Method for repairing anti-seepage weathering bedrock at bottom of waste slag or tailings storage yard

A repair method and weathering technology, applied in infrastructure engineering, protective devices, buildings, etc., can solve problems such as insufficient strength, environmental pollution, etc., and achieve the effect of increasing bearing strength and ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

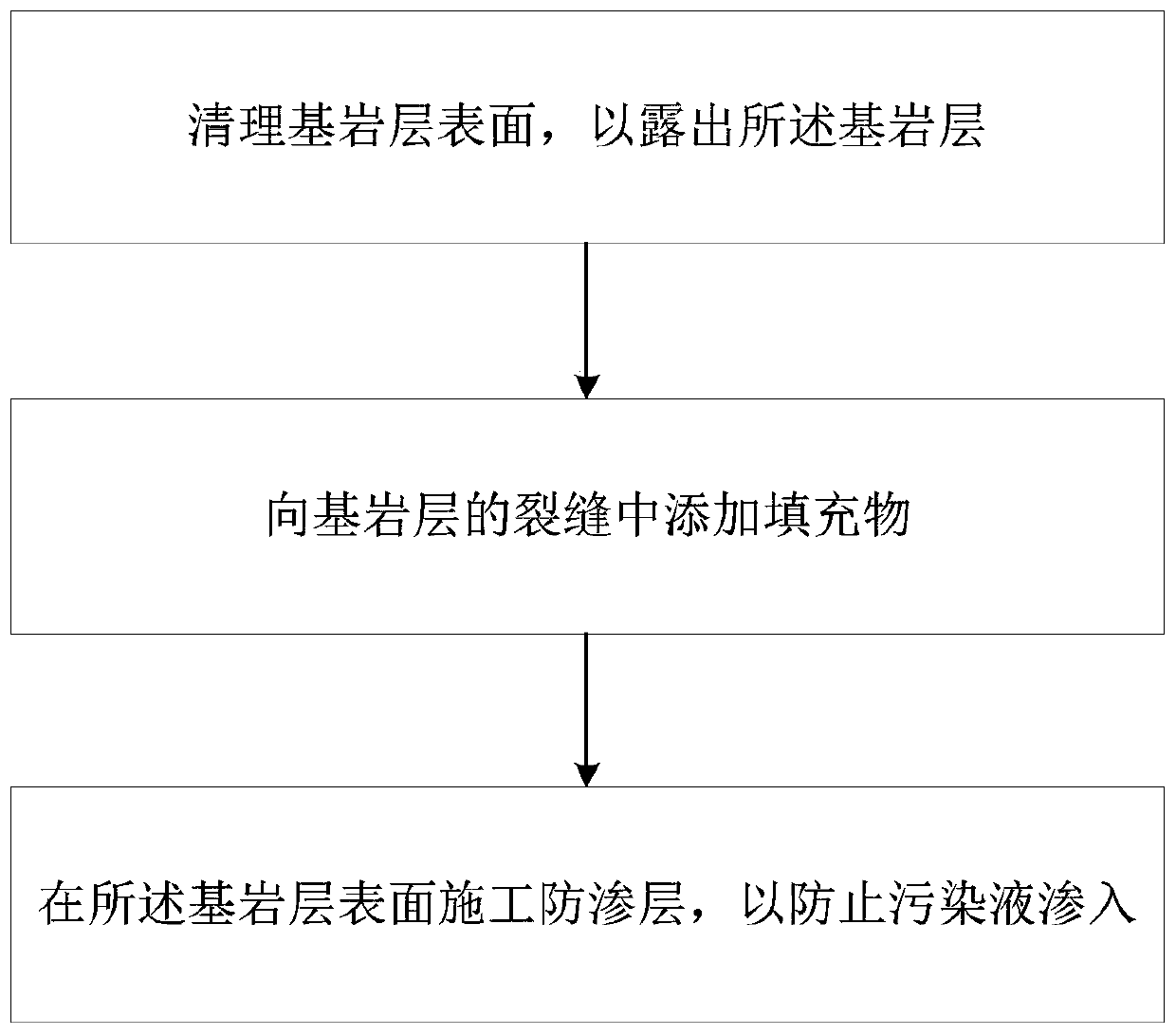

[0034] An embodiment of the present invention provides a method for repairing anti-seepage and weathered bedrock at the bottom of a waste residue or tailings stockyard, comprising the following steps:

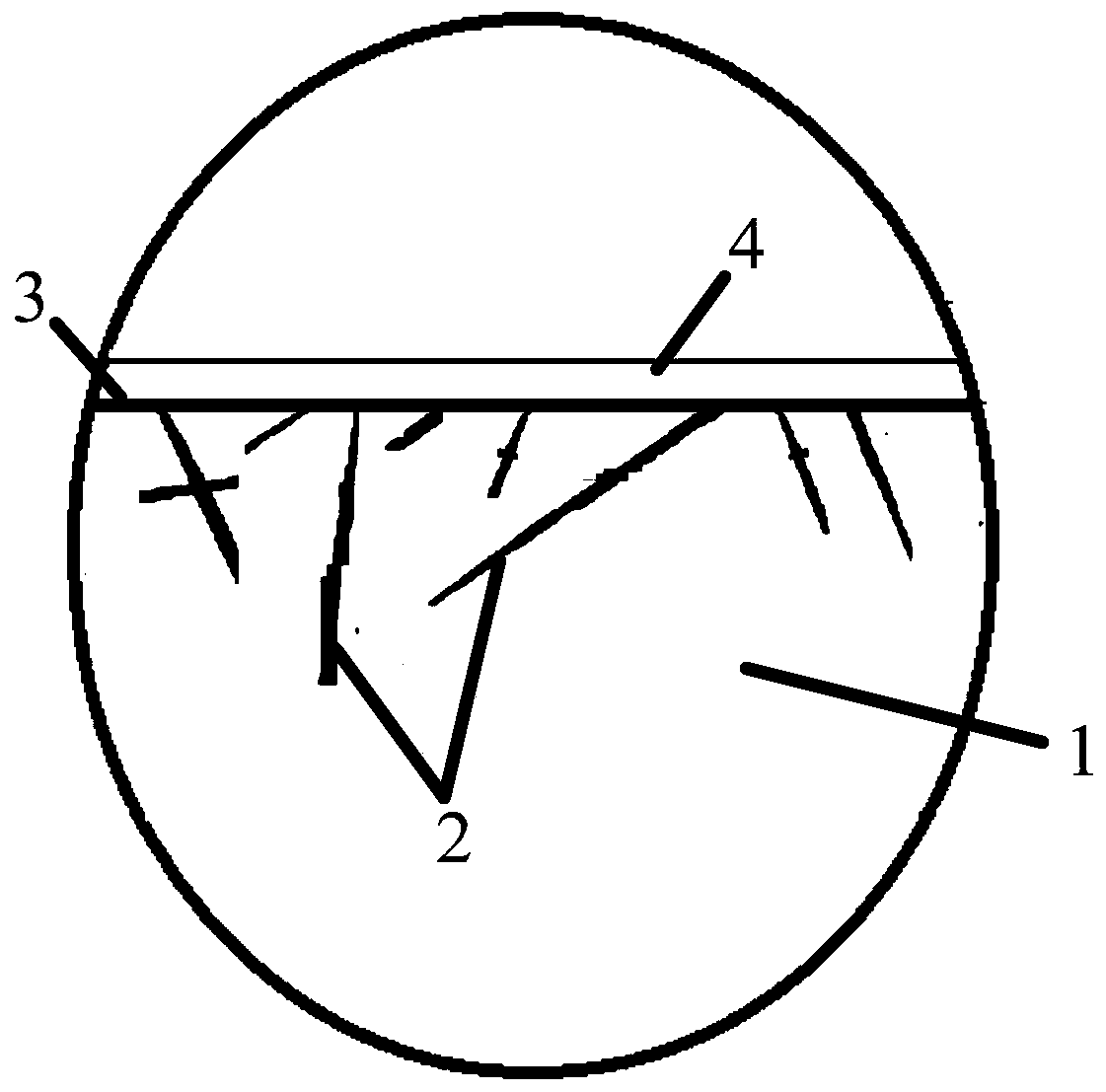

[0035] S1 cleaning the surface of the bedrock layer (1) by means of negative pressure suction to expose the bedrock layer 1;

[0036] S2 Adding polymer glue to the crack 2 of the bedrock layer 1, the polymer glue is a colloid formed by reusing slag, which has the advantage of environmental protection;

[0037] S3 Constructing an anti-seepage layer 3 on the surface of the bedrock layer 1 to prevent the infiltration of polluted liquid. By adding the polymer glue in the cracks 2 of the bedrock layer 1, the bearing strength of the bedrock layer 1 can be effectively increased to ensure construction safety. Moreover, the anti-seepage layer 3 on the surface of the above-mentioned polymer glue and the bedrock layer 1 can effectively prevent industrial waste, process waste liquid, chem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com