Method for modifying and reinforcing rock and soil layer by injecting materials

A rock soil layer modification technology, applied in soil protection, construction, infrastructure engineering, etc., to achieve the effect of reducing energy consumption, small energy consumption, reducing procedures and construction volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

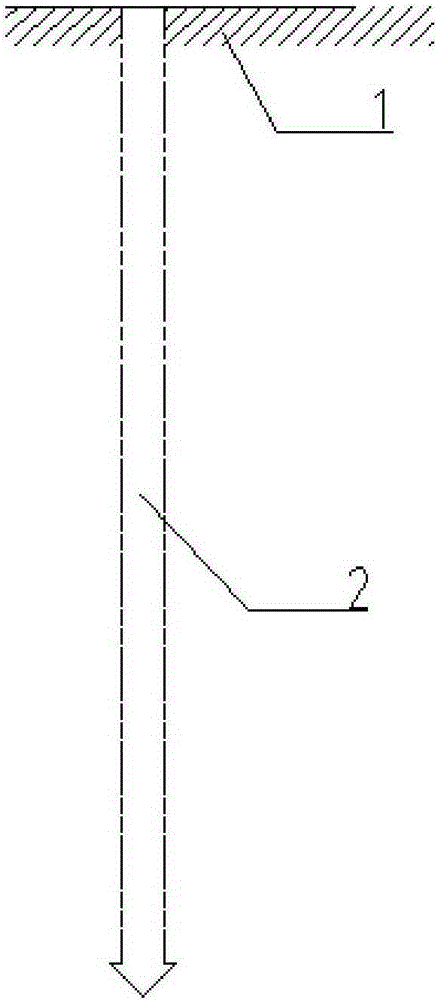

[0040] A method for modifying and strengthening rock and soil layers by injecting materials, comprising the following steps,

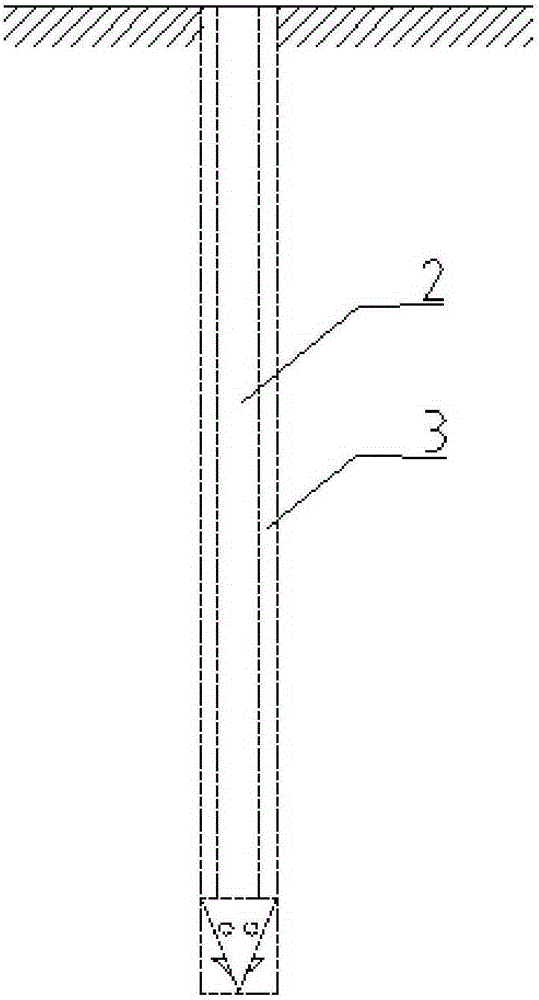

[0041] Drill the rock and soil layer from the ground 1 to form a hole with a diameter of 15 mm and a hole depth of 1 m. Insert the high-pressure gas explosion spray gun 2 into the hole, and fill the gap between the high-pressure gas explosion spray gun 2 and the hole wall with glass glue The space 3 between; Then carry out explosion fracturing to rock-soil layer with high-pressure gas explosion injection gun 2, because the high-pressure gas explosion injection gun 2 of use is the deep application injection gun of soil, the deep application injection gun of described soil The gun head is provided with openings arranged in a ring around the gun head, so that when the rock-soil layer is blasted, radial cracks 4 are formed in the rock-soil layer. When the high-pressure gas explosion spray gun 2 sprays high-pressure air, it will produce an instantaneous com...

Embodiment 2

[0045] On the basis of embodiment 1, the rock and soil layer is drilled from the ground 1 to form a hole with a diameter of 200mm and a hole depth of 200m. The high-pressure gas blasting spray gun 2 is inserted into the hole, and the high-pressure gas blasting is filled with cement The gap 3 between the spray gun 2 and the hole wall; and then use the high-pressure gas explosion spray gun 2 to blast and fracture the rock and soil layer, so that radial cracks 4 are formed in the rock and soil layer.

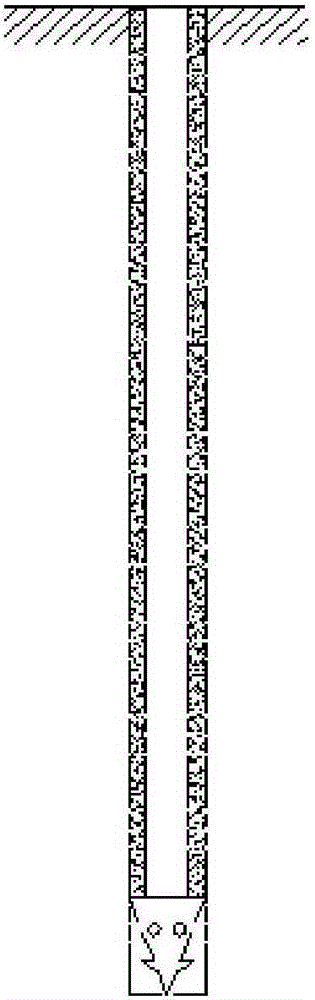

[0046] Then use the high-pressure gas spray gun 2 to spray fine sand in the radial crack 4 (if the rock and soil layer is a permafrost layer, inject industrial salt or deicing agent while spraying fine sand), the fine sand is sprayed to the blast In the formed radial fissure 4, pull back the high-pressure gas explosion spray gun 2 upwards for 20m, then use the high-pressure gas explosion injection gun 2 to blast the rock and soil layer, and spray fine sand, repeat this operation unt...

Embodiment 3

[0048] On the basis of Example 1, the rock and soil layer is drilled from the ground 1 to form a hole with a diameter of 350mm and a hole depth of 300m. The high-pressure gas blasting spray gun 2 is inserted into the hole, and the high-pressure gas is filled with viscous mud The gap 3 between the explosion spray gun 2 and the hole wall; and then the high-pressure gas explosion injection gun 2 is used to blast and fracturing the rock-soil layer, so that radial cracks 4 are formed in the rock-soil layer.

[0049] Then use the high-pressure gas spray gun 2 to spray fine sand in the radial crack 4 (if the rock and soil layer is a permafrost layer, inject industrial salt or deicing agent while spraying fine sand), the fine sand is sprayed to the blast In the formed radial fissure 4, pull back the high-pressure gas explosion spray gun 2 upwards by 50m, then use the high-pressure gas explosion injection gun 2 to blast the rock and soil layer, and spray fine sand, repeat this operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com