Imbibition bottle fluid adding device and method for imbibition experiment

A filling device and experimental technology, applied in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of hindering the downward flow of permeate, discontinuous permeate, time-consuming and labor-intensive problems, etc. problems, to achieve the effect of shortening filling time, simplifying manual operation and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

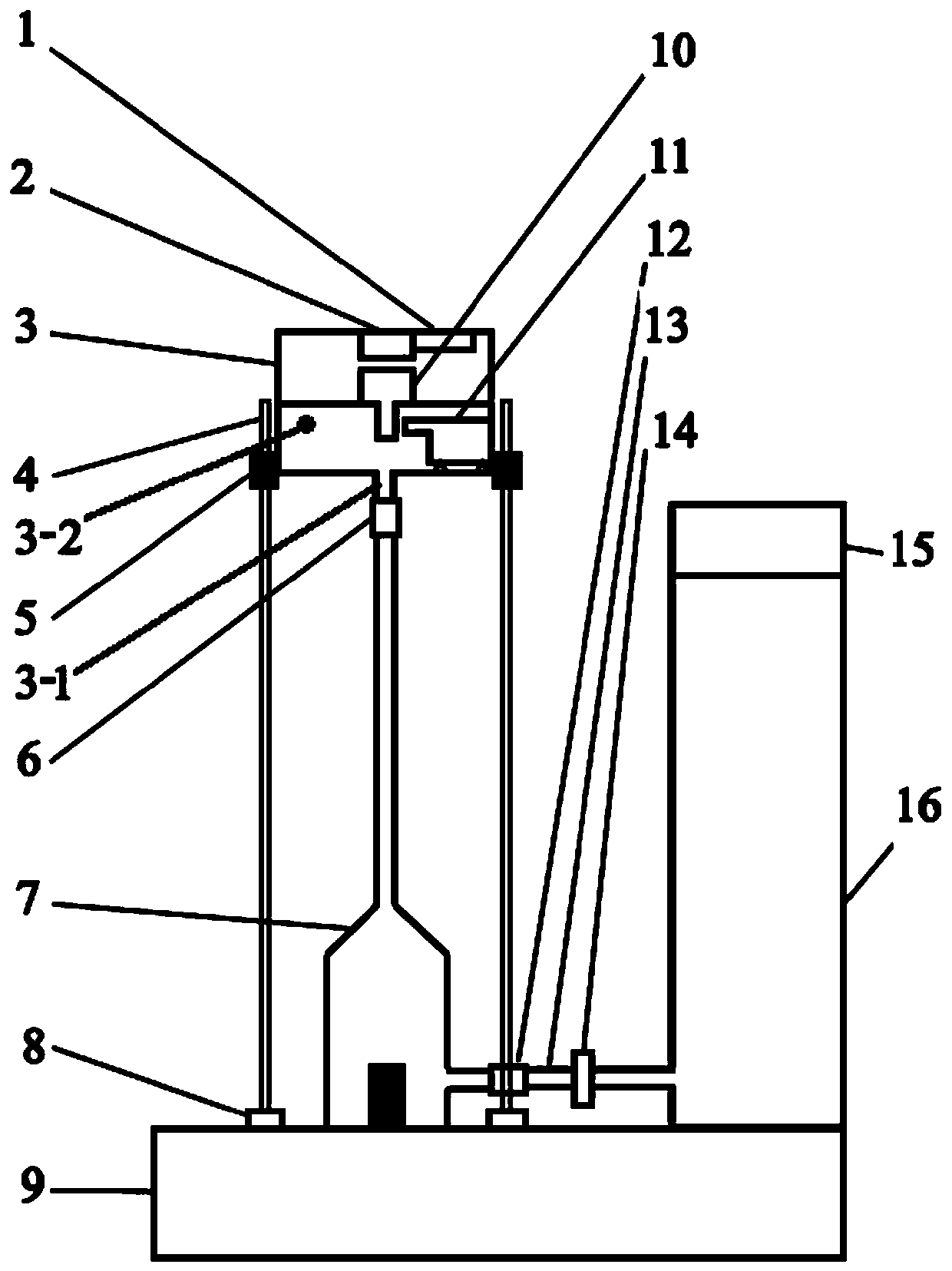

[0054] Such as figure 1 As shown, the fluid filling device for the osmosis bottle used in the osmosis experiment of this embodiment operates through the cooperation of the mechanical device and the control circuit, and converts the process of filling the osmosis liquid in the osmosis bottle from a traditional purely manual operation to a mechanical operation. Mainly, supplemented by manual operation, it effectively overcomes the problems of cumbersome operation and long time-consuming when using the traditional permeate filling method to fill the permeate bottle, and can significantly improve the accuracy of the experimental results , significantly reducing the operational difficulty of the permeate filling link, significantly shortening the time-consuming process of permeate filling, and significantly improving the efficiency of indoor simulation experiments.

[0055] The fluid filling device for the osmosis bottle used in the osmosis experiment includes a guide rail lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com