Fabric with cotton filling stereoscopic effect and weaving method thereof

A three-dimensional effect and fabric technology, applied in textiles and papermaking, textiles, fabrics, etc., can solve problems such as complex processing processes, and achieve the effects of simple weaving methods, increased swelling, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

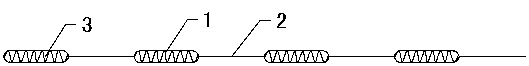

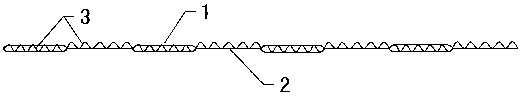

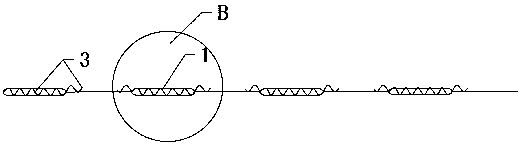

[0037] The convex parts 1 and the concave parts 2 on both sides of the fabric prepared in this example are arranged in a checkerboard shape, the convex parts 1 and the concave parts 2 are squares with a side length of about 2 cm, and the side parts of each convex part 1 are The concave part 2 and the convex part 1 are double-layered weave composed of surface weave and inner weave, and high shrinkage yarn 3 is arranged between the surface weave and the inner weave.

[0038] 1) First design the pattern effect and select the type of yarn: such as Figure 1~2 As shown, the surface organization of the convex part 1 and the concave part 2 is a plain weave, and the warp and weft use 8 different colors of cotton yarns of A, B, C, D, E, F, G, H, and the surface of the fabric presents ordinary yarns The yarn-dyed lattice effect, the solid color lattice and the yarn-dyed lattice are interlaced, the solid color lattice is partially raised, the yarn-dyed lattice is partially concave, and t...

Embodiment 2

[0043] The front and back sides of the fabric prepared in this embodiment present the same concavo-convex effect, such as Image 6 As shown, the protruding part 1 is in the shape of "convex", a plurality of protruding parts 1 are evenly arranged in parallel rows, and the rest are concave parts 2.

[0044] 1) First design the pattern effect and select the type of yarn: the surface texture of the convex part 1 and the concave part 2 are twill weave, and the warp and weft are made of yarns of two different colors and materials, A and B, and the surface of the convex part 1 Light pink yarn A is displayed, dark blue yarn B is displayed on the surface of concave part 2, yarn A is polyester spun yarn, yarn B is polyester-cotton blended yarn, and concave part 2 is composed of surface weave and inner weave Hollow double tissue. In this embodiment, the high-shrinkage yarn 3 is a 400D heat-shrinkable high-elastic nylon filament, which is woven with the two yarns A and B to form a semi-f...

Embodiment 3

[0049] The front and back sides of the fabric prepared in this embodiment present the same concavo-convex effect, such as Figure 7 As shown, the raised part 1 presents the shape of "口", each side of the word "口" is a raised part 1, the middle and surrounding of the word "口" is a concave part 2, and a plurality of raised parts in the shape of "口" 1 are horizontally and vertically parallel and evenly arranged.

[0050] 1) First design the pattern effect and select the type of yarn: the convex part 1 is hollowed out on the surface, and the concave part 2 is a single-layer plain weave. The warp and weft are made of four different colors and materials of yarns A, B, C and D. The surface of the rising part 1 shows the effect of pure color A, and the surface of the concave part 2 shows the effect of A, B, C and D blended lattice, the yarns of A and C are worsted wool yarns, and the yarns of B and D are cotton yarns. The present embodiment high-shrinkage yarn 3 is 500D heat-shrinkab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com