Excavation blind area pretreatment method and tunnel excavation construction method

A tunnel boring machine and pretreatment technology, which is applied in the pretreatment of blind areas in excavation and tunnel excavation construction, can solve the problems of excavation path deviation, boring machine topping, etc., and achieve the effect of convenient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0067]It is an object of the present invention to facilitate a stratum tunneling machine (non-circular:, but not limited to, rectangular, horseshoe, etc.) in a stratospheric, partial rock or pile foundation. Digging in the blind zone, and the blind zone is unable to cut into, which in turn makes a deviation of the digging path of the excavator, and even the problem of dying, and provides a new tunnel excavation construction method.

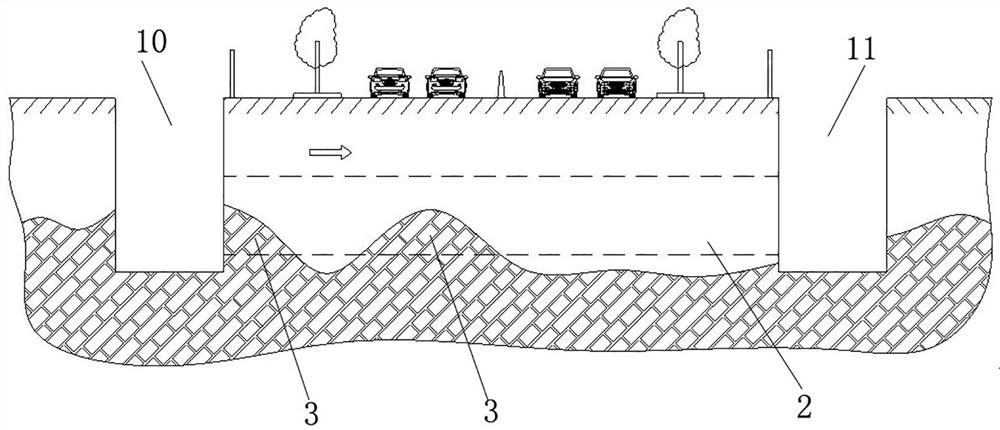

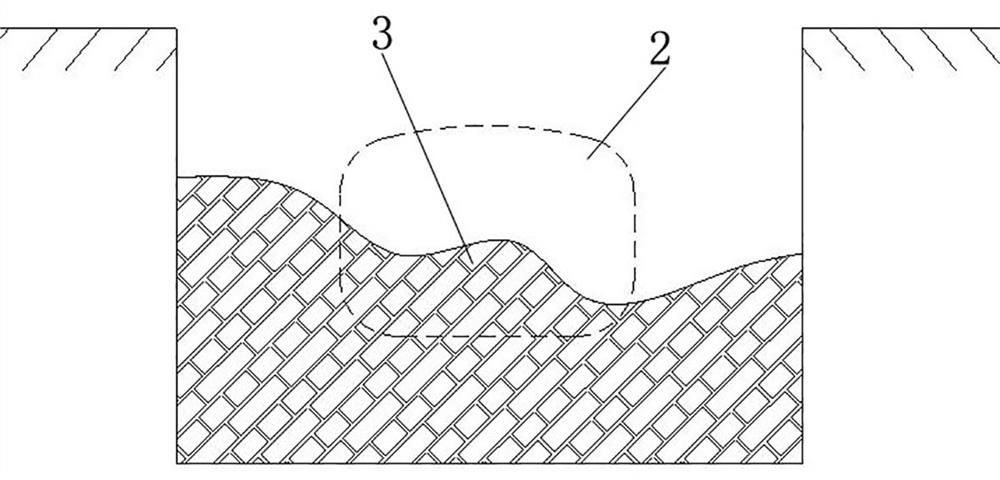

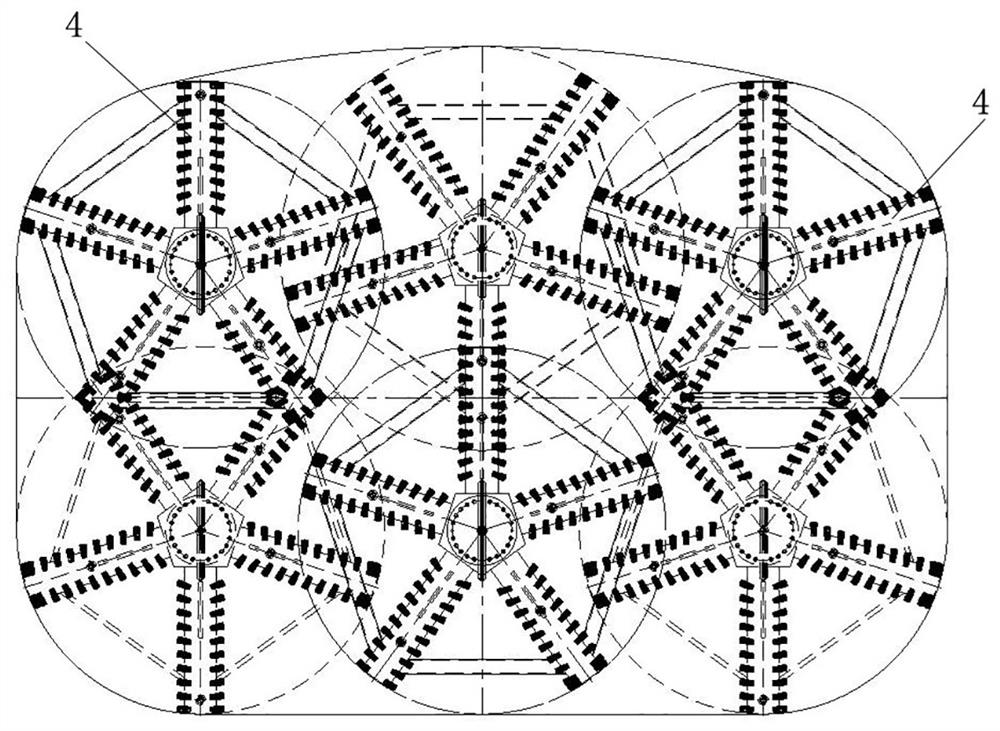

[0068]CombineFigure 1-14In this embodiment, through the geological exploration of the tunneling position, it is determined that the position of the base rock 3 in the soft soil 20 is determined, and the shaped section tunneling, the selection of the excavation machine needs to maximize the efficiency of the later digging machine. Stable excavation, and the shaped cross-sectionalging machine should have a stirring device, a foam injection system, and a bentonite improvement system, ensuring that the stabilization effect of the soil pressure or mud water bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com