Gypsum casting method for large-sized thin-walled aluminum alloy castings

An aluminum alloy casting and gypsum molding technology, applied in the field of aluminum alloy casting, can solve problems such as the quality of large thin-walled aluminum alloy castings to be improved, achieve uniform and controllable filling temperature, prevent inhalation and secondary oxidation, and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

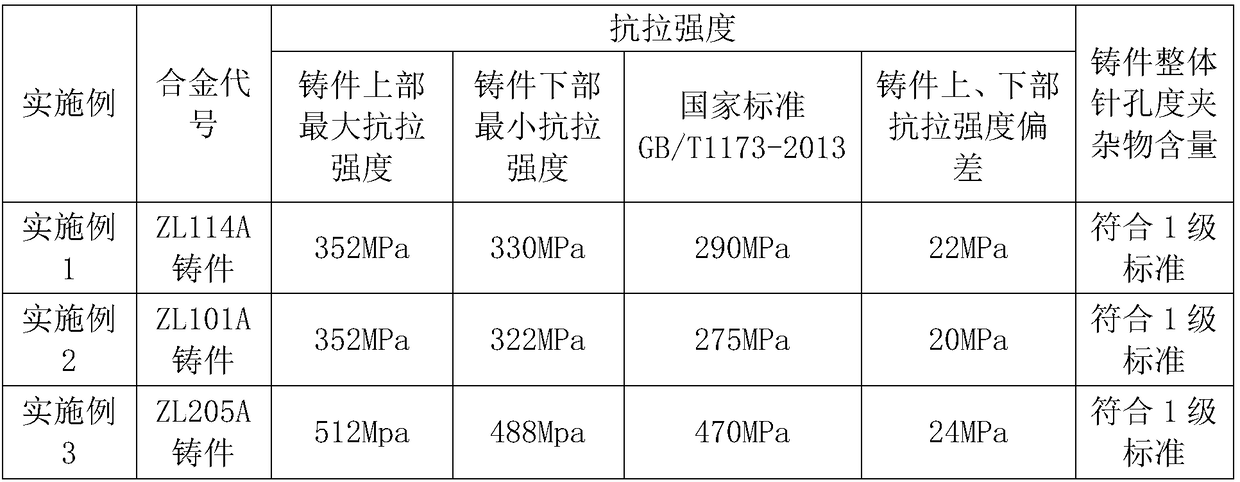

[0033] The aluminum alloy material is ZL114A aluminum alloy ingot, the casting height is required to be 1760mm, and the main body wall thickness is 3.5mm.

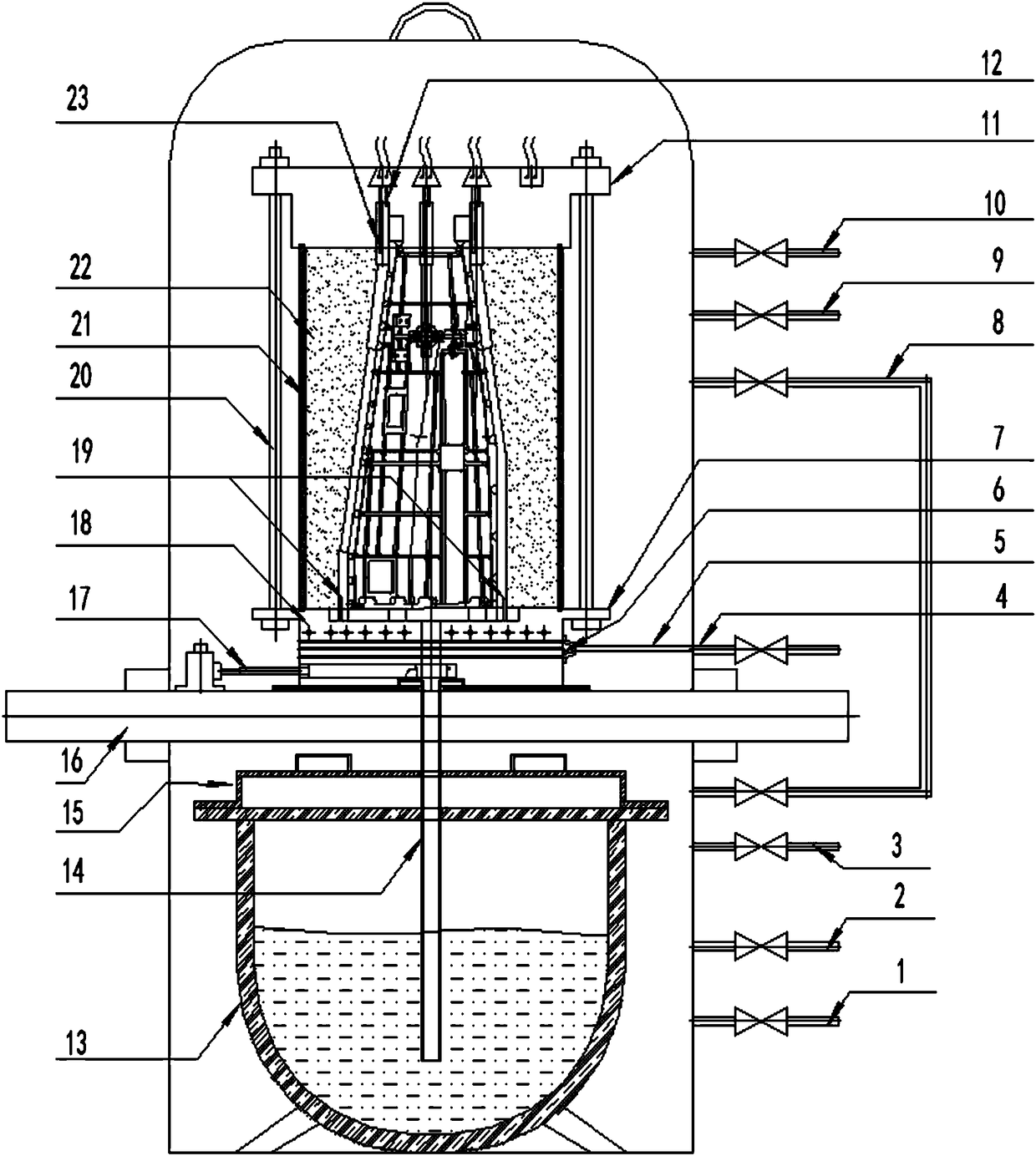

[0034] Casting equipment such as figure 1 As shown, wherein, the fast sealing mechanism 17 includes an oil cylinder, the oil cylinder is connected to one end of the telescopic rod, and the other end of the telescopic rod is connected to the shut-off member, and the quick sealing mechanism 17 can be activated to quickly close the riser pipe 14 and cut off the melt supply.

[0035] The concrete steps of this casting gypsum casting method are as follows.

[0036] Step 1, melting and slag removal: evenly stack the aluminum alloy ingots in the silicon carbide crucible 13 in the lower tank of the differential pressure casting machine 8, set the furnace temperature to 790°C, and heat up and melt at full speed; when the aluminum alloy ingots are completely melted, use Graphite slag scoop removes scum on the surface of the aluminu...

Embodiment 2

[0045] The aluminum alloy material is ZL101A aluminum alloy ingot, the casting height is required to be 1620mm, and the main body wall thickness is 3mm.

[0046] Casting equipment such as figure 1 shown.

[0047] The concrete steps of this casting gypsum casting method are as follows.

[0048] Step 1, melting and slag removal: evenly stack the aluminum alloy ingots in the silicon carbide crucible in the lower tank of the differential pressure casting machine, set the furnace temperature to 780°C, and heat up and melt at full speed; when the aluminum alloy ingots are completely melted, use graphite material Use the slag scoop to remove the scum on the surface of the aluminum alloy melt, and adjust the melt temperature to 735°C;

[0049] Step 2, gas-powder compound refining: when the temperature of the aluminum alloy melt reaches 735°C, use argon gas and aluminum alloy refining agent AJ01C for gas-powder compound refining treatment. The refining time is 15 minutes. After the r...

Embodiment 3

[0057] The aluminum alloy material is ZL205A aluminum alloy ingot, and the casting height is required to be 1580mm, and the main body wall thickness is 3.2mm.

[0058] Casting equipment such as figure 1 shown.

[0059] The concrete steps of this casting gypsum casting method are as follows.

[0060] Step 1, melting and slag removal: evenly stack the aluminum alloy ingots in the silicon carbide crucible in the lower tank of the differential pressure casting machine, set the furnace temperature to 800°C, and heat up and melt at full speed; when the aluminum alloy ingots are completely melted, use graphite material Use the slag scoop to remove the scum on the surface of the aluminum alloy melt, and adjust the melt temperature to 745°C;

[0061] Step 2, gas-powder compound refining: when the temperature of the aluminum alloy melt reaches 745°C, use argon and aluminum refining agent AJ203 for gas-powder compound refining treatment, the refining time is 15 minutes, after refining,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com