Variable-suction-hole dual-disc air-aspiration type precise seeding device

An air-suction, double-disc technology, applied in the field of agricultural machinery, can solve the problems of easy-to-break pneumatic seed metering device sealing, performance degradation of seed metering device, cumbersome disassembly of equipment, etc., so as to improve seed filling performance and avoid sealing Sexual destruction, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with specific embodiments, so that those skilled in the art can understand.

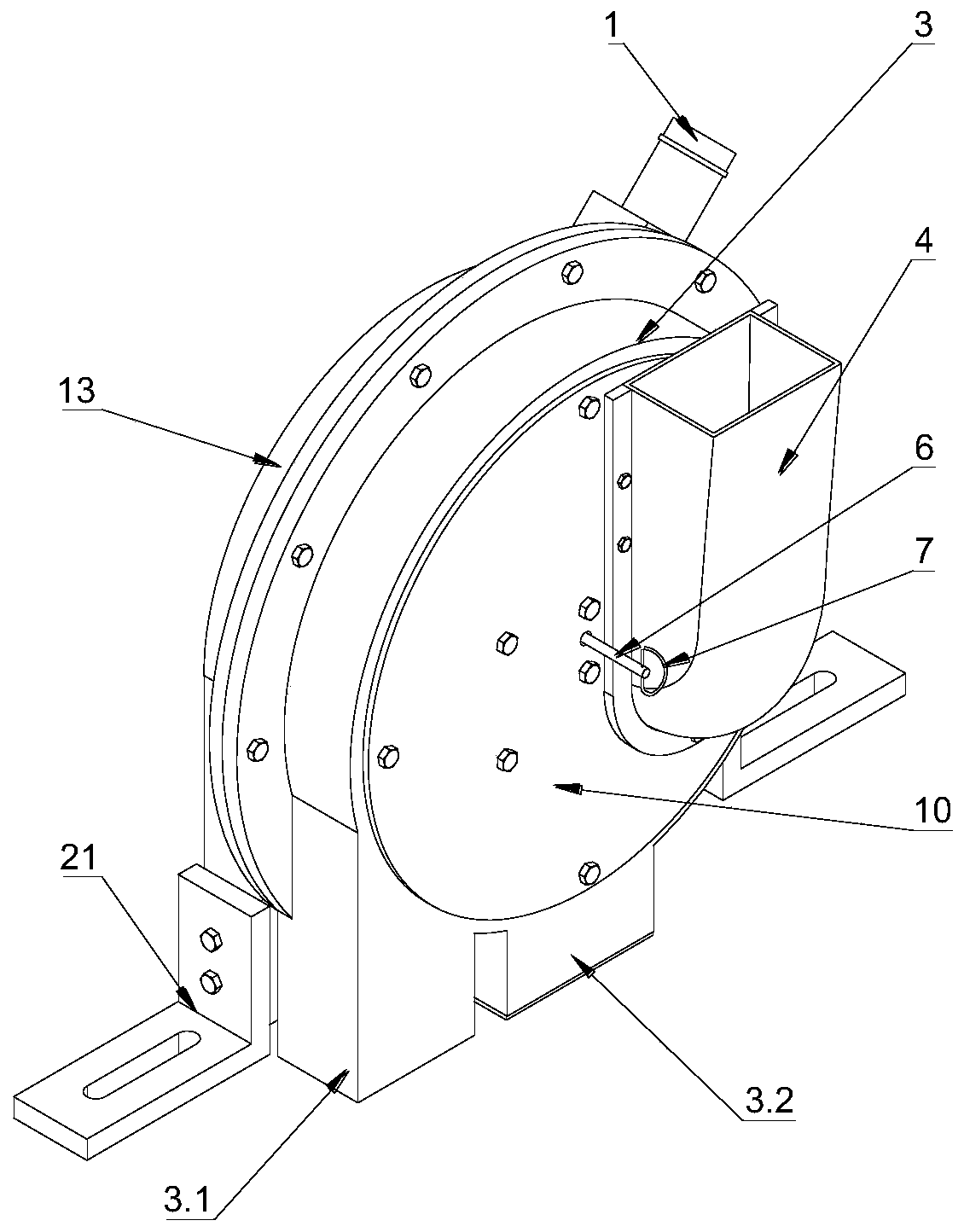

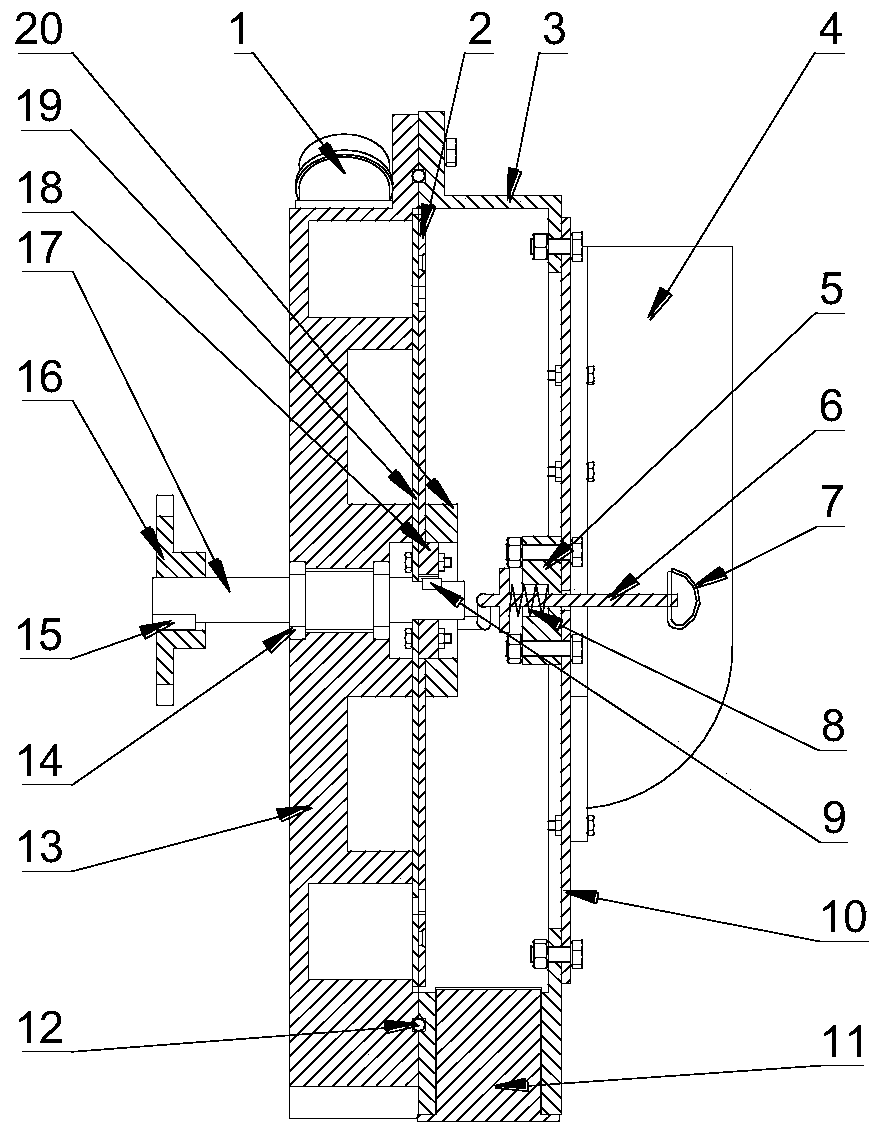

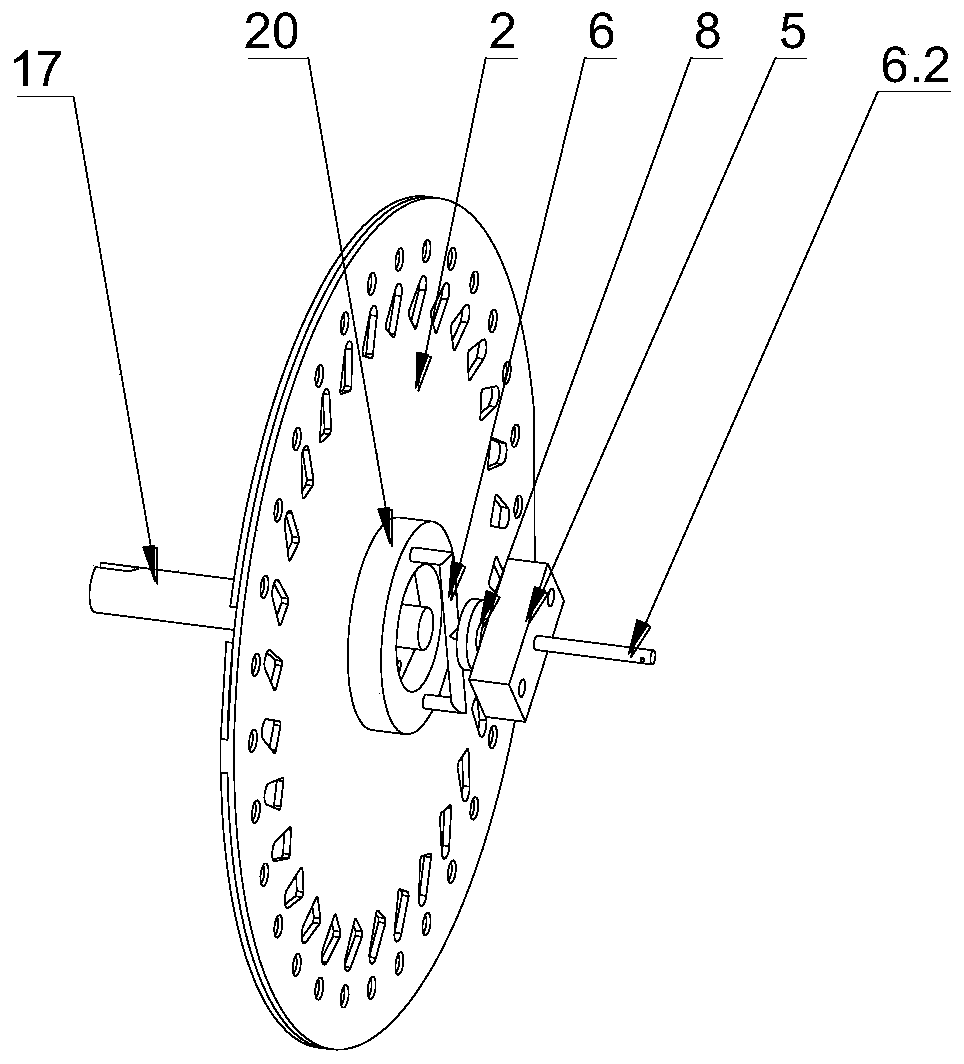

[0034] Such as Figure 1-14 The shown variable suction hole double-disk air-suction precision seed metering device includes a seed metering box, and the seed metering box is composed of an air chamber casing 13 and a front cover arranged symmetrically on the left and right, and the air chamber casing 13 is composed of CNC machining of aluminum alloy material, L-shaped base 21 is symmetrically arranged on both sides of the air chamber shell 13 through bolts; a 3 / 4 arc horseshoe-shaped negative pressure area 13.1 is arranged inside the air chamber shell 13; the negative pressure area 13.1 starts Directly below, finally to the left; the top of the air chamber housing 13 is provided with a suction port 1, and the suction port 1 is arranged in the central area of the negative pressure area; the suction port 1 and the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com