Closed type pasting method and device of screen protection film

A screen protection film and protective film technology, applied in packaging and other directions, to achieve the effect of ensuring the quality of the film, accurate positioning, and easy pasting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] Taking a conventional flat-screen mobile phone as an example, the sticking device in this embodiment uses positioning holes corresponding to positioning columns for positioning.

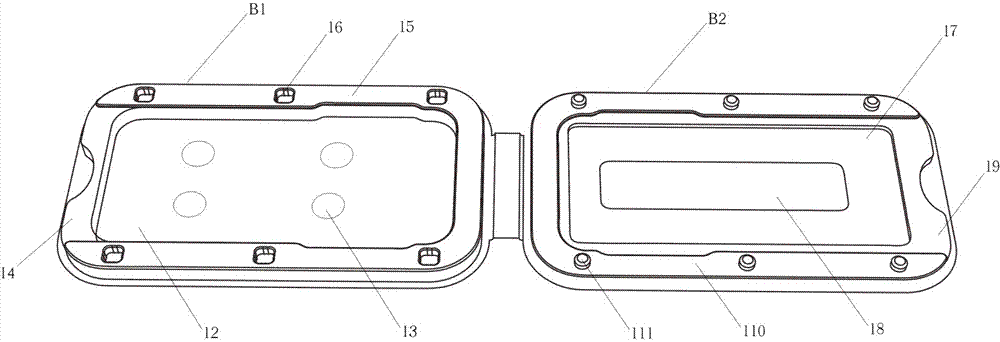

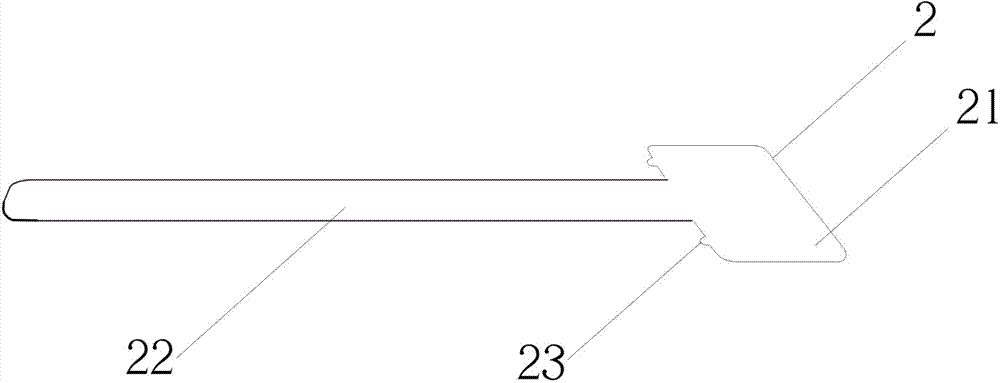

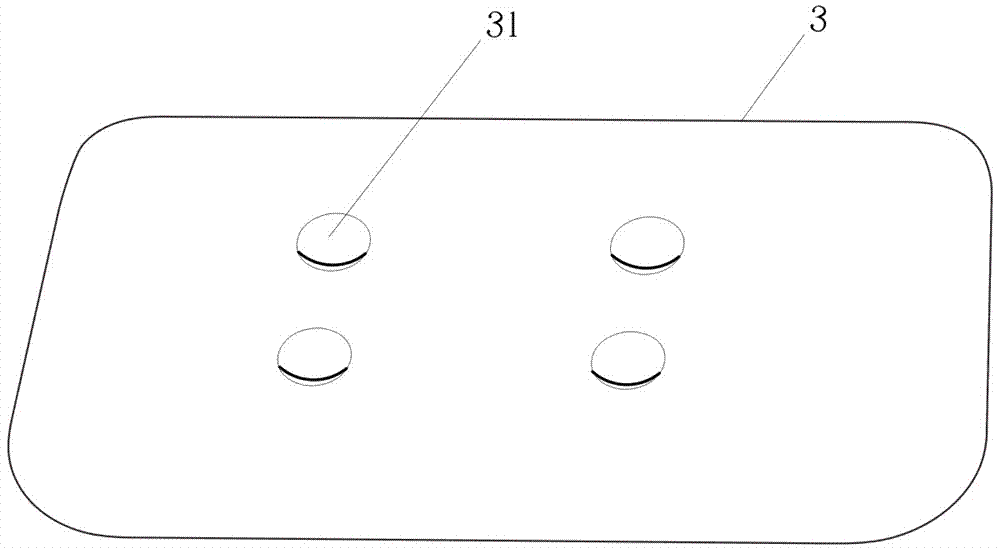

[0044] refer to Figure 1-3 , the film sticking device of the present invention comprises:

[0045] Base B connected by hinges 1 and Base B 2 ,in:

[0046] Base B 1 , the front is a positioning cavity 12 for a flat-screen mobile phone, and there are four penetrating bases B at the bottom of the cavity 1 The lifting working holes 13 are distributed axially symmetrically; the shape of the cavity matches the flat screen mobile phone, the cavity depth (that is, the height from the bottom of the cavity to the cavity surface) is equal to the thickness of the flat screen mobile phone plus about 1mm, and the upper surface of the cavity edge away from the hinge end 14 It is about 1 mm lower than the upper surface 15 of the edge of other chambers; the upper surface 15 of the edge of the chamber is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com