Preparation method of TiO2 photocatalyst for loading on ceramic surface

A technology of ceramic surface and photocatalyst, which is applied in the field of preparation of TiO2 photocatalyst supported on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

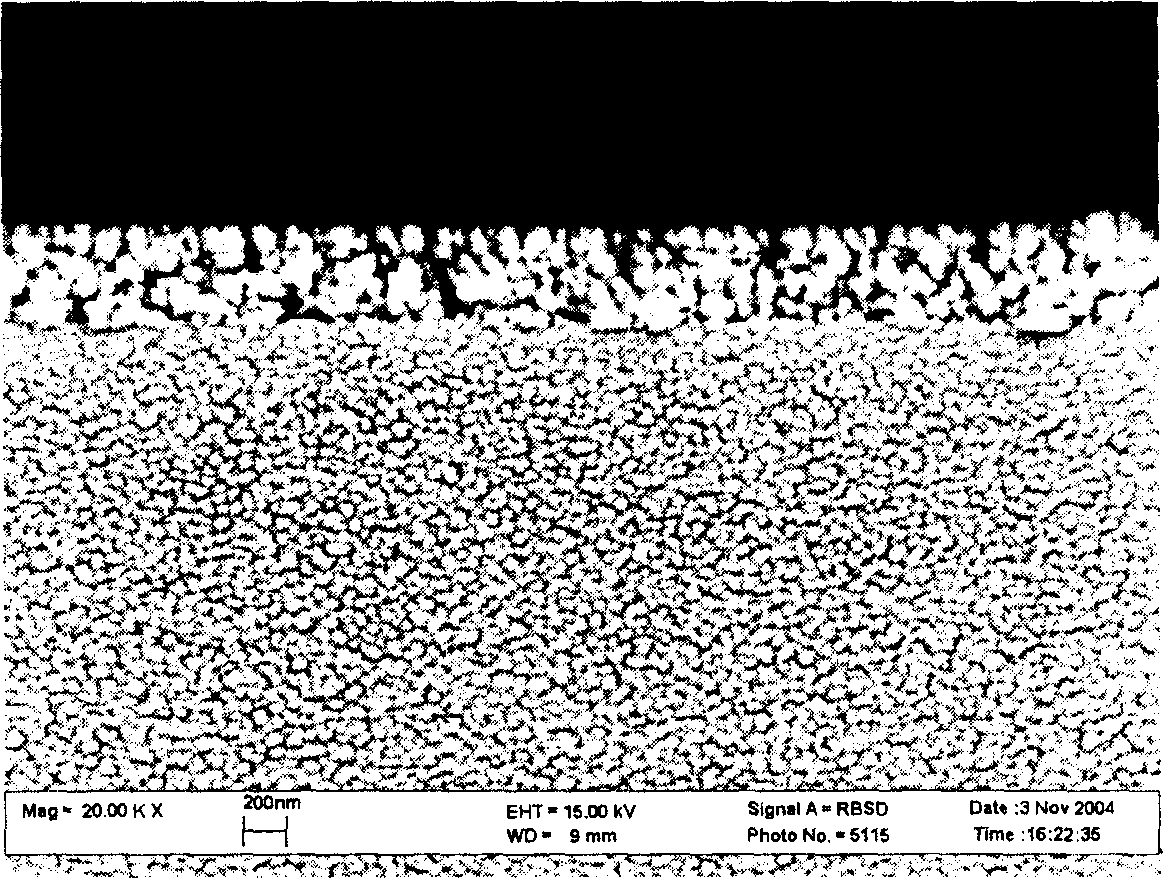

Image

Examples

Embodiment Construction

[0019] Preparation of ceramic carrier: general ceramics can be used, especially ceramic formulations that ensure that the product has high mechanical strength, anti-vibration, damage resistance, and low-cost carrier materials, generally kaolin-based. A better formula is as follows (high strength, low cost):

[0020] The mixed raw materials for preparing stoneware ceramics are Xingzi soil, Jinjiang soil, Donghu soil, Shunchang soil, Xikou soil, Ningguo soil, quartz, Mujie soil, Langxi soil, Guangfu soil, Suzhou soil, etc. The percentage content is: SiO 2 62.63, Fe 2 o 3 is 0.77, Ae 2 o 3 is 26.34, CaO is 0.47, MgO is 0.14, K 2 O is 1.30, Na 2 O is 0.71, loss on ignition is 7.64. The ceramic carrier is divided into two types: tubular and sheet: the length of the ceramic tube is 400mm, the inner diameter is 100mm, and the wall thickness is 20mm; the shape of the ceramic sheet is 90mm×45mm×3mm. Slurry, making mud, drying, biscuit firing, shaping, glazing, drying, and glaze...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com