Patents

Literature

30results about How to "Improve anti-vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

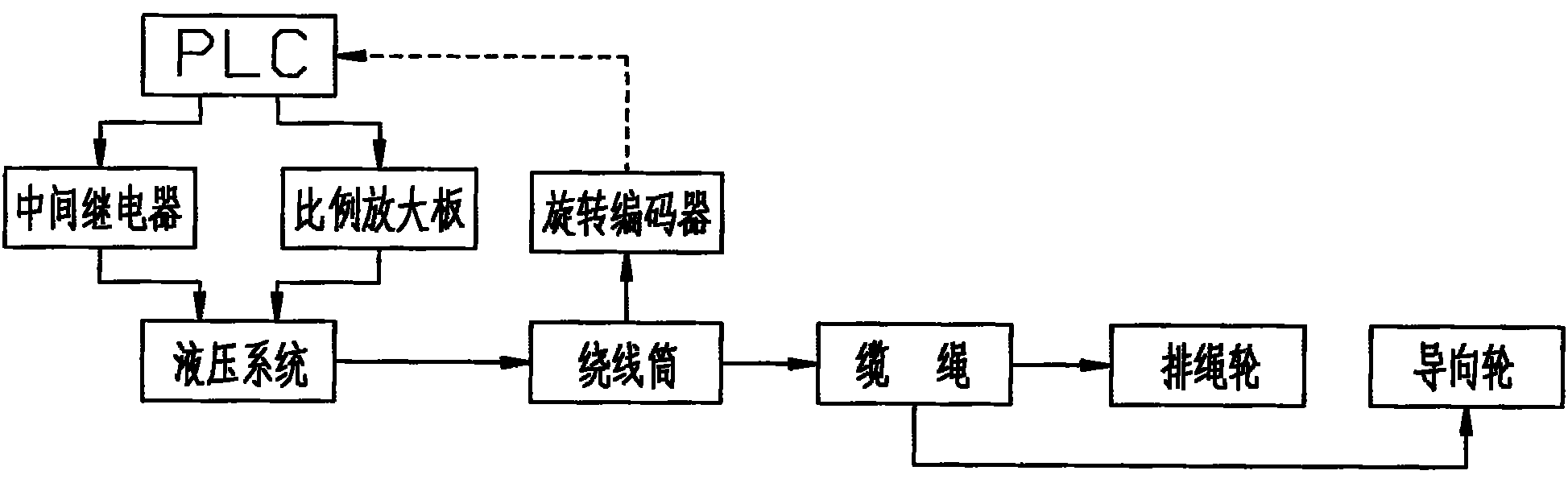

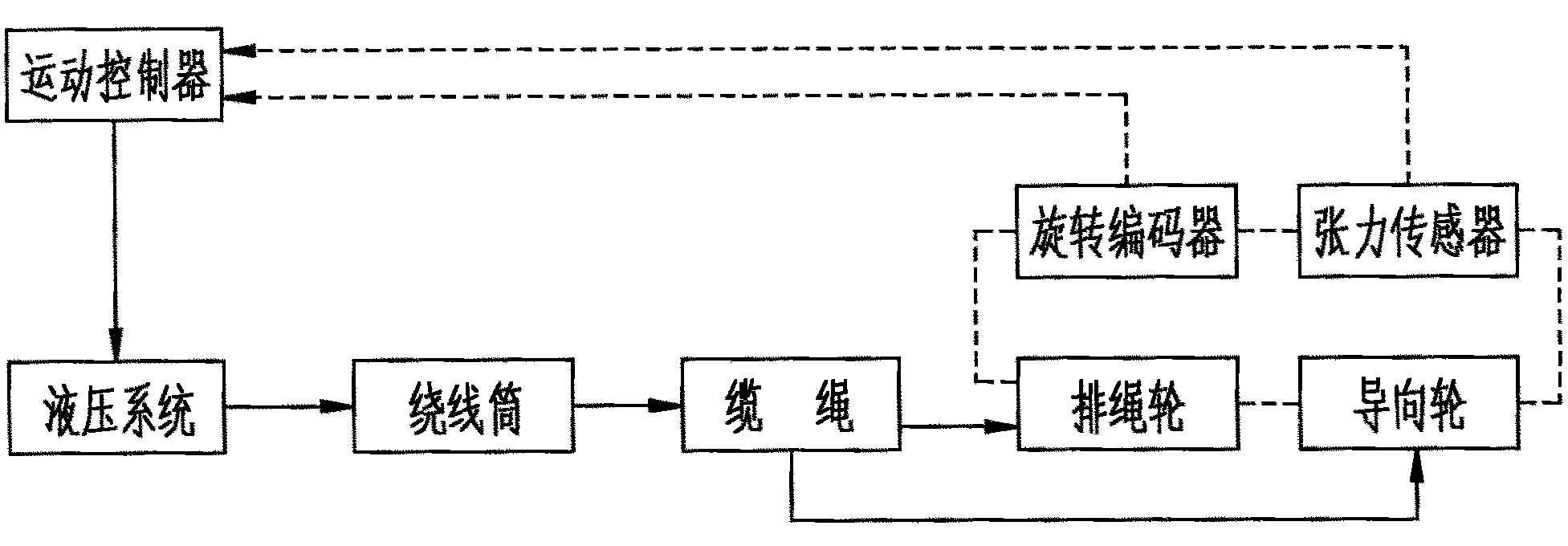

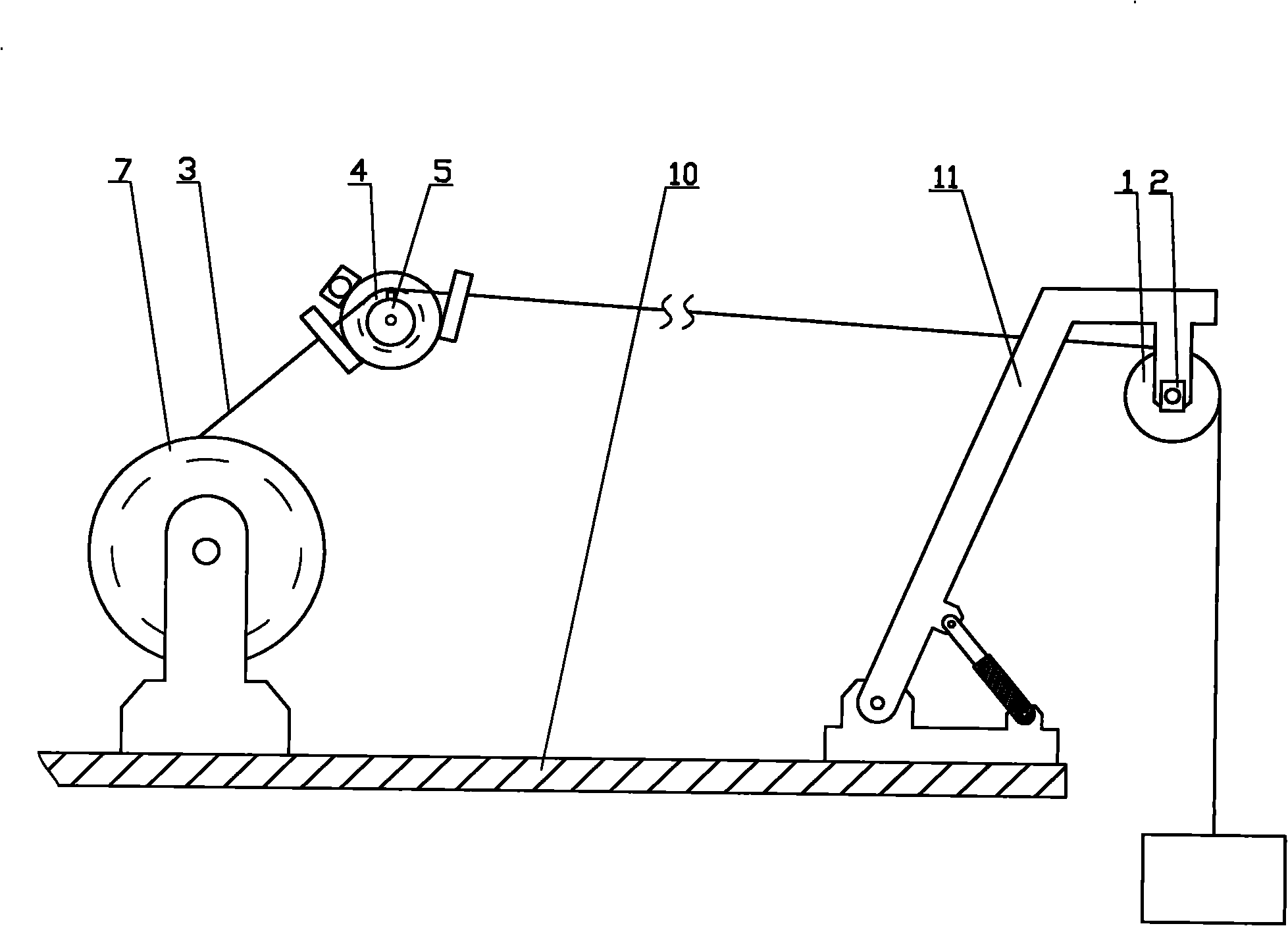

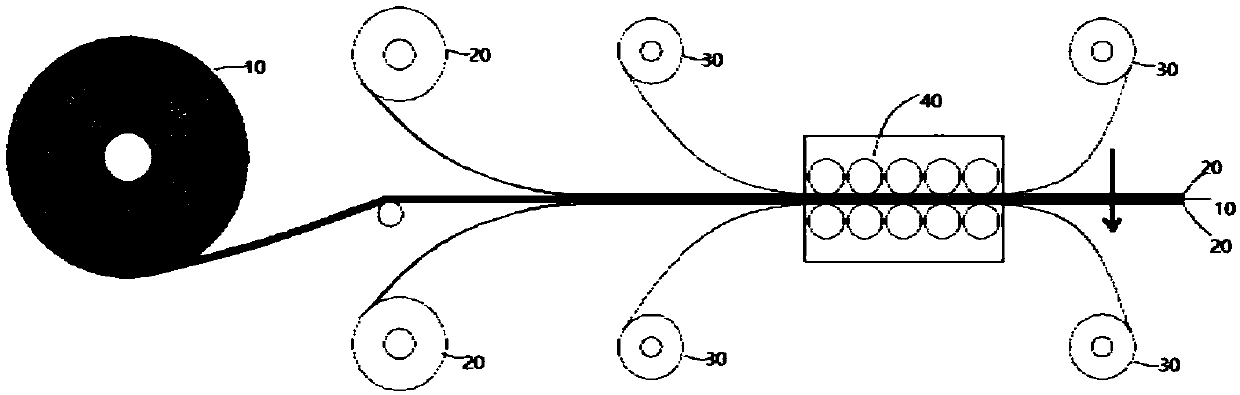

Cable taking-up/paying-off control system of hydrographic winch

InactiveCN102336376AReduce volumeQuick and easy job completionCargo handling apparatusPassenger handling apparatusRotary encoderMovement control

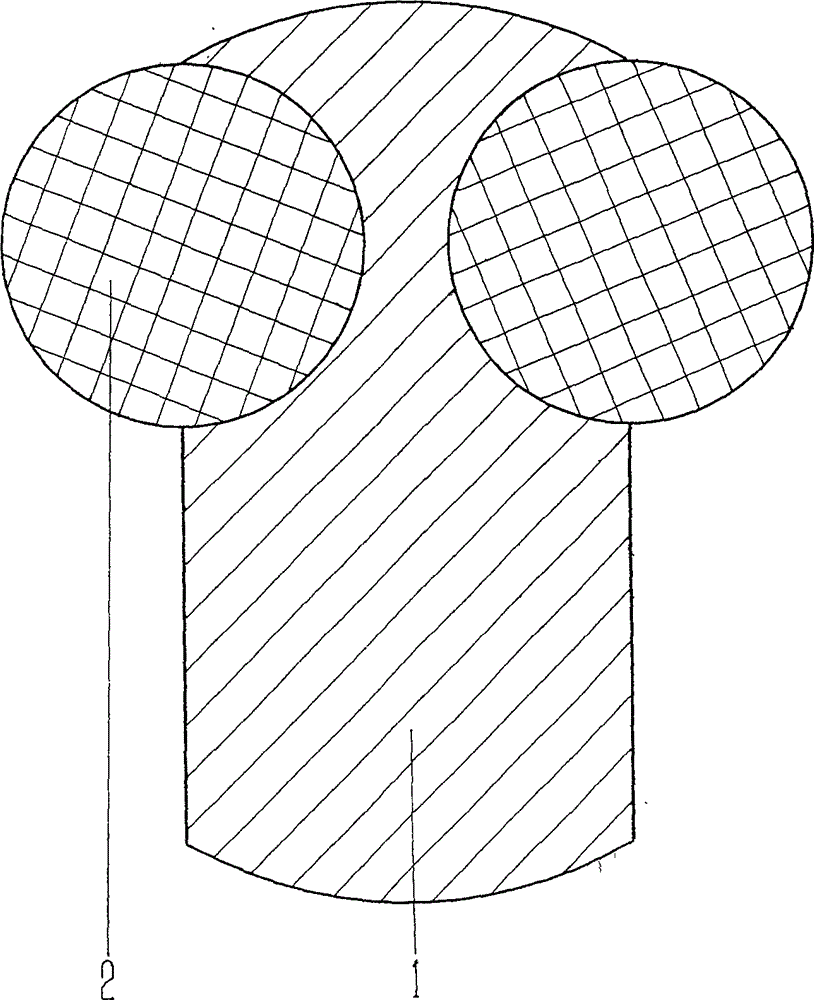

The invention discloses a cable taking-up / paying-off control system of a hydrographic winch, wherein a rope arranging wheel and a guide wheel are configured in parallel fore and aft in the withdrawing direction of a cable rope on a winding reel fixed on a deck; the withdrawing end of the cable rope passes by the upper edges of the rope arranging wheel and the guide wheel, is withdrawn downwards and is put into water for hanging a load; a rotary encoder is configured on the rotary central axis of the rope arranging wheel or the guide wheel; the rotary encoder sends a count pulse signal to a movement controller; the accumulative amount of pulses sent by the rotary encoder corresponds to the cable taking-up / paying-off length of the cable rope; and the count pulse number of the rotary encoder in a current sampling period corresponds to the current cable taking-up / paying-off speed of the cable rope. The cable taking-up / paying-off control system of the hydrographic winch can precisely measure and calculate the cable taking-up / paying-off length, the current cable taking-up / paying-off speed and the pulling force of the cable rope; the movement control is taken as a control core, and a control system directly drives the valve members of various valve sets of a hydraulic pump station; and the whole system has a simple structure, high reliability, impact resistance, shock resistance, water proofing and dust proofing effects, is more applicable to a ship or equipment moving outdoors, and is convenient for a user to mount and place.

Owner:上海派恩科技有限公司

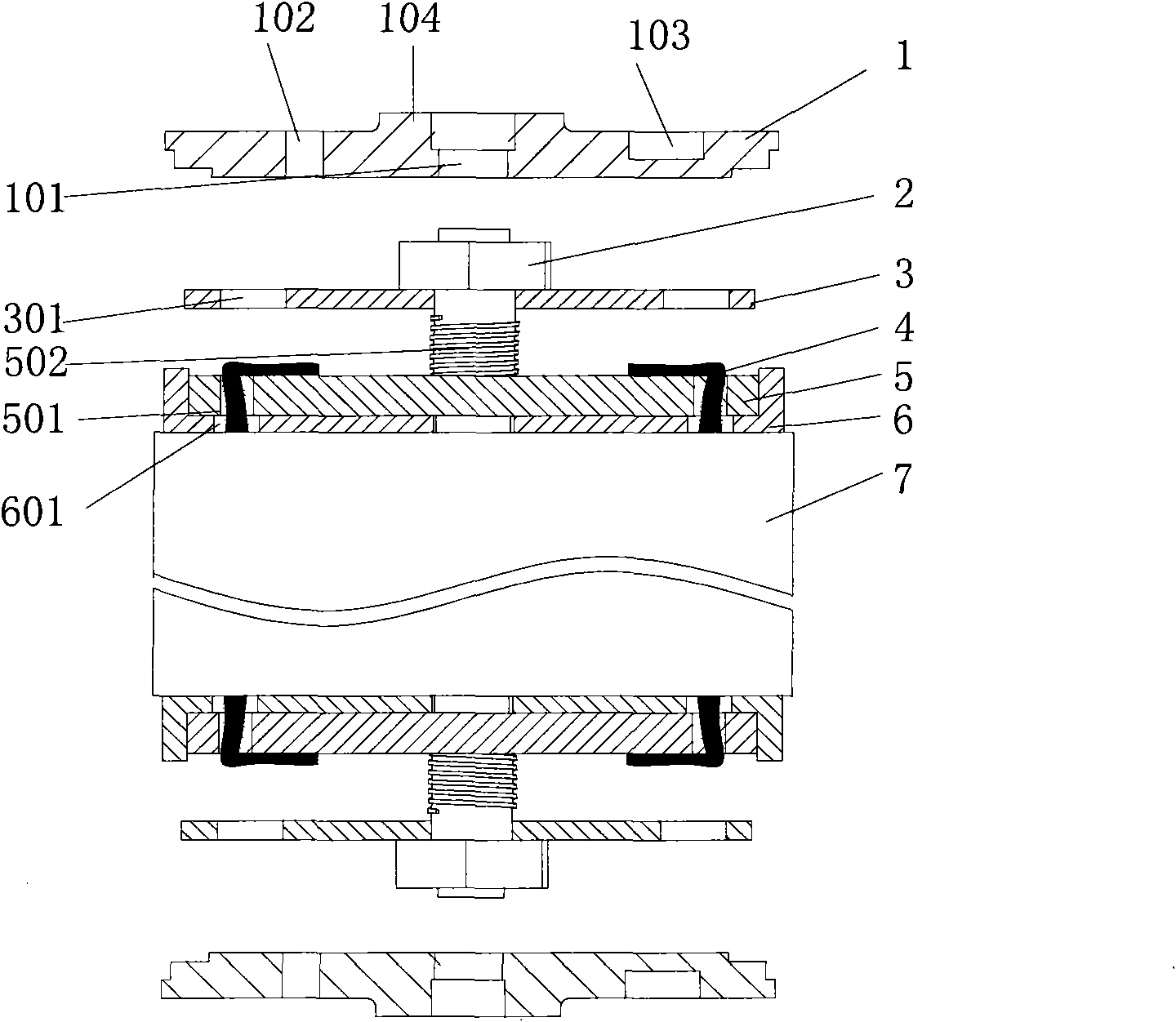

Method for assembling lugs and cover plate of battery

InactiveCN101651186AFirmly connectedIncrease the effective contact areaSecondary cellsCell component detailsInternal resistanceBattery cell

The invention discloses a method for assembling lugs and a cover plate of a battery, which comprises the following steps: a) placing a lug lead-out device at the end of a battery coil core; b) electrically contacting a plurality of lugs extending out of the end of the coil core and a conductive layer of the lug lead-out device; c) compressing the lugs on the lug lead-out device through a second gasket; and d) placing the cover plate of the battery on the upper surface of the second gasket, and sealing the periphery of the cover plate of the battery and a shell of the battery. Step b) also comprises the following subsequent step: b1) bending the lugs and then welding the lugs on the conductive layer of the lug lead-out device. The lugs are welded to the lug lead-out device and mechanicallycompressed through the second gasket so as to ensure reliable connection of the lugs and posts of a battery cell, reduce the inner resistance of the battery and ensure firm fixation of the coil core.The method is simple in assembly process, is suitable for line production, is suitable for assembling the batteries of hybrid electric automobiles with multiple lugs and large volume and pure electricautomobiles and can also be used for assembling large energy-storage batteries.

Owner:SHENZHEN BAK BATTERY CO LTD

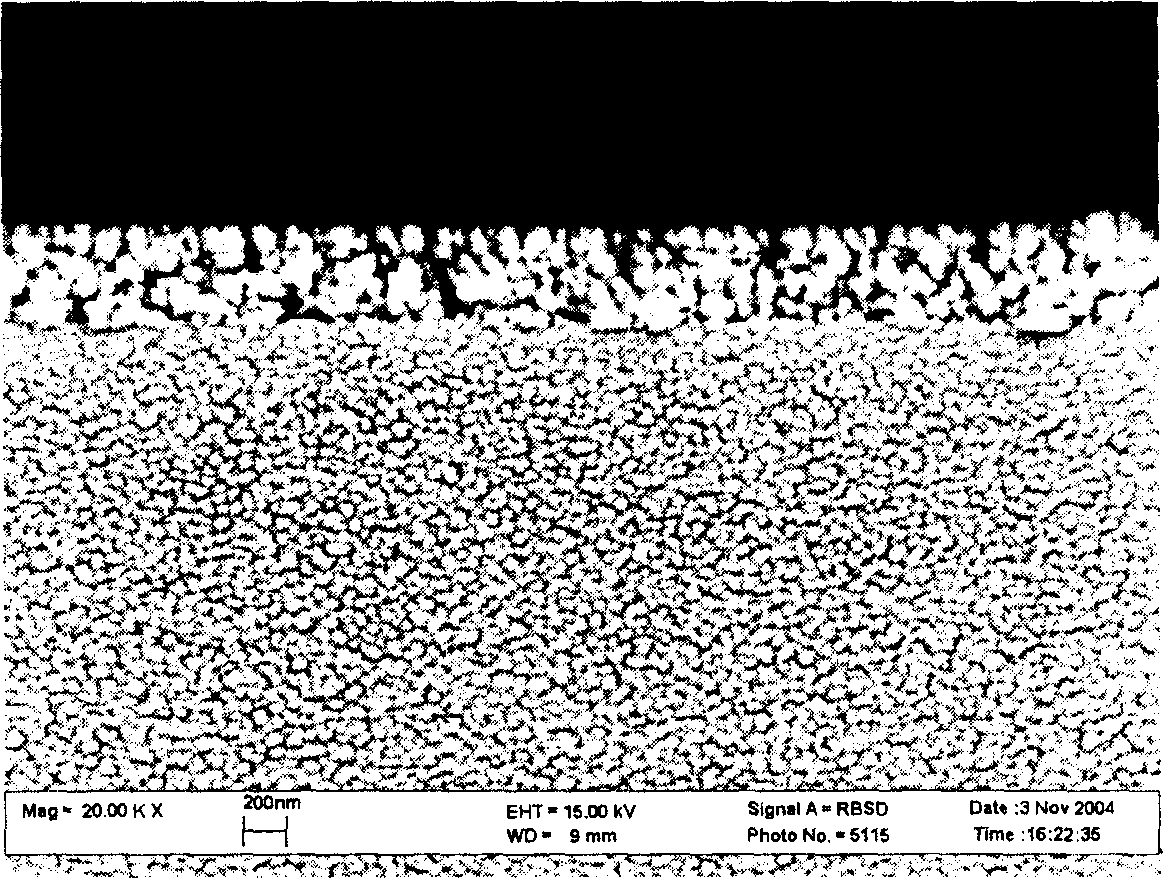

Preparation method of TiO2 photocatalyst for loading on ceramic surface

The invention relates to the process for preparing TiO2 photo-catalyst carrier on ceramic surface, wherein the compact ceramic carrier material is supported with TiO2 colloidal sol through sol-gal process, the TiO2 colloidal sol is prepared through dissolving butyl titanate or propyl titanate into acids, alcohols and water, washing and drying the finished ceramic carrier into TiO2 colloidal sol for 2-40 minutes, seasoning, sintering the carrying agent with carried colloidal sol in the furnace, elevating the temperature from room temperature to 80-250 deg. C, heat preserving for 10-80 minutes, elevating temperature again to 250-400 deg. C, heat preserving for 20-80 minutes, elevating the temperature to 450-550 deg. C, heat preserving for 40-90 minutes, furnace cooling to room temperature. A stabilized catalytic activity can be achieved by the invention.

Owner:NANJING UNIV

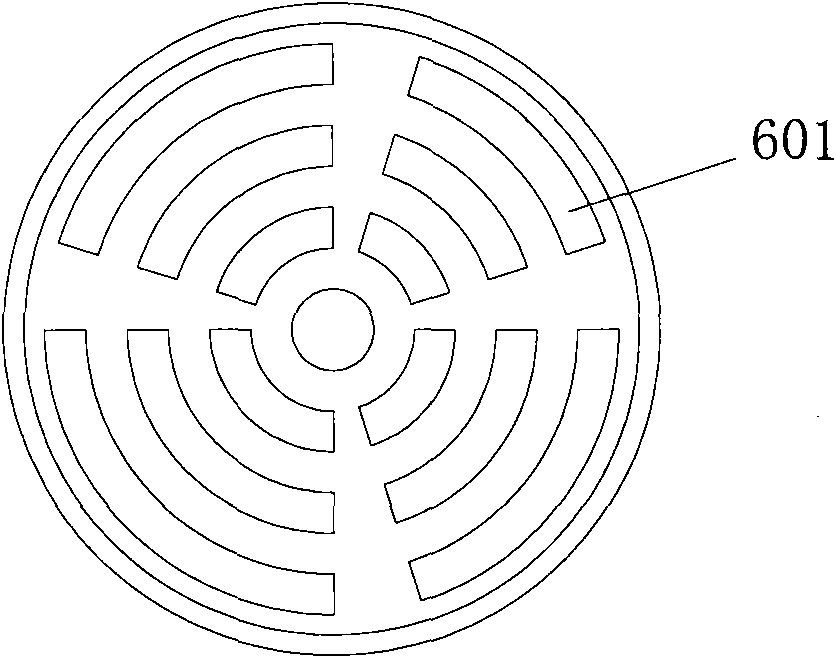

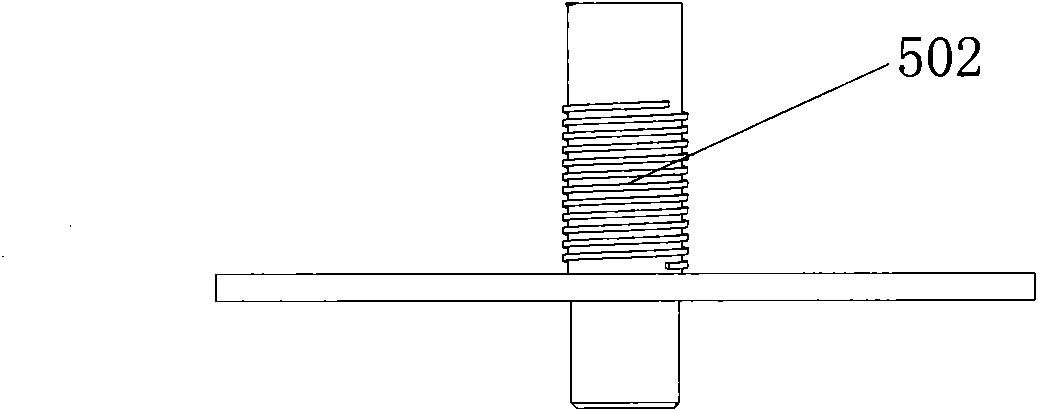

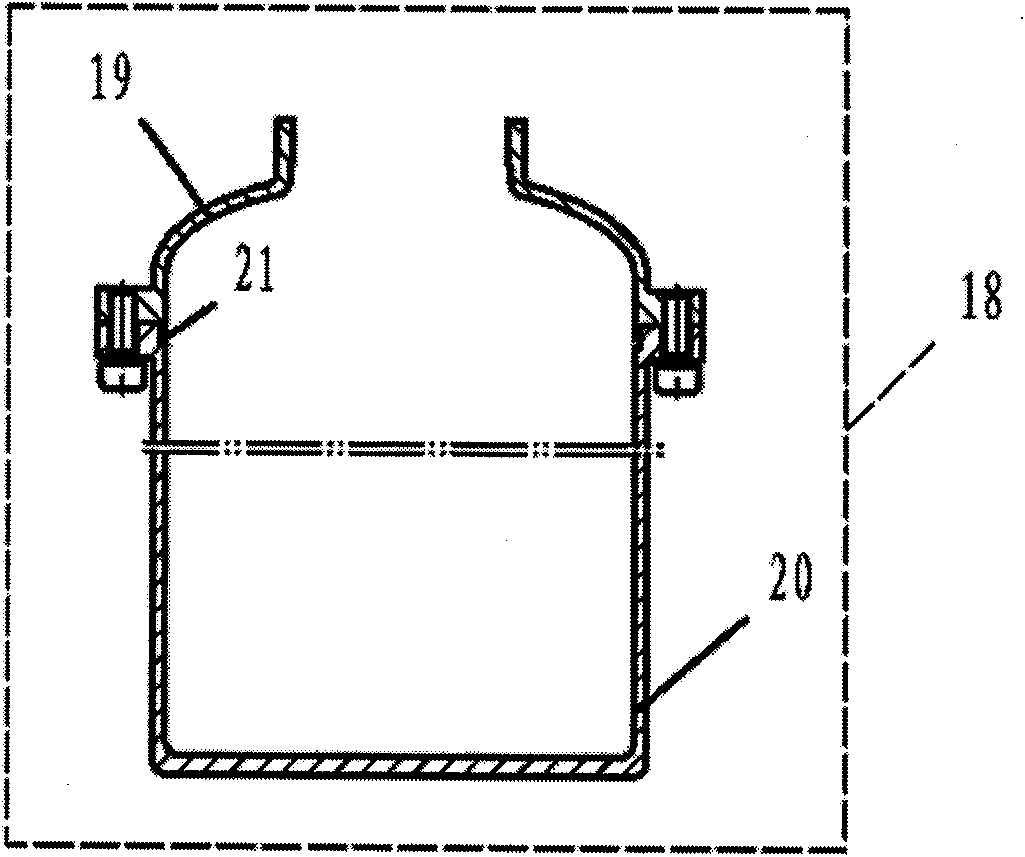

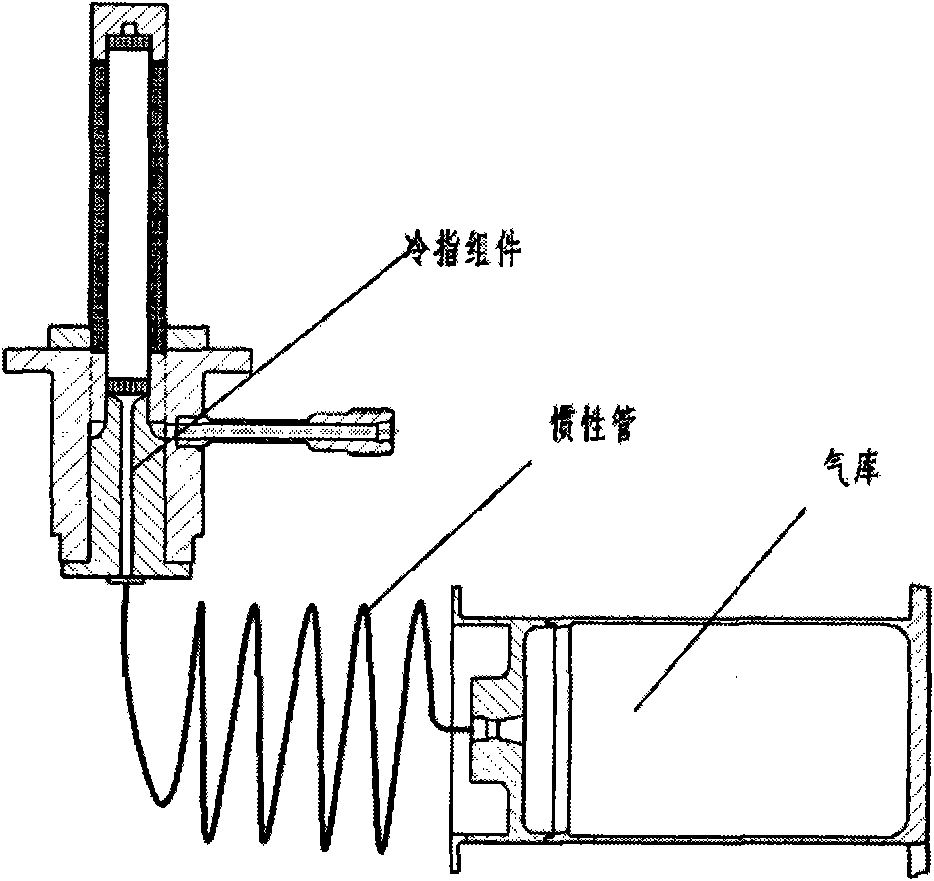

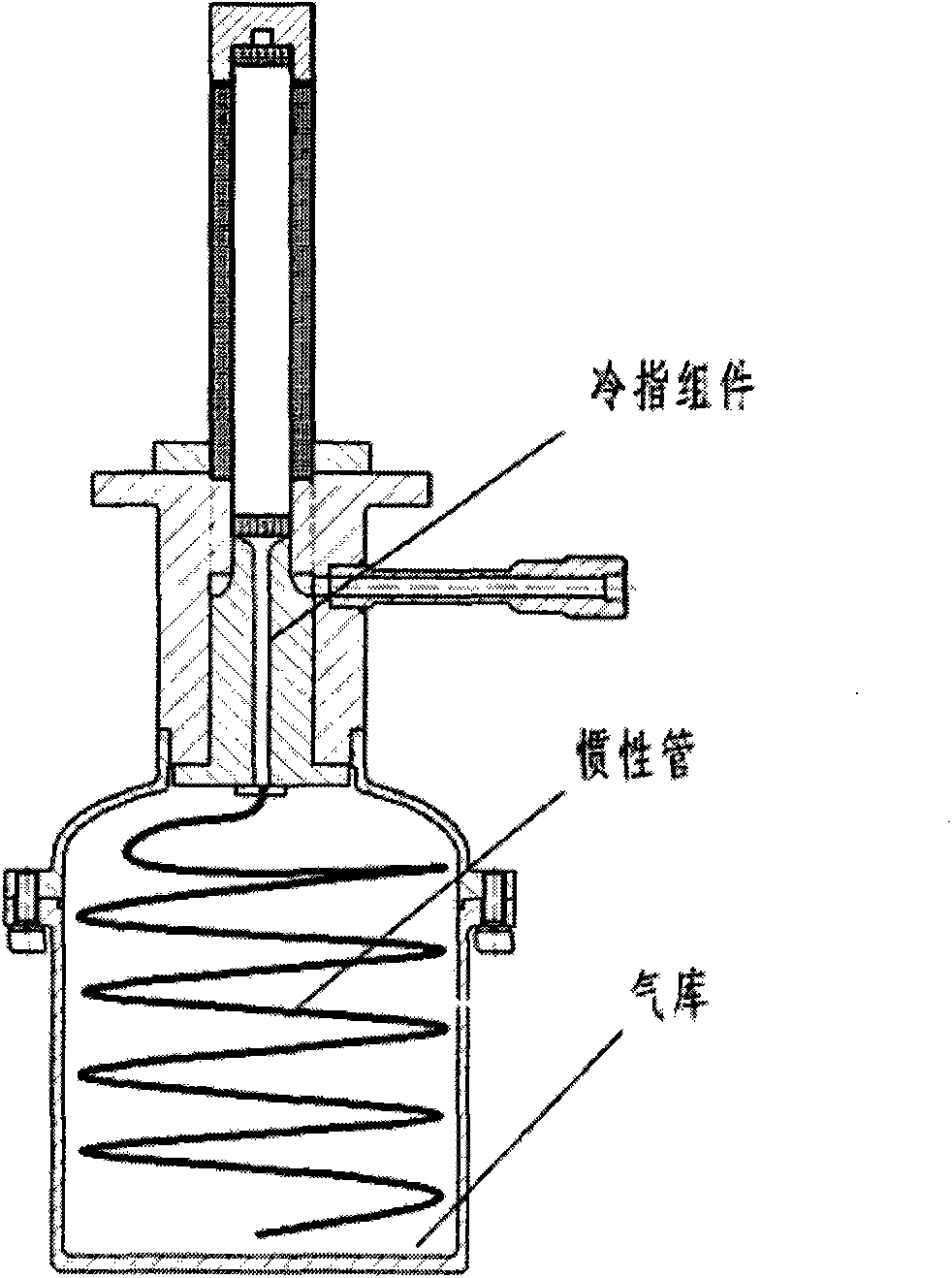

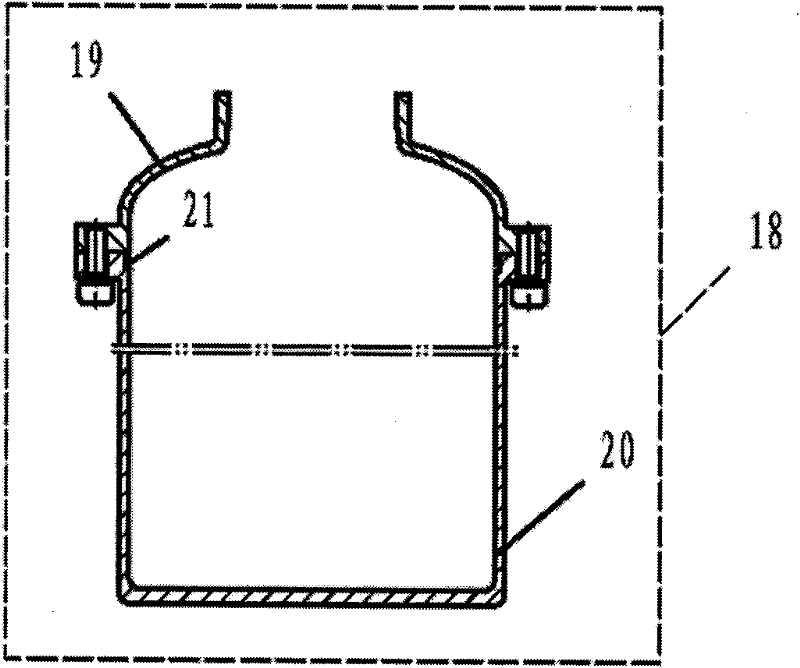

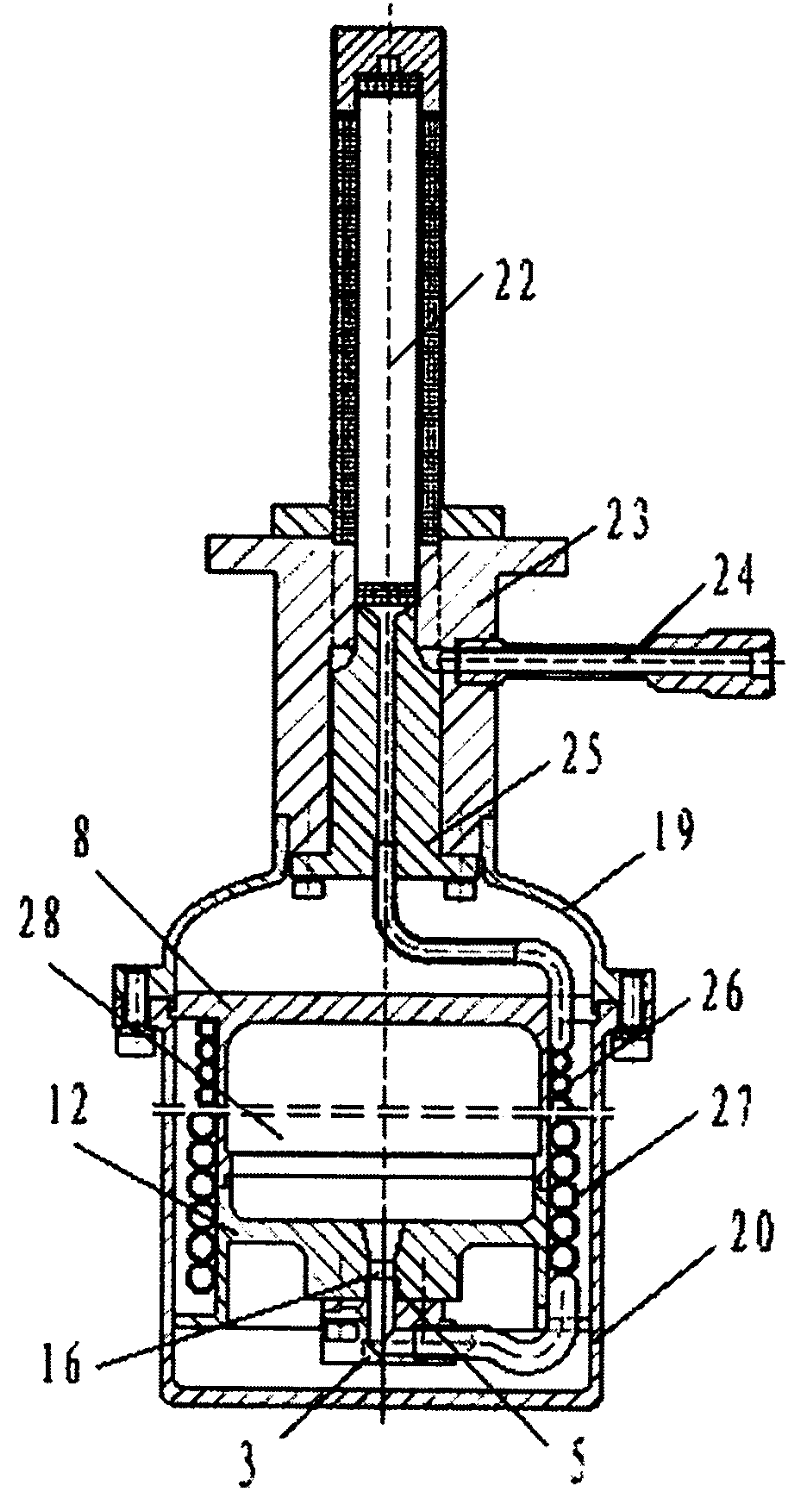

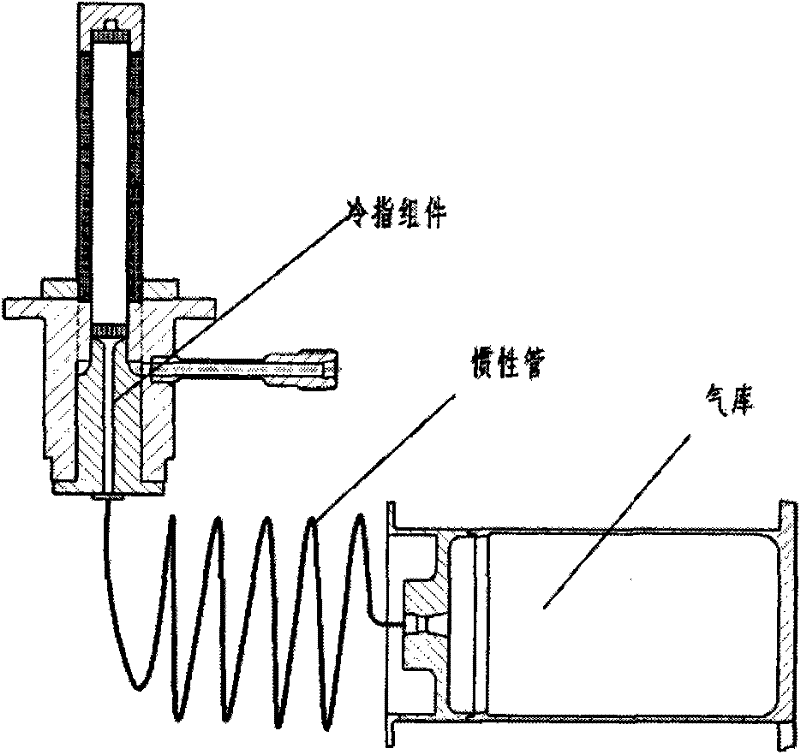

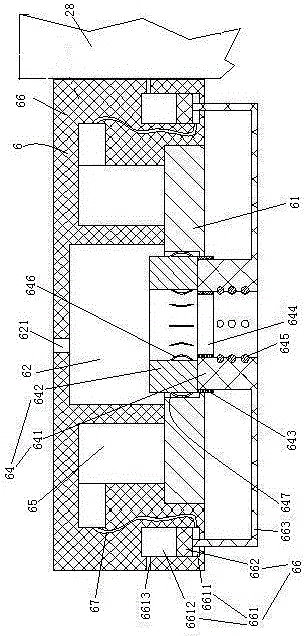

Integrated hot end phase adjusting structure of inertance-tube type pulse tube cooler and manufacturing method of phase adjusting structure

InactiveCN102032703AGuaranteed integrityGuaranteed stabilityCompression machinesGas cycle refrigeration machinesWorking lifePulse tube refrigerator

The invention discloses an integrated hot end phase adjusting structure of an inertance-tube type pulse tube cooler and a manufacturing method of the phase adjusting structure. In the structure, joint phase adjustment of the inertance tube and a gas storage is adopted; and the structure comprises two inertance tubes with different diameters and lengths as well as the stable-pressure inner gas storage. An integrated inertance tube component is connected with a hot end gas outlet of a pulse tube and the stable-pressure inner gas storage, and wound on the outer surface of the inner gas storage; then the inertance tube component and the inner gas storage are integrally placed in a special protective cover. The novel hot end phase adjusting structure has the advantages that: the hot end phase adjusting capability is maximized; and the integrity and stability of the effective volume of working medium in the gas storage are ensured. The gas working medium in the system is protected from pollution of the phase adjusting device; the structure is simple and compact; and the anti-vibration and anti-impact capabilities are enhanced. The mechanical and thermodynamic performance of the pulse tube cooler is improved in a great degree, and the long-term operation reliability and a relatively long working life are guaranteed.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

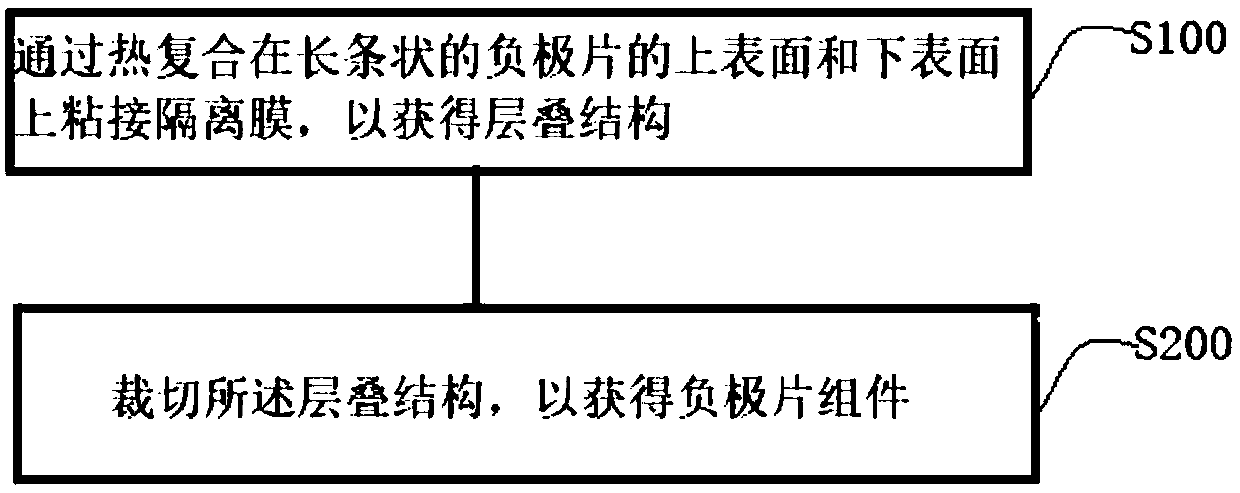

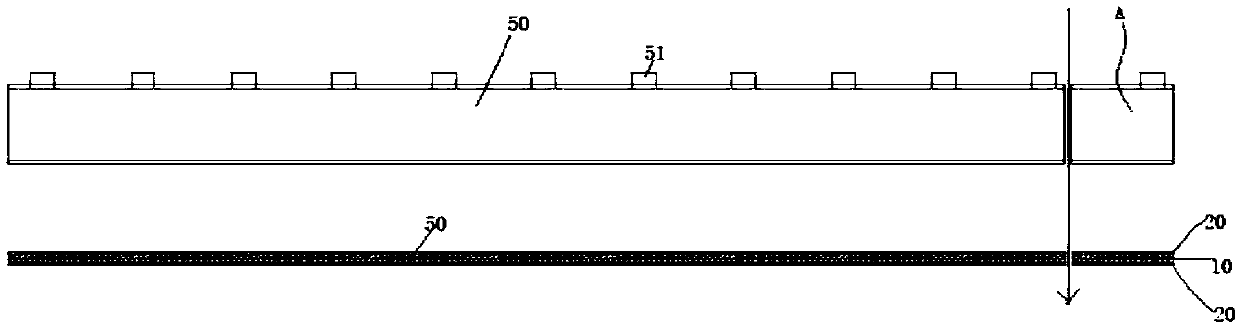

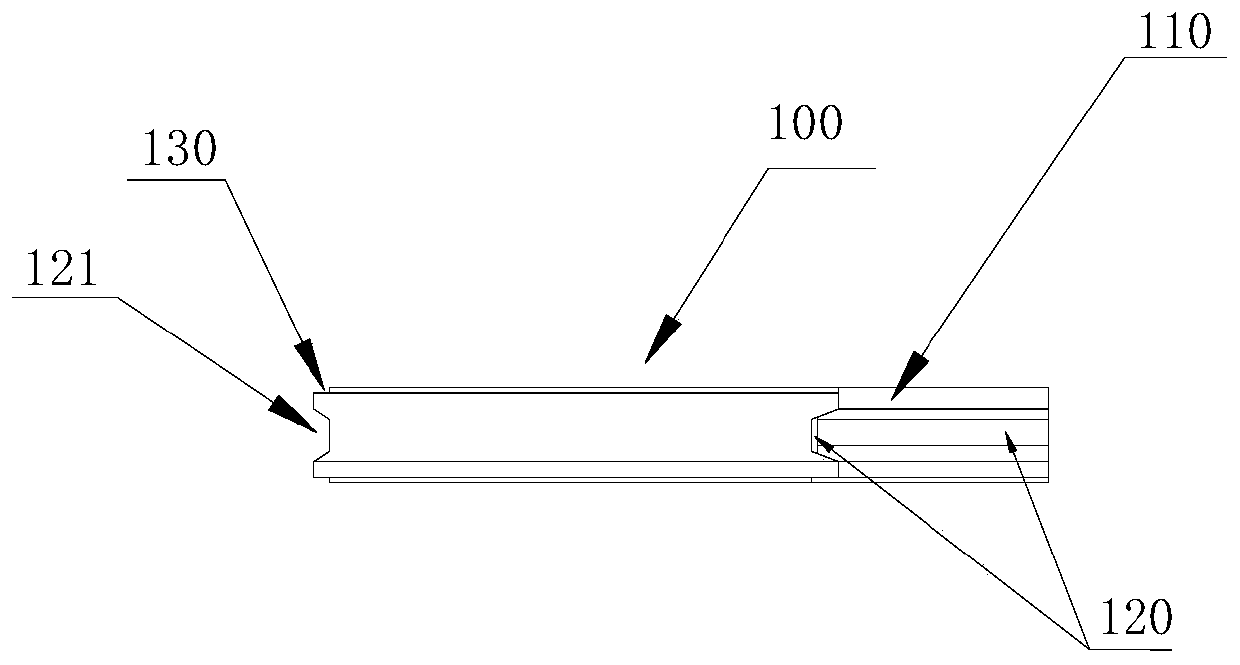

Negative electrode sheet module and preparation method thereof, method for manufacturing battery and battery

InactiveCN109560253AFast preparationEfficient manufacturingFinal product manufactureNon-aqueous electrolyte accumulator electrodesEngineeringElectrical and Electronics engineering

The invention provides a negative electrode sheet module and a preparation method thereof, a method for manufacturing battery and a battery. The preparation method of the negative electrode sheet assembly comprises the steps of: adsorbing a separation film on the upper surface and the lower surface of an elongated negative electrode sheet through thermal recombination to obtain a laminated structure, wherein a protective film is used at the outer surface of the separation film when the hot rolling process of the thermal recombination is performed; and cutting the laminated structure to obtaina negative electrode sheet module. The negative electrode sheet module is employed to prepare the battery, the steps are greatly simplified in the assembling process, the working efficiency is obviously improved, for the laminated battery, the lamination efficiency can be improved for three times, the absorption combination is achieved between the layers of structures of the battery obtained through preparation, the anti-impact, anti-shock and safety performances of the battery are greatly improved, the product quality is improved, and when the hot rolling is performed, the outer surface of the separation film adds the protection film to effectively prevent the coating at the surface of the separation film from falling off or being bonded at the surface of the hot rolling compression roller.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

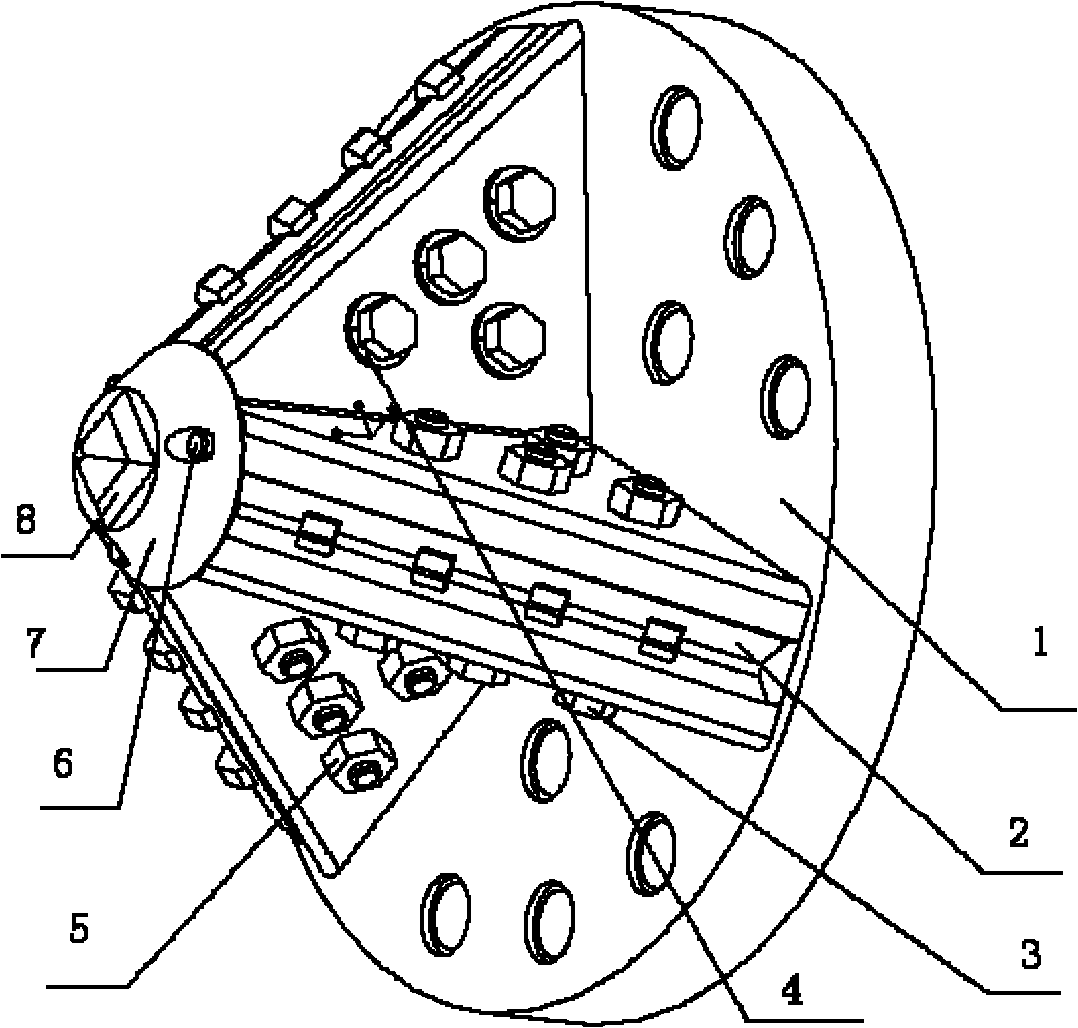

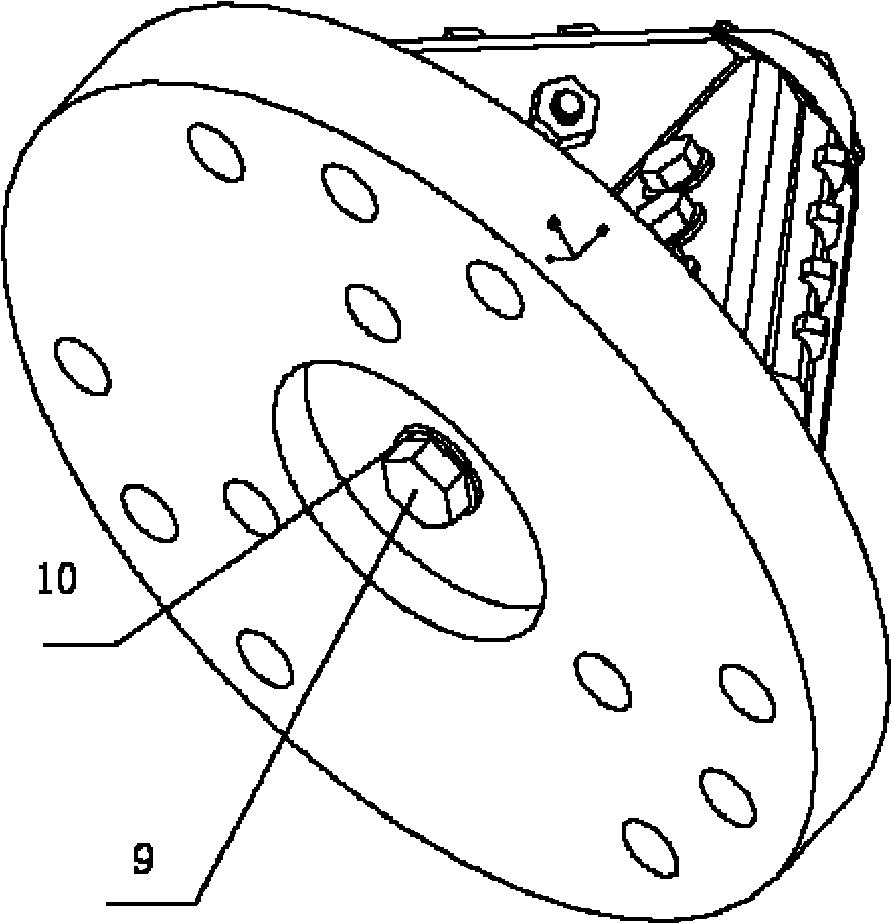

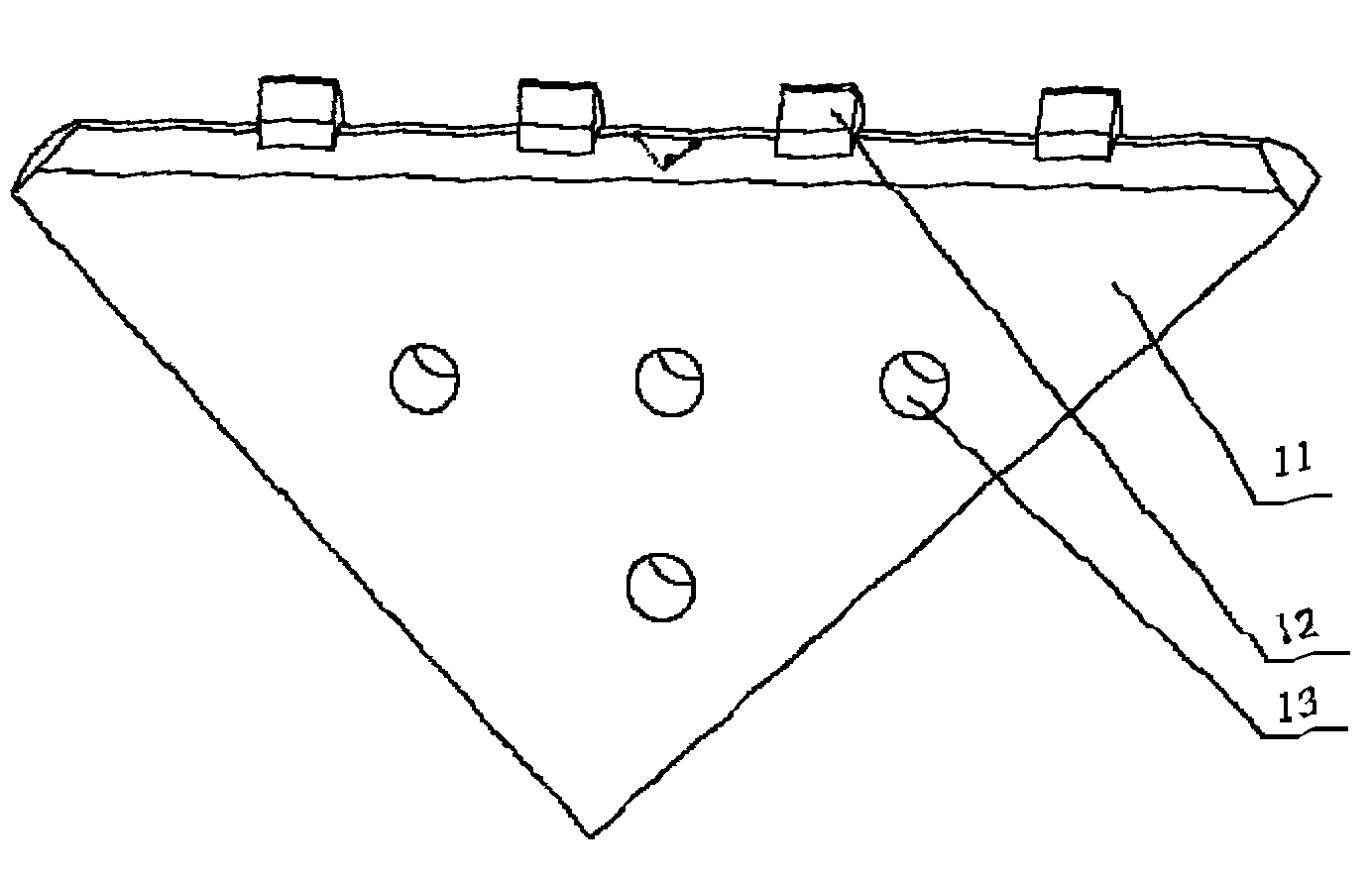

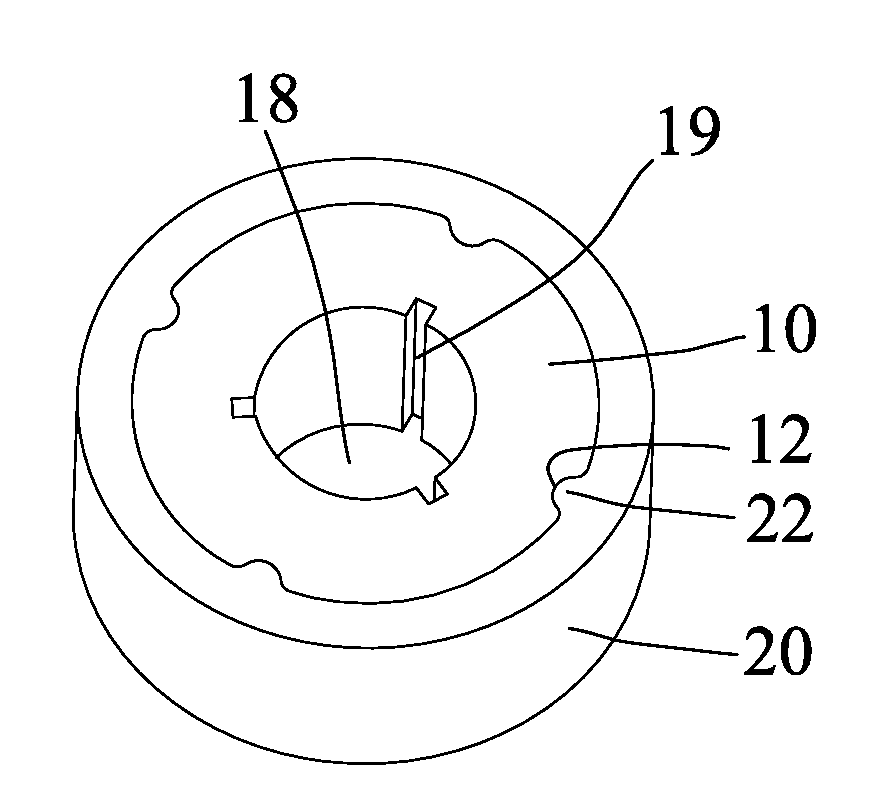

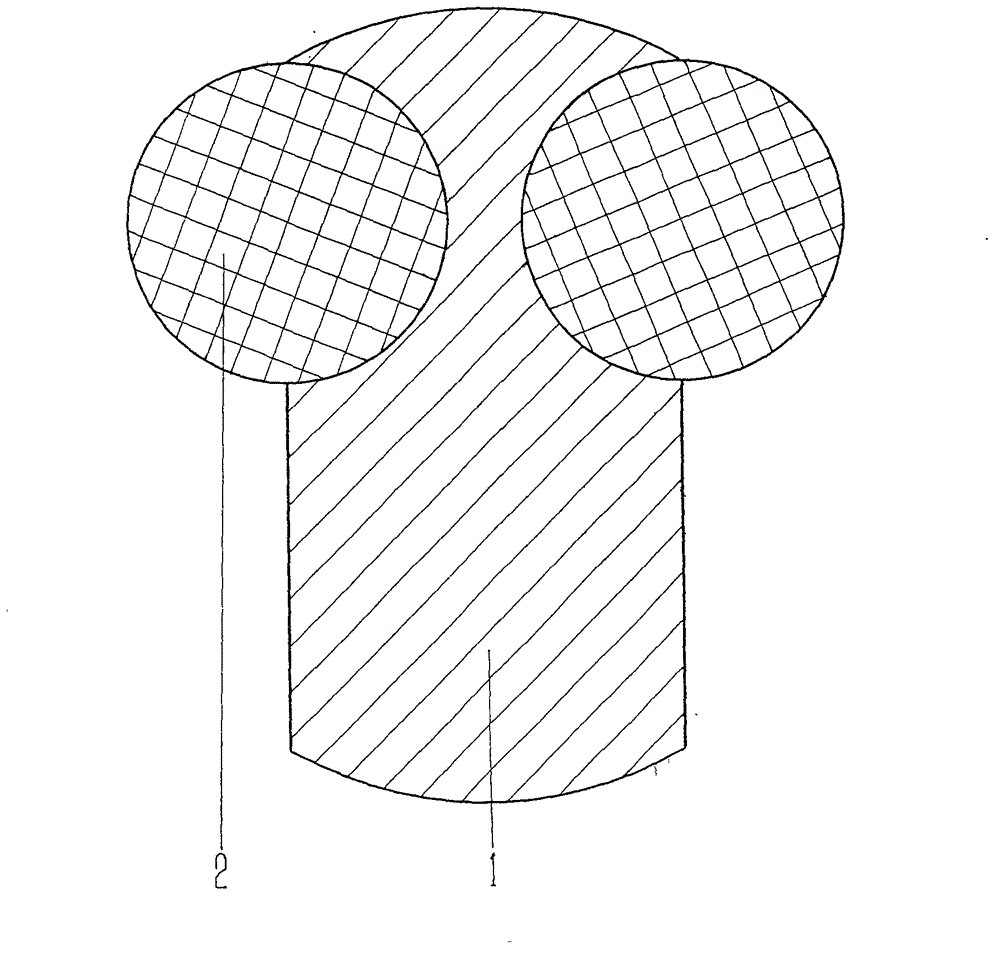

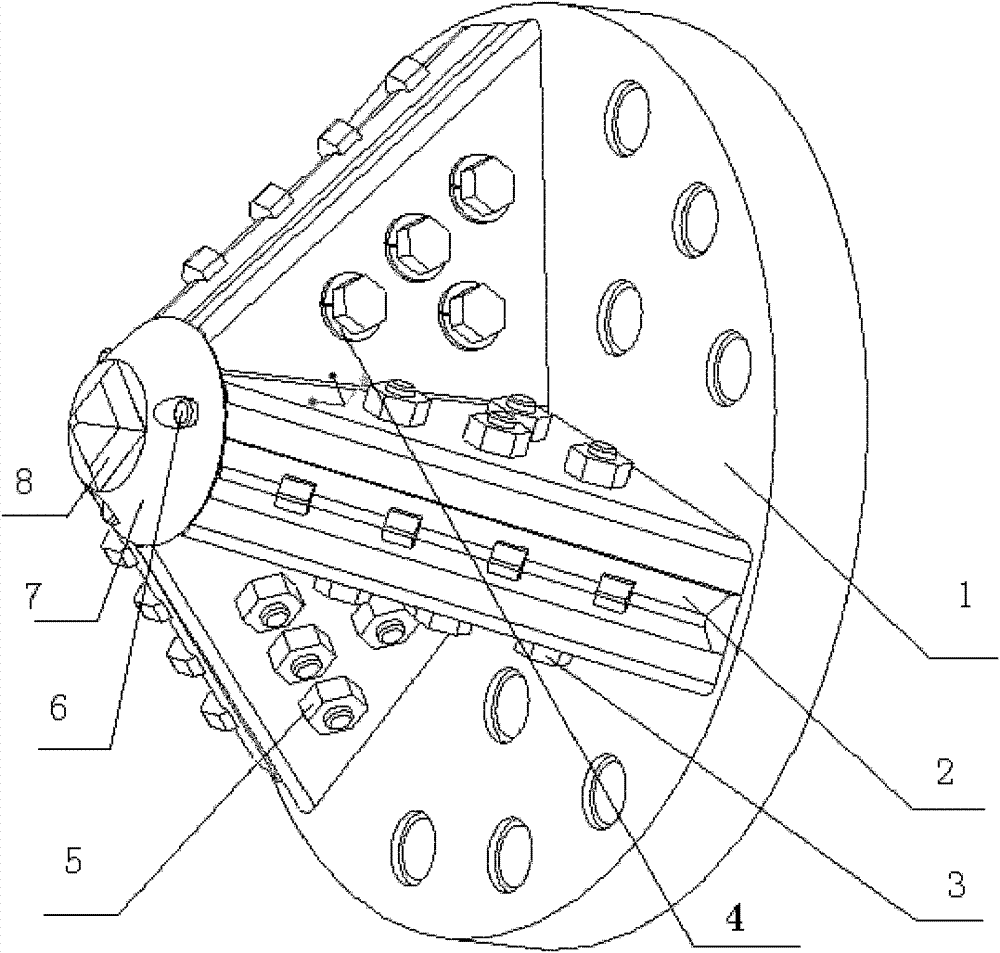

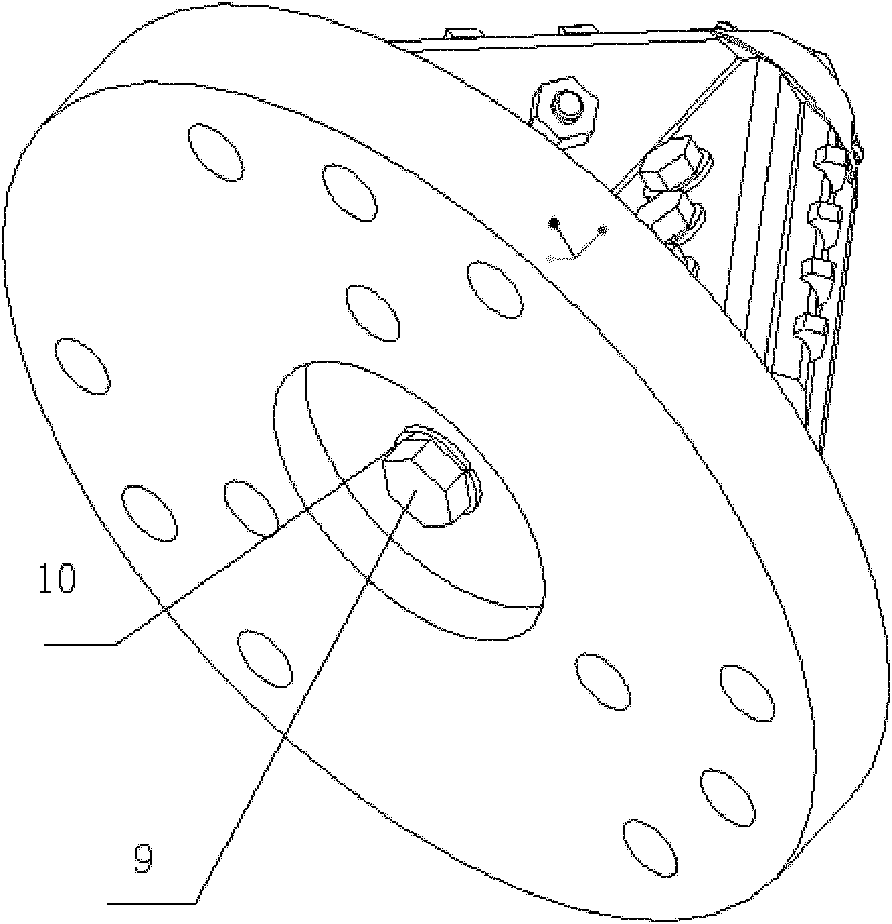

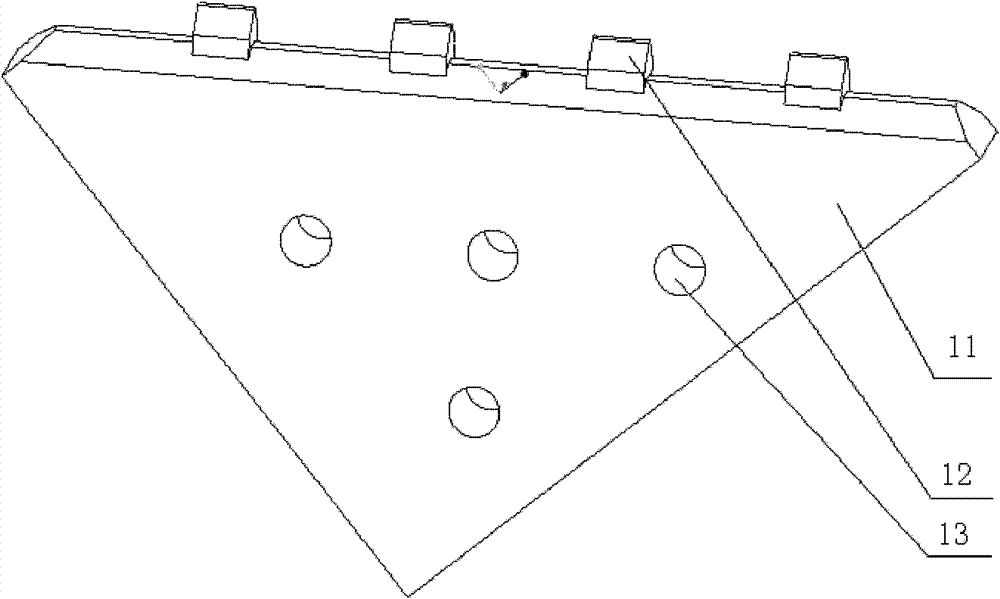

Exchangeable blade type center cutter for shield machine

The invention belongs to the technical field of tunneling assembly, relating to an exchangeable blade type center cutter for a shield machine; the center cutter comprises a blade seat, a center cutter block and three side cutters; a center cutter block locating post and three knife rests are arranged on the blade seat; the middle part of the locating post is provided with a center cutter block locating hole; the bottom part of the center cutter block is fixedly connected with the blade seat; a cone-shaped lug boss is fixedly connected with the end of the locating post; an inner hole is arranged on the cone-shaped lug boss; the sizes of the inner hole of the lug boss and the center cutter block locating hole are matched with that of the center cutter block; three knife rests are arranged on the periphery of the center cutter block locating post; a groove joint which is fixedly connected with the side cutter is arranged on each knife rest; locating holes are arranged on the three side cutters and are respectively fixedly connected in the groove joints of three knife rests through bolts; three cutter arms formed by the side cutters and the knife rests form an included angle of 120 degrees. The center cutter has better stability in the tunneling process, higher impact resistance and abrasion resistance, and is easy to replace the blade, so that the waste of resource is avoided and the construction cost is saved; therefore, the center cutter has higher economical value.

Owner:TIANJIN UNIV

Connection structure of lugs and cover plate of battery

InactiveCN101651187AGuaranteed connection locationAccurate welding positionCell component detailsInsulation layerInternal resistance

The invention discloses a connection structure of lugs and a cover plate of a battery, which comprises the lugs and the cover plate, wherein the lugs are led out from the end of a battery coil core and are also provided with a lug lead-out device arranged at the end of the coil core; the lug lead-out device is provided with an insulation layer contacting the end of the coil core and a conductive layer far away from the end of the coil core; the lugs are electrically connected with the conductive layer; and the conductive layer is electrically connected with the cover plate. The connection structure also comprises a connecting piece and a second gasket stacked between the conductive layer of the lug lead-out device and the cover plate; and the connecting piece tightly compresses the lugs between the second gasket and the conductive layer of the lug lead-out device. The lugs are connected to the lug lead-out device and are mechanically compressed through the second gasket so as to ensurereliable connection of the lugs and the cover plate, reduce the inner resistance of the battery and ensure firm fixation of the coil core. The connection structure is simple in assembly process, is suitable for line production and is suitable for assembling the batteries of hybrid electric automobiles with multiple lugs and large volume and pure electric automobiles or is used for assembling large storage batteries.

Owner:SHENZHEN BAK BATTERY CO LTD

Secondary battery

ActiveCN101604737AGuaranteed connection locationAccurate welding positionWound/folded electrode electrodesCell lids/coversInternal resistancePure electric vehicle

The invention discloses a secondary battery comprising a winding core and a cover plate, wherein the end part of the winding core extends with a pole lug and is also provided with a pole lug leading device placed on the end part of the winding core, the pole lug leading device is provided with an insulating layer contacted with the end part of the winding core and a conducting layer far away from the end part of the winding core, the pole lug is electrically connected with the conducting layer, and the conducting layer is electrically connected with the cover plate. The secondary battery also comprises a connecting piece and a second spacer arranged between the conducting layer of the pole lug leading device and the cover plate in an overlapping way, and the pole lug is tightly pressed between the second spacer and the conducting layer of the pole lug leading device by the connecting piece. The secondary battery is provided with the pole lug leading device, and the pole lug is welded on the pole lug leading device and is mechanically contacted with and tightly pressed on the pole lug leading device through the second spacer, thereby the invention ensures the pole lug of an electric core to be reliably connected with a pole column, reduces the internal resistance of a battery, ensures the firm fixing of the winding core, has simple assembly technology, is adapted to line production and suitable for batteries of a hybrid electric vehicle with multiple pole lugs and a large volume and a pure electric vehicle and can also be suitable for large-sized energy storage batteries.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

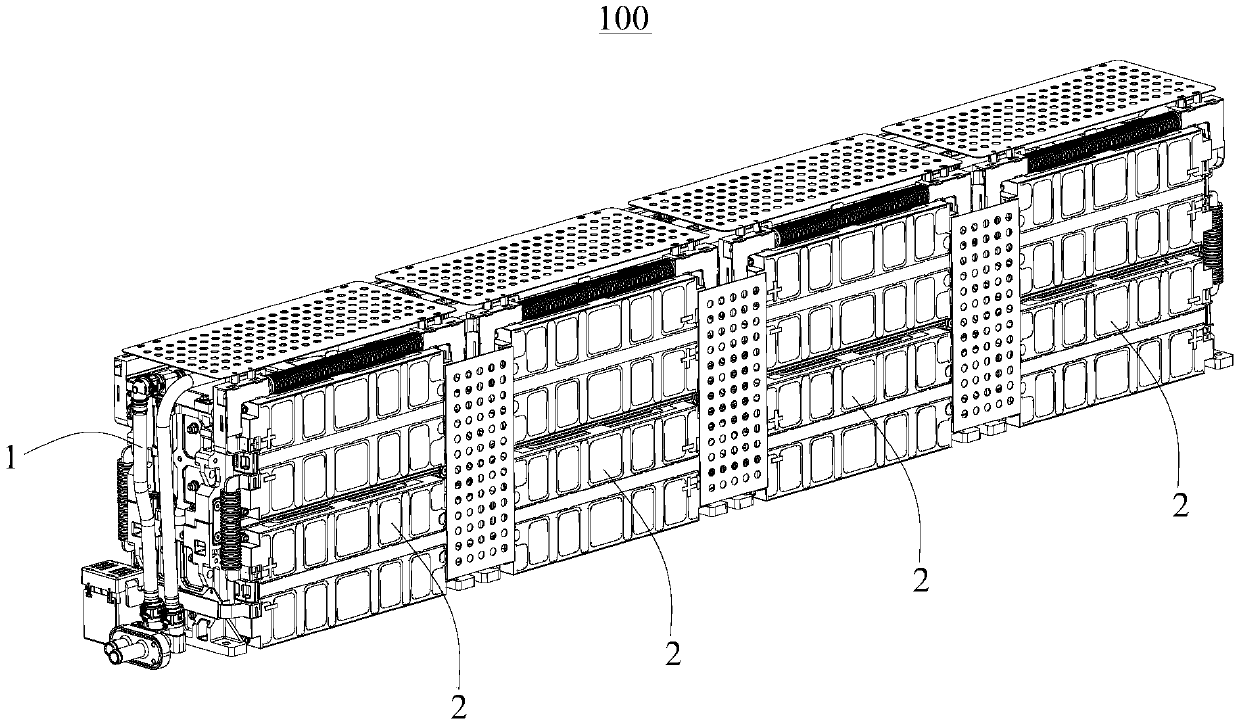

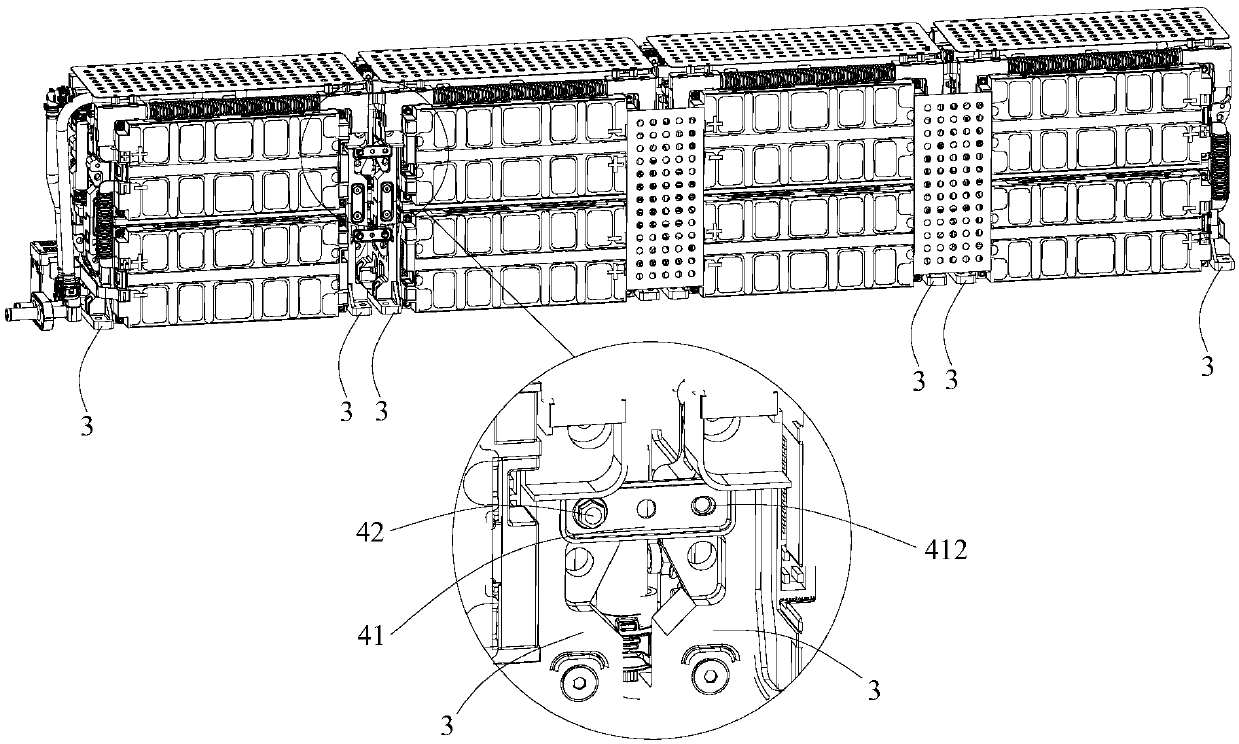

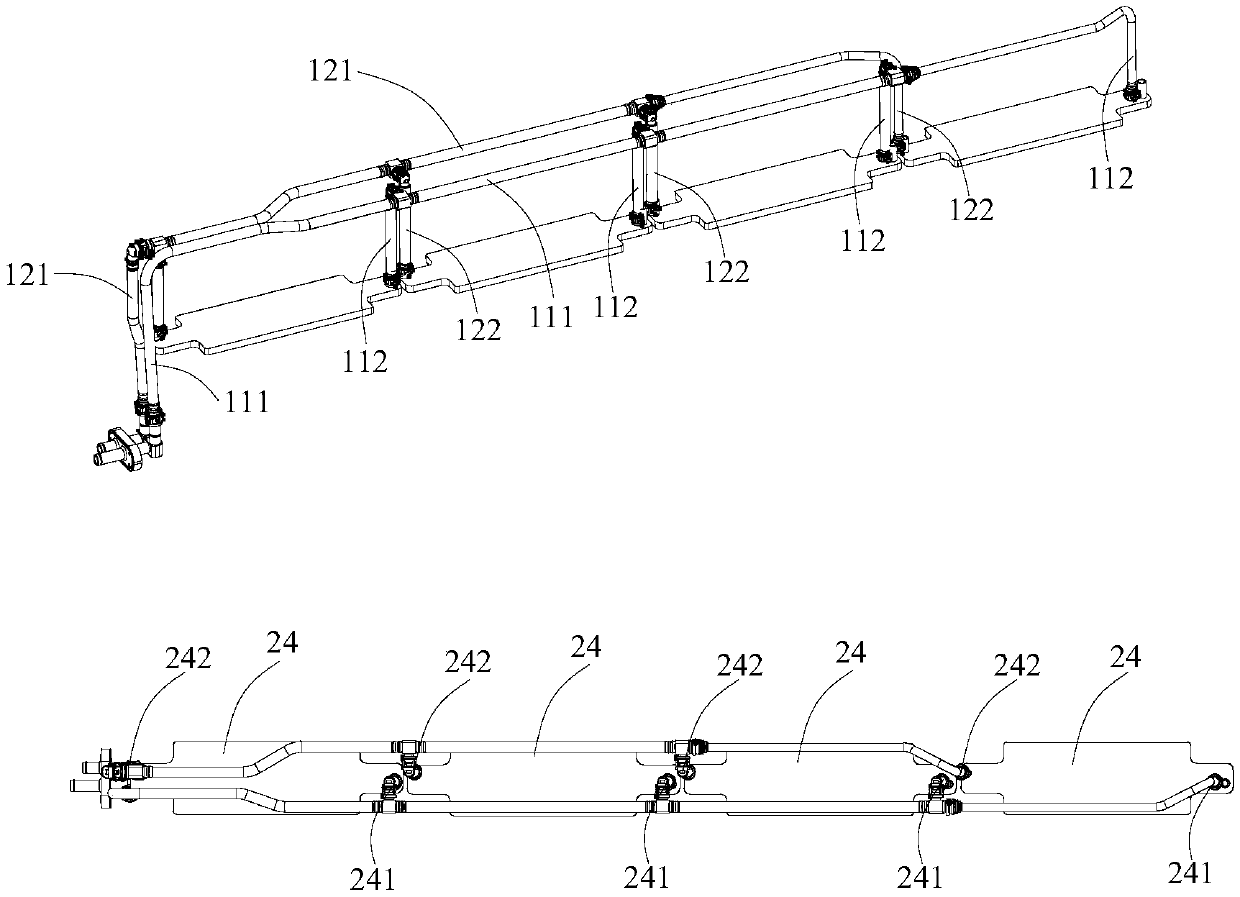

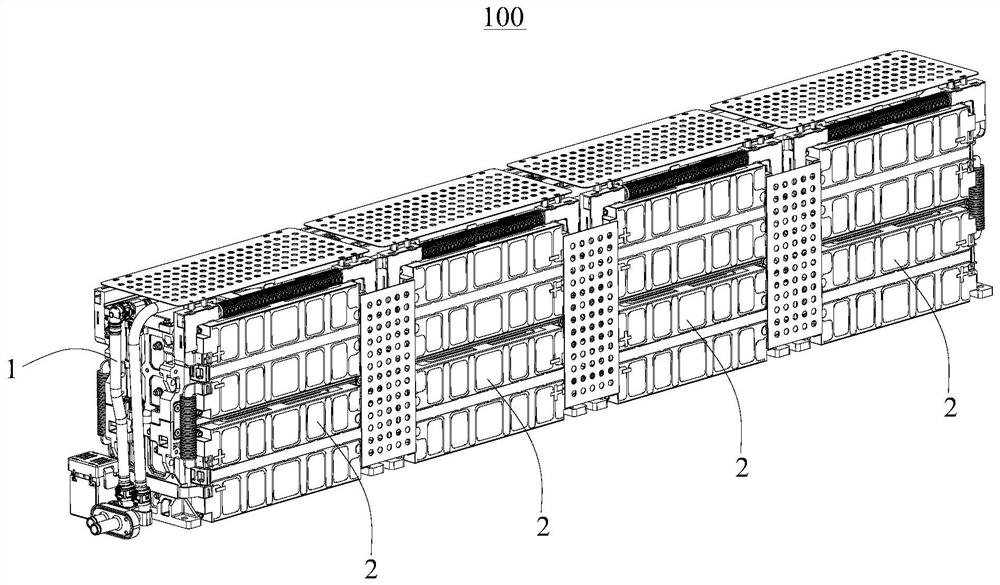

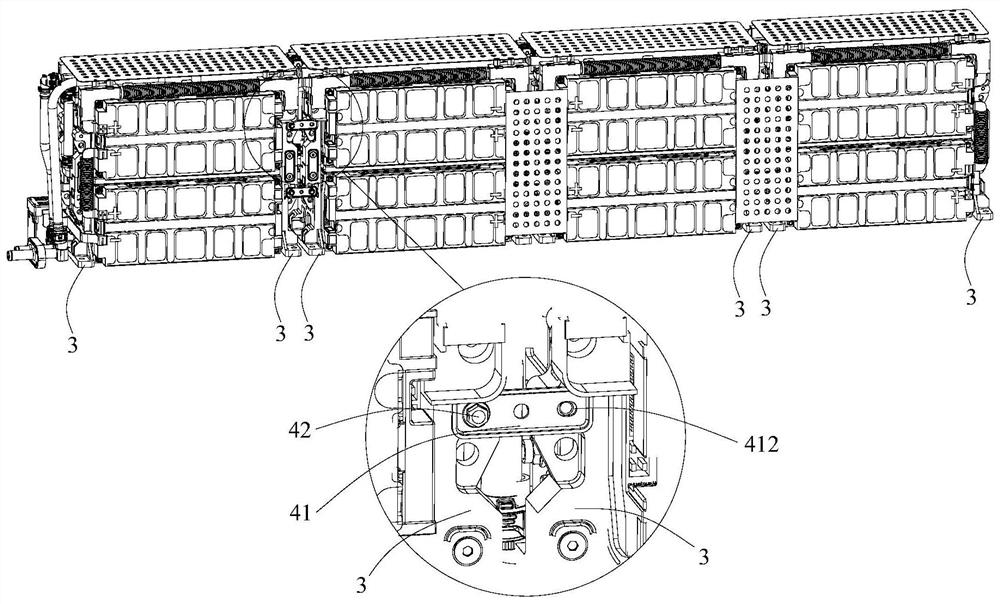

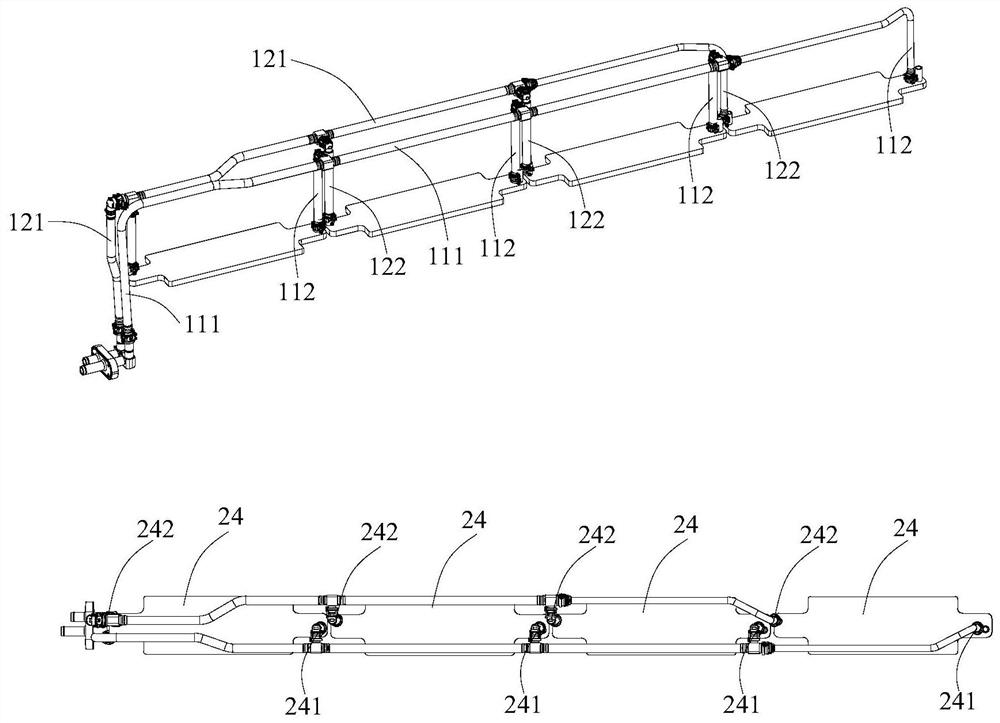

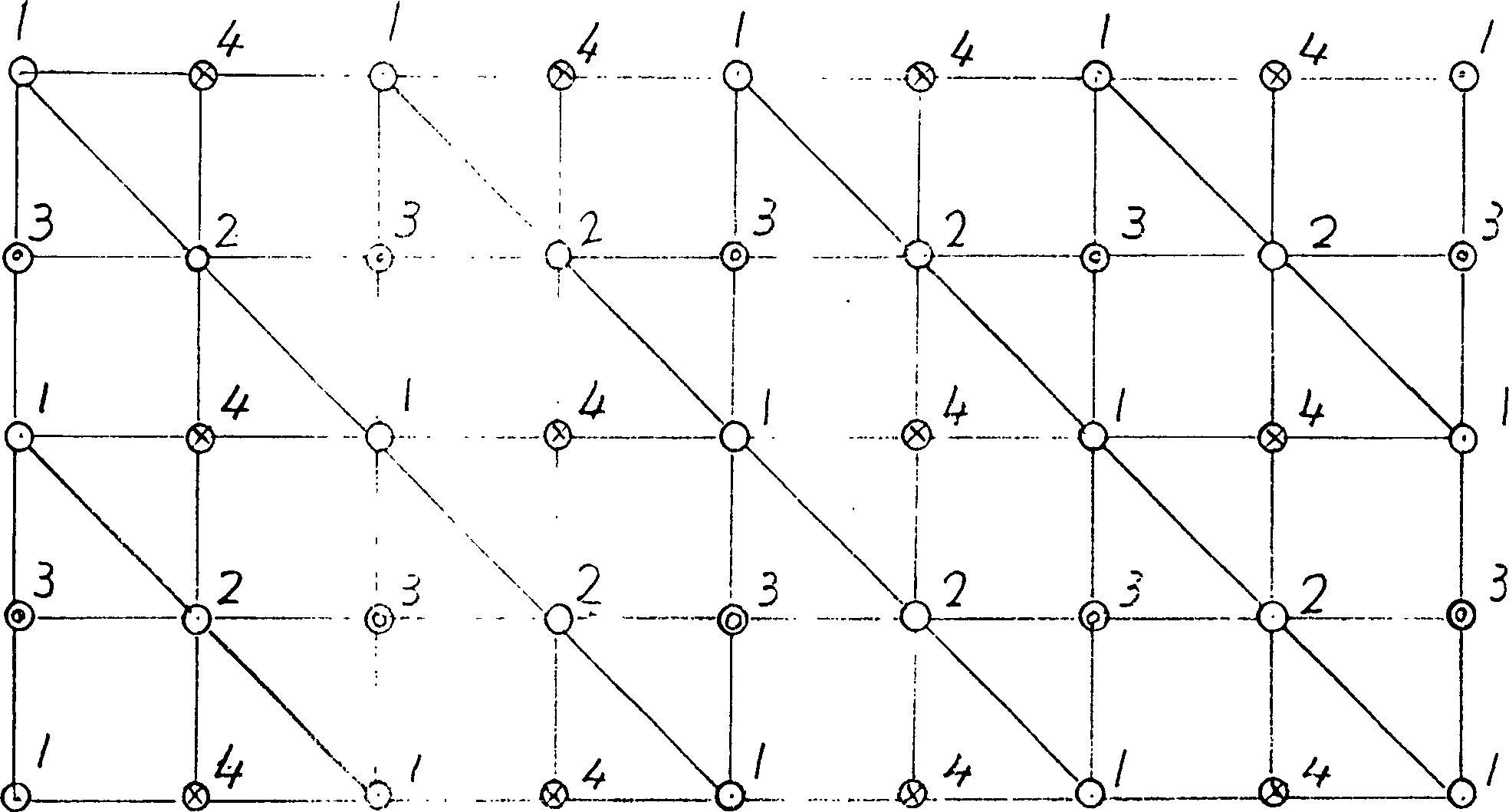

Multilayer soft-package battery module and multilayer soft-package battery module system

ActiveCN109524593AEven heat dissipationReliable coolingSecondary cellsCell component detailsPower batteryHeat management

An embodiment of the invention relates to the technical field of power batteries, and particularly speaking, relates to a multilayer soft-package battery module and a multilayer soft-package battery module system. A liquid inlet pipe and a liquid outlet pipe of the multilayer soft-package battery module are both communicated with a liquid-cooled plate arranged on each multilayer soft-package battery unit; the uniform and reliable heat dissipation of the multilayer soft-package battery module can be realized; two adjacent multilayer soft-package battery units are fixedly connected through a connecting piece; the anti-vibration and anti-shear ability of the multilayer soft-package battery module can be improved; and thus, the safety of the multilayer soft-package battery module can be ensured from two aspects of heat management and structure in the running process of an electric vehicle.

Owner:HUATING HEFEI POWER TECH

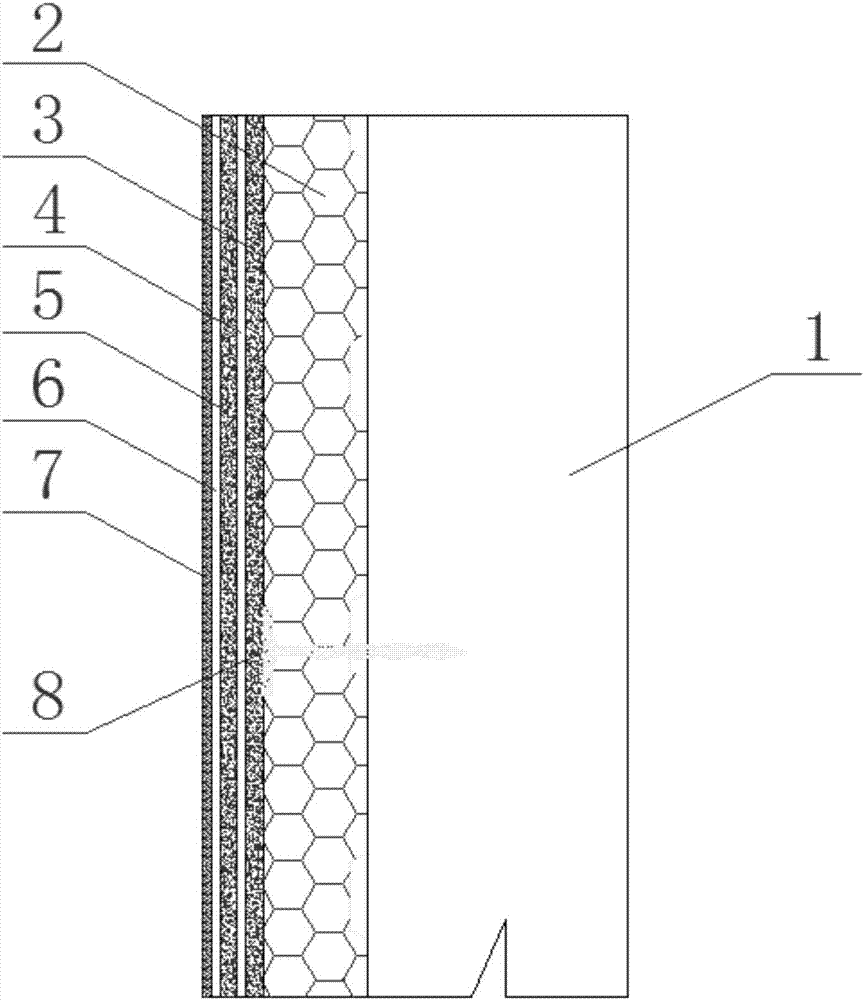

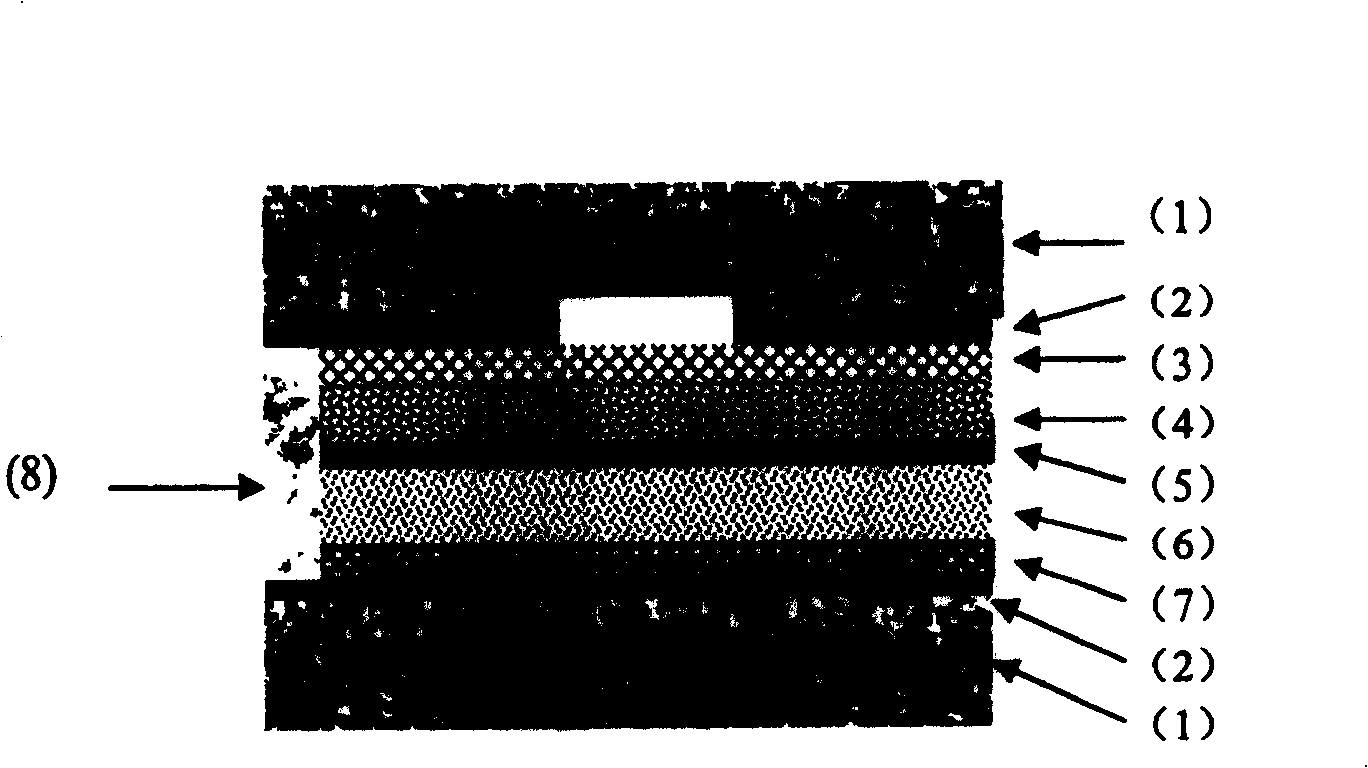

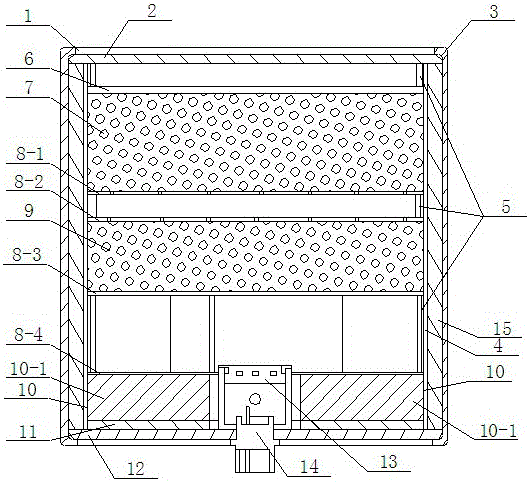

Novel decorative heat-insulating integrally-prefabricated external wall panel and construction process thereof

InactiveCN107246118ALose weightEmission reductionCovering/liningsBuilding material handlingForming processesWall plate

The invention discloses a novel decorative heat-insulating integrally-prefabricated external wall panel and a construction process thereof. The external wall panel comprises a base wall, a heat-insulating plate is arranged on the base wall through anchor bolts, a first plastering mucilage layer is arranged on the heat-insulating plate, alkali-resistant grid cloth is arranged on the first plastering mucilage layer, a second plastering mucilage layer is arranged on the alkali-resistant mucilage layer, a waterproof putty layer is arranged on the second plastering mucilage layer, and a coating layer is arranged on the waterproof putty layer. The construction process includes: cleaning a die platform and a die; cutting and pre-paving the heat-insulating plate on the die platform; completing heat-insulating integration reverse forming process operation of the base wall and the heat-insulating plate; building the first plastering mucilage layer on the homogeneous heat-insulating plate, and constructing the second plastering mucilage layer; coating the flexible waterproof layer on the second plastering mucilage layer, and coating the coating layer. The external wall panel prepared by the construction process has the advantages of long service life and high construction efficiency.

Owner:安徽海龙建筑工业有限公司

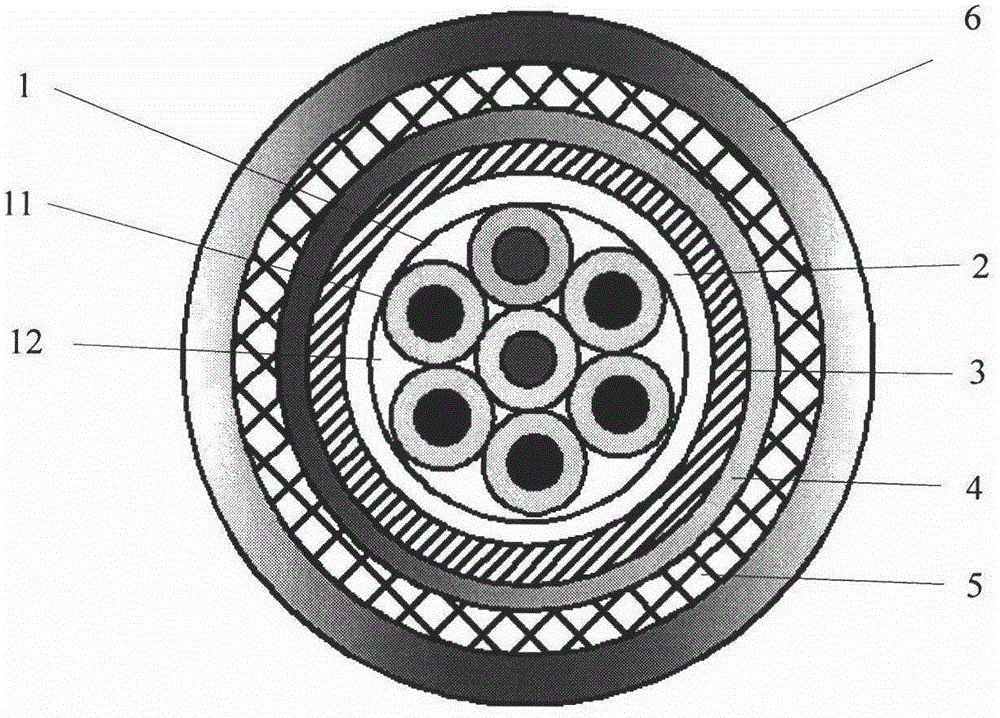

High-intensity sheath high-speed railway cable

InactiveCN105895214AHigh strengthImprove adaptabilityInsulated cablesInsulated conductorsPolyolefinHigh intensity

The present invention discloses a high-intensity sheath high-speed railway cable. The cable comprises a cable core unit, the cable core unit is internally provided with a plurality of insulation cores and filler, and the cable core unit is coated with polyolefin oversheath. An enhanced insulation wrapping layer, a welding aluminum alloy sheath, an extruded enhanced polyolefin middle sheath and an alloy aluminum strip chain armor coat from inside to outside between the cable core unit and the polyolefin oversheath. The high-intensity sheath high-speed railway cable uses enhanced protection materials with different forms from the cable core welding materials, a shielding layer, a middle protection layer to an armor layer according to the features of the processing process layer by layer, so that the vibration resistance, the impact resistance and the extruding resistance performances of the cable are effectively improved, and the machinery performance and the safety usage performance of the cable are greatly improved.

Owner:JIANGSU DONGQIANG

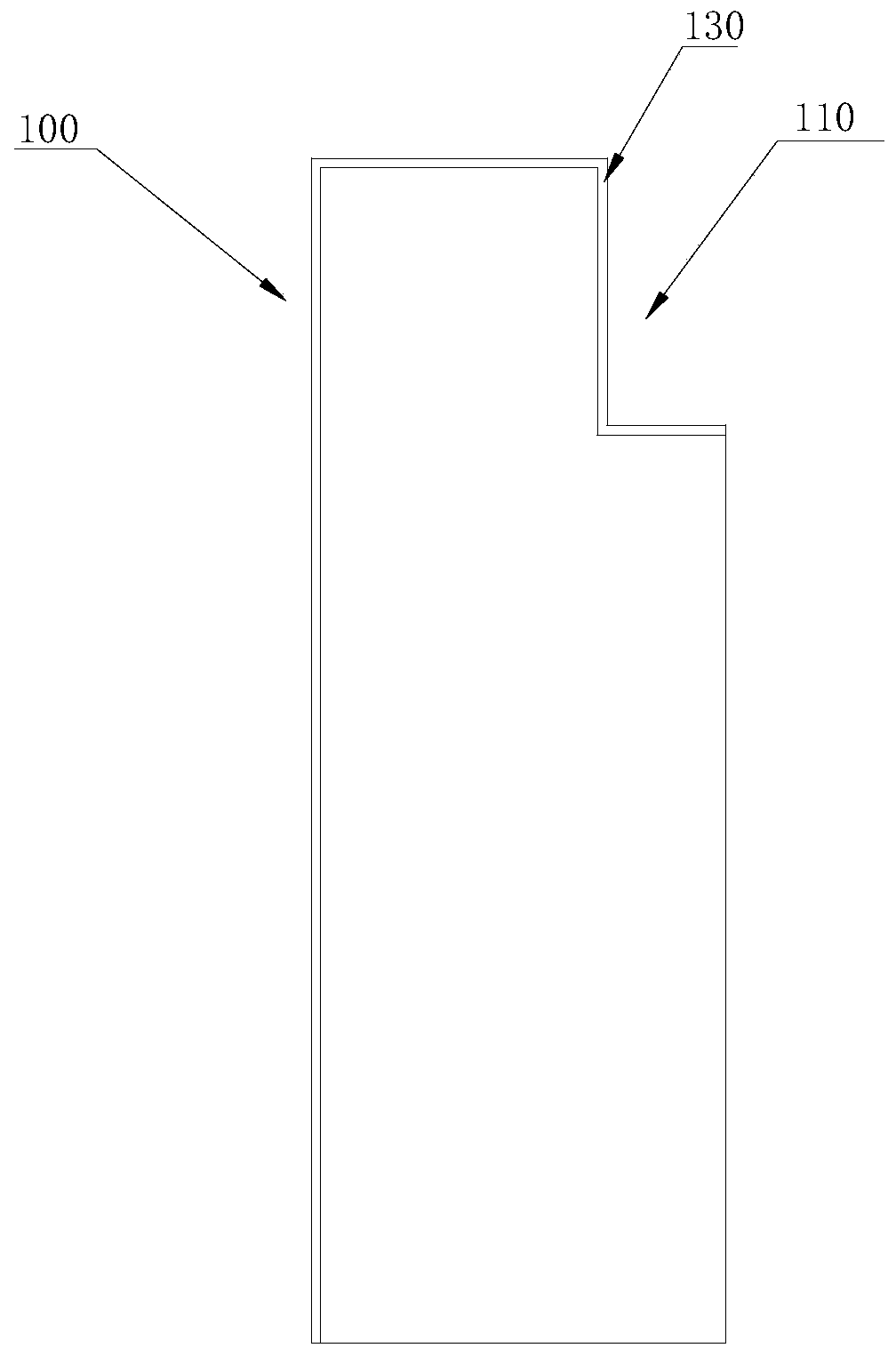

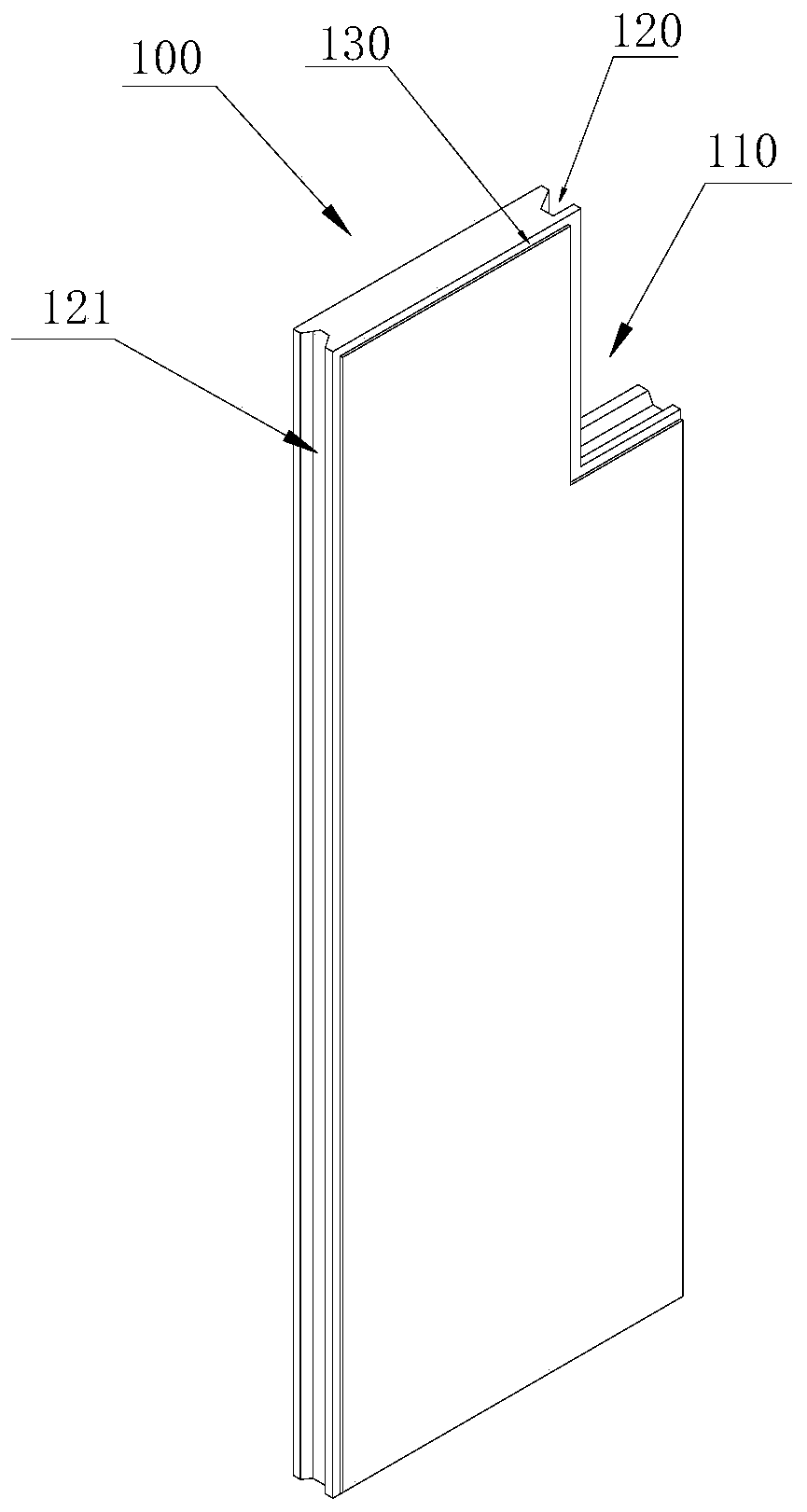

Prefabricated anti-cracking door frame vertical board for ribbon board internal parting wall door opening structure

PendingCN110029773AAvoid Live CutsImprove construction efficiencyConstruction materialUltimate tensile strengthElectrical and Electronics engineering

The invention discloses a prefabricated anti-cracking door frame vertical board for a ribbon board internal parting wall door opening structure. The prefabricated anti-cracking door frame vertical board comprises prefabricated door frame vertical board bodies; L-shaped notches are formed in the upper parts of the prefabricated door frame vertical board bodies, so that the prefabricated door framevertical board bodies are connected with prefabricated door head boards in a joint-staggering engaged mode to improve the connecting firmness of the prefabricated door frame vertical board bodies andthe prefabricated door head boards; prefabricated grouting grooves are formed in the outer side faces of the prefabricated door frame vertical board bodies, during door opening splicing, the prefabricated door head boards are inserted in the L-shaped notches of the two corresponding prefabricated door frame vertical board bodies to form a door opening, internal parting wall ribbon boards are spliced on the side face of the door opening, and prefabricated mortar storage grooves are compactly filled with mortar to form secondary connecting bodies with the internal bolting effect to be fixedly connected; and jointing grooves are formed in the edges of the outer sides of the L-shaped notches correspondingly and spliced with the adjacent prefabricated door head boards with jointing grooves andthe internal parting wall ribbon boards during door opening splicing to define anti-cracking edge sealing grooves, net laying and mortar smearing are conducted on the interiors of the anti-cracking edge sealing grooves to form anti-cracking connecting bodies, the connecting strength of joints is improved, and the phenomenon that as for an existing door opening structure, due to frequent opening and closing and vibration of a door, the spliced positions of the door opening are prone to being cracked is effectively avoided.

Owner:舒浪平 +1

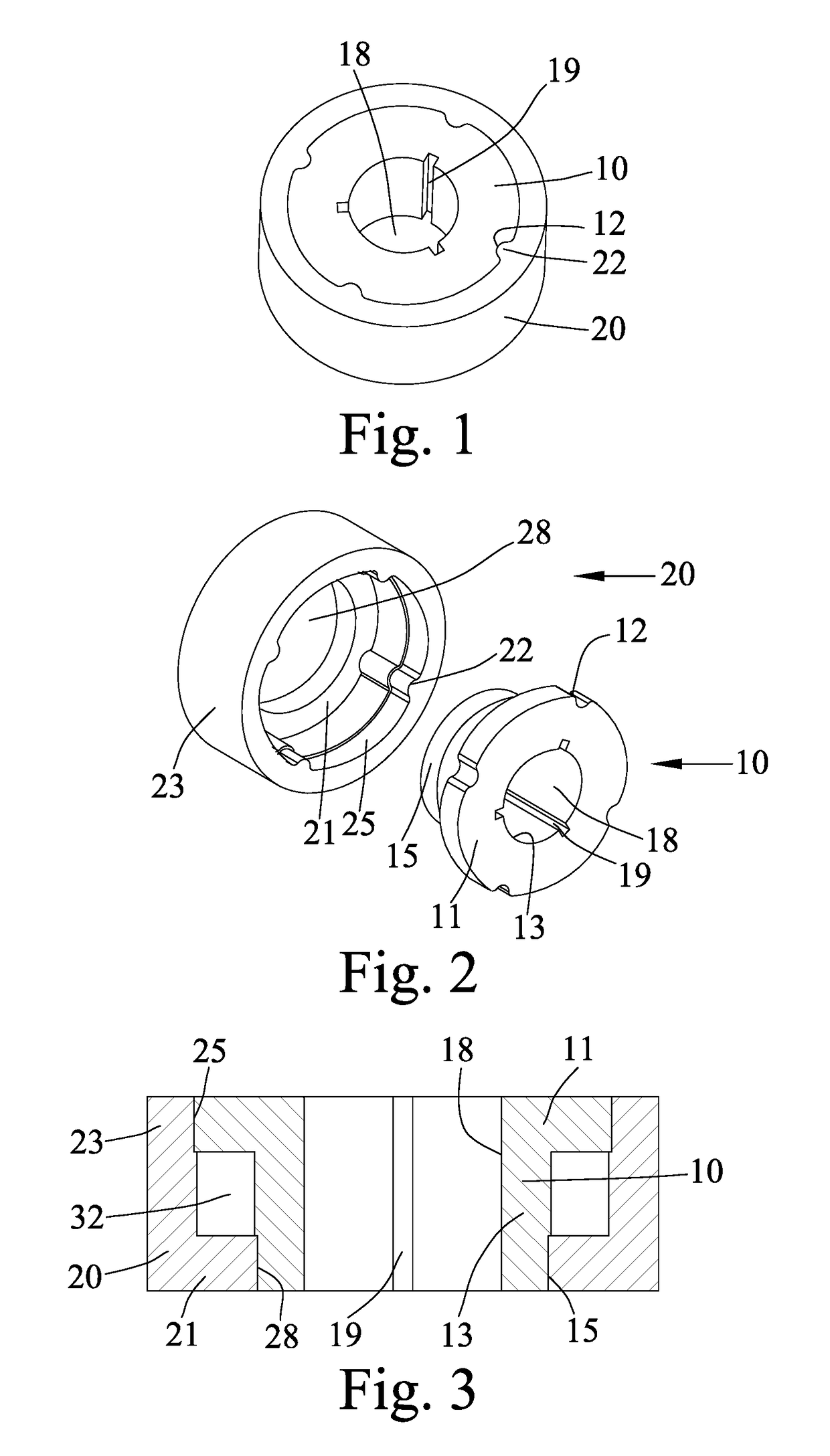

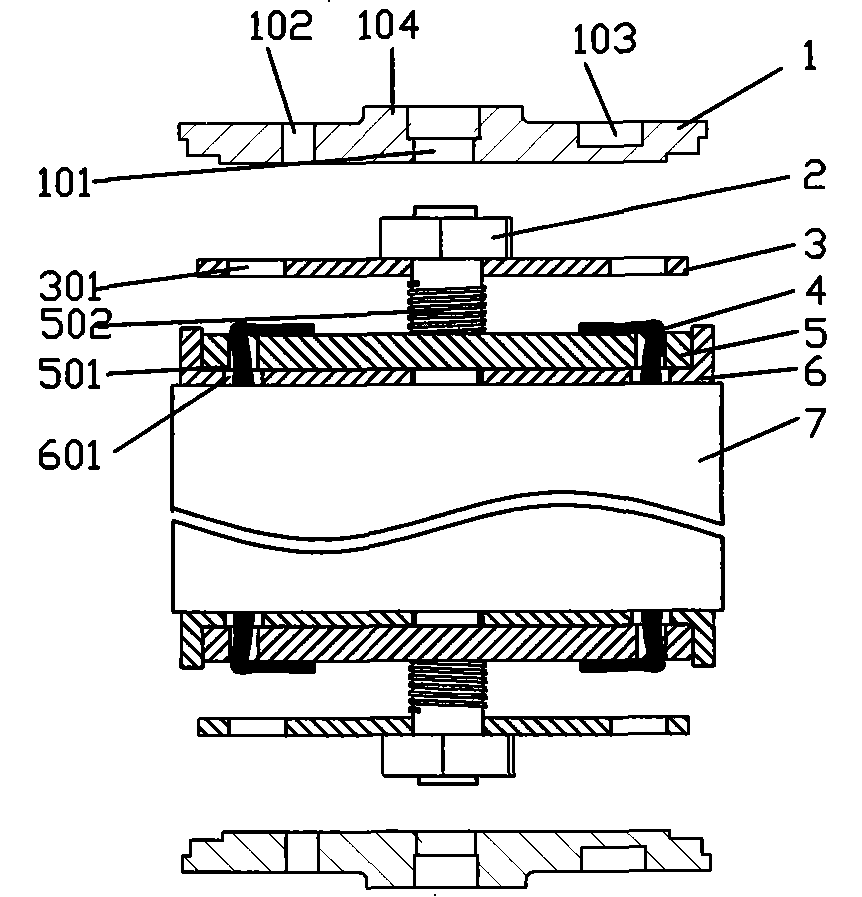

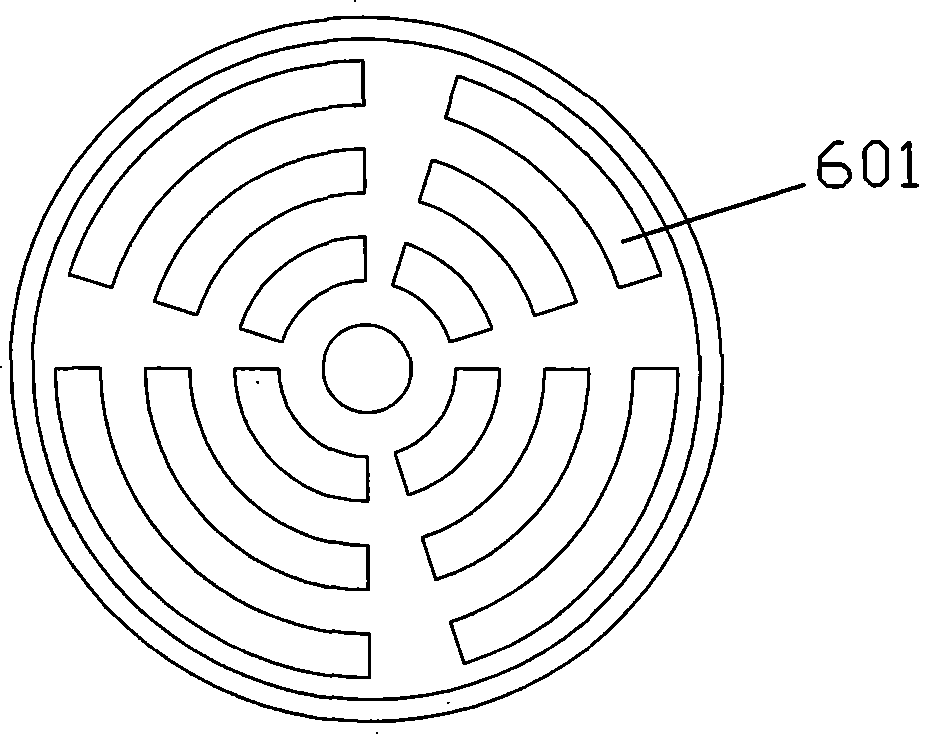

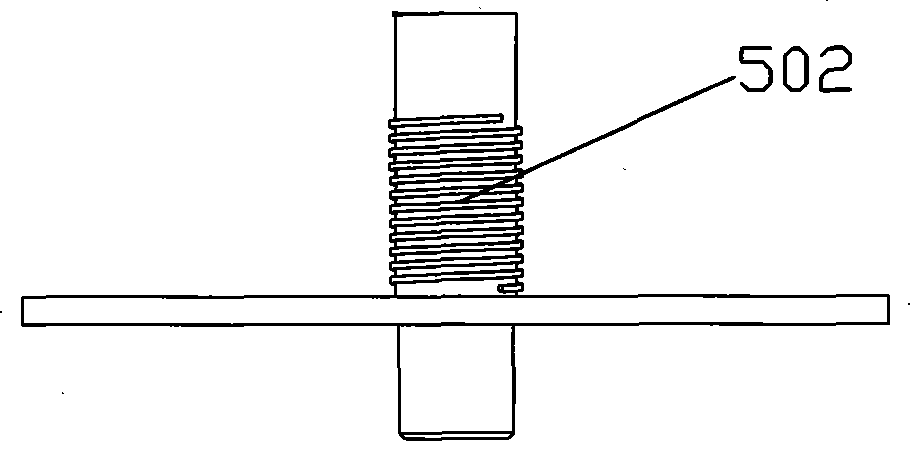

Bush assembly

InactiveUS20170130772A1Extended service lifeLimit its operationBearing assemblyShaft assemblyEmbedded system

Owner:SHINE YING

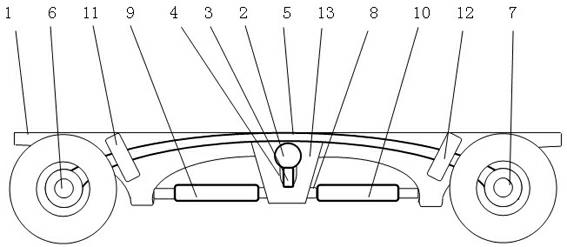

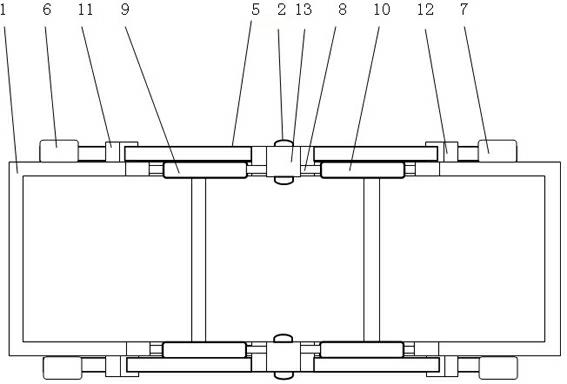

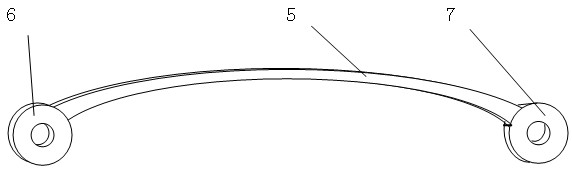

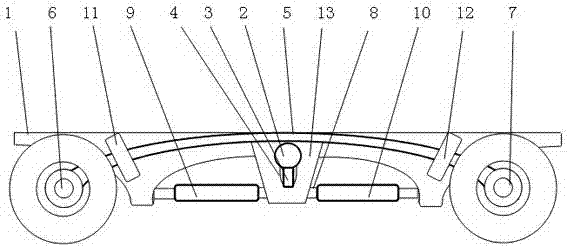

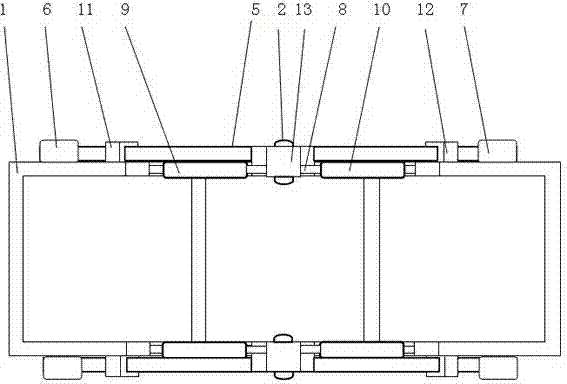

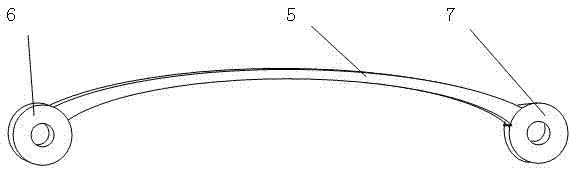

Shockproof anti-jolt chassis of passenger car

InactiveCN102139614AImprove anti-vibrationEnhanced bump resistanceInterconnection systemsSimple componentEngineering

The invention relates to a shockproof anti-jolt chassis of a passenger car. The shockproof anti-jolt chassis comprises a car frame, a central axle, a central spring, a wheel bow frame, a front wheel axle, a rear wheel axle and a central socket sleeve, wherein the front wheel axle is arranged at the front end of the wheel bow frame, and the rear wheel axle is arranged at the rear end of the wheel bow frame. The central axle is fixed in the middle of the car frame and is connected with the wheel bow frame on two edges of the car frame; the wheel bow frame is downwardly bow-shaped, the lower middle part of the wheel bow frame is fixedly connected with the central socket sleeve; a transverse middle hole groove is formed in the middle of the central socket sleeve, the central axle penetrates through the upper part of the middle hole groove, the central spring is mounted in the middle hole groove, and the central axle is supported by the upper end of the central spring; and the wheel bow frame, the central socket sleeve, the central axle and the central spring constitute the shockproof anti-jolt mechanism of the passenger car. In the invention, with the integrated structure of the wheelbow frame, the central axle, a front axle spring and a rear axle spring in the entire passenger car, the traditional separately-arranged structure of the front and the rear wheel sets is changed, therefore shockproof and anti-jolt effects of the passenger car are greatly improved. The shockproof anti-jolt chassis provided by the invention has the advantages of firm structure, simple components, good shockproof effect and especially obvious anti-jolt effect.

Owner:SHANGHAI INST OF TECH

Integrated hot end phase adjusting structure of inertance-tube type pulse tube cooler and manufacturing method of phase adjusting structure

InactiveCN102032703BGuaranteed integrityGuaranteed stabilityCompression machinesGas cycle refrigeration machinesWorking lifePulse tube refrigerator

The invention discloses an integrated hot end phase adjusting structure of an inertance-tube type pulse tube cooler and a manufacturing method of the phase adjusting structure. In the structure, joint phase adjustment of the inertance tube and a gas storage is adopted; and the structure comprises two inertance tubes with different diameters and lengths as well as the stable-pressure inner gas storage. An integrated inertance tube component is connected with a hot end gas outlet of a pulse tube and the stable-pressure inner gas storage, and wound on the outer surface of the inner gas storage; then the inertance tube component and the inner gas storage are integrally placed in a special protective cover. The novel hot end phase adjusting structure has the advantages that: the hot end phase adjusting capability is maximized; and the integrity and stability of the effective volume of working medium in the gas storage are ensured. The gas working medium in the system is protected from pollution of the phase adjusting device; the structure is simple and compact; and the anti-vibration and anti-impact capabilities are enhanced. The mechanical and thermodynamic performance of the pulse tube cooler is improved in a great degree, and the long-term operation reliability and a relatively long working life are guaranteed.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Copper-clad steel combined special-shaped contact wire for electrified railway

InactiveCN102881354ASimple structureEasy to makeNon-insulated conductorsWear resistanceCopper-clad steel

The invention relates to a copper-clad steel combined special-shaped contact wire for an electrified railway. The contact wire comprises a conductive part and a steel cable part, and is characterized in that the conflicting basic functions such as conductivity, wear resistance, tensile resistance, vibration resistance and fatigue resistance of the contact wire are separated and are combined and realized by the characteristic conductive part and steel cable part. Compared with the prior art, the copper-clad steel combined special-shaped contact wire for the electrified railway has the advantages of separated functions, complementary effect, strong combination, high conductivity, wear resistance, tensile resistance, vibration resistance and fatigue resistance, long service life and low cost, is easy to manufacture and convenient to use and is safe, reliable, energy-saving and environment-friendly, so that the contact wire is high in popularization and use value.

Owner:嘉善瑞佳运动器材有限公司

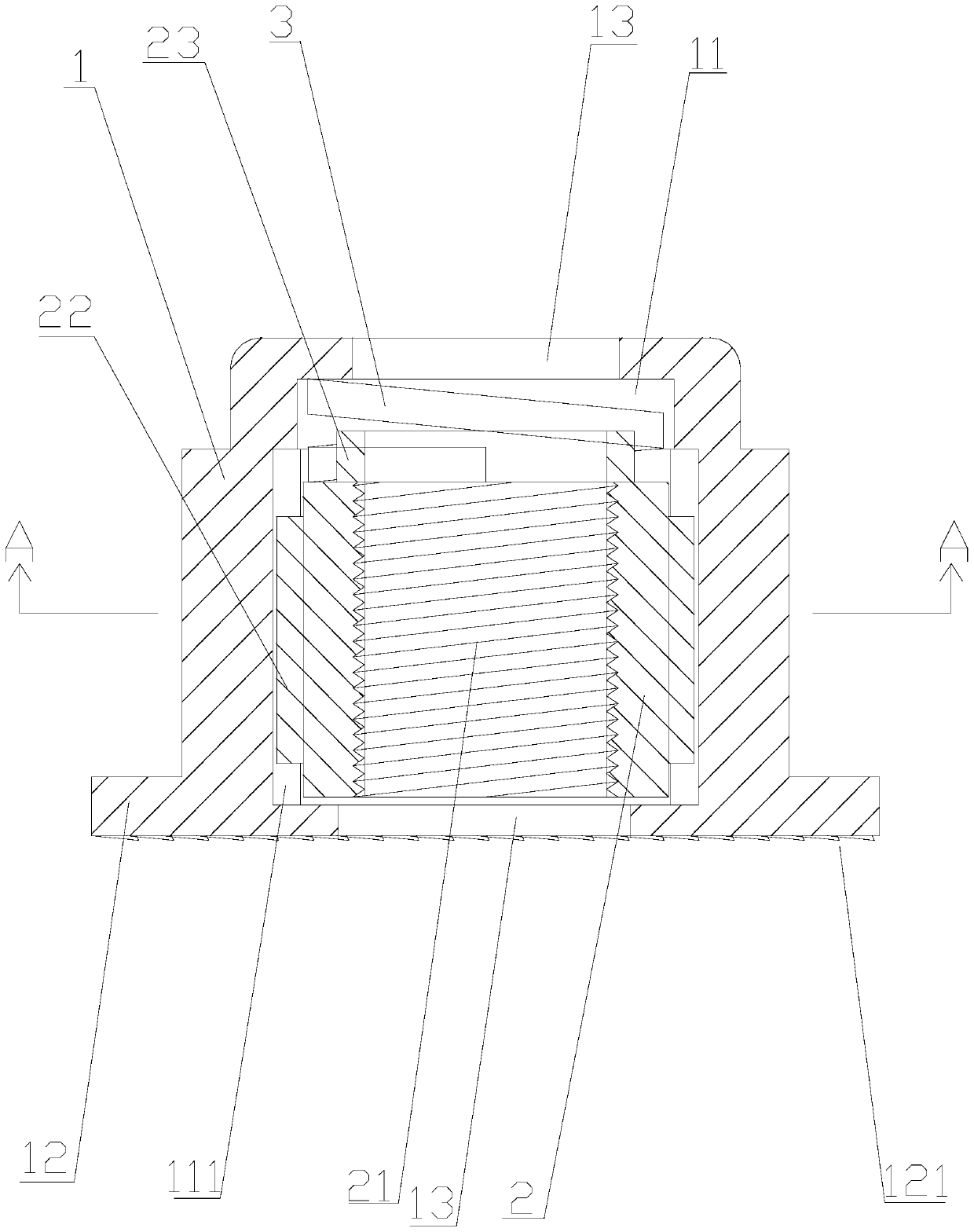

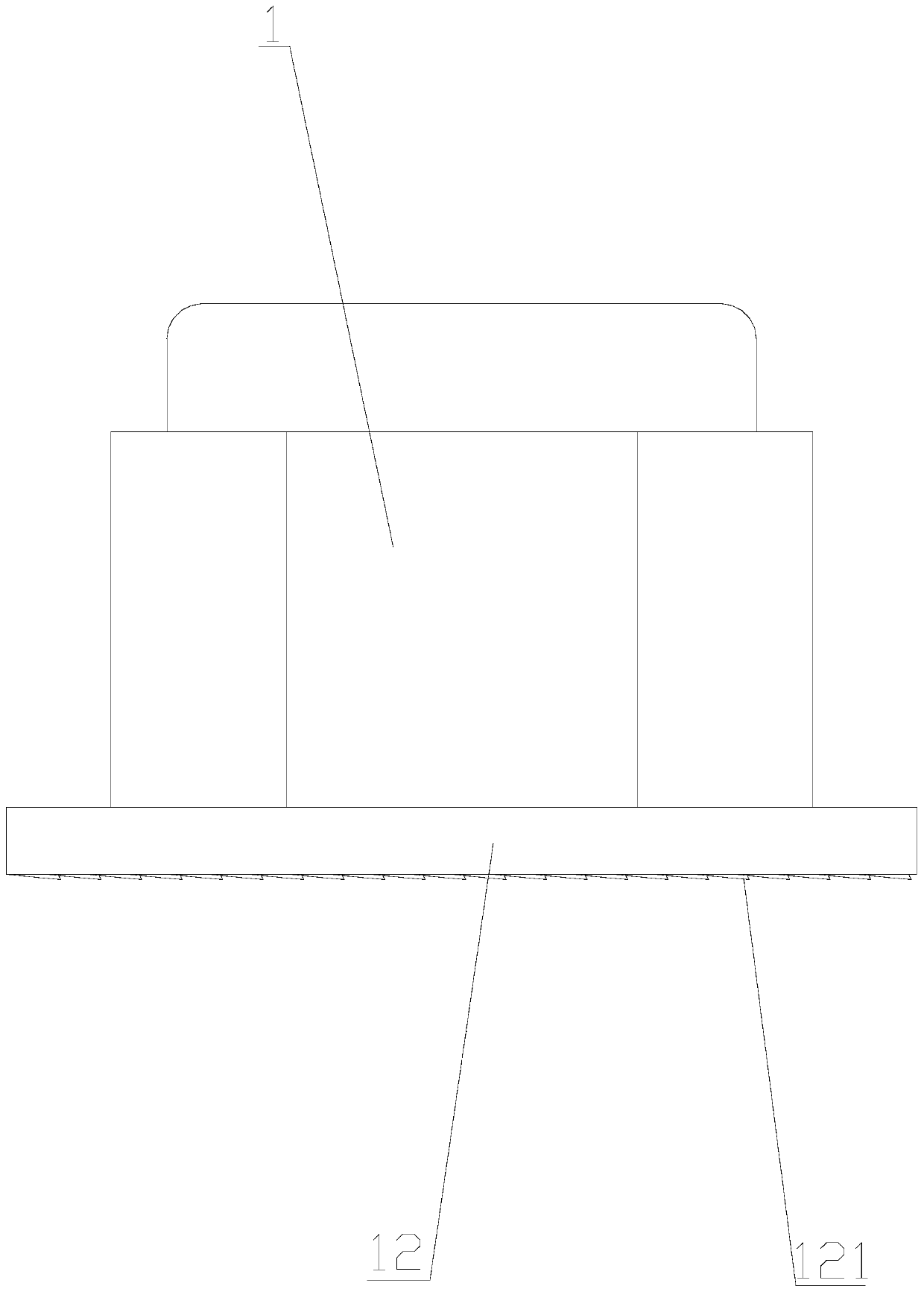

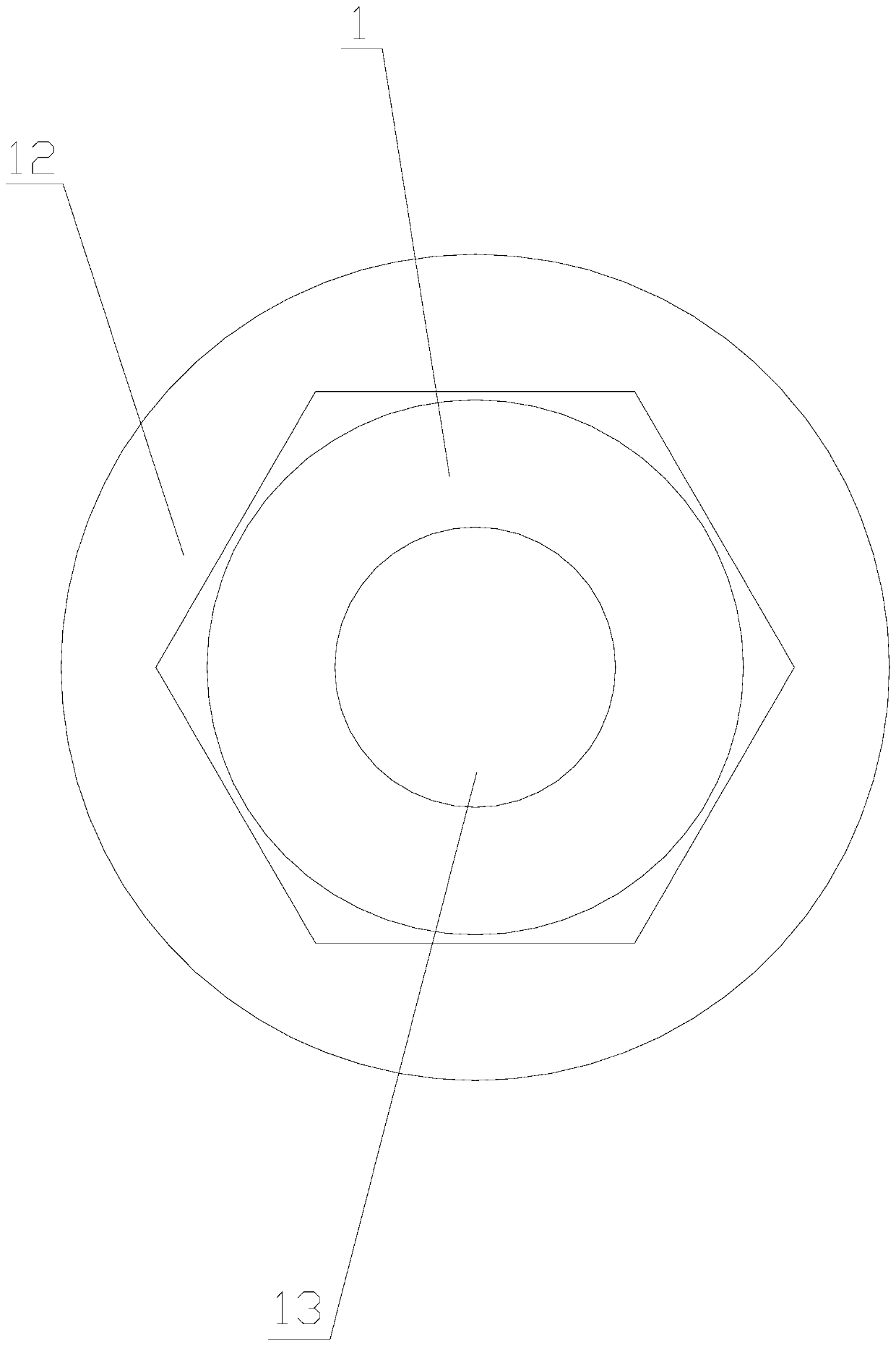

Spring nut with good anti-loosening performance

InactiveCN110107586AImprove anti-loosening performanceImprove anti-vibrationNutsBoltsFree stateEngineering

The invention discloses a spring nut with a good anti-loosening performance. The spring nut with the anti-loosening performance comprises a nut body, an inner nut and a spring washer, wherein an innernut installation chamber matched with the inner nut is arranged in the nut body; the inner nut is vertically arranged in the inner nut installation chamber and is up-and-down slidably connected withthe inner nut installation chamber; a screw-thread through hole is vertically formed in the center of the inner nut; the spring washer is arranged at the upper end of the inner nut; the upper end of the spring washer is matched with the top wall of the upper end of the inner nut installation chamber; and the spring washer downwards presses against the inner nut under a free state. According to thespring nut with the anti-loosening performance provided by the invention, the inner nut and the spring washer are arranged in the nut body, the inner nut and a bolt can be fixed in a matching way, and when the inner nut is screwed down, the spring washer at the upper end of the inner nut can be matched with the inner nut, so that anti-vibration and anti-loosening performances of the inner nut canbe improved.

Owner:海盐海马五金有限公司

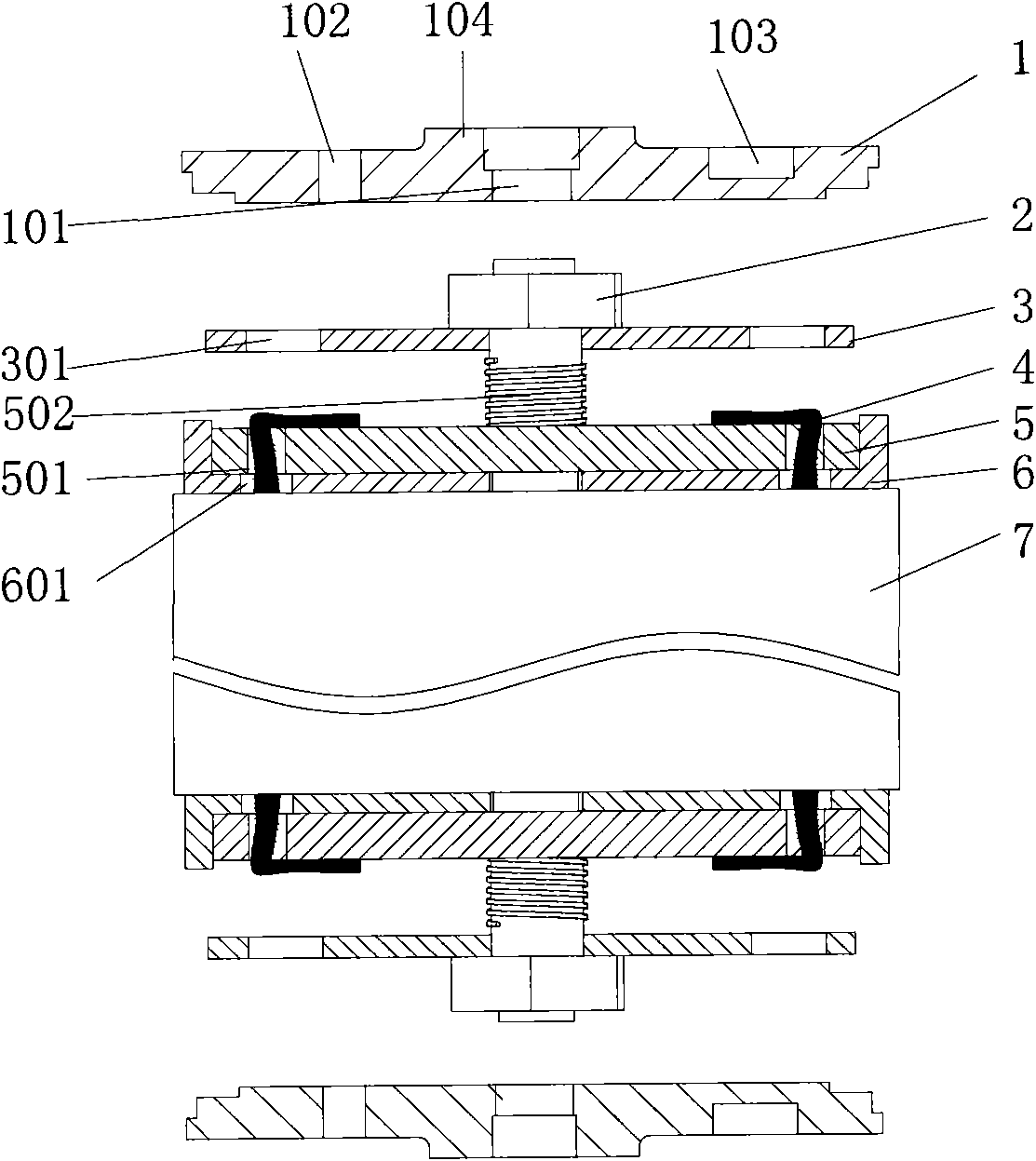

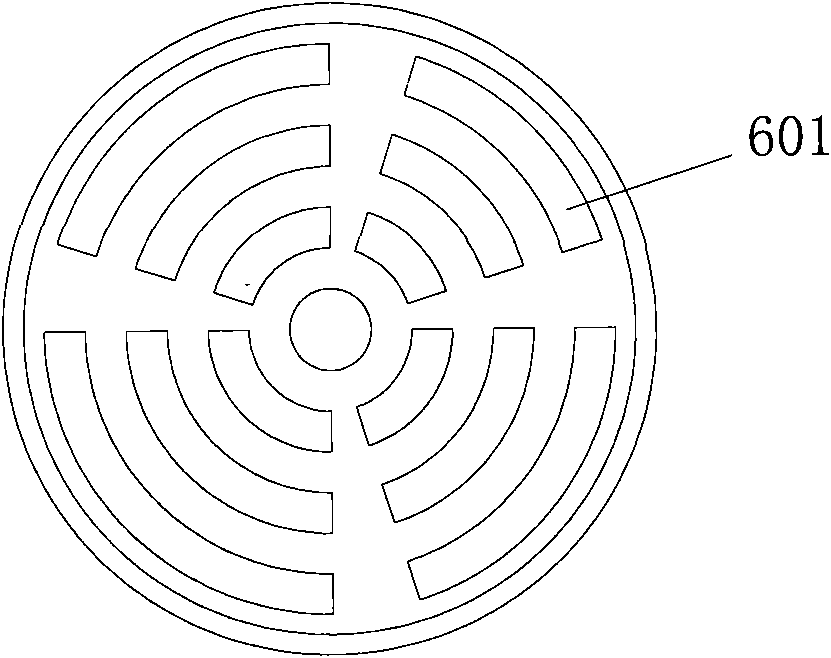

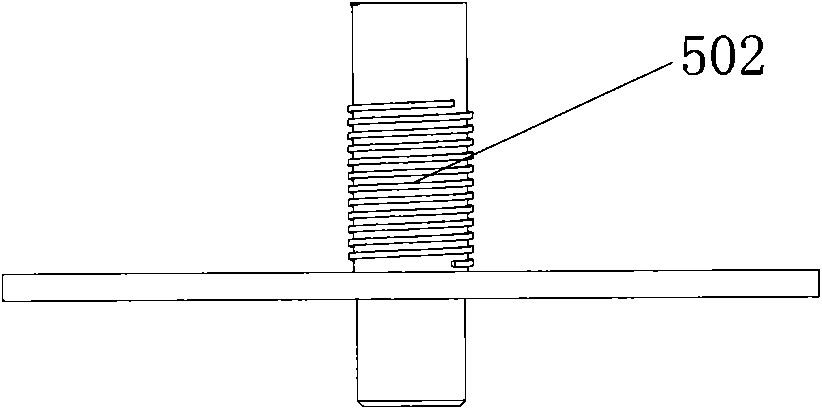

Plate type solid oxide fuel cell cathode flexible contact material and battery pile structure

InactiveCN100435395CGuaranteed long-term stabilityExtended service lifeFuel cells groupingCell electrodesElectrical batteryManganate

This invention relates to a cathode flexible contact material of a panel solid oxide fuel cell (SOFC) stack structure and a cell stack structure, in which, the composition of the cathode flexible contact material includes: CaTi ore, spinel, or ferrite, cobaltate, nickelate, chromate, manganate or galliumate of inverse spinel mine in the structure of cloth, felt, net or foam, the cell stack structure is made up of overlapped cell units composed of a connection pole, anode Ni net or a foam Ni contact layer, anode, electrolyte, cathode and cathode flexible contact layer.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Secondary battery

ActiveCN101604737BGuaranteed connection locationAccurate welding positionWound/folded electrode electrodesCell lids/coversInternal resistanceElectrical and Electronics engineering

Owner:SHENZHEN BAK POWER BATTERY CO LTD

Exchangeable blade type center cutter for shield machine

The invention belongs to the technical field of tunneling assembly, relating to an exchangeable blade type center cutter for a shield machine; the center cutter comprises a blade seat, a center cutter block and three side cutters; a center cutter block locating post and three knife rests are arranged on the blade seat; the middle part of the locating post is provided with a center cutter block locating hole; the bottom part of the center cutter block is fixedly connected with the blade seat; a cone-shaped lug boss is fixedly connected with the end of the locating post; an inner hole is arranged on the cone-shaped lug boss; the sizes of the inner hole of the lug boss and the center cutter block locating hole are matched with that of the center cutter block; three knife rests are arranged on the periphery of the center cutter block locating post; a groove joint which is fixedly connected with the side cutter is arranged on each knife rest; locating holes are arranged on the three side cutters and are respectively fixedly connected in the groove joints of three knife rests through bolts; three cutter arms formed by the side cutters and the knife rests form an included angle of 120 degrees. The center cutter has better stability in the tunneling process, higher impact resistance and abrasion resistance, and is easy to replace the blade, so that the waste of resource is avoided and the construction cost is saved; therefore, the center cutter has higher economical value.

Owner:TIANJIN UNIV

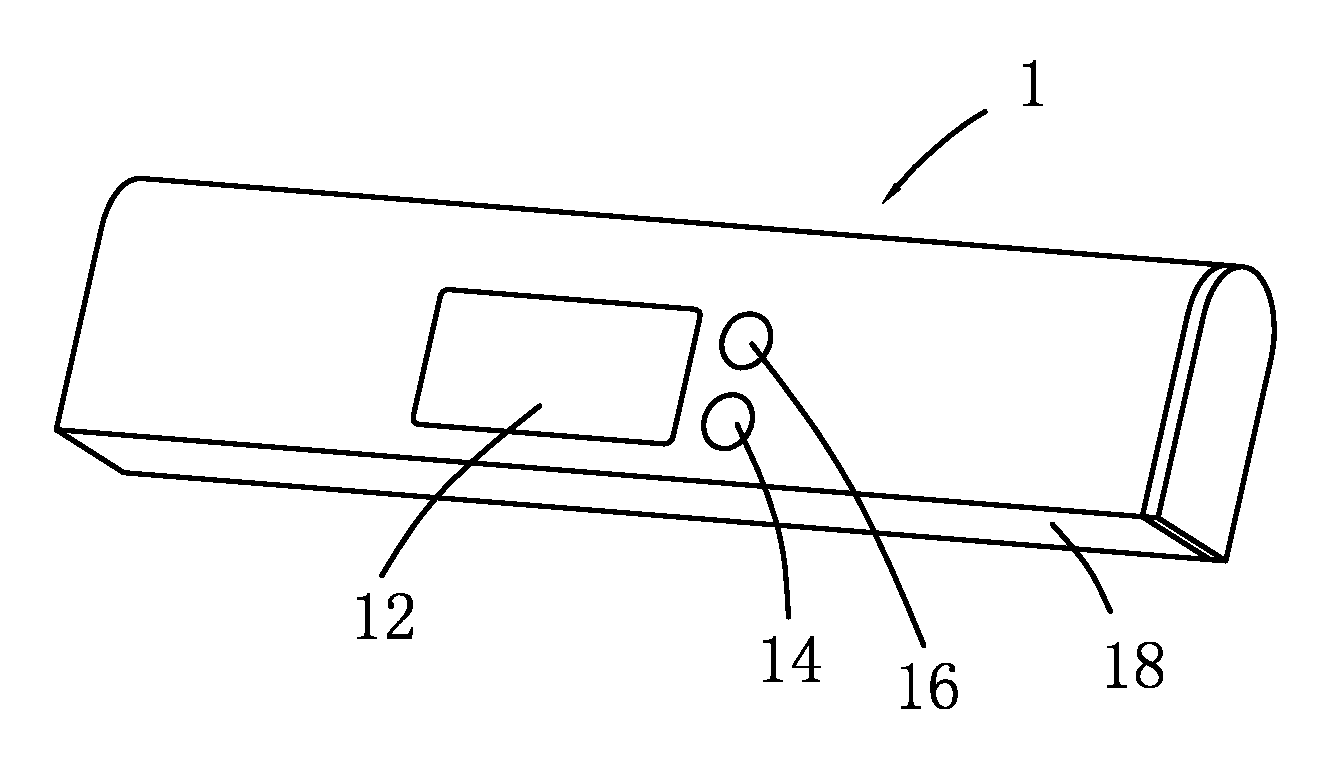

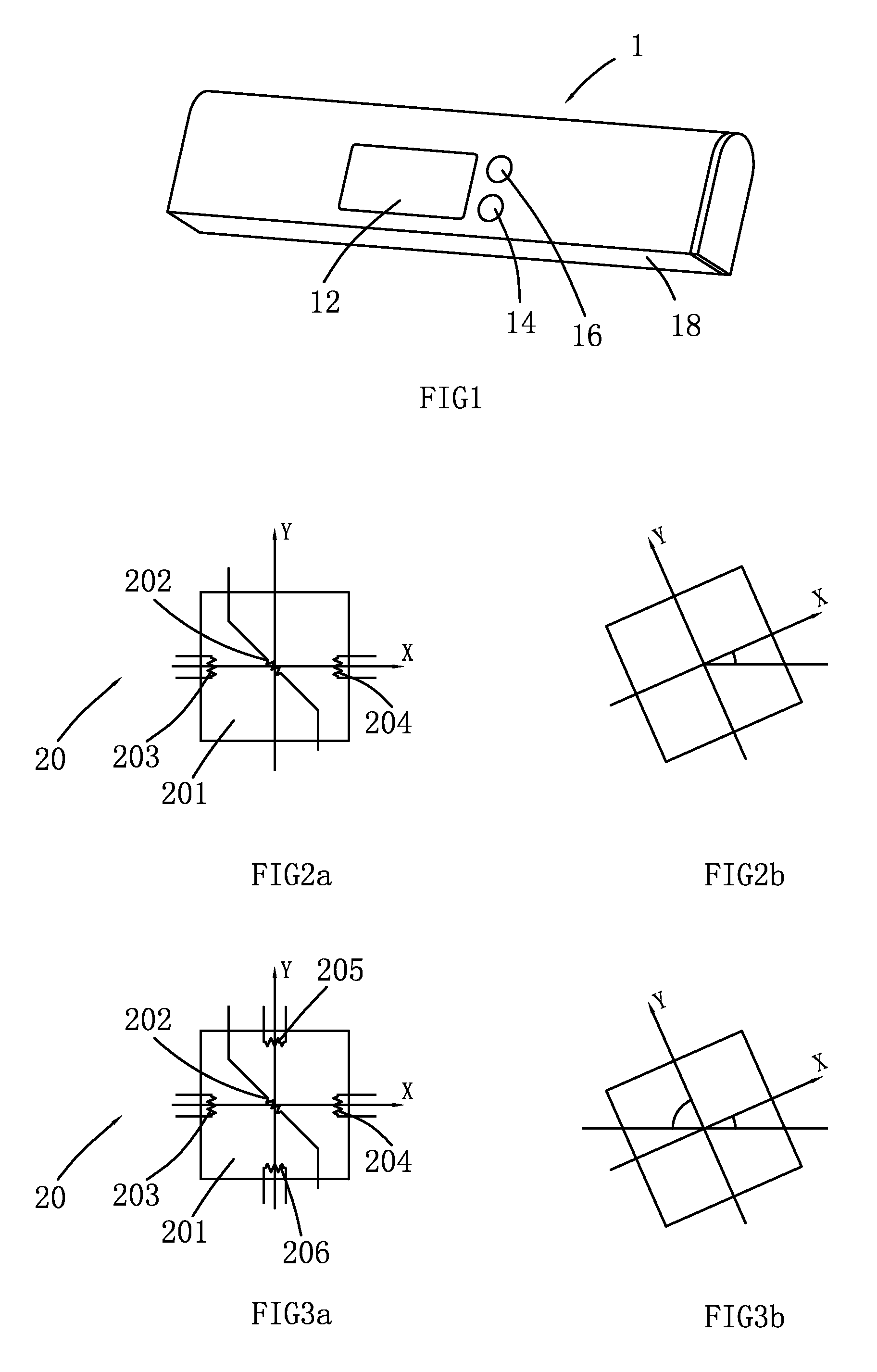

Portable inclinometer

InactiveUS20060285573A1Simple structureImprove anti-vibrationMaterial thermal analysisIncline measurementInclinometerHeating element

The present invention is to provide a portable electronic inclinometer with simplified structure, improved anti-impact and anti-vibration properties, and high precision. The inclinometer comprises a casing, a display unit and a set of operational buttons provided on the casing, a measuring circuit installed inside the casing and a power supply supplying power to the display unit and the measuring circuit. The casing includes a reference measuring surface. The measuring circuit includes a tilting angle sensing unit. The tilting angle sensing unit comprises a gas-filled sealed chamber, a heating element and a set of temperature sensing elements arranged inside the chamber. The set of temperature sensing elements comprises at least one pair of temperature sensing elements symmetrically arranged about the heating element. The tilting angle sensing unit has a first axis extending across the heating element. A first pair of temperature sensing elements symmetrically arranged about the heating element is disposed along the first axis. The first axis is parallel to the reference measuring surface of the casing.

Owner:NANJING CHERVON IND

Copper-clad steel combined special-shaped contact wire for electrified railway

The invention relates to a copper-clad steel combined special-shaped contact wire for an electrified railway. The contact wire comprises a conductive part and a steel cable part, and is characterized in that the conflicting basic functions such as conductivity, wear resistance, tensile resistance, vibration resistance and fatigue resistance of the contact wire are separated and are combined and realized by the characteristic conductive part and steel cable part. Compared with the prior art, the copper-clad steel combined special-shaped contact wire for the electrified railway has the advantages of separated functions, complementary effect, strong combination, high conductivity, wear resistance, tensile resistance, vibration resistance and fatigue resistance, long service life and low cost, is easy to manufacture and convenient to use and is safe, reliable, energy-saving and environment-friendly, so that the contact wire is high in popularization and use value.

Owner:嘉善瑞佳运动器材有限公司

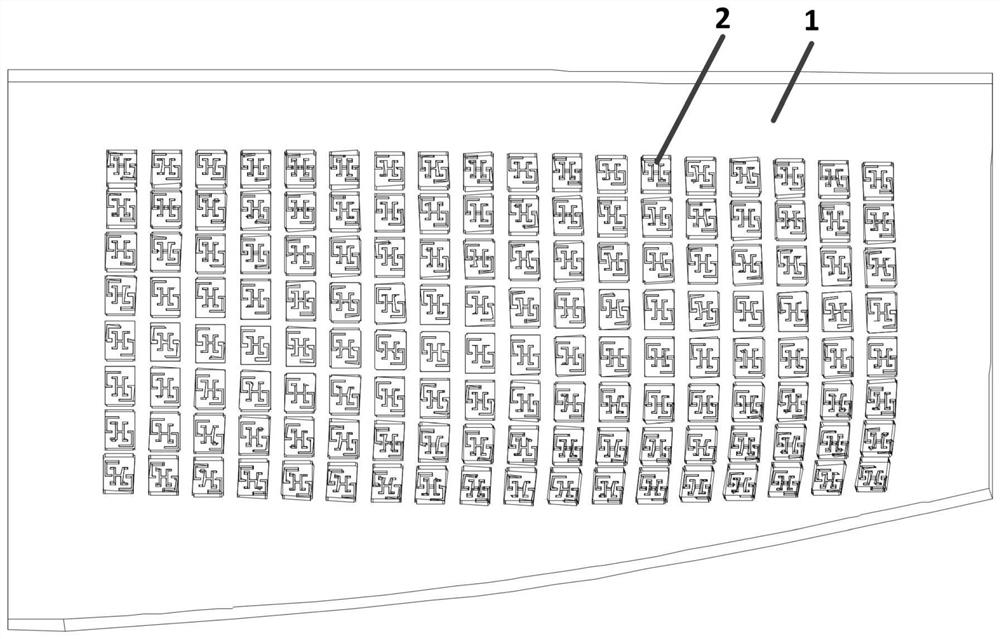

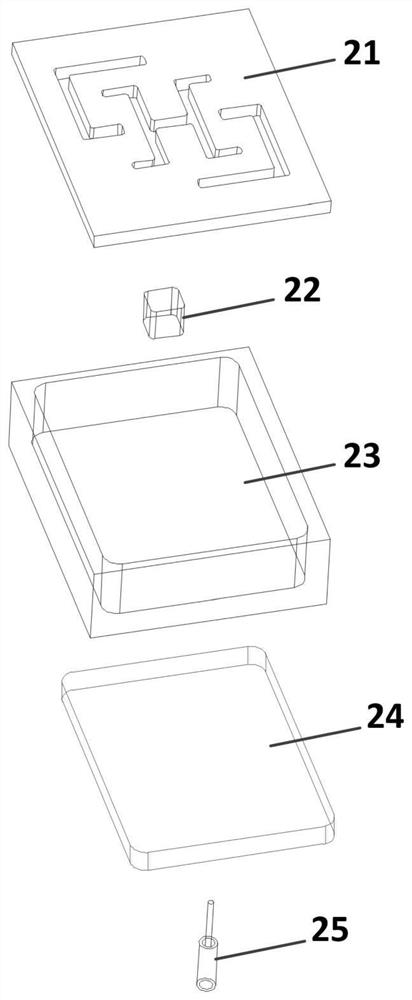

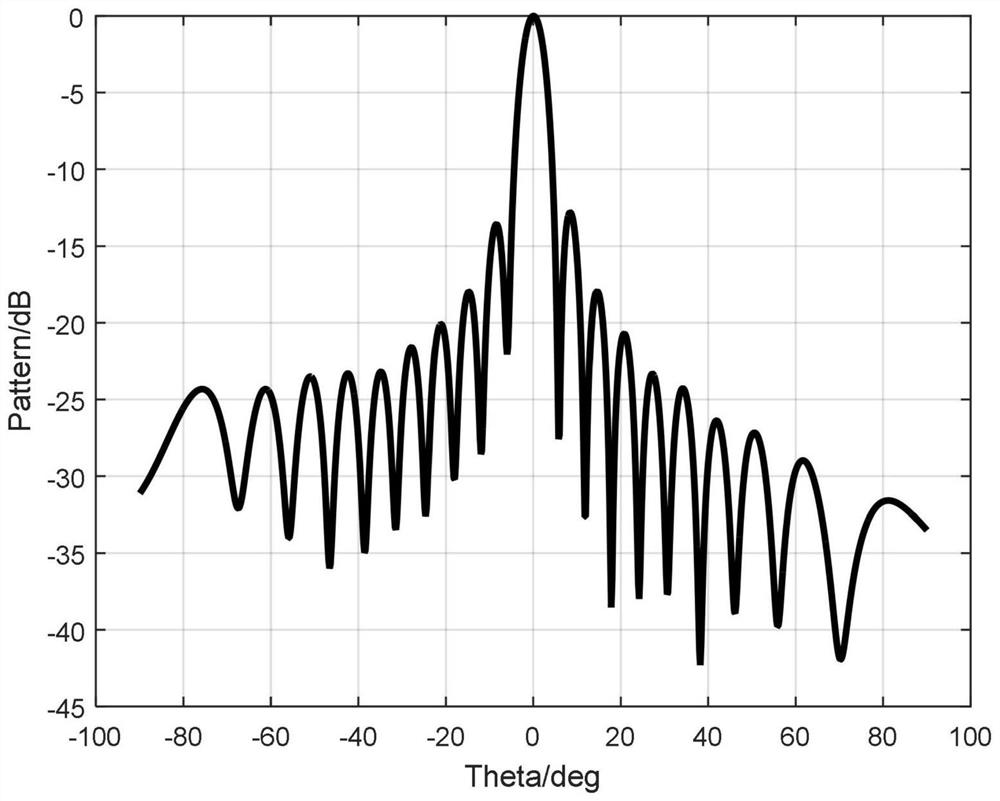

A kind of ultra-low profile slot array antenna and manufacturing method

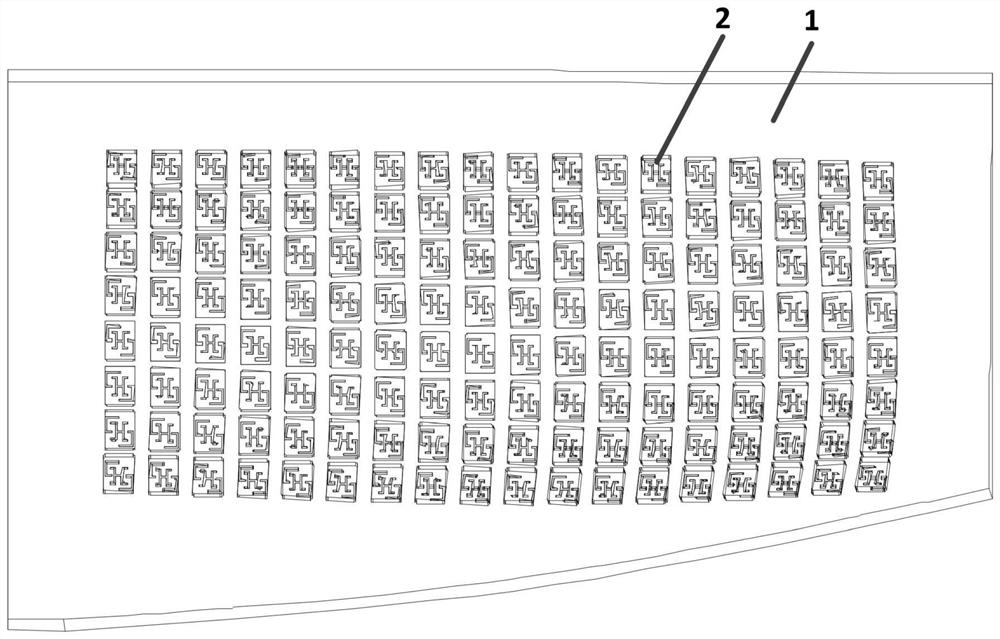

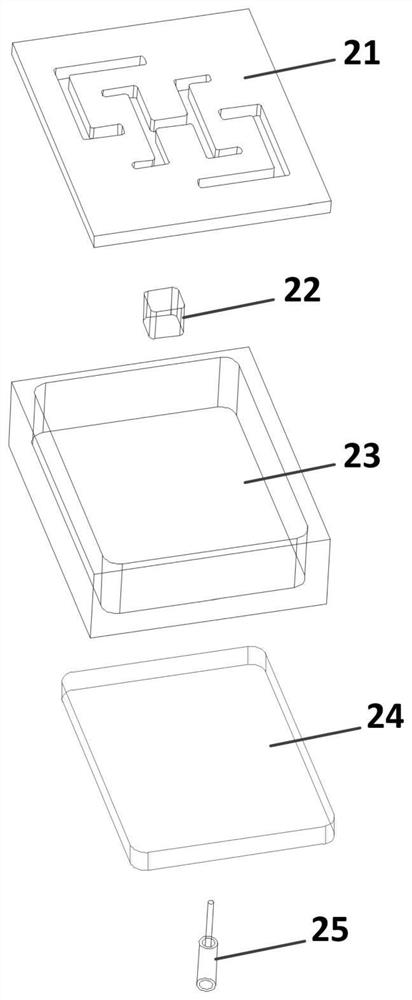

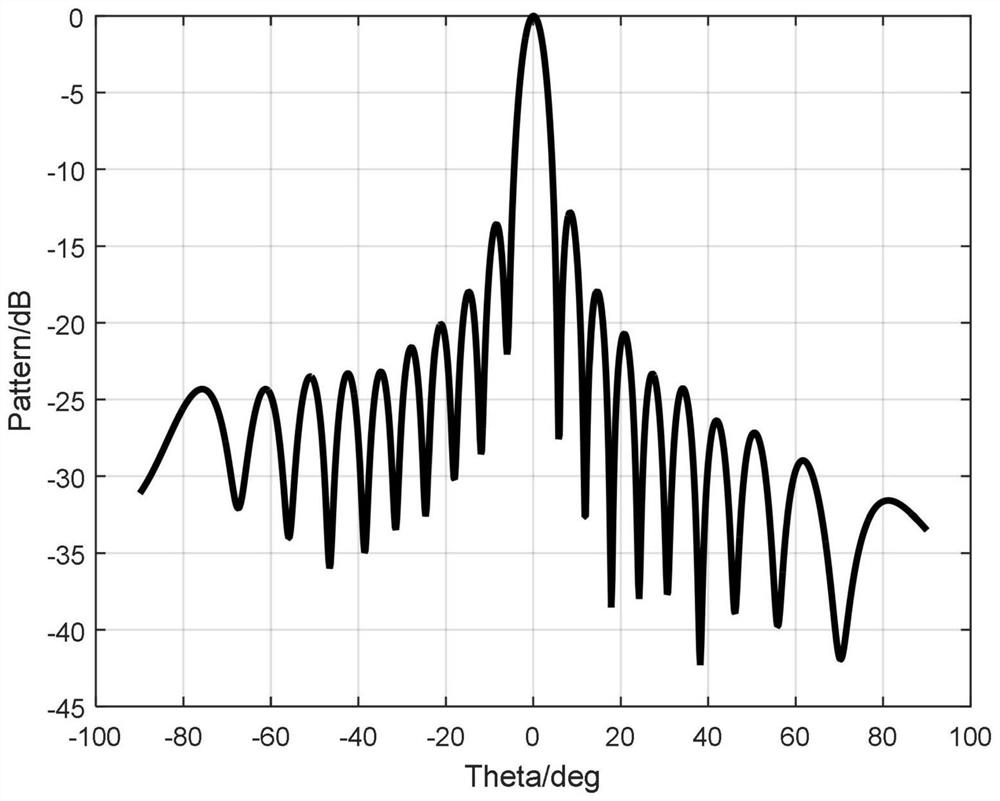

ActiveCN113193373BImprove structural strengthImprove corrosion resistanceAntenna arraysDesign optimisation/simulationResonant cavityFlight vehicle

The invention discloses an ultra-low profile slot array antenna, comprising a complex carrier and an oblique diagonal slot antenna unit, wherein the oblique diagonal slot antenna unit is arranged on the complex carrier; the surface of the complex carrier is a curved surface; the oblique diagonal slot The antenna unit includes a slotted plate, a resonant cavity, an impedance matching block, a resonant cavity backplane and a feeding structure; the slotted plate is located at the top of the diagonally diagonal slotted antenna unit, and the upper surface of the slotted plate is the surface of the complex carrier. With the curved surface set, the slot plate is provided with a slot, and the lower surface of the slot plate is a plane; the resonant cavity is located directly under the slot plate; the impedance matching block is located in the resonant cavity and below the slot plate, and the impedance matching block is close to the slot. The back plate of the resonant cavity is located at the bottom of the resonant cavity; the invention realizes the zero section height of the forward antenna of the carrier, minimizes the influence of the array antenna on the aerodynamics and other properties of the carrier, and greatly improves the dynamic performance of platforms such as aircraft and stealth performance.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Multi-layer pouch battery module and system

ActiveCN109524593BEven heat dissipationReliable coolingSecondary cellsCell component detailsPower batteryHeat management

The embodiment of the present invention relates to the technical field of power batteries, in particular, to a multilayer pouch battery module and system, the liquid inlet pipe and the liquid outlet pipe of the multilayer pouch battery module are connected to each The liquid cooling plates of the multi-layer pouch battery units are connected, which can realize the uniform and reliable heat dissipation of the multi-layer pouch battery module. The anti-vibration and anti-shear ability of the battery module can ensure the safety of the multi-layer pouch battery module from two aspects of thermal management and structure during the driving of the electric vehicle.

Owner:HUATING HEFEI POWER TECH

Construction method for treating soft foundation by reverse method

InactiveCN1193142CSolve engineering construction problemsEasy to handleSoil preservationArchitectural engineeringBearing capacity

Owner:长治市晋建加固防水技术开发有限公司

Preparation method of TiO2 photocatalyst for loading on ceramic surface

Owner:NANJING UNIV

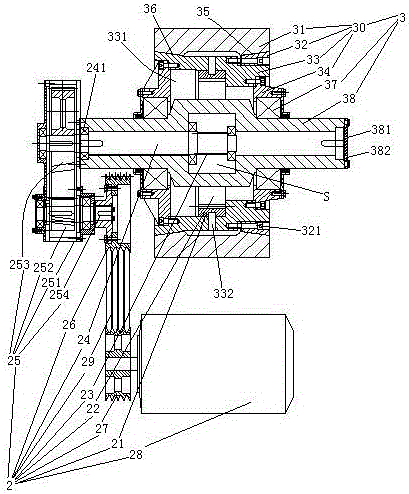

Internal driving conveying belt for petroleum processing

InactiveCN105936404AUniform loadOverall small sizeConveyorsControl devices for conveyorsGear driveDrive shaft

The invention relates to auxiliary equipment for petroleum processing, and discloses an internal driving conveying belt for petroleum processing. The internal driving conveying belt comprises a rack, wherein the rack is provided with a conveying belt, a main driving shaft and a driving mechanism driving the main driving shaft to rotate; the main driving shaft comprises an outer roller and a main shaft; the outer roller is arranged on the main shaft in a sleeving manner and is rotatably connected with the main shaft; the main driving shaft is connected with the rack through the main shaft; the driving mechanism comprises an inner gear ring connected in the outer roller, a gear transmission shaft rotatably connected with the main shaft, a gear box driving the gear transmission shaft to rotate, and a motor outputting power to the gear box; the gear transmission shaft is provided with a first gear; and the first gear is connected with the inner gear ring through planetary gears. According to the internal driving conveying belt for petroleum processing provided by the invention, a gear train is arranged inside the main driving shaft for driving, and the problem that the size is large due to the fact that a power motor of a conventional conveying belt drives the main driving shaft through the gear box is solved.

Owner:ZHEJIANG OCEAN UNIV

Shockproof anti-jolt chassis of passenger car

InactiveCN102139614BImprove anti-vibrationEnhanced bump resistanceInterconnection systemsSimple componentWheel and axle

Owner:SHANGHAI INST OF TECH

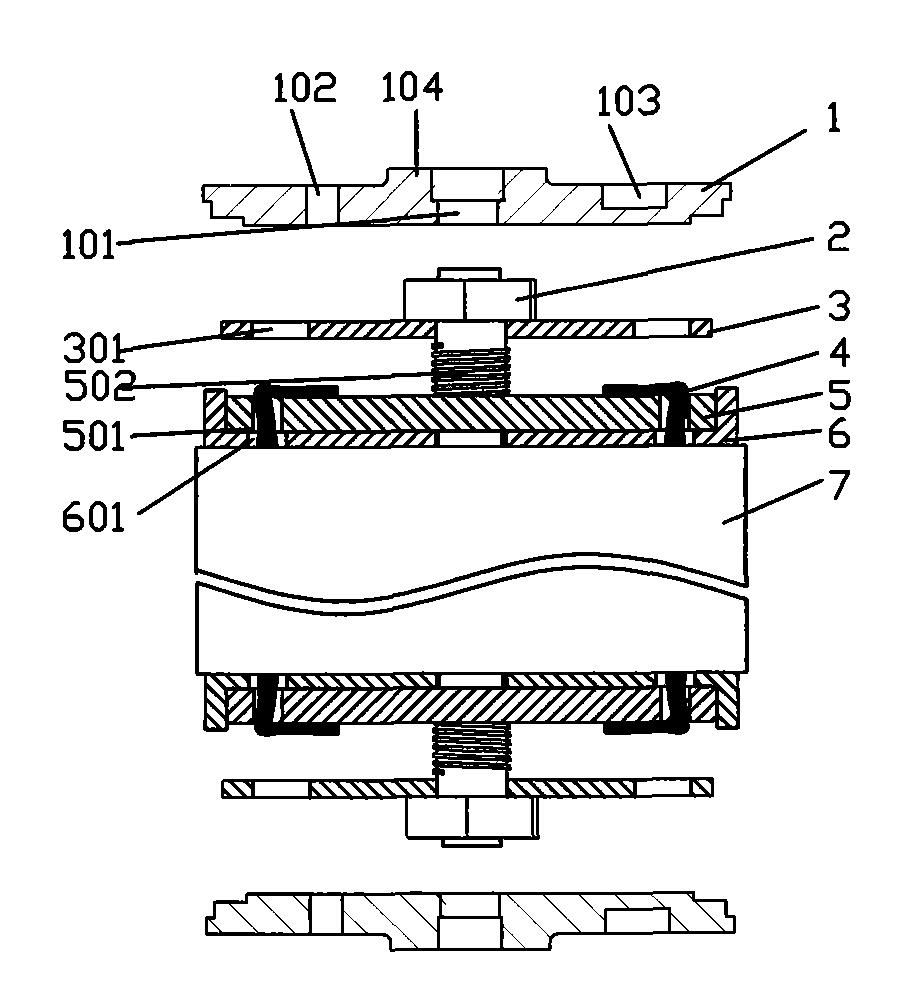

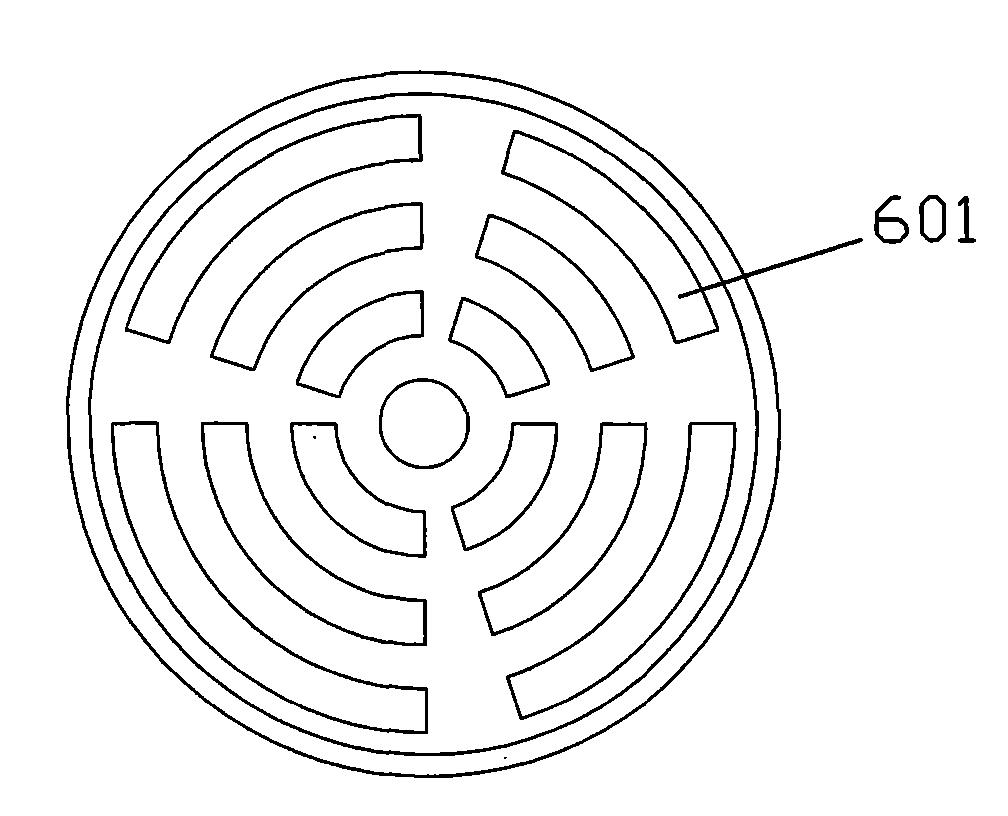

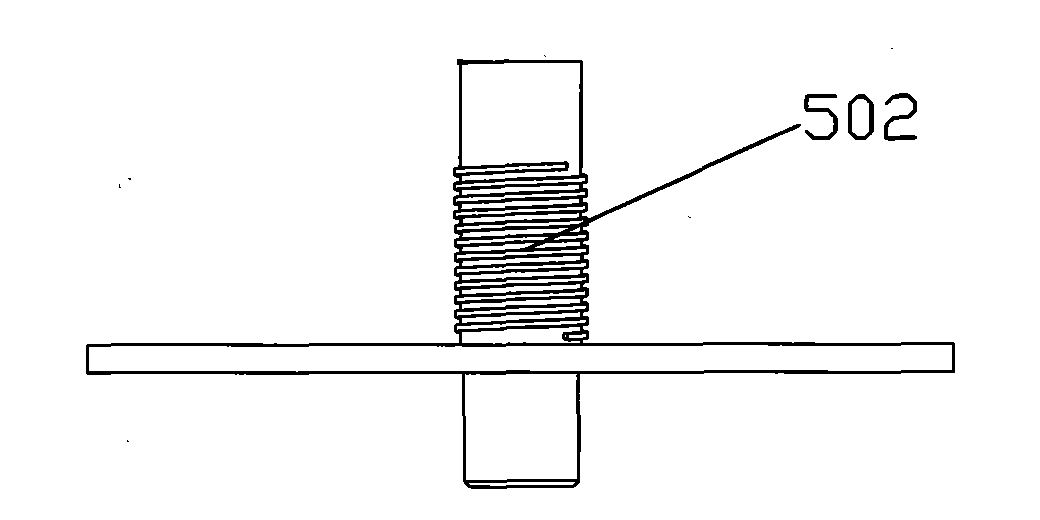

A kind of aerosol fire extinguishing device and assembly method

An aerosol fire extinguishing device and an assembly method thereof, which relate to the technical field of fire fighting equipment; its nozzle plate (2) is bonded to the flange of the upper end of the shell (1) through a high-temperature sealant, and the bottom plate (12) is bonded to the flange of the upper end of the casing (1) through a high-temperature sealant. The flange at the lower end of the shell (1) is bonded, the inner side of the spout plate (2) is provided with a sealing film (3), the inner cylinder (4) is set on the inner side of the shell (1), and the shell insulation plate (15) is set on the Between the shell (1) and the inner cylinder (4), between the nozzle plate (2) and the coolant (7), between the coolant (7) and the flame suppressant (9), between the flame suppressant (9) and the fire extinguisher Spacer rings (5) are arranged between the agents (10), the starting charge (13) is arranged in the middle of the fire extinguishing agent (10), and the lower end of the starting charge (13) is connected with the receiver (14). It has high moisture-proof, vibration-proof, improved sealing, and simple and fast assembly, which can realize large-scale and mechanized production.

Owner:胡永华

Ultra-low profile slot array antenna and manufacturing method

ActiveCN113193373AImprove structural strengthImprove corrosion resistanceAntenna arraysDesign optimisation/simulationResonant cavityFlight vehicle

The invention discloses an ultra-low profile slot array antenna, which comprises a complex carrier and diagonal slot antenna units, and the diagonal slot antenna units are arranged on the complex carrier. The surface of the complex carrier is a curved surface; each diagonal slot antenna unit comprises a slot plate, a resonant cavity, an impedance matching block, a resonant cavity back plate and a feed structure; the slot plate is located at the uppermost part of the diagonal slot antenna unit, the upper surface of the slot plate is a curved surface matched with the surface of a complex carrier, the slot plate is provided with a slot, and the lower surface of the slot plate is a plane; the resonant cavity is located under the slot plate. The impedance matching block is located in the resonant cavity and below the slot plate, and the impedance matching block is tightly attached to the slot plate; the resonant cavity backboard is located at the bottom of the resonant cavity. According to the invention, the zero profile height of the forward antenna of the carrier is realized, the influence of the array antenna on the aerodynamics and other performances of the carrier is reduced to the minimum, and the dynamic performance and stealth performance of platforms such as aircrafts and the like are greatly improved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com