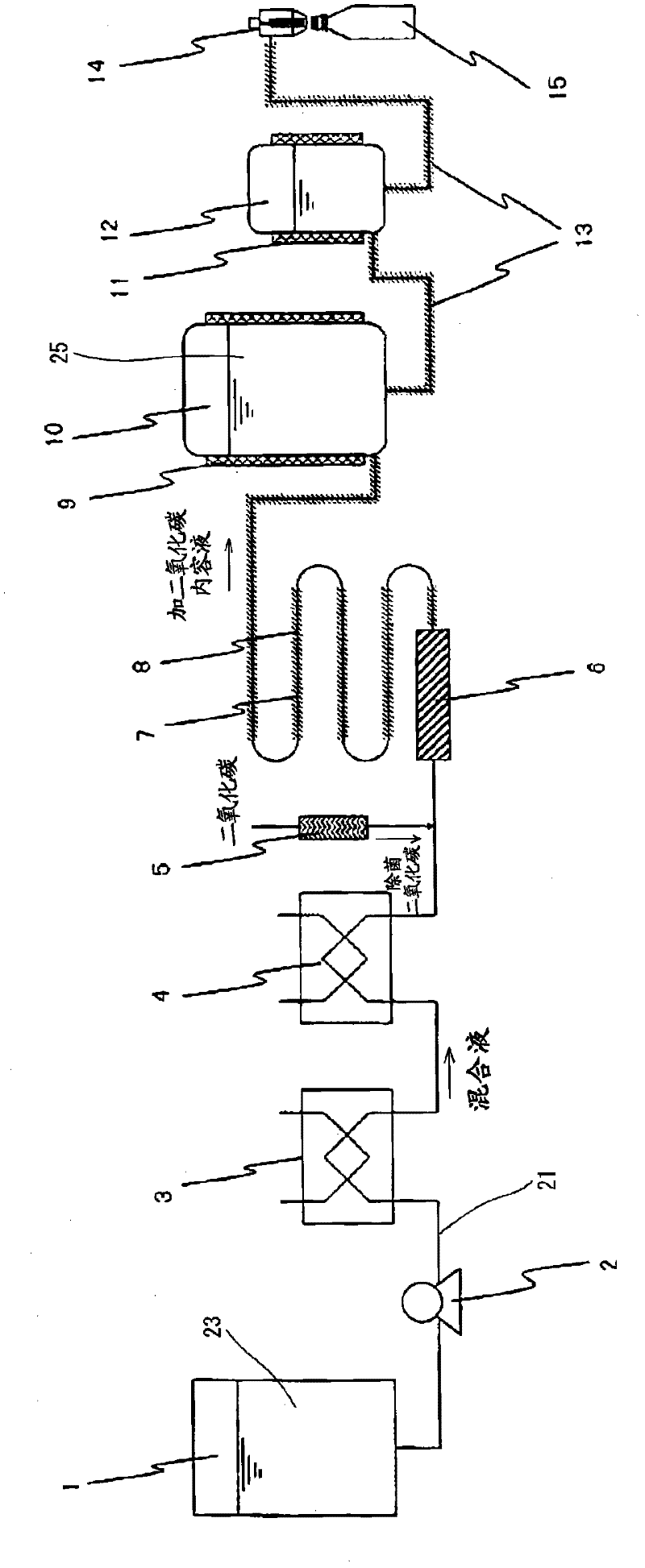

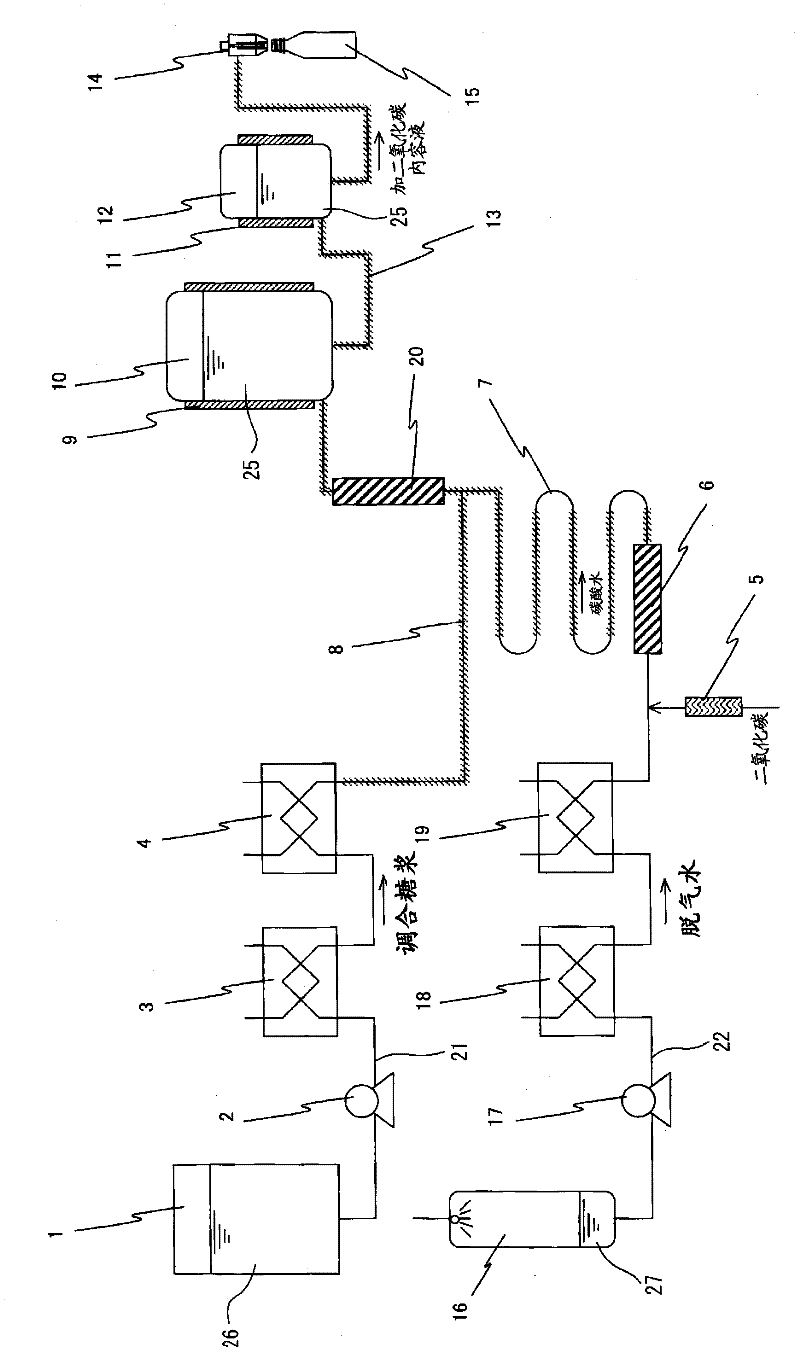

[0044] use figure 1 In the system shown, a fruit juice drink blended with 10% by weight of lemon juice, 10% by weight of sucrose, and 80% by weight of water is sterilized at 95° C. for 40 seconds, and then cooled.

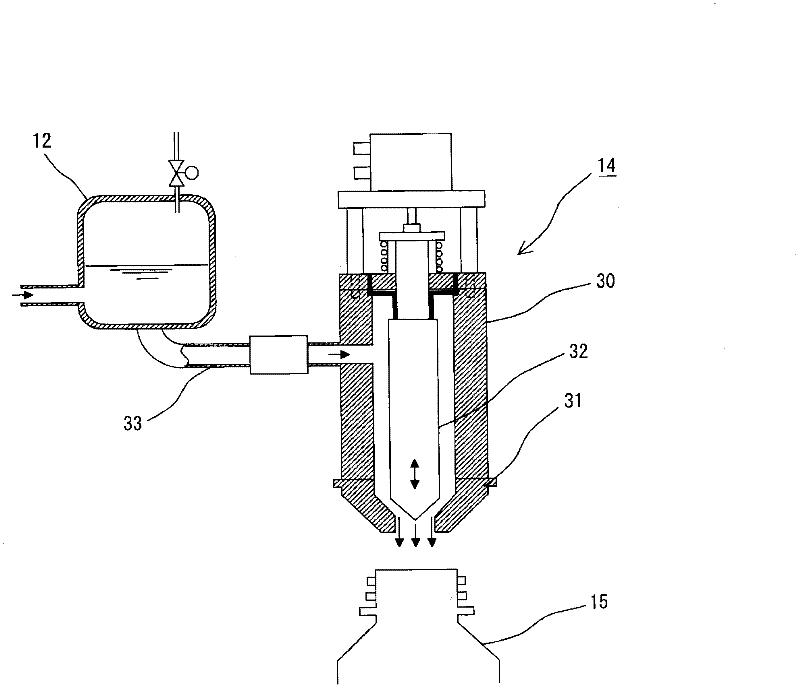

[0045] Then, the above-mentioned sterilized fruit juice drink was mixed with sterilized carbon dioxide, cooled, and the carbon dioxide pressure of the fruit juice carbonated drink when it was supplied to the filling valve was set to a gas volume of 2.1. Fill the fruit juice carbonated drink into a polyester resin bottle with an inner capacity of 500ml sterilized by warm water with a non-contact filling valve, and then seal it with a sterilized plastic bottle cap to prepare a fruit juice with a standard carbon dioxide pressure of 1.8 gas capacity. Carbonated soft drink bottled drink. In addition, the above cooling temperature was set to 4°C, and the filling temperature was set to 6°C.

[0046] In the preparation of the above-mentioned bottled beverage, the foam ov...

Embodiment 2

[0048] Except having made cooling temperature 3 degreeC and filling temperature 5 degreeC, it carried out similarly to Example 1, prepared the bottled drink, and evaluated it.

Embodiment 3

[0050] The carbon dioxide pressure of the carbonated beverage with fruit juice when it is supplied to the filling valve is set to a gas capacity of 2.3, the cooling temperature is set to 1°C, and the filling temperature is set to 3°C, and the standard carbon dioxide pressure of the product after filling and sealing, that is, the gas capacity of 1.9 is prepared. Bottled beverages containing fruit juice carbonated drinks were prepared in the same manner as in Example 1, and evaluated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com