Method for filling goaf with different materials alternately

A goaf and filling zone technology, applied in the fields of filling, mining equipment, earth-moving drilling, etc., can solve the problems such as the inability to give full play to the advantages of different filling methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention proposes a method of alternate filling with different materials in the goaf, which integrates the advantages of paste filling and ultra-high water material filling, and realizes reducing filling costs and improving filling efficiency on the basis of ensuring the ground filling effect to the greatest extent. The annual output is more than one million tons.

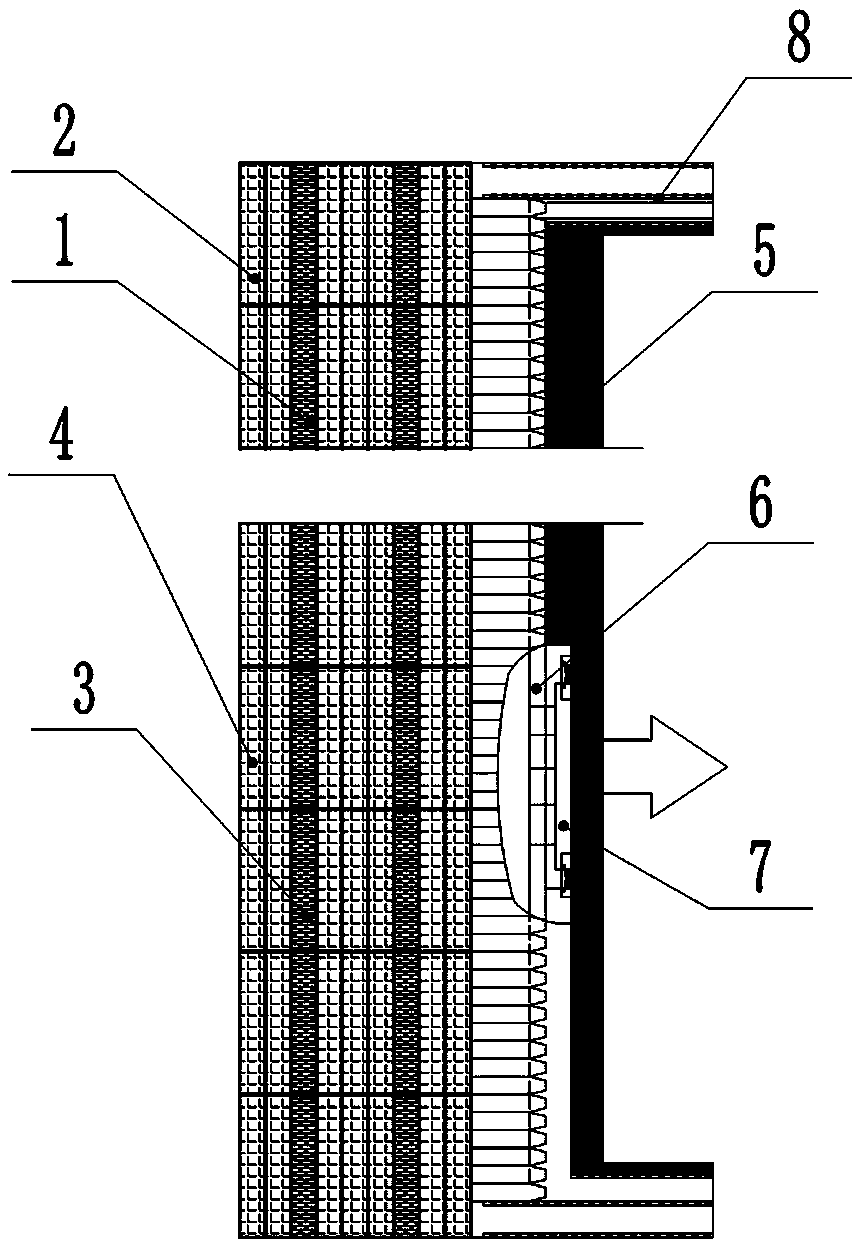

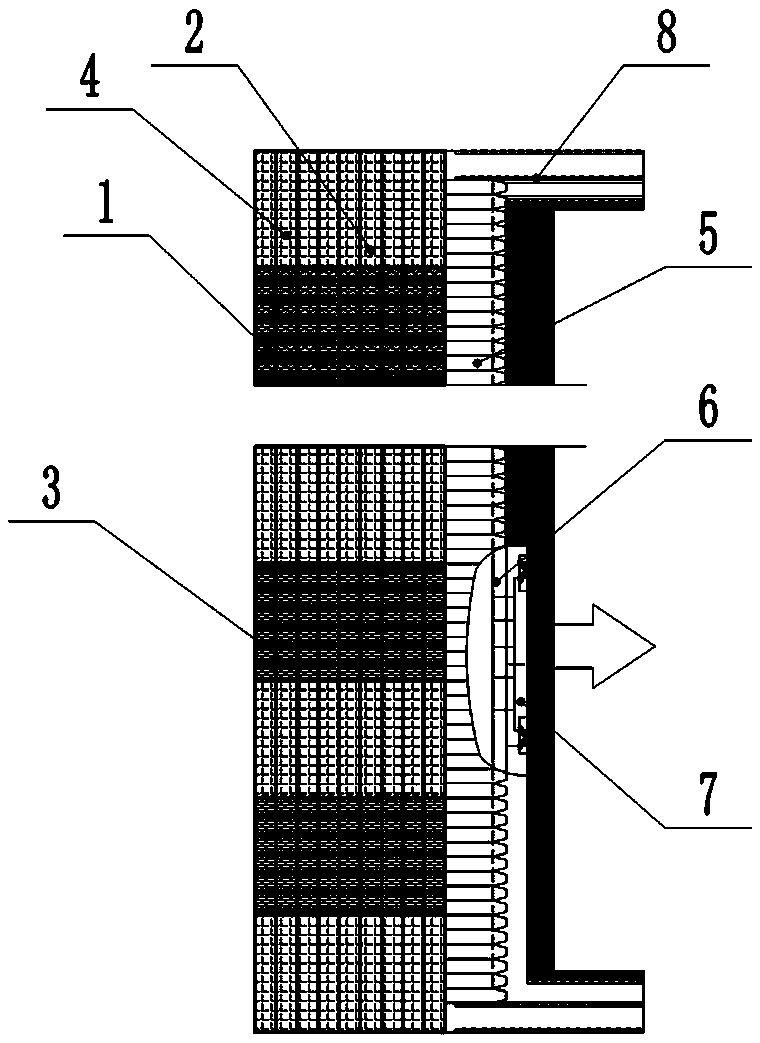

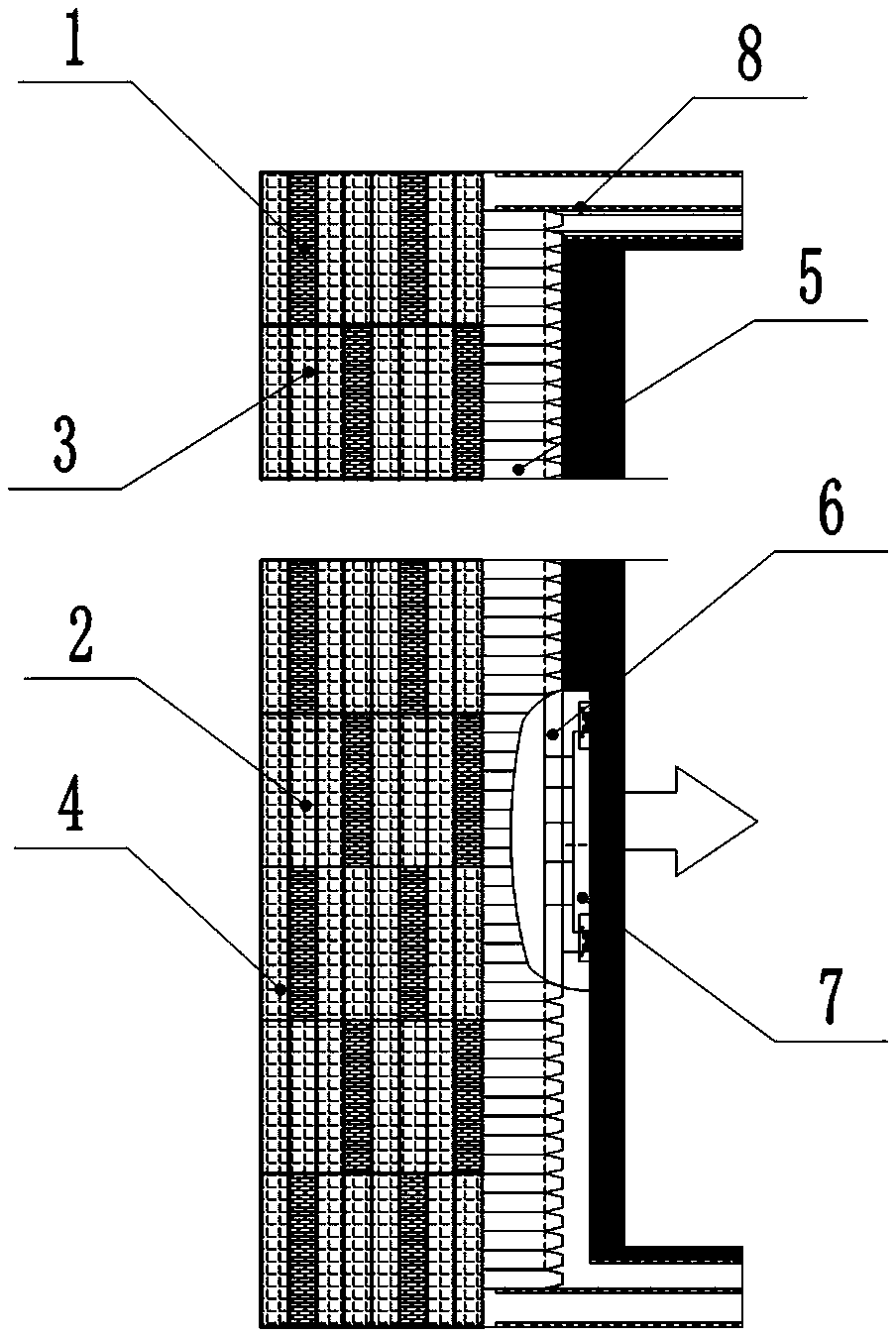

[0035] A method for alternately filling different materials in a goaf according to the present invention, its specific implementation is as follows Figure 1-3 As shown, the specific scheme is as follows:

[0036] A method for alternately filling different materials in a goaf, using multiple filling packs for filling in the same filling face in the goaf, the multiple filling packs including multiple paste filling packs 3 and multiple ultra-high water filling materials Pack 4.

[0037] Part of the same filling face in the goaf is filled with paste filling package 3, and this part of the area meets the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com