Deep inclined coal seam mining roadway mine pressure control mining method

A technology of mining roadway and mining method, which is applied in ground mining, mining equipment, underground mining, etc., and can solve problems such as excessive mine pressure in the mining roadway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

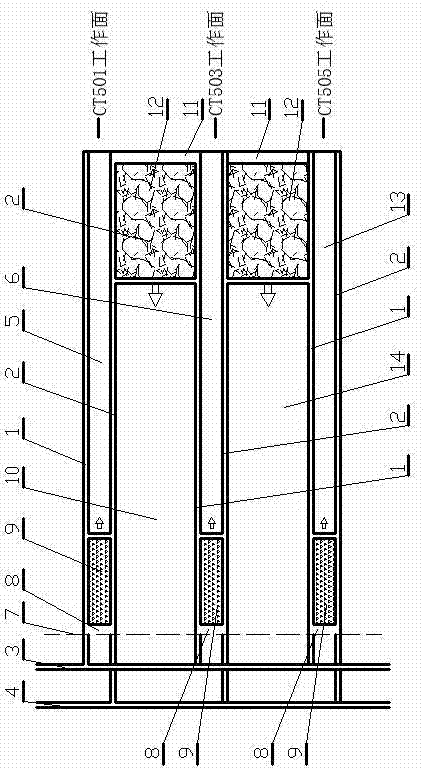

[0023] The present invention will be further described below in conjunction with the accompanying drawings and examples.

[0024] Taking the mining area of a deep inclined coal seam as an example, the mine is mining the No. 7 coal seam in the Ⅲ5 mining area. The depth of the coal seam is -620m~-950m, the average inclination angle is 15°, and the average thickness of the immediate roof is 1.40m. It is mainly gray mudstone. The average thickness of the basic top is 5.52m, mainly dark gray sandy mudstone, and the average thickness of the immediate bottom is 4.15m, mainly gray black mudstone. In the process of mining in adjacent mining areas at the same level, small coal pillars of 7m were left between the working faces, and the section shrinkage rate of the mining roadway reached 60% during the trial period. In view of this situation, mining area Ⅲ5 adopts backfill mining strips and fully mechanized mining Coal seam mining method with coordinated arrangement of working faces t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com