Patents

Literature

30results about How to "Enhanced bump resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

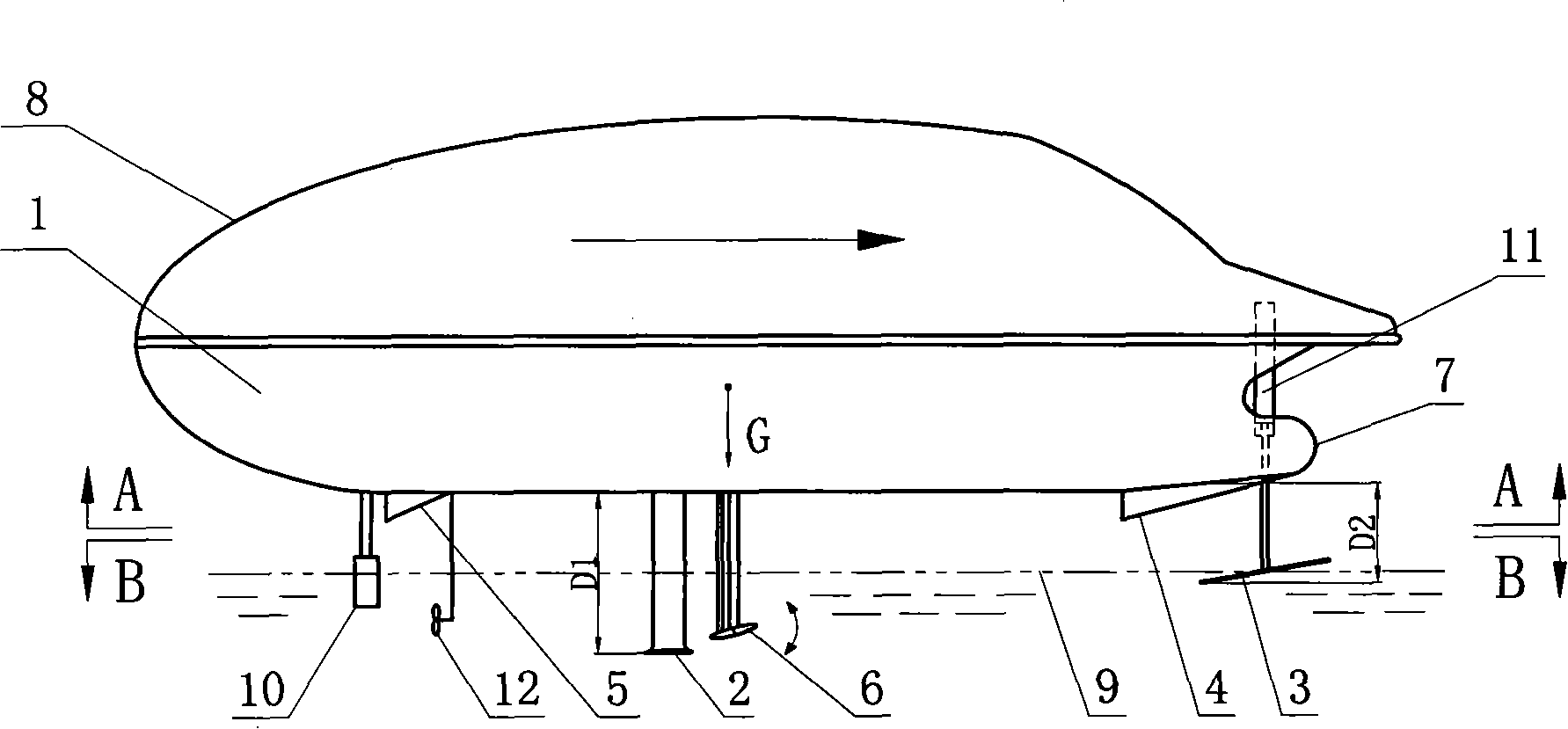

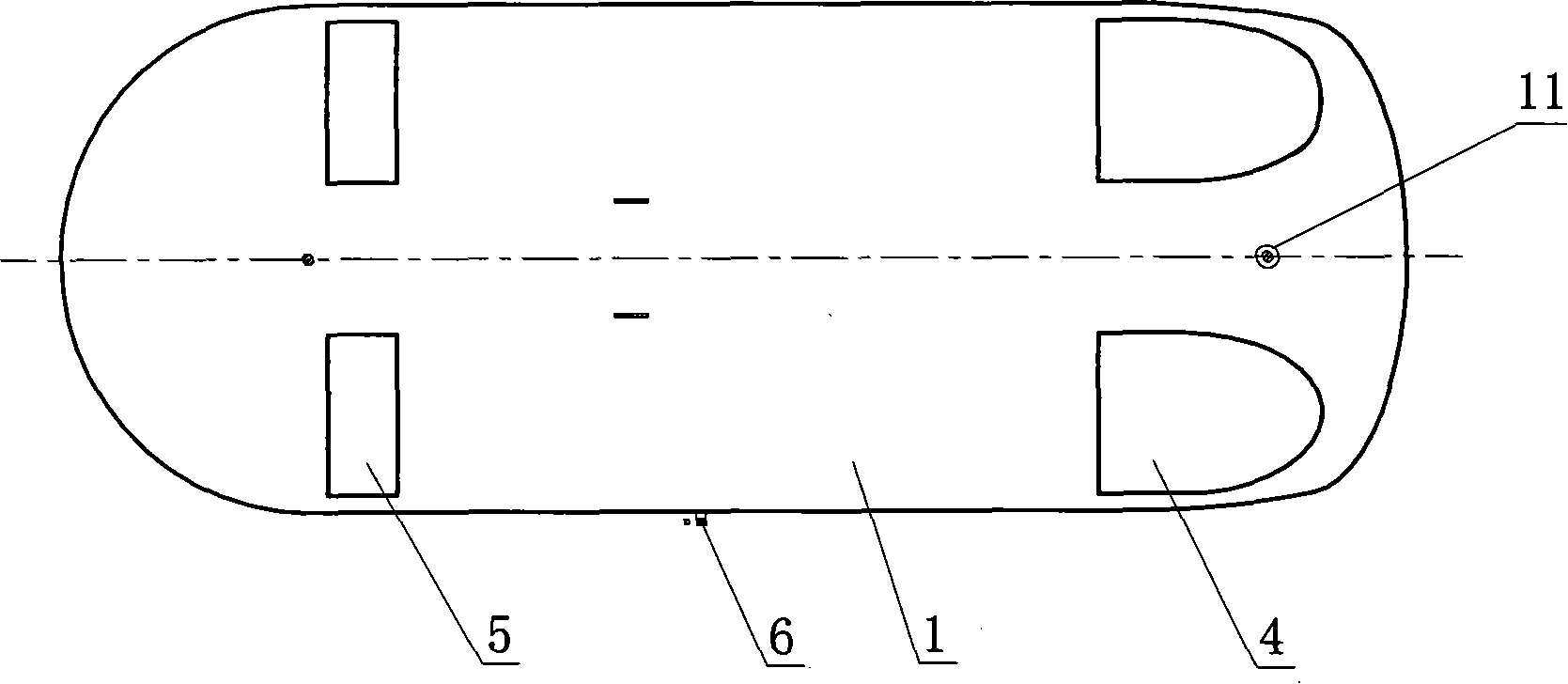

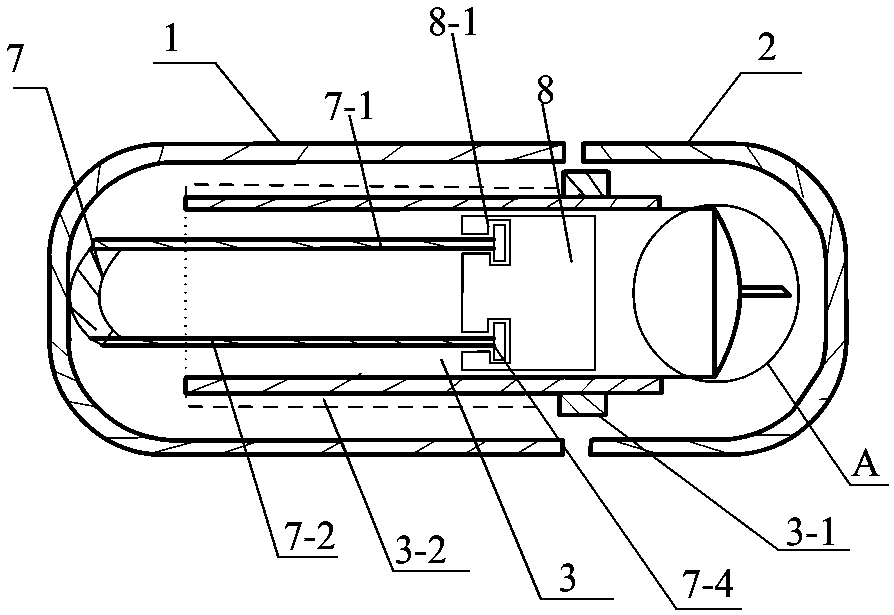

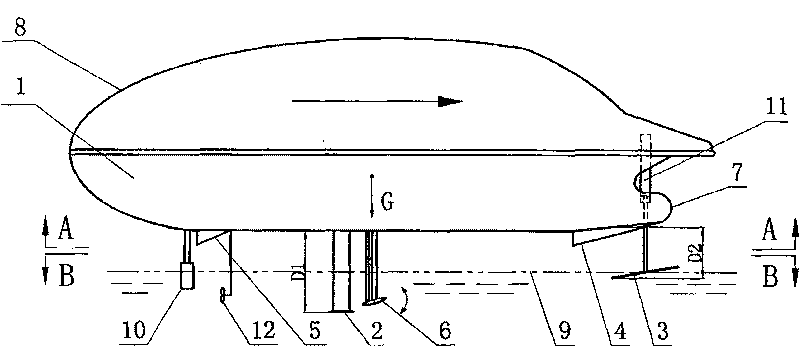

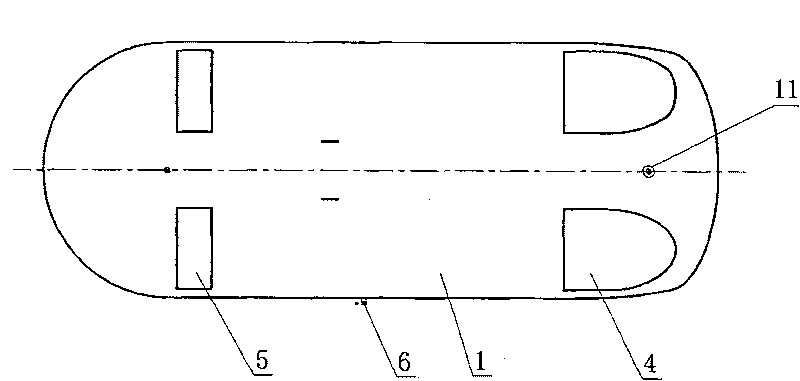

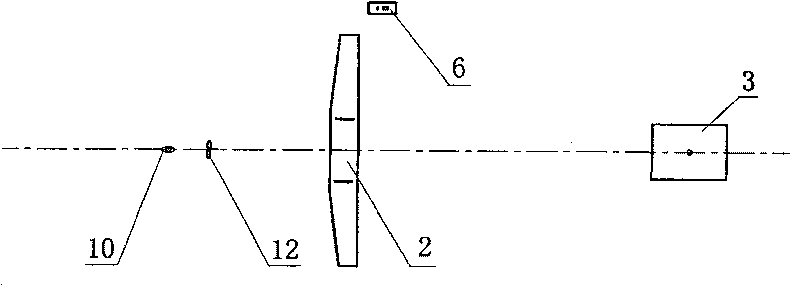

Hydrofoil craft having hydroplane function

InactiveCN101249873AReduce consumptionEnhanced bump resistanceHydrodynamic/hydrostatic featuresFast speedGravitation

The invention discloses a hydrofoil ship with a displacement boat function, which comprises a main hull, a propulsion device and a stern rudder, wherein a deep-wetted hydrofoil and a movable sliding hydrofoil which can achieve lift adjustment are arranged at the bottom of the main hull, the deep-wetted hydrofoil is arranged at the rear portion of the gravity of the main hull while the movable sliding hydrofoil is arranged on the head portion of the main hull, and the distance between the deep-wetted hydrofoil and the main hull is longer than that between the movable sliding hydrofoil and the main hull. The hydrofoil ship has the advantages of fast route speed, sound dynamic stability, high safety, energy-saving and low production cost.

Owner:周洪斌

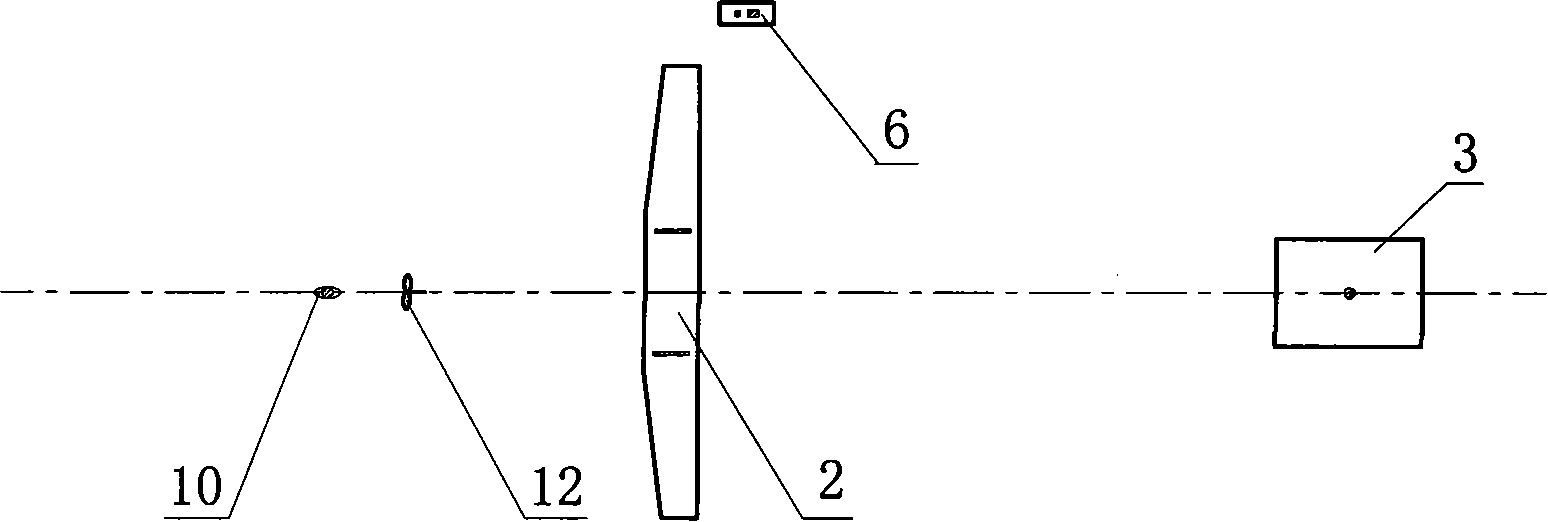

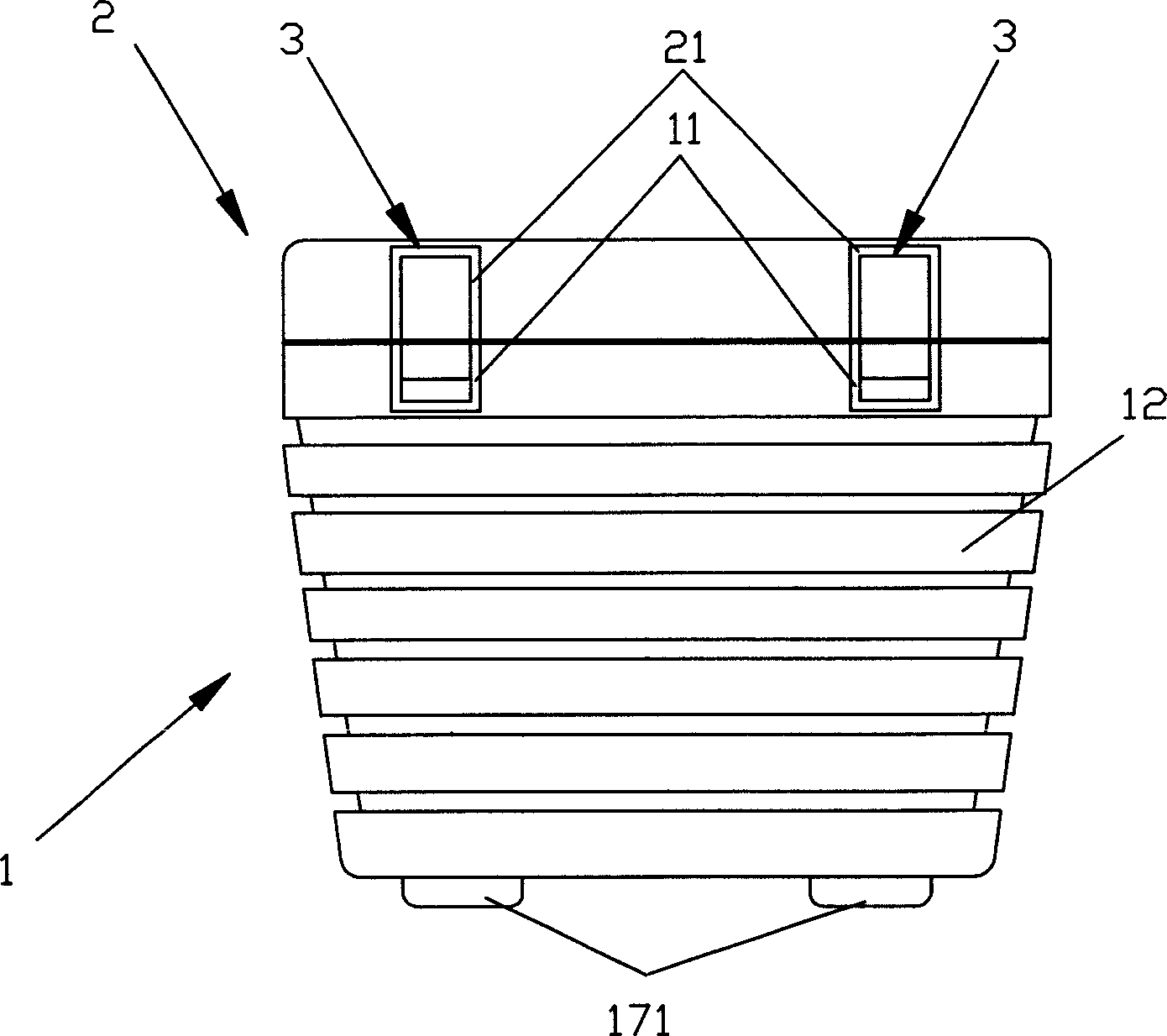

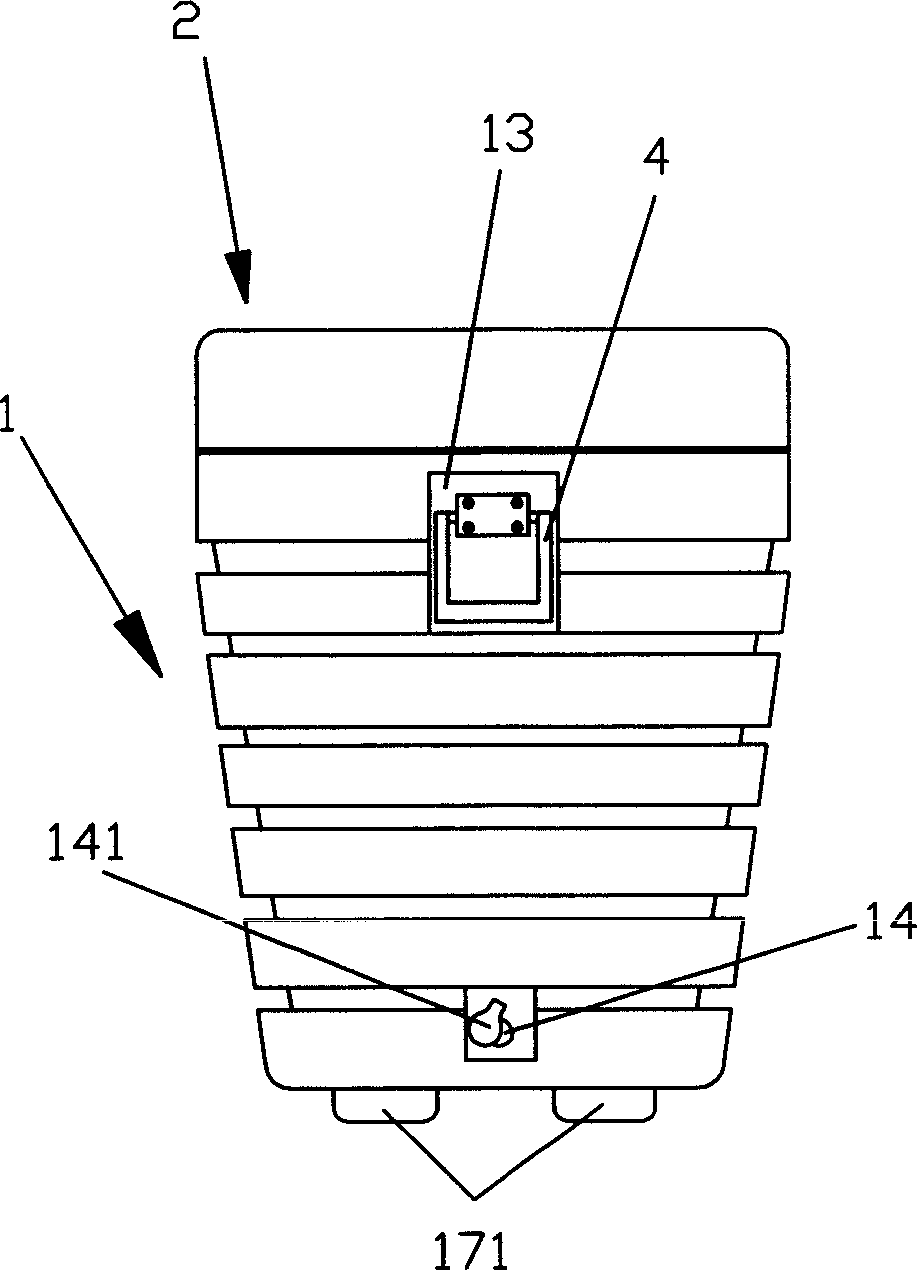

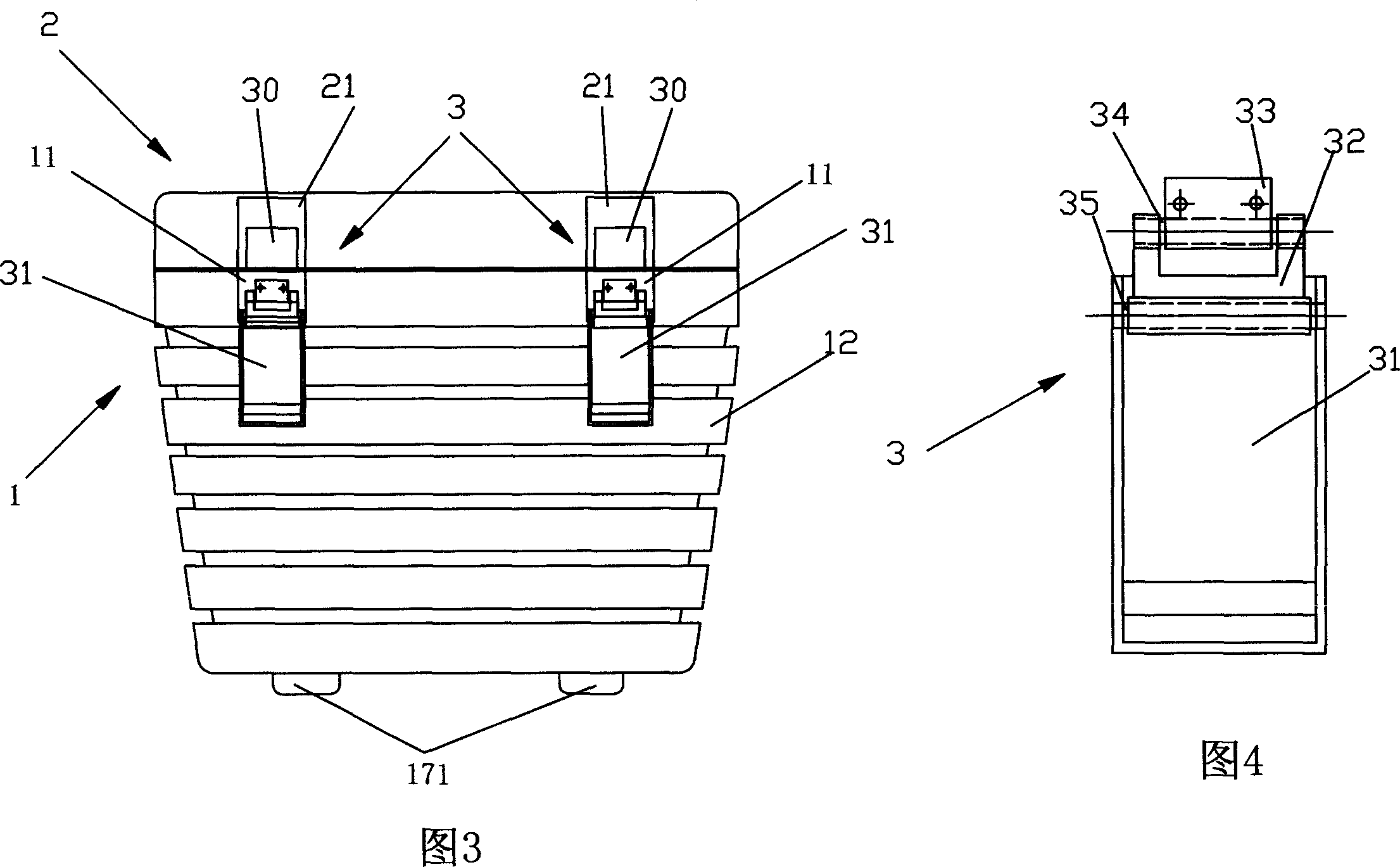

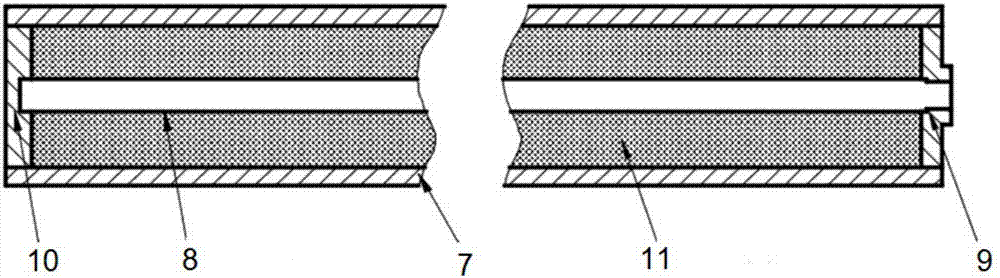

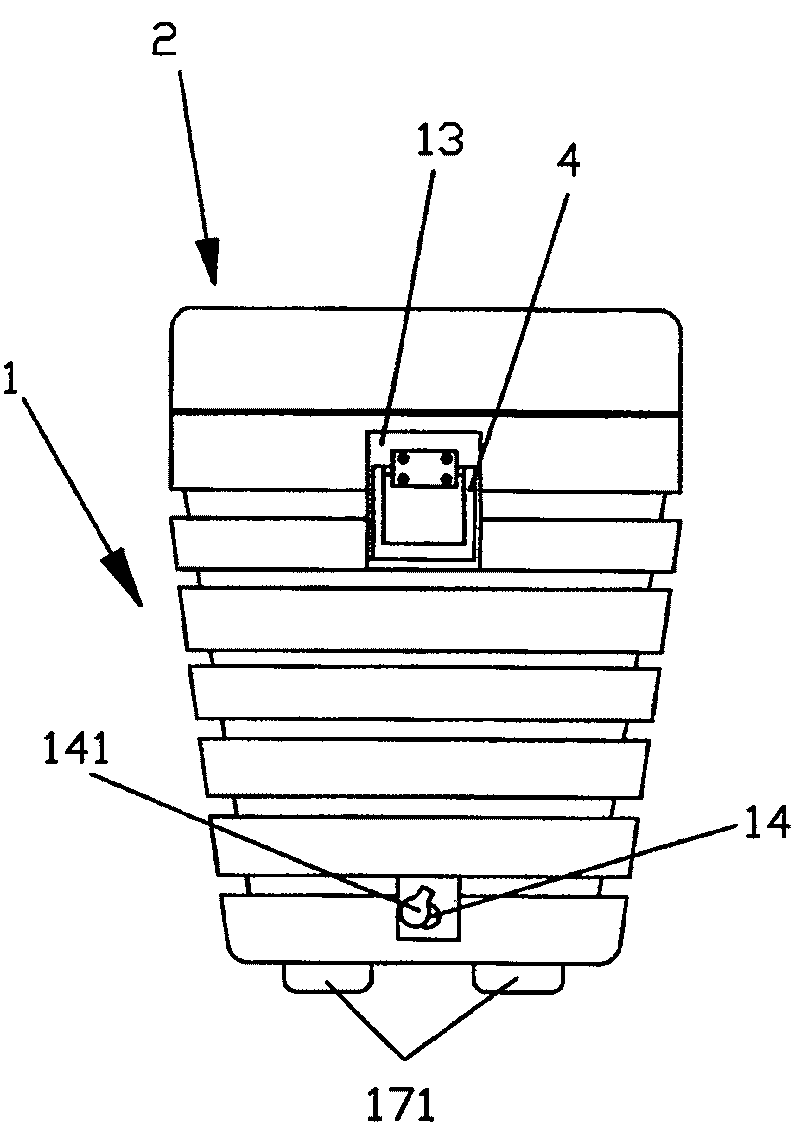

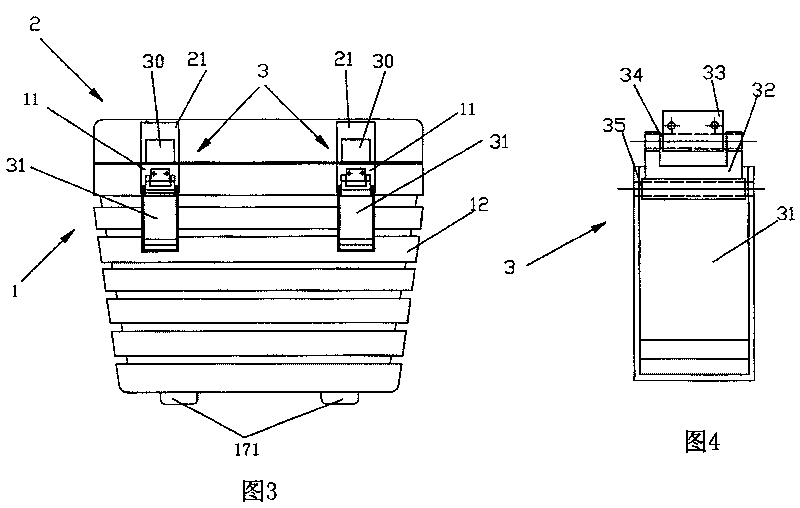

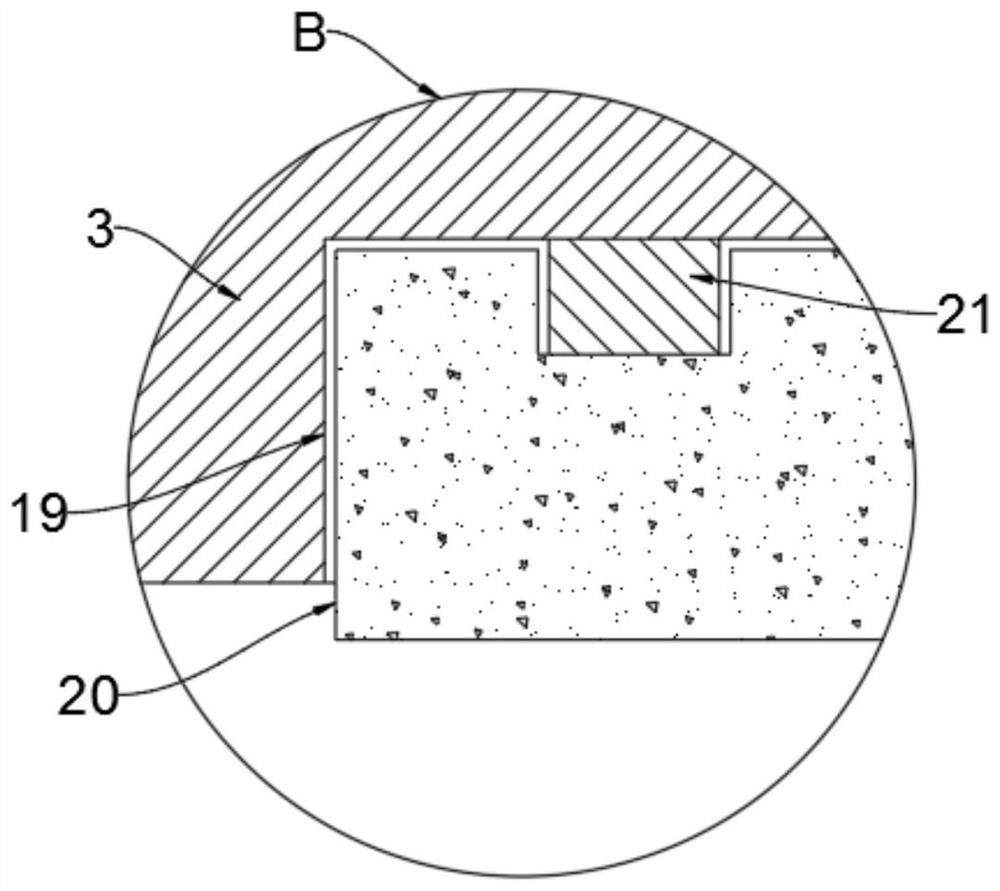

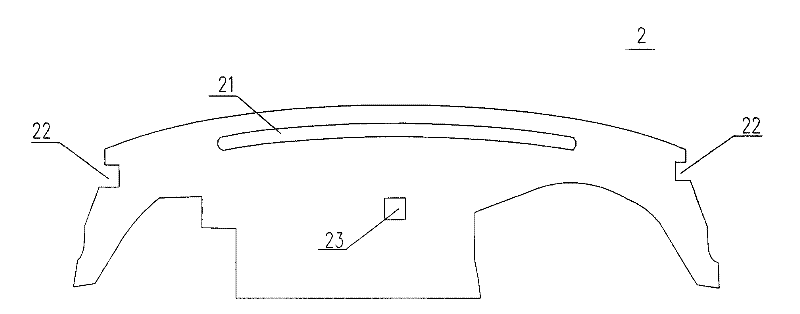

Cold, hot food insulation box

InactiveCN1911756AImprove insulation performanceWide range of applicationsDomestic cooling apparatusLighting and heating apparatusEngineeringBody cavity

The heat insulating box for cold and hot food includes one box body in hollow structure filled with heat insulating material and one box cover. The box cover has notch with embedded sealing strip in the inner wall and limiting notch in the surface; and the box body has limiting boss on the bottom. The heat insulating box features the box cover with one sealing boss in the inner wall, the joint between the box body and box cover with at least one pair of notches and slap in the outer side board wall, the inner and outer surfaces of the box cover and the outer wall of the box body with reinforcing ribs, and the box body cavity bottom with one capped through hole. The present invention has the features of high sealing performance, long temperature maintaining period, great box cavity capacity and good heat insulating performance.

Owner:福记联合(上海)餐饮有限公司

Power engineering tool box with tools convenient to sort

InactiveCN109834677AEasy to placeEasy accessWork tools storageOther workshop equipmentPower engineeringEngineering

The invention discloses a power engineering tool box with tools convenient to sort. The tool box comprises a tool box body, an installing plate and an upper cover, the installing plate is arranged atone end of the tool box body, shock-absorbing assemblies are uniformly arranged between the installing plate and the tool box body, universal wheels are installed at four corners of the bottom of theinstalling plate through bolts, the upper cover is movably installed on the top of one side of the tool box body through a hinge, two elastic fixing belts are installed on the inner side of the uppercover side by side, a storage drawer is movably installed at the bottom of the other side of the tool box body, second placing chambers are uniformly placed in the storage drawer, first storage chambers are arranged in the tool box body through baffles, and elastic cushions are arranged on the inner side walls of the first placing chambers. The elastic cushions are arranged on the inner side wallsof the first placing chambers, the shock-absorbing assemblies are uniformly arranged between the installing plate and the tool box body, so that the bumping resisting capability of the tool box bodyis effectively improved, and tools in the tool box body are protected.

Owner:天津市雅森工贸有限公司

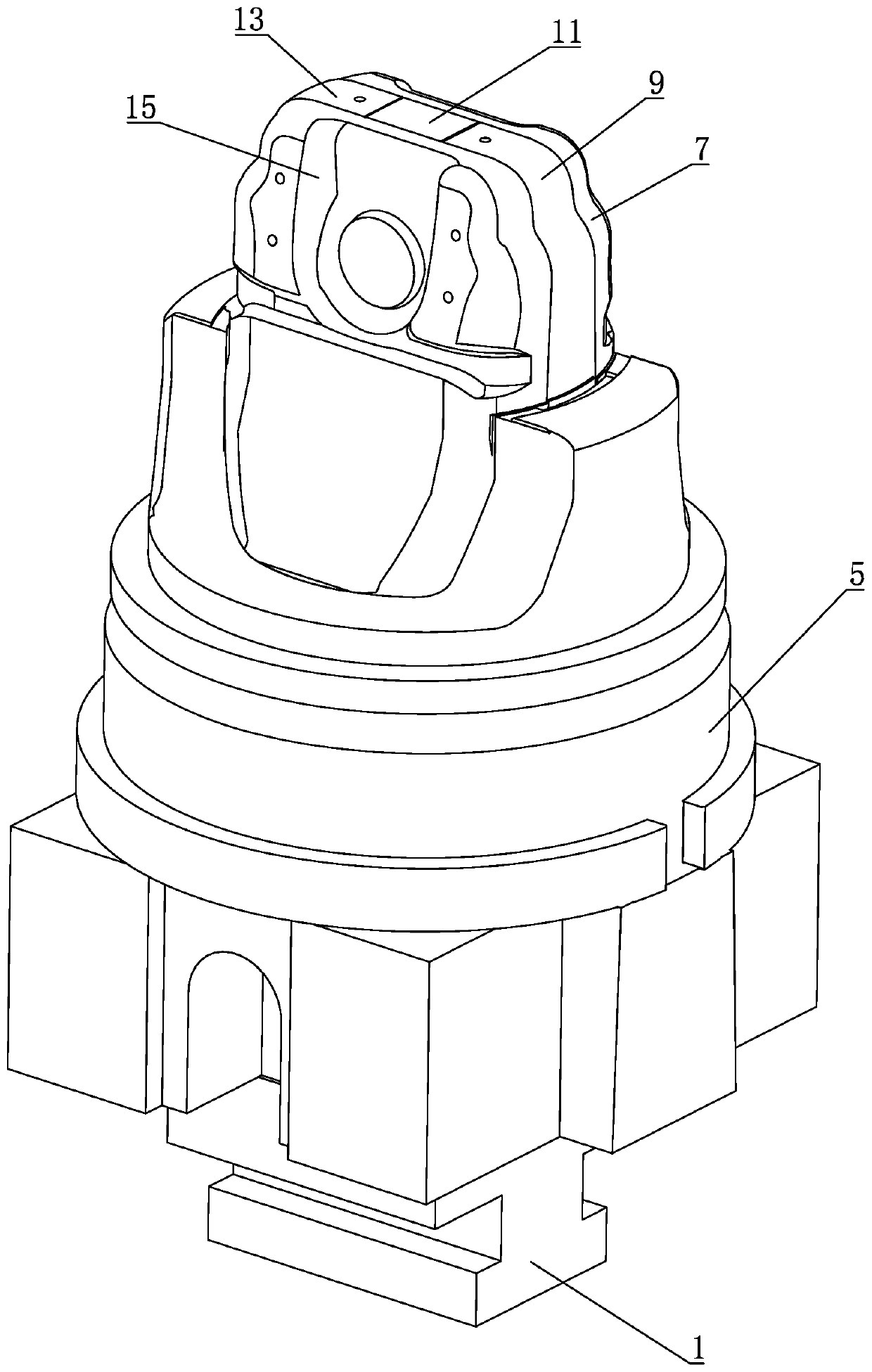

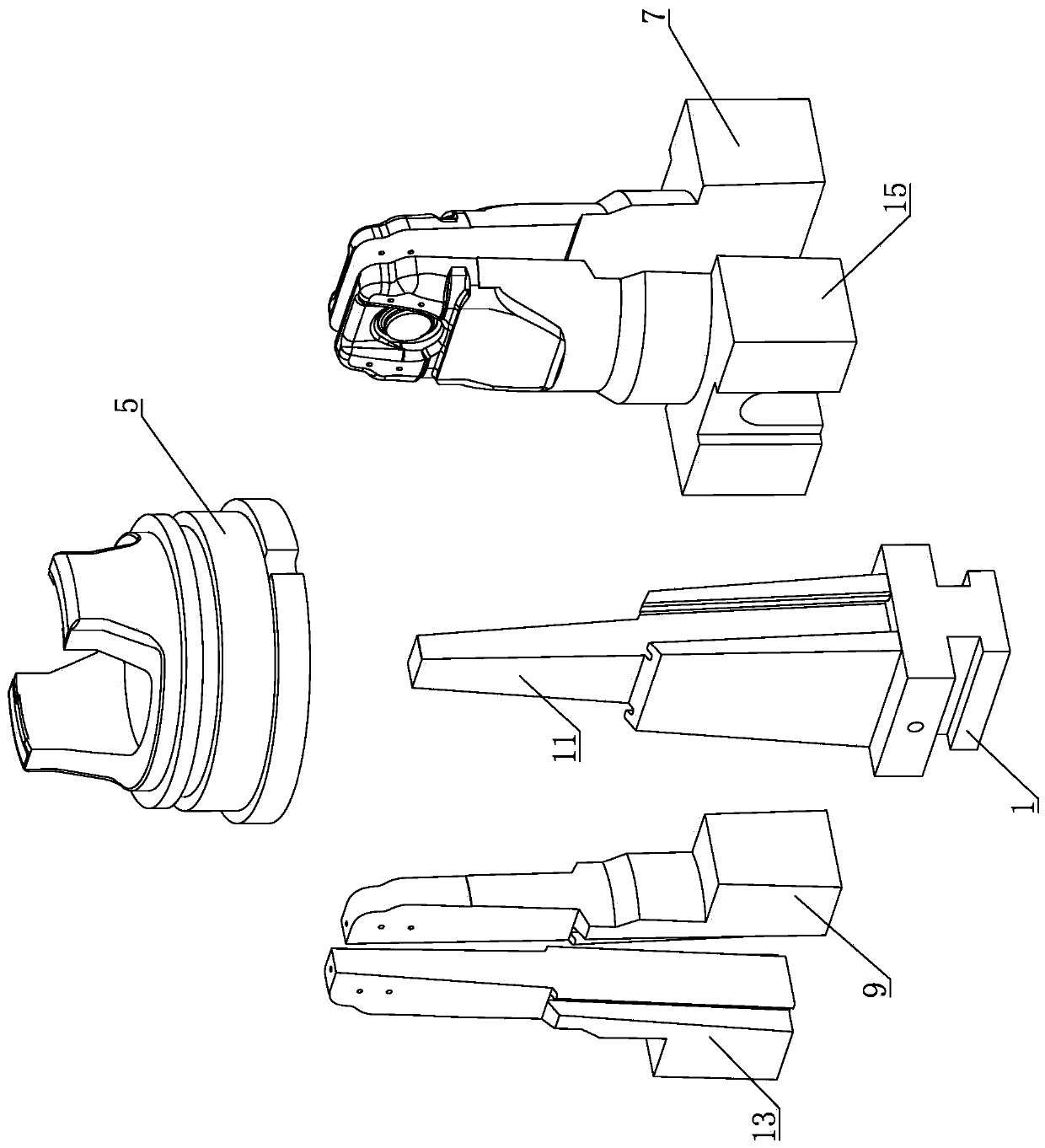

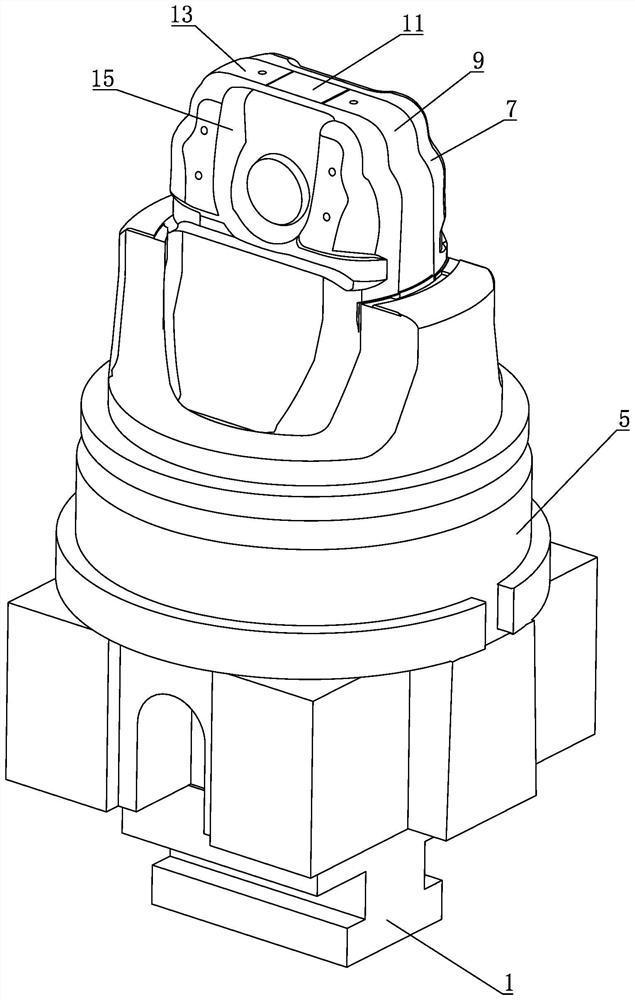

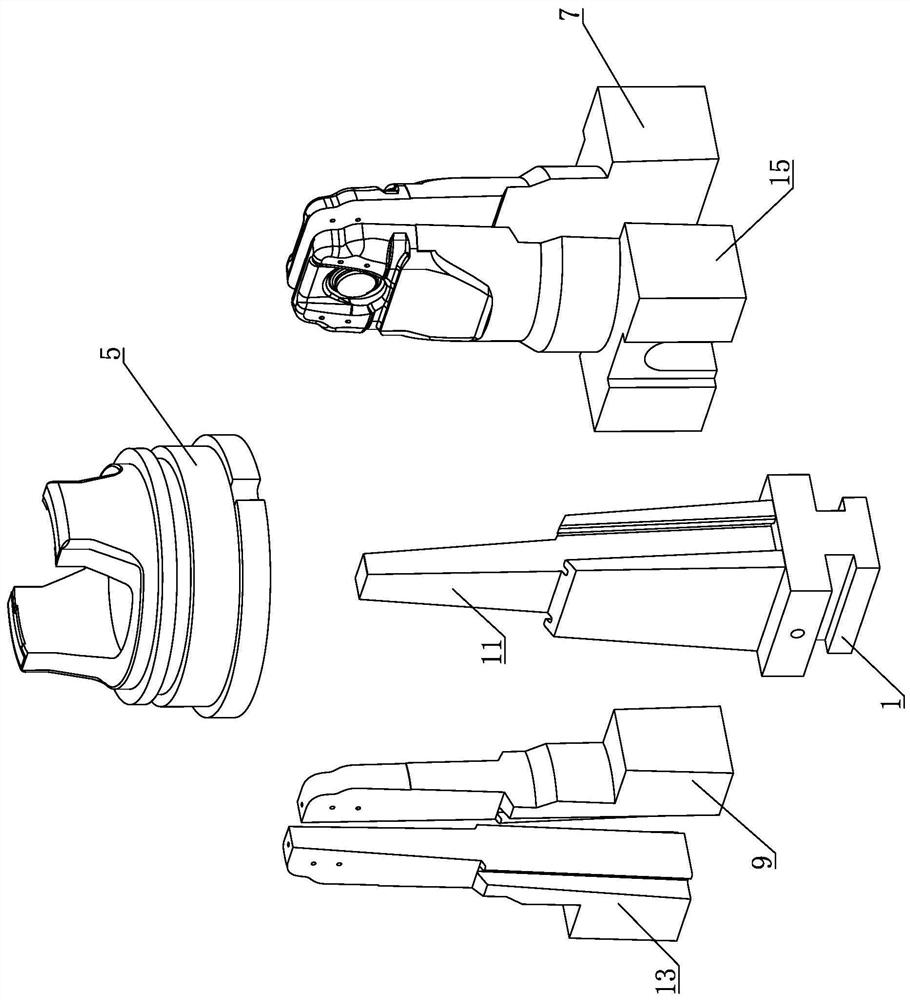

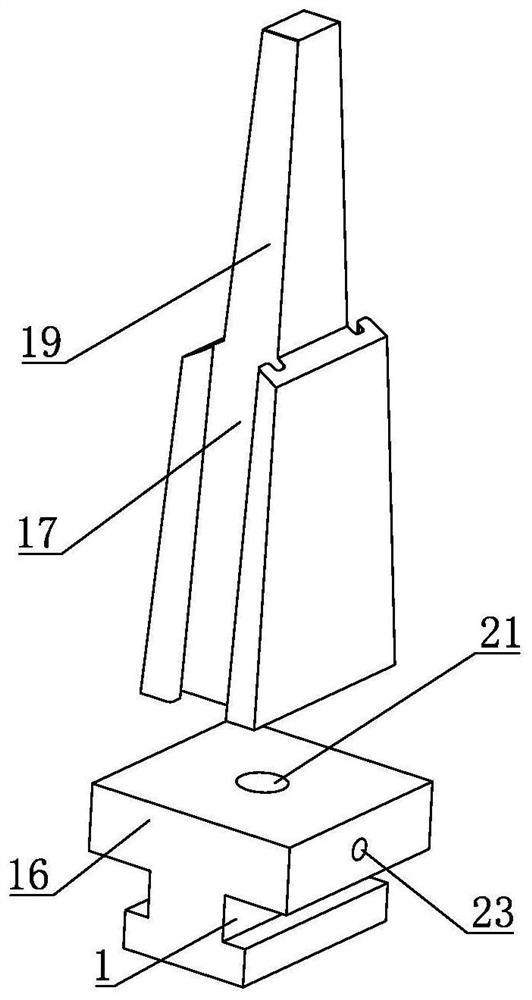

Mold assembly improved structure for greatly improving casting precision of light aluminum piston

ActiveCN111421114APrevent side swingEliminate distractionsFoundry mouldsFoundry coresEngineeringPiston

The invention relates to a mold assembly improved structure for greatly improving casting precision of a light aluminum piston. The mold assembly improved structure is applied to batch production of high-precision light aluminum pistons. The mold assembly improved structure comprises an outer mold, a pin hole mold, a sliding block mold and a core mold. The core mold comprises a piston core mold center piece. The piston core mold center piece is composed of a rectangular pyramid column and a supporting table connected with the rectangular pyramid column. The mold assembly improved structure ischaracterized in that a through groove is formed in a supporting rail along the center line, a straight rod is arranged at the bottom of the pin hole mold, the straight rod and the through groove areequal in width, and the straight rod extends into the through groove; and a T-shaped guide rail groove is formed in the upper portion of the pin hole mold, a T-shaped guide rail is arranged on the upper portion of the interior of a cavity of the outer mold, and the T-shaped guide rail is sleeved with the T-shaped guide rail groove. The pin hole mold is provided with a pin column hole lower pressing block. The rectangular pyramid column and the supporting table are connected in a fastened mode through a bolt with a tangential plane. An end face hole in the tail end of the bolt communicates witha side hole of the bolt, and a rectangular pyramid column deep hole is formed in the lower end face of the rectangular pyramid column. The mold assembly improved structure has the advantages that various abnormal abrasion of the pin hole mold is avoided, the bumping resistance is greatly improved, and the precision of the thickness of a radial casting involved in the sliding block mold in production is improved.

Owner:HUAMIN NANPING AUTOMOBILE FITTINGS GROUP

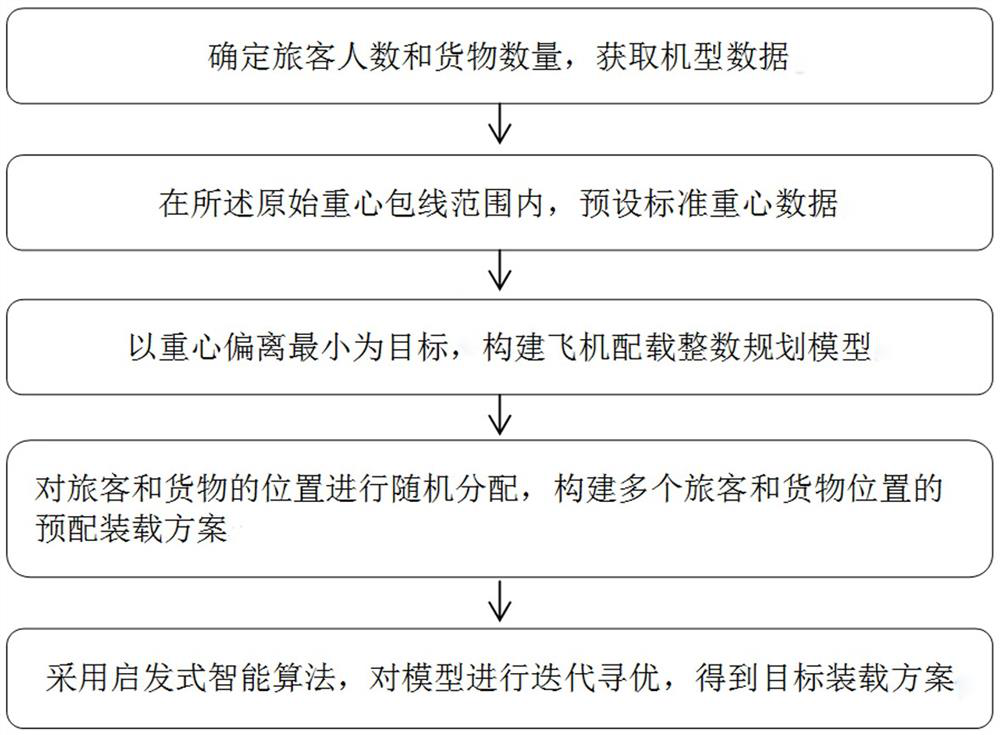

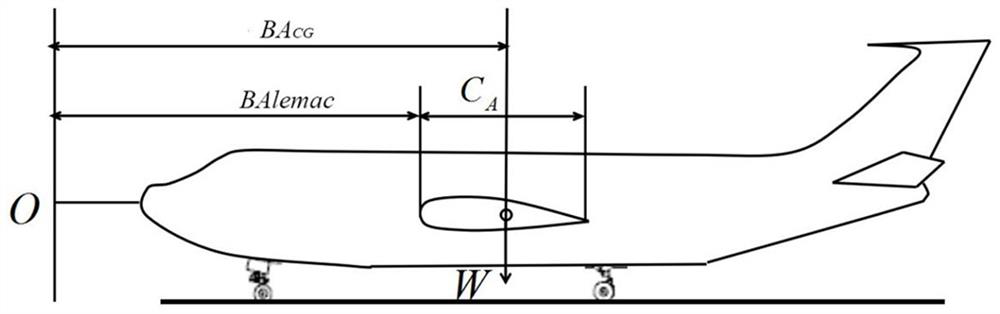

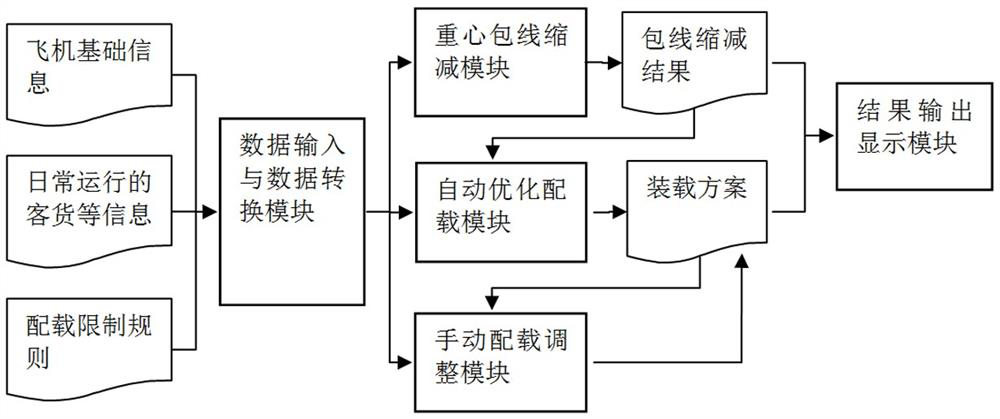

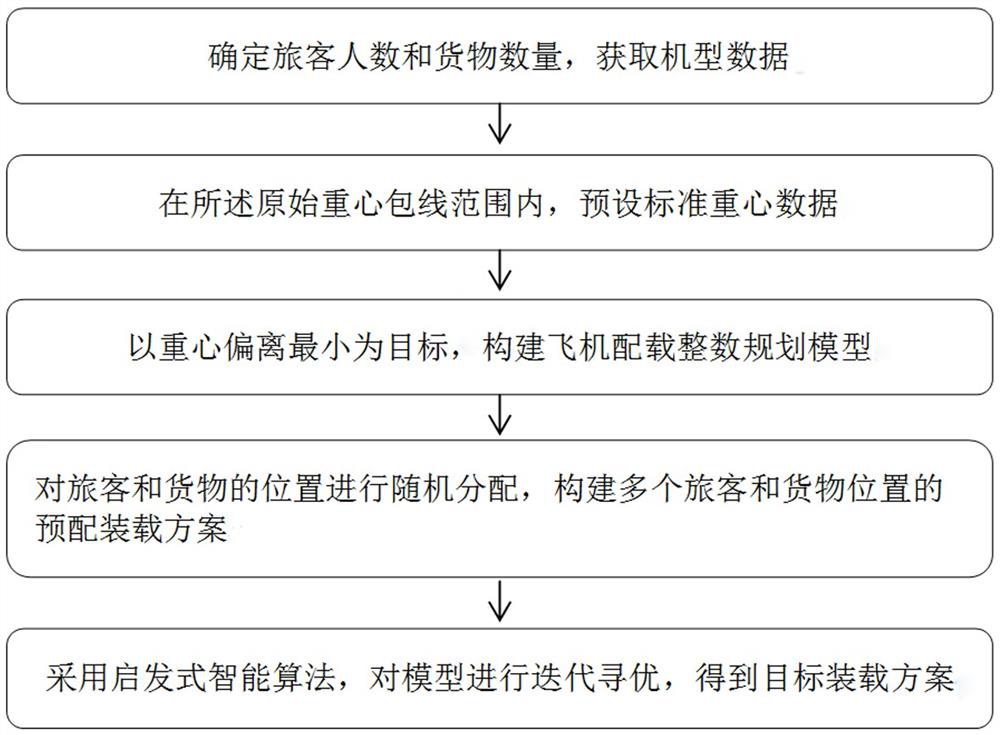

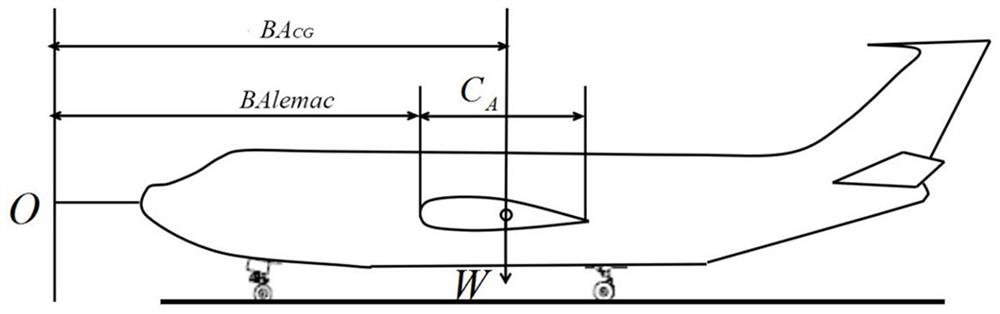

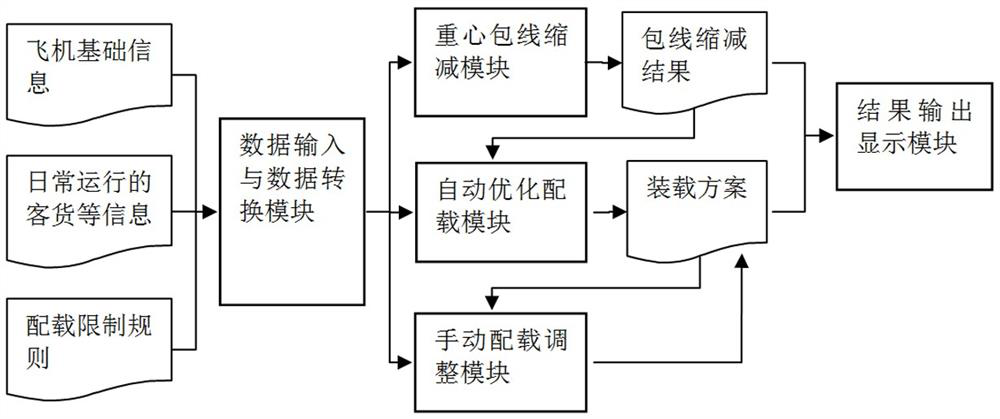

Balancing loading method and device for passenger aircraft

ActiveCN113492982ASmall center of gravity deviationSmall center of gravity deviation from optimal positionFreight handlingGround installationsData packGravity center

The invention mainly relates to a balancing loading method of a passenger aircraft. The method comprises the following steps: acquiring aircraft model data which comprises an original gravity center envelope, a passenger cabin layout, and a cargo cabin layout; presetting standard gravity center data in an original gravity center envelope range; determining the number of passengers and the number of cargos, building an aircraft stowage integer programming model based on the passenger cabin layout and the cargo cabin layout with the minimum gravity center deviation as the target, pre-distributing the positions of the passengers and the cargos, adopting a heuristic intelligent algorithm, carrying out iterative optimization on the model, and determining a target loading scheme. Based on the balancing loading method provided by the invention, the positive effects of loading visualization, one-key optimization, loading gravity center deviation analysis and the like can be realized.

Owner:CIVIL AVIATION UNIV OF CHINA

Oil Compsition for heat treatment of gear and gear treated therewith

An oil composition for the treatment of gears which comprises as a base oil a mineral oil having a dynamic viscosity at 100 deg.C of 5 to 40 mm2 / sec and incorporated therein (a)0.01 to 5 wt% phosphoric ester compound based on the whole composition. It optionally further contains, based on the whole composition, (b) 0.5 to 10 wt% alkenylsuccinimide compould, alkylsuccinimide compound, or boron adduct of either and (c) 0.5 to 10 wt.% at least one member selected among the salicylates, phenates, and sulfonates of alkaline earth metals. The oil composition is used in a gear hardening step, in which the composition forms a surface coating film simultaneously with gear hardening. Thus, it can impart pitching resistance to the gear.

Owner:IDEMITSU KOSAN CO LTD

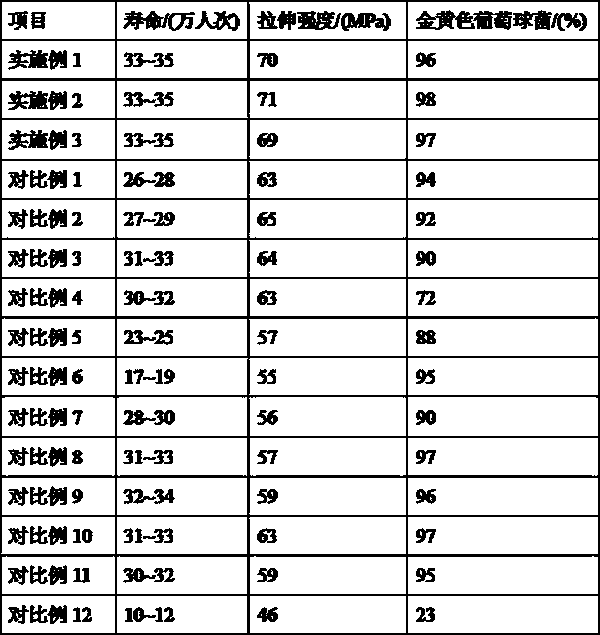

Wear-resistant inflatable swimming pool

InactiveCN108017850AImprove wear resistanceExtended service lifePolymethyl methacrylateChlorinated paraffins

The invention mainly relates to the technical field of high polymer materials and discloses a wear-resistant inflatable swimming pool. The wear-resistant inflatable swimming pool is prepared from thefollowing raw materials: PVC resin, chlorinated paraffin, fumed silica, nano-titania, zinc oxide, antibacterial sepiolite, a stabilizer, polymethyl methacrylate and aminophylline. The inflatable swimming pool is high in strength and wear resistance, germs are inhibited effectively, the service life of the swimming pool is enabled to reach 0.33-0.35 million people, and use demands of consumers aremet. The PVC resin, the chlorinated paraffin, the stabilizer graphene and polymethyl methacrylate are heated slowly to be mixed sufficiently, the heat-resistant temperature and the tensile strength ofthe PVC resin are enhanced, the wear resistance is improved, the flowability and the softness of the raw materials are enhanced, and later forming is facilitated; then the antibacterial sepiolite andthe aminophylline are added to a premix, the antibacterial sepiolite is promoted to be crosslinked with the PVC resin sufficiently, germ proliferation is inhibited, sepiolite swells after absorbing water, thickness of the swimming pool can be increased, wear resistance and bump resistance are improved, and the service life of the swimming pool is prolonged.

Owner:刘辉

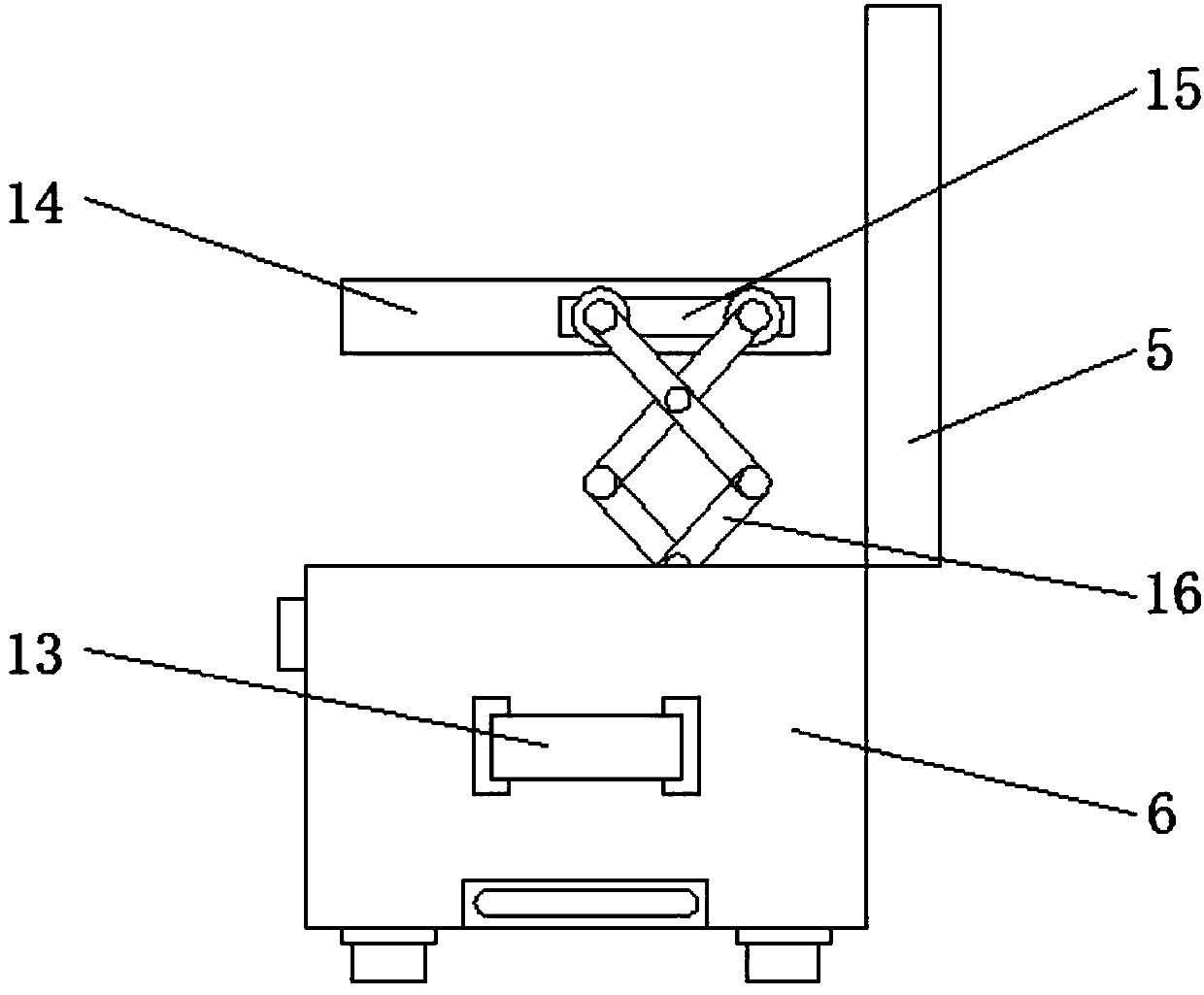

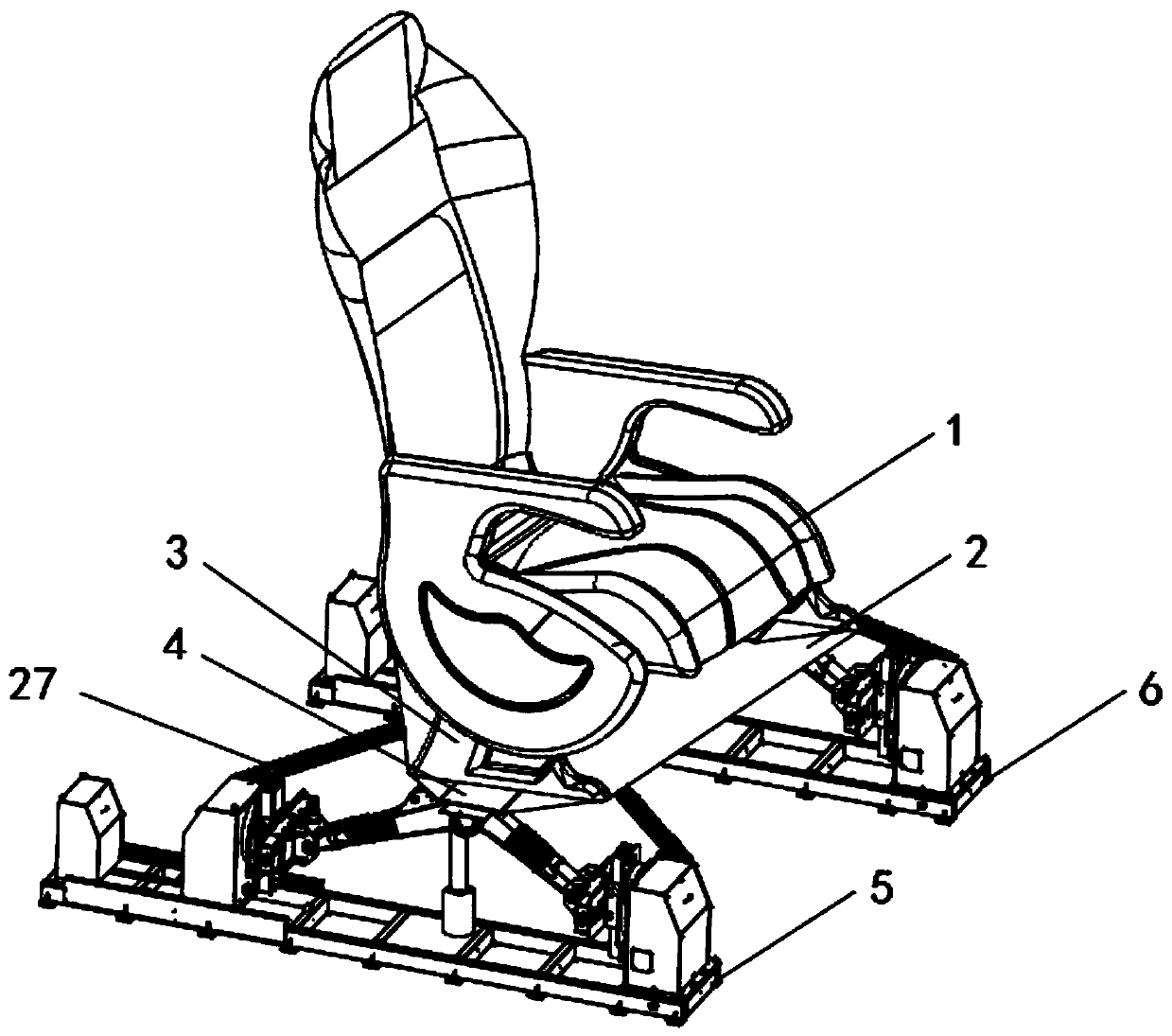

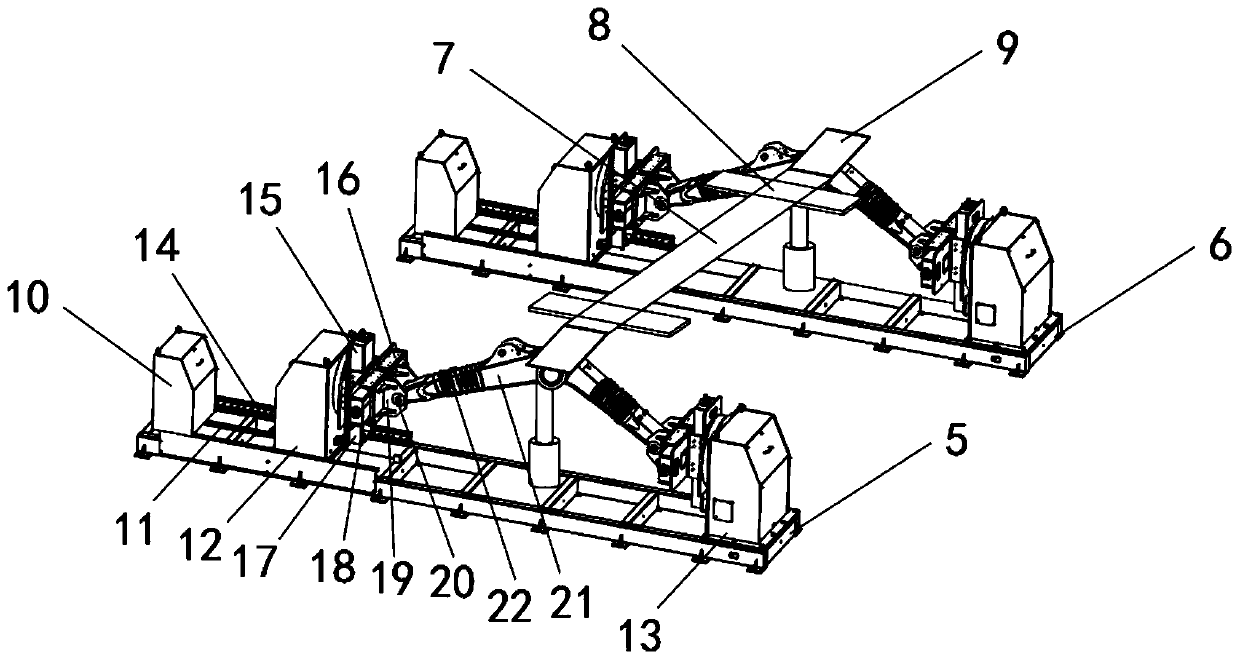

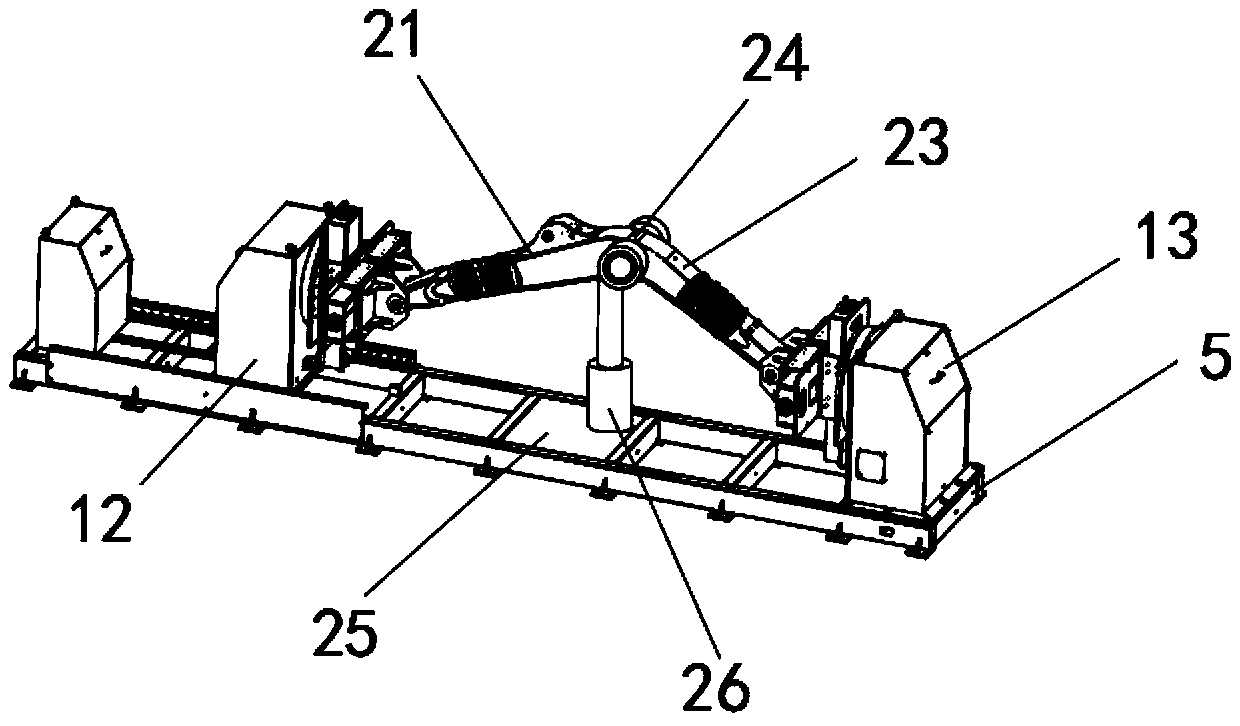

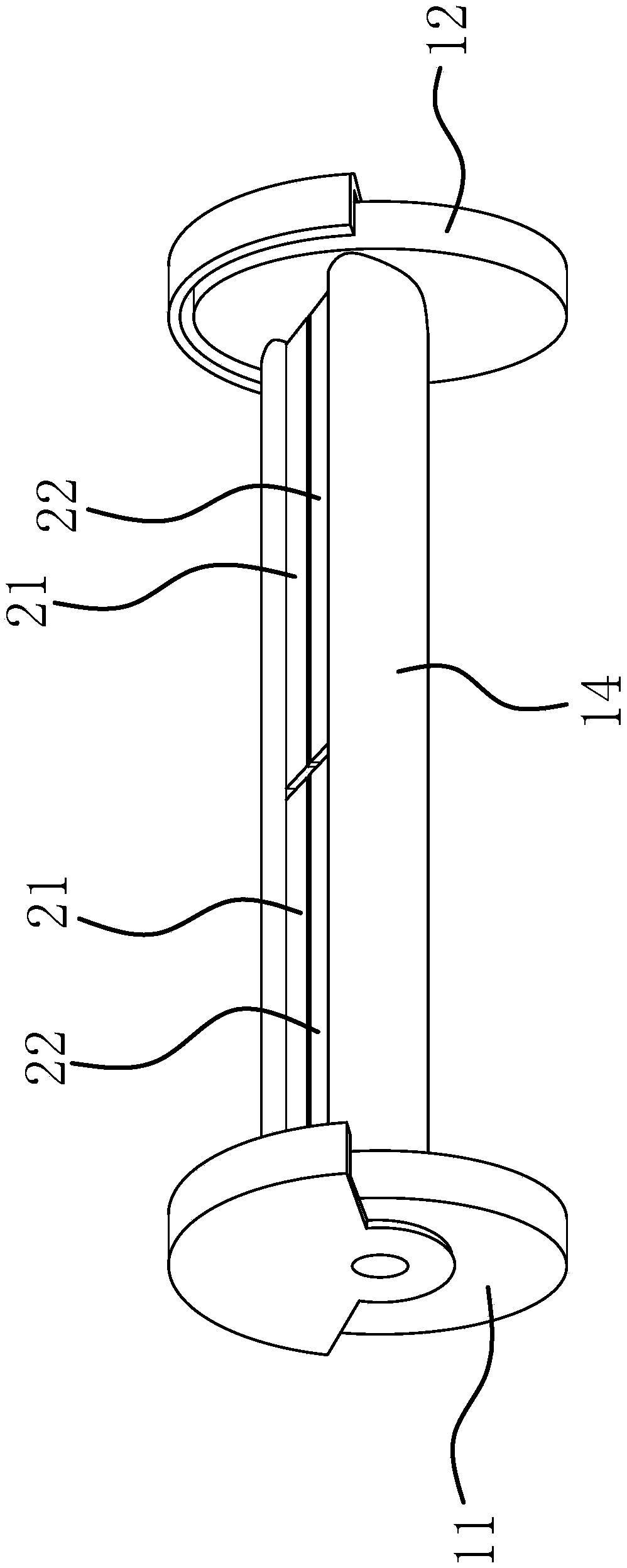

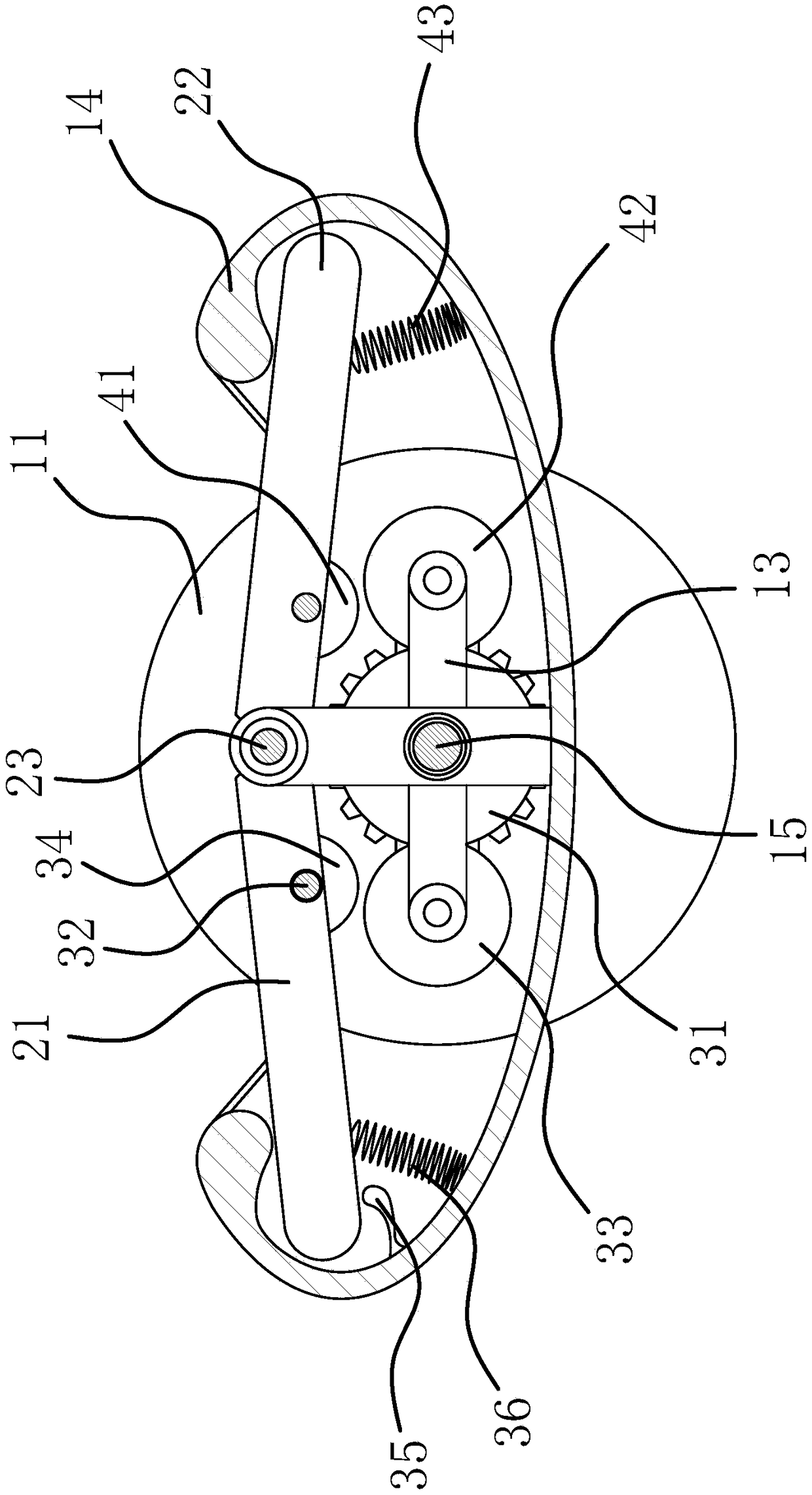

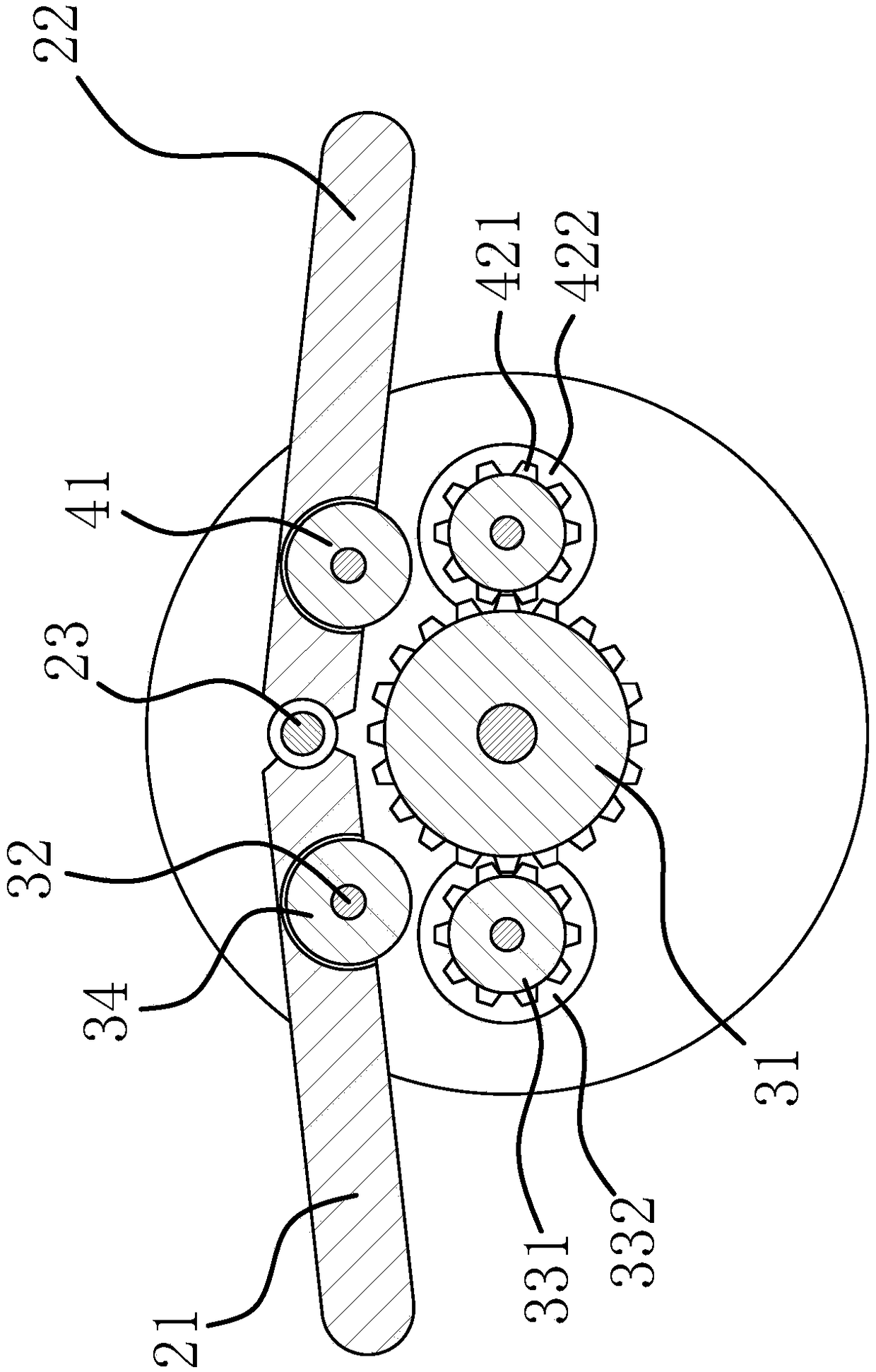

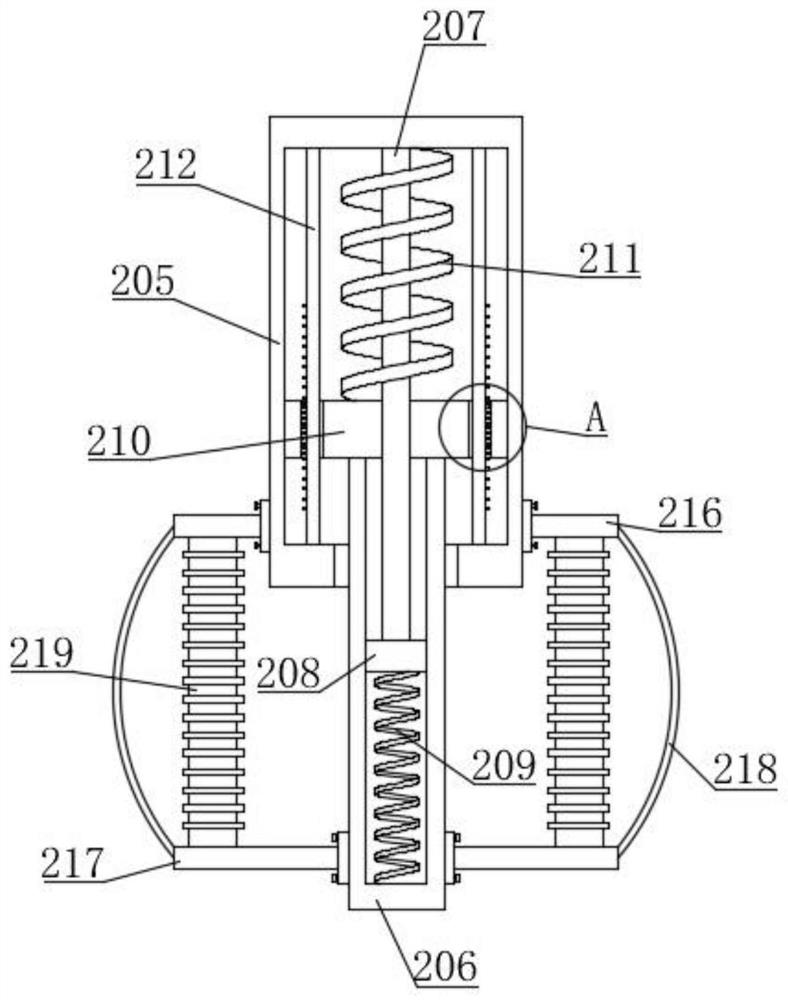

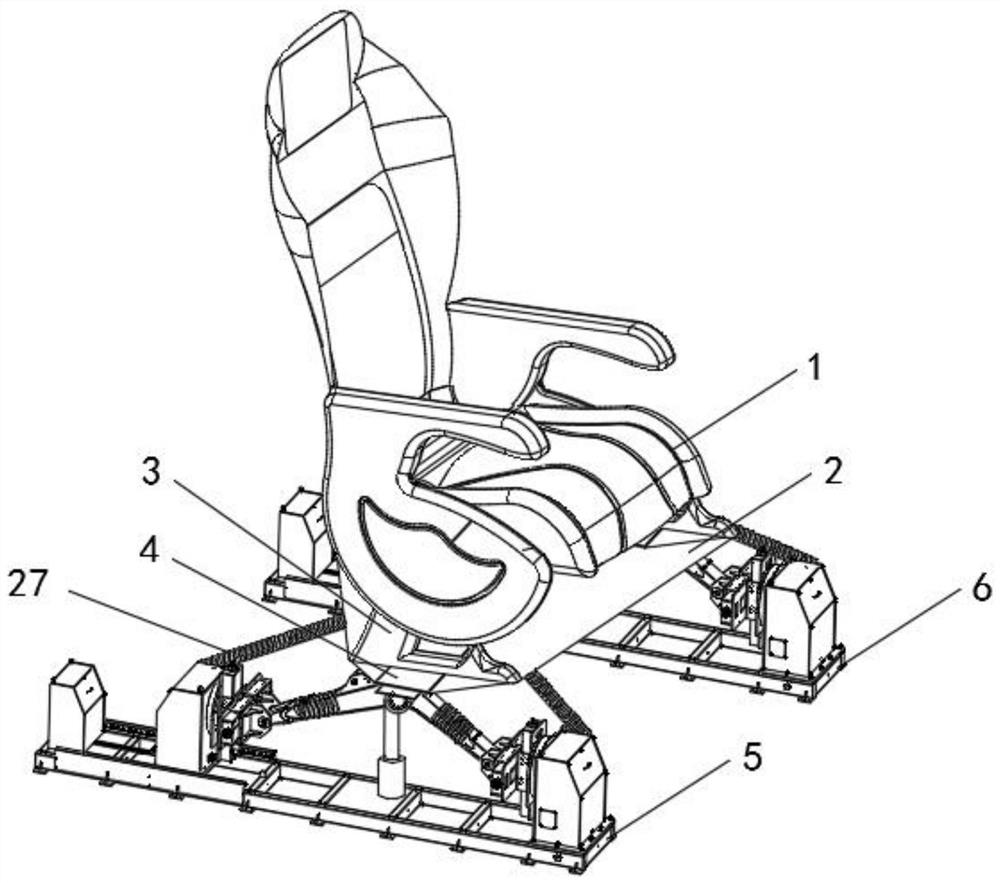

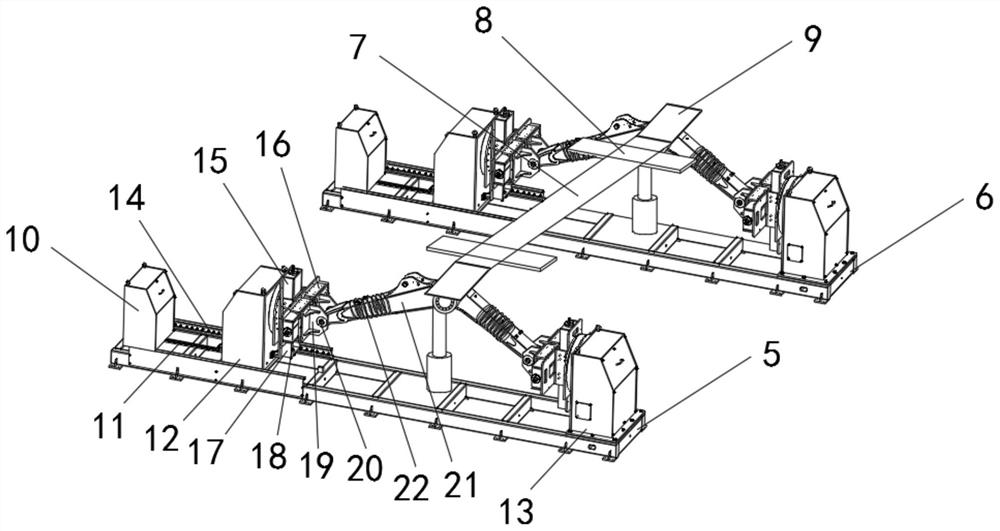

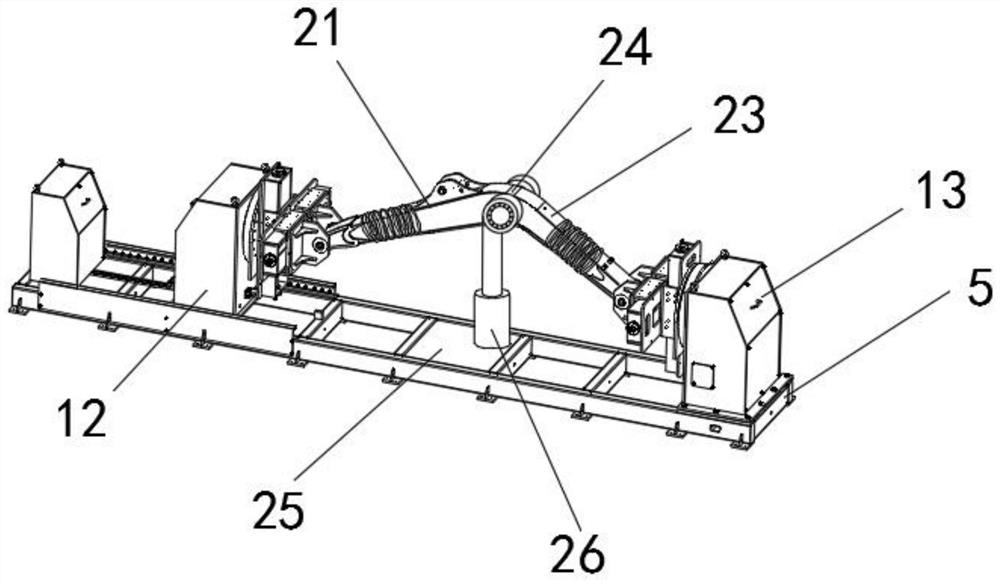

Anti-bumping automobile seat

ActiveCN109895662APlay the role of anti-seismic and anti-turbulenceStrong anti-seismic and anti-turbulence abilityMovable seatsSeat suspension devicesEngineeringMechanical engineering

The invention discloses an anti-bumping automobile seat. The anti-bumping automobile seat can solve the problem that, even provided with an anti-bumping shock absorbing structure, an existing automobile seat is still poor in anti-bumping capability to result in poor sitting comfort level as well as solve the defects that the existing automobile seat cannot automatically select and adjust the anti-bumping capability according to different road conditions but only resist shock and bumping according to the set function of the anti-bumping shock absorbing structure to result in poor adaptability.The anti-bumping automobile seat comprises a seat body and a base arranged at the bottom of the seat body, the bottoms of both ends of the base are provided with a left bottom support and a right bottom support respectively, both ends of the base are provided with side supports connected with the bottom of the seat body, and the bottoms of the two side supports are welded with connecting bases; the left bottom support and the right bottom support are identical in structure, one ends of the tops of the left bottom support and the right bottom support are respectively provided with an air pump,and the other ends of the top of the left bottom support and the right bottom support are respectively provided with a fixing base.

Owner:湖南长丰汽车沙发有限责任公司

Braking mechanism of self-balancing scooter

PendingCN109398584APlay the role of resetImprove buffering effectWheel based transmissionRotary transmissionsConductor CoilTraction belt

Owner:HUBEI UNIV OF SCI & TECH

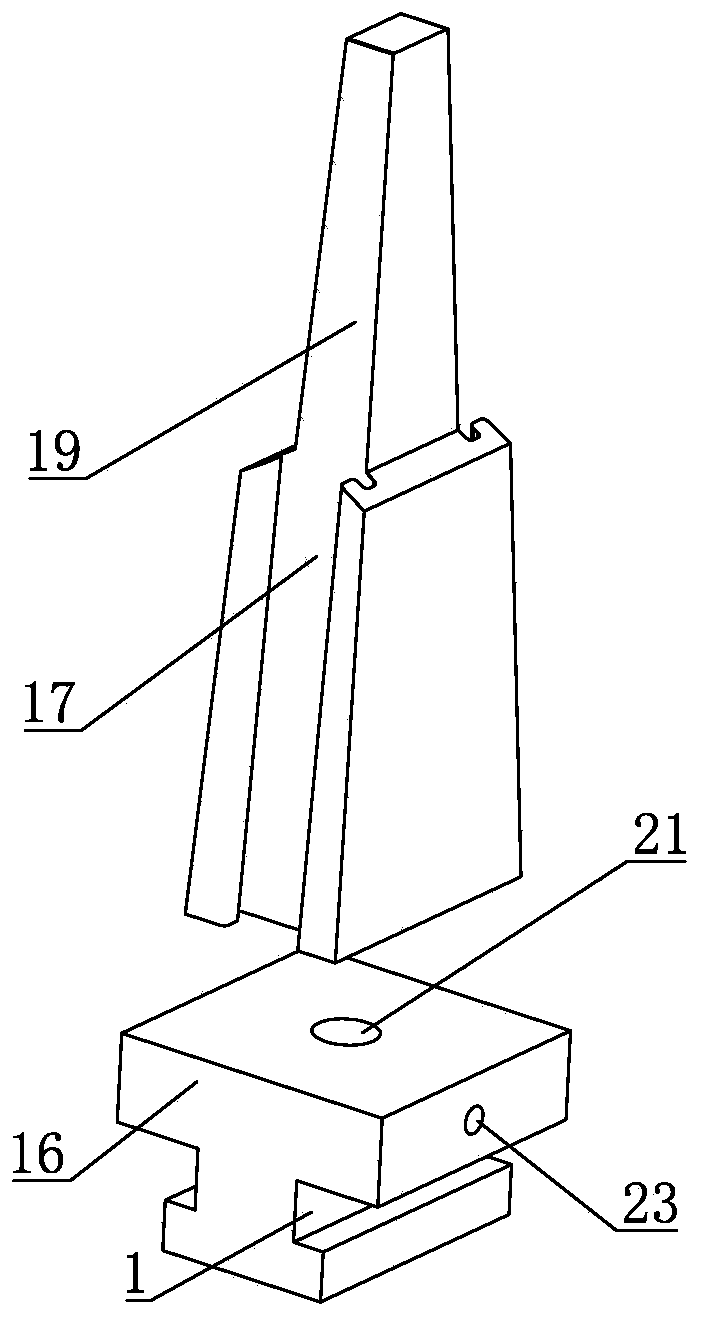

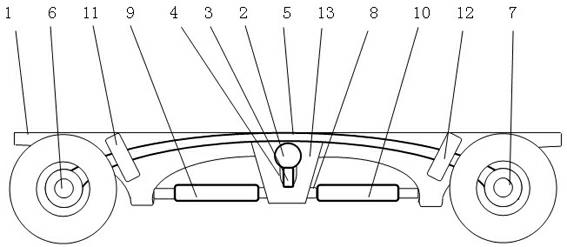

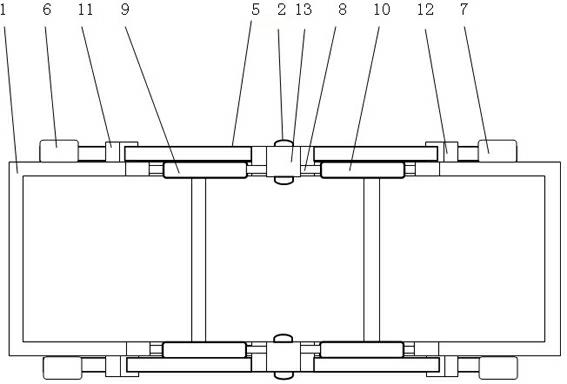

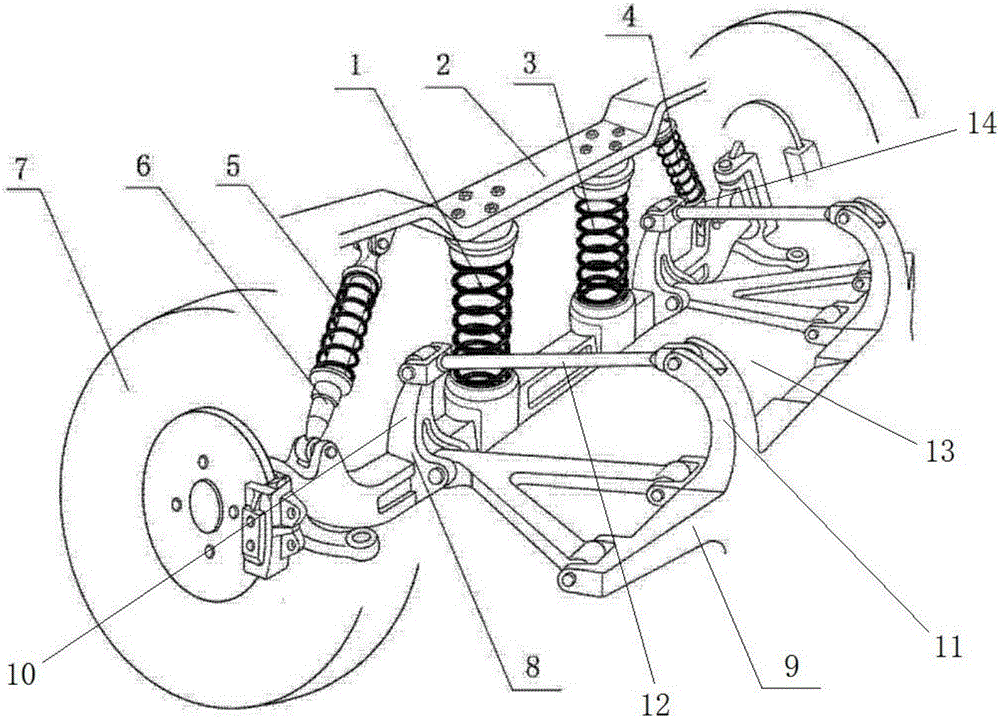

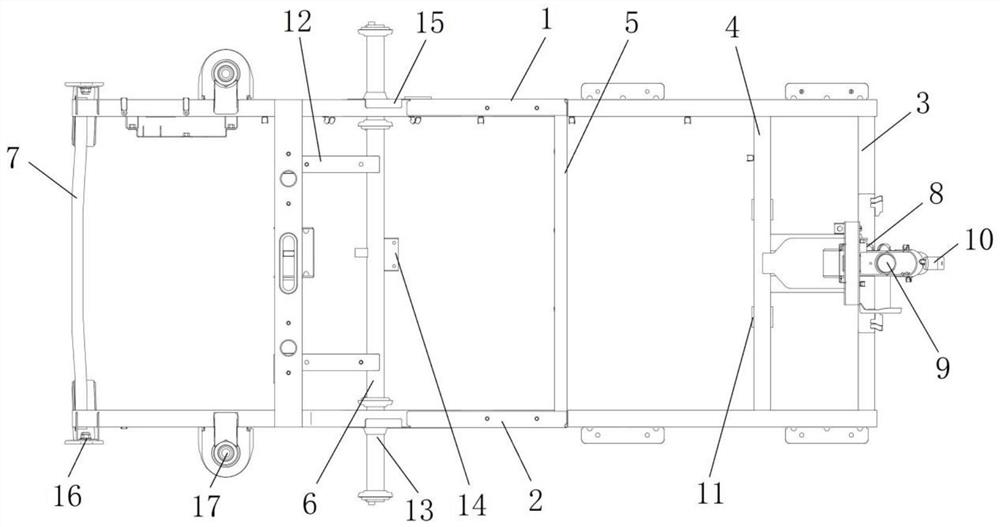

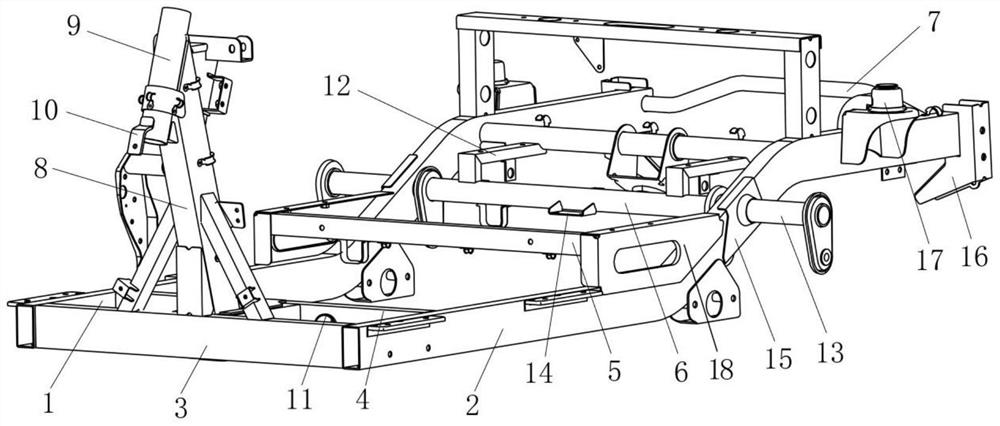

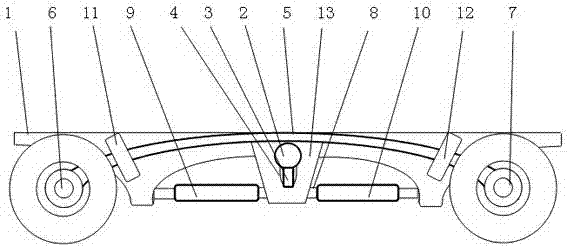

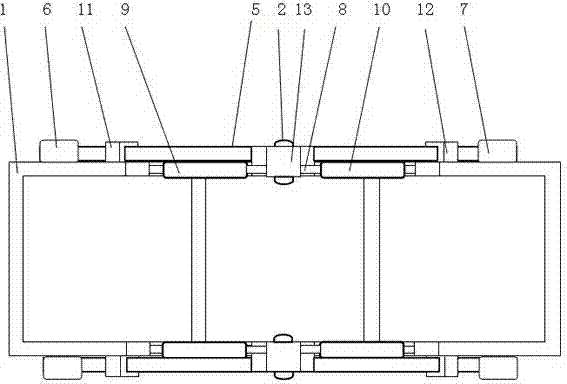

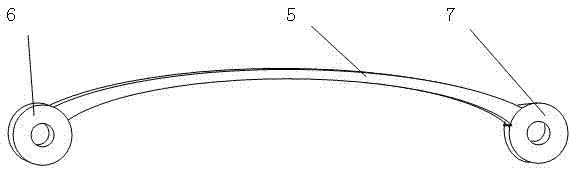

Shockproof anti-jolt chassis of passenger car

InactiveCN102139614AImprove anti-vibrationEnhanced bump resistanceInterconnection systemsSimple componentEngineering

The invention relates to a shockproof anti-jolt chassis of a passenger car. The shockproof anti-jolt chassis comprises a car frame, a central axle, a central spring, a wheel bow frame, a front wheel axle, a rear wheel axle and a central socket sleeve, wherein the front wheel axle is arranged at the front end of the wheel bow frame, and the rear wheel axle is arranged at the rear end of the wheel bow frame. The central axle is fixed in the middle of the car frame and is connected with the wheel bow frame on two edges of the car frame; the wheel bow frame is downwardly bow-shaped, the lower middle part of the wheel bow frame is fixedly connected with the central socket sleeve; a transverse middle hole groove is formed in the middle of the central socket sleeve, the central axle penetrates through the upper part of the middle hole groove, the central spring is mounted in the middle hole groove, and the central axle is supported by the upper end of the central spring; and the wheel bow frame, the central socket sleeve, the central axle and the central spring constitute the shockproof anti-jolt mechanism of the passenger car. In the invention, with the integrated structure of the wheelbow frame, the central axle, a front axle spring and a rear axle spring in the entire passenger car, the traditional separately-arranged structure of the front and the rear wheel sets is changed, therefore shockproof and anti-jolt effects of the passenger car are greatly improved. The shockproof anti-jolt chassis provided by the invention has the advantages of firm structure, simple components, good shockproof effect and especially obvious anti-jolt effect.

Owner:SHANGHAI INST OF TECH

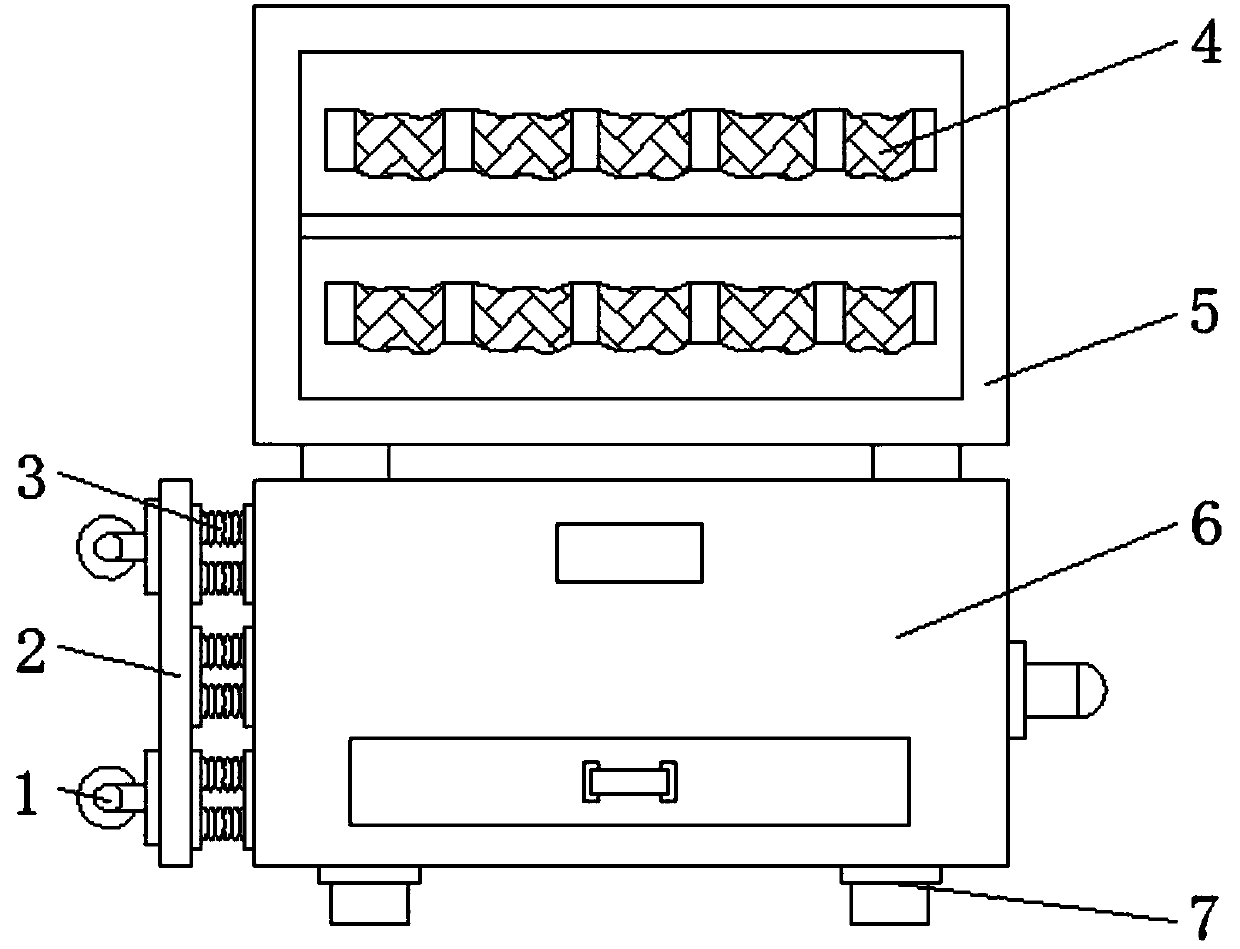

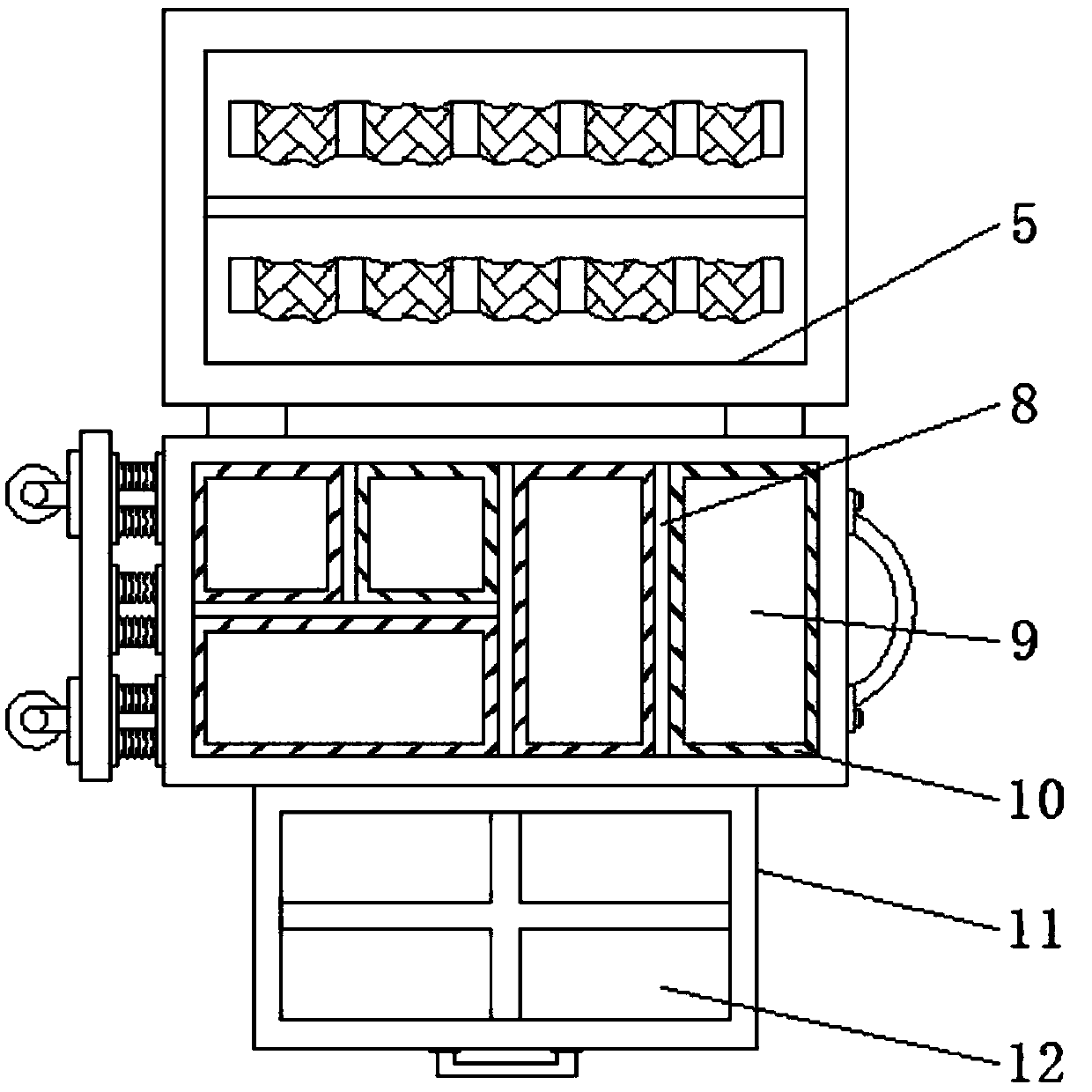

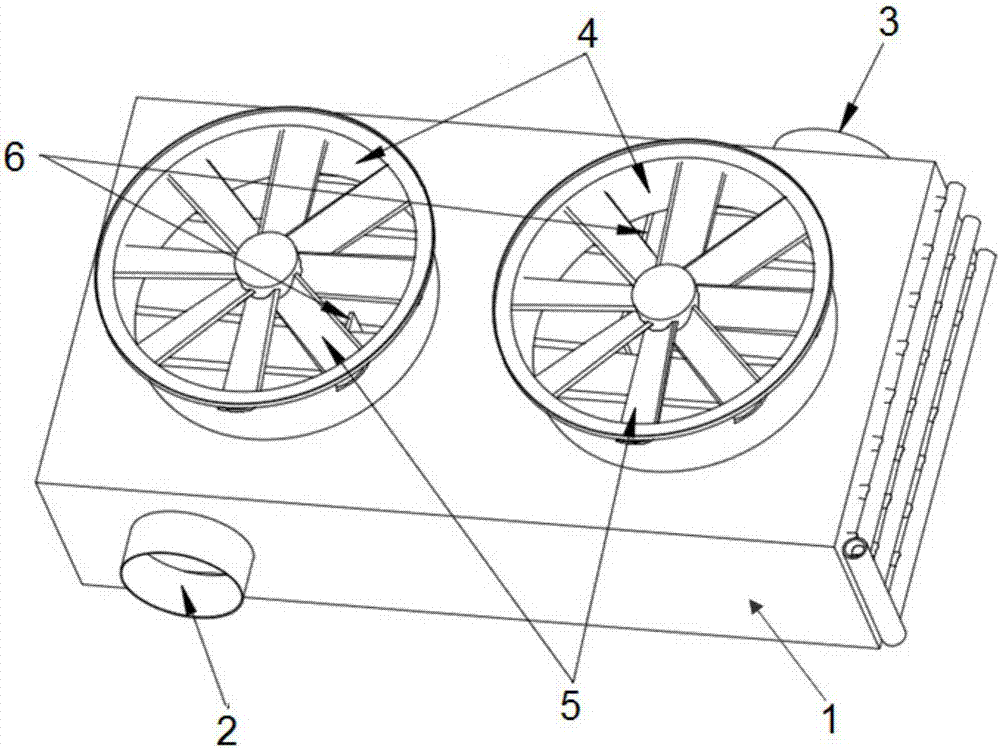

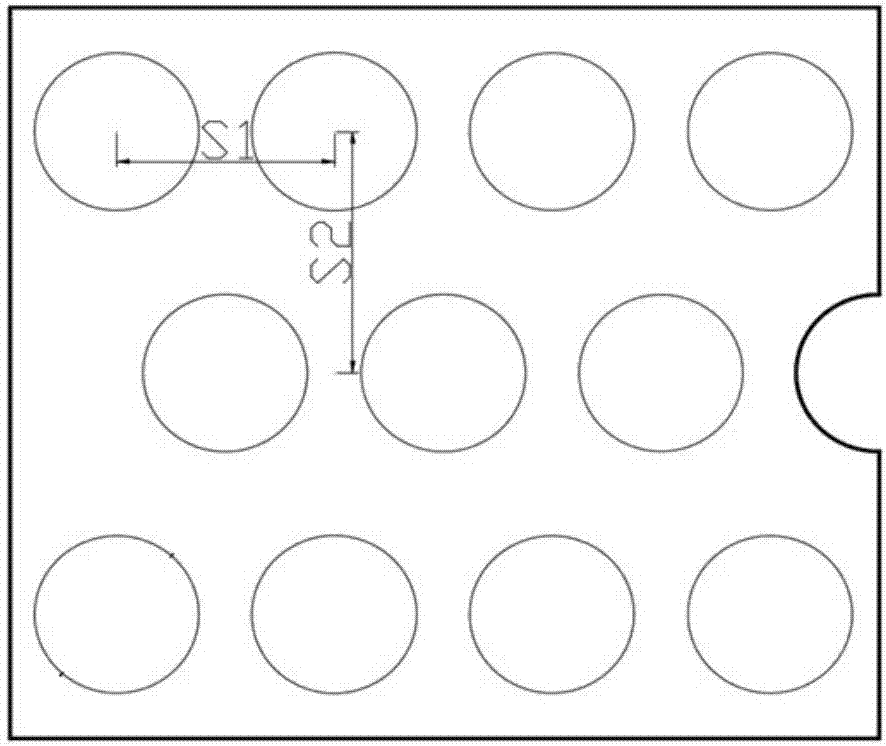

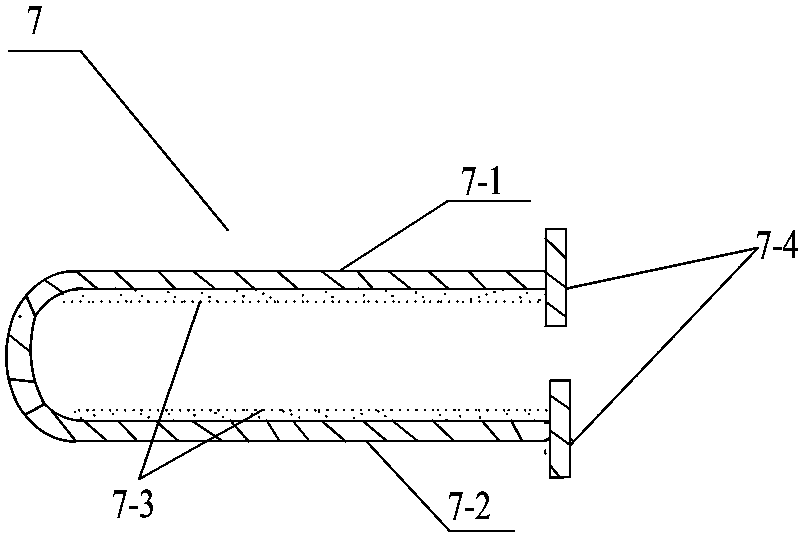

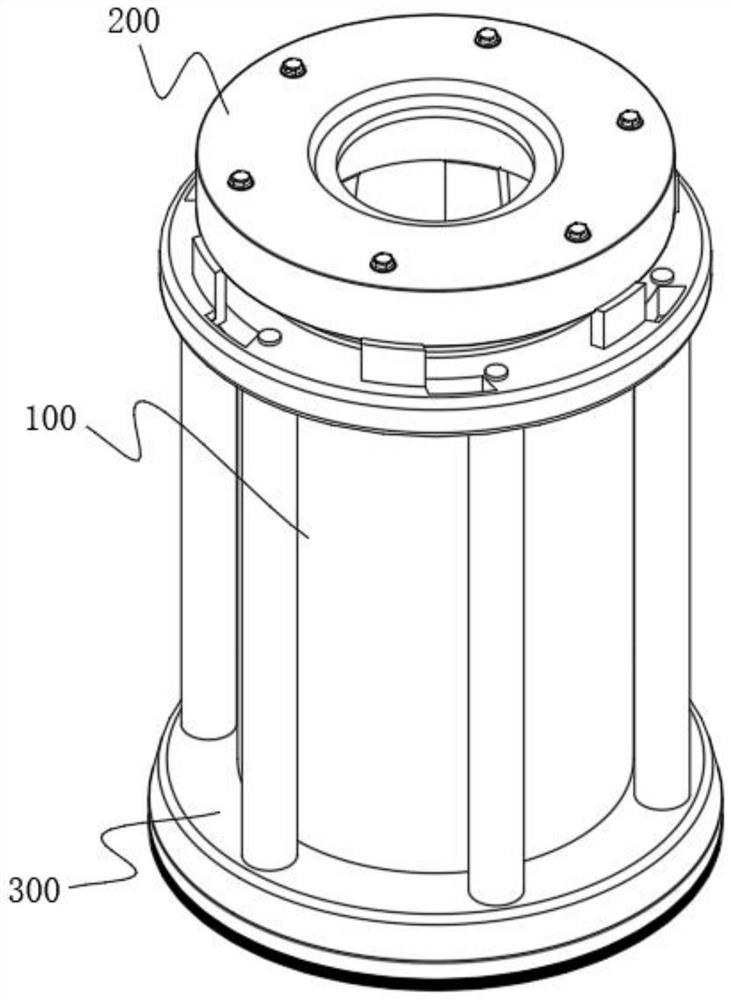

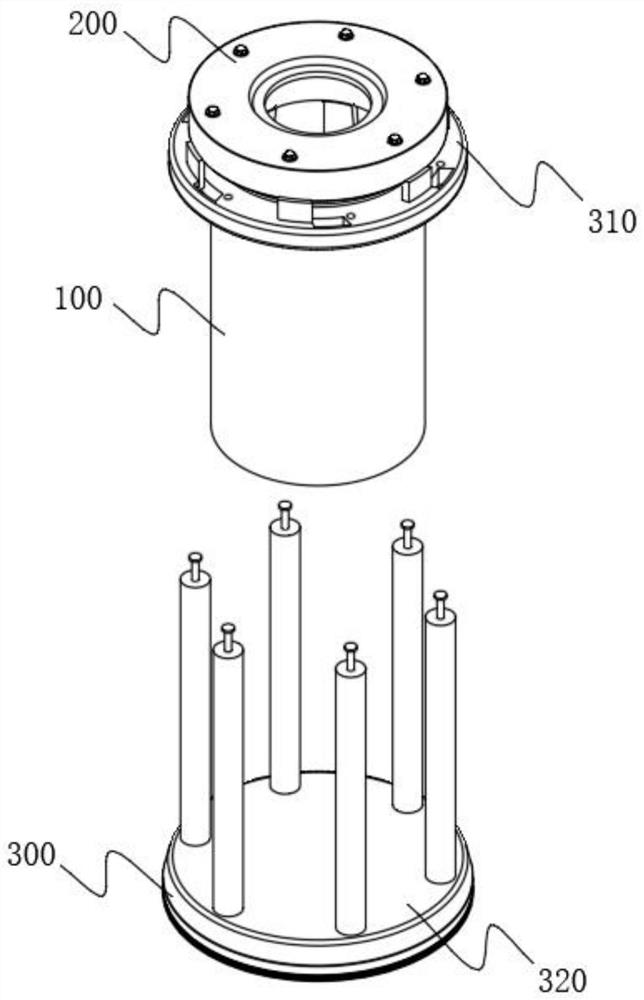

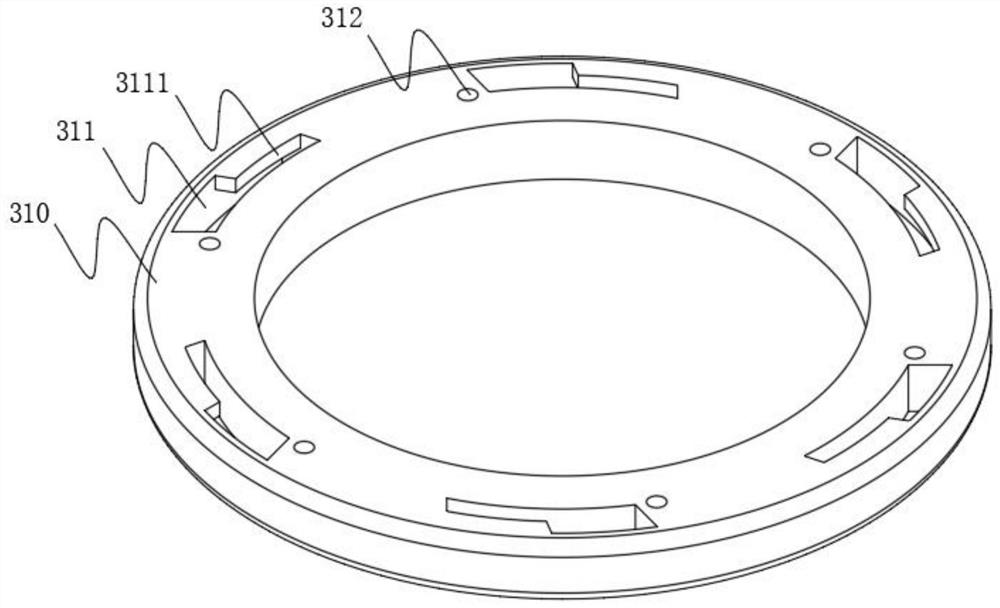

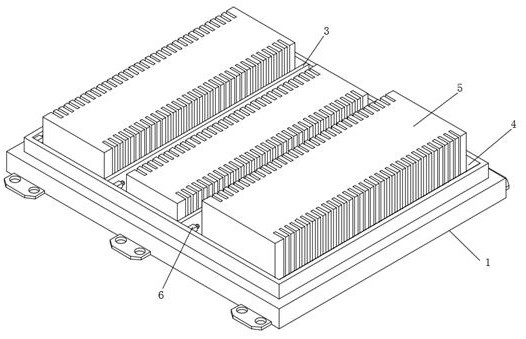

Modular adsorption bed structure

InactiveCN107166810ASpeed up coolingImprove system performanceClimate change adaptationAbsorbers/adsorbersEngineeringAbsorption refrigerator

The invention discloses a modular adsorption bed structure, and belongs to the technical field of adsorption refrigeration and energy storage. The modular adsorption bed structure comprises an adsorption bed shell, a plurality of unit tubes, a cooling fan, a baffle plate and a gate valve; an inlet and an outlet of an external heat source and a cold source are formed in the adsorption bed shell; the unit tubes are arranged in the adsorption bed shell in a staggered manner, the flow direction of the external heat source and the flow direction of the cold source are perpendicular to the unit tubes, and each unit tube comprises an outer metal tube, a metal net tube with a spring inner core, an open front end cover, a sealed rear end cover and a single-salt or multi-salt composite adsorbent filling the unit tube; the external heat source and the cold source are circulated outside the metal tubes; and the gate valve is arranged between the cooling fan and the adsorption bed shell and needs to be opened in the cooling process and closed in the heating process. According to the modular adsorption bed structure, compactness and light weight can be realized, heat exchange is effectively enhanced, and cleaning convenience is improved.

Owner:高娇

Battery electric vehicle for the disabled

InactiveCN106080080AImprove shock absorptionDrive stabilityResilient suspensionsHydraulic cylinderBattery electric vehicle

The invention provides a battery electric vehicle for the disabled. According to the technical scheme, a supporting frame and a suspension axle are connected through two sets of main springs, so that a damping effect is guaranteed in the vertical direction; and meanwhile, in order to solve the problem that a battery electric vehicle low in self-weight generates severe lateral deviation when jolting, oblique hydraulic cylinders are arranged on the edges of the supporting frame and the edges of the suspension axle, and therefore the damping effect is improved. In addition, a horizontal tray is welded between a chassis and the suspension axle, the tray is surrounded by protruding portions and connecting rods, and thus the tray can be used for fixing a battery pack due to the structure. In this mode, the large-weight battery pack is moved forwards to the vehicle head, the self-weight of the vehicle head is increased, and therefore the dragging stability of an engine is improved, and meanwhile vibration and jolting are further relieved. According to the battery electric vehicle, the damping performance of the battery electric vehicle is greatly improved due to the creative design of a front suspension assembly, and the battery electric vehicle is driven more stably and is particularly suitable for the disabled.

Owner:天津中科先进技术产业有限公司

The improved structure of mold components that greatly improves the casting precision of lightweight aluminum pistons

ActiveCN111421114BPrevent side swingEliminate distractionsFoundry mouldsFoundry coresClassical mechanicsStructural engineering

The invention relates to an improved structure of a mold assembly for greatly improving the casting precision of lightweight aluminum pistons, which is applied to mass production of high-precision lightweight aluminum pistons. It includes outer mold, pin hole mold, slider mold and core mold. The mandrel includes a piston mandrel centerpiece. The central part of the piston mandrel consists of a quadrangular pyramid column and a supporting platform connected with the quadrangular pyramid column. It is characterized in that the support rail opens the groove along the center line, the bottom of the pin hole mold has a straight rod, the straight rod is as wide as the through groove and extends into the through groove; the upper part of the pin hole mold has a T-shaped guide rail groove, and the upper part of the outer mold cavity With T-shaped guide rail, the T-shaped guide rail groove is set on the T-shaped guide rail. The pin hole die has a lower pressing block for the pin hole. The quadrangular pyramid column and the supporting platform are fastened and connected by bolts with chord sections. The end face hole of the bolt is connected with the side hole of the bolt, and a deep hole of the square pyramid column is opened on the lower end surface of the square pyramid column. It has the advantages of avoiding various abnormal wear and tear of the pin hole mold, greatly enhancing the anti-turbulence performance, and improving the precision of the thickness of the radial casting involved in the slider mold during production.

Owner:HUAMIN NANPING AUTOMOBILE FITTINGS GROUP

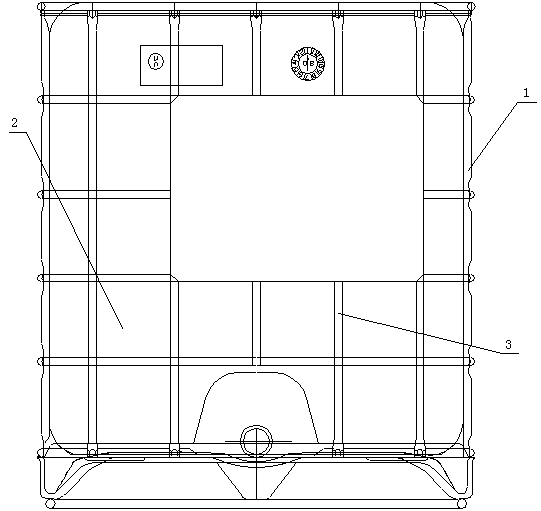

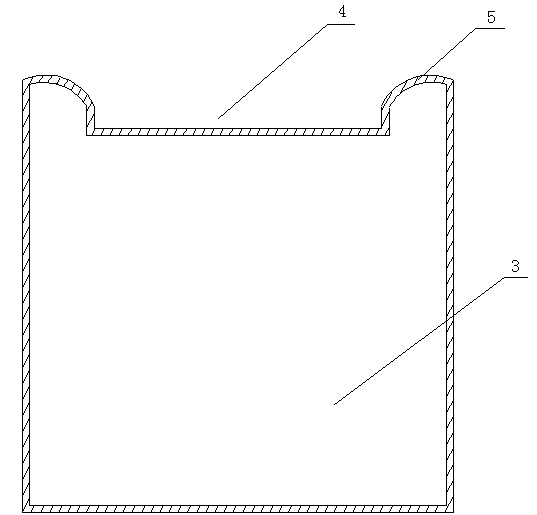

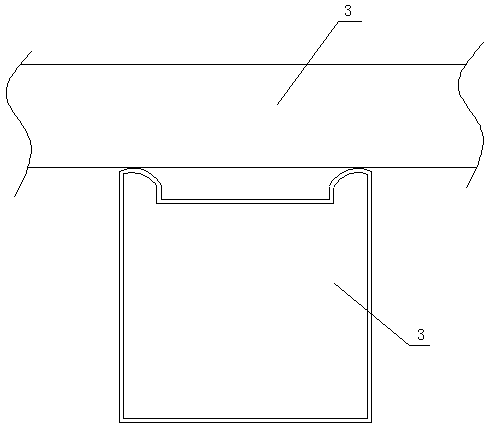

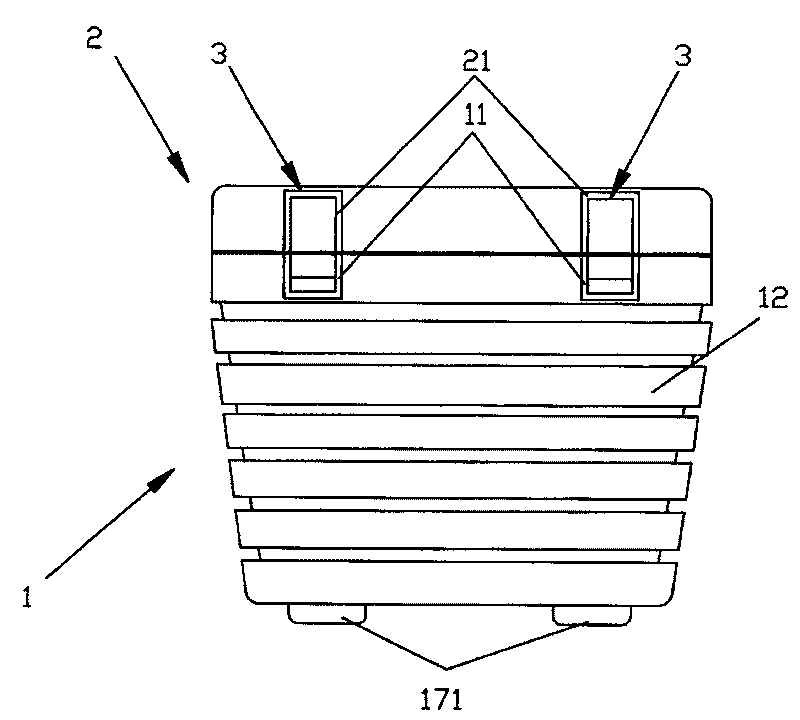

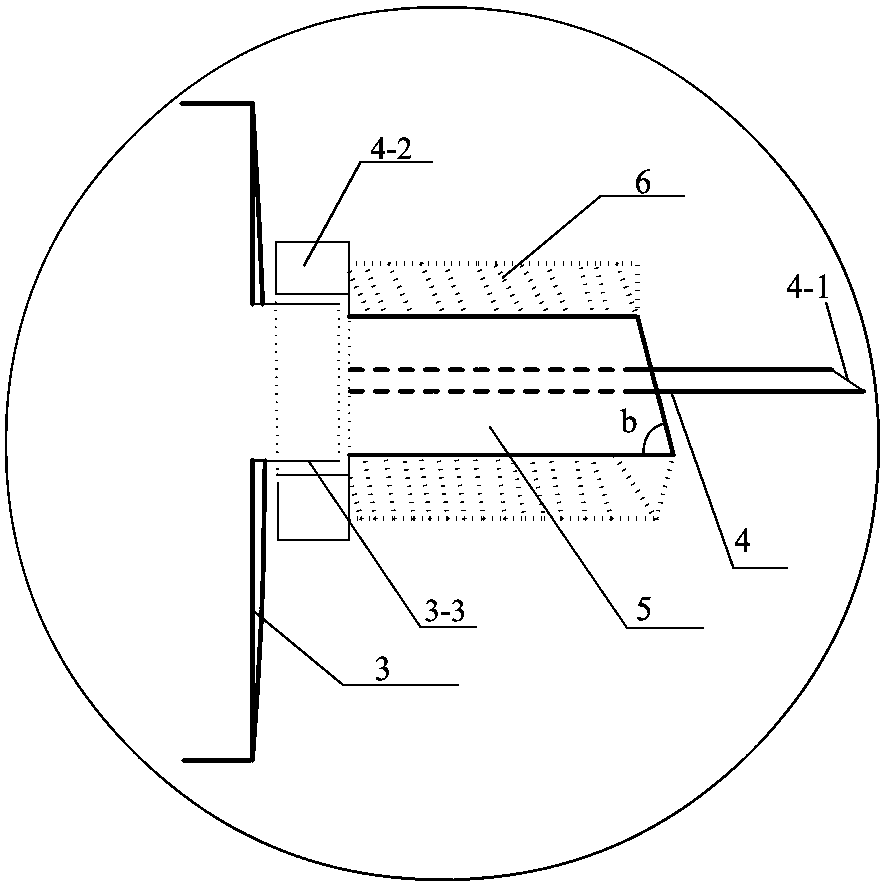

Middle-sized bulk container

InactiveCN102862722AQuality improvementImprove tensile propertiesLinings/internal coatingsRigid containersIntermediate bulk containerEngineering

The invention relates to a middle-sized bulk container, which is firm in welding points of a pipe of a peripheral framework and not easy to brake, and belongs to the technical field of a package container. The middle-sized bulk container is characterized by comprising a framework (1) and an internal barrel (2), wherein the internal barrel (2) is arranged inside the framework (1), the framework (1) is formed by welding a plurality of square pipes (3) which are distributed in transverse direction and longitudinal direction, the top surface of each square pipe (3) is provided with a groove (4), and two sides of each groove (4) are protruded to form a welding surface (5). The middle-sized bulk container is simple in manufacturing process and low in production cost; and moreover, the welding points of the pipes are firm, and the breaking phenomenon is not easy to happen.

Owner:江阴康爱特包装股份有限公司

Cold, hot food insulation box

InactiveCN1911756BImprove insulation effectImprove bearing capacityDomestic cooling apparatusLighting and heating apparatusEngineeringBody cavity

The heat insulating box for cold and hot food includes one box body in hollow structure filled with heat insulating material and one box cover. The box cover has notch with embedded sealing strip in the inner wall and limiting notch in the surface; and the box body has limiting boss on the bottom. The heat insulating box features the box cover with one sealing boss in the inner wall, the joint between the box body and box cover with at least one pair of notches and slap in the outer side board wall, the inner and outer surfaces of the box cover and the outer wall of the box body with reinforcing ribs, and the box body cavity bottom with one capped through hole. The present invention has the features of high sealing performance, long temperature maintaining period, great box cavity capacityand good heat insulating performance.

Owner:盛贸(上海)食品有限公司

Easy-to-carry injection device based on protection structure

InactiveCN110772686AAvoid stabbingEasy to operateInfusion syringesInfusion needlesStructural engineeringSyringe needle

The invention discloses an easy-to-carry injection device based on a protection structure. The easy-to-carry injection device is characterized in that a right end of a shell is covered with a shell cover; an injection cylinder is located in the shell; a rubber piston is plugged in the injection cylinder; T-shaped grooves are formed in an upper part and a lower part of a left face of the rubber piston correspondingly; a left end of a push-pull block I is connected with a left end of a push-pull block II, and T-shaped blocks are arranged at a right end of the push-pull block I and a right end ofthe push-pull block II correspondingly; a push-pull device is arranged in the shell in an inserted mode, and a left end of the push-pull device is connected with the middle of a left face in the shell; the push-pull block I and the push-pull block II are inserted into the injection cylinder, the T-shaped block at the right end of the push-pull block I is embedded in the T-shaped groove in the upper part of the left face of the rubber piston, and the T-shaped block at the right end of the push-pull block II is embedded in the T-shaped groove in the lower part of the left face of the rubber piston; a syringe needle is mutually connected with a rubber head of the injection cylinder through a pintle; an outer surface of an outer tube is wrapped with an alcohol cotton layer; and a left end ofthe outer tube is arranged at a right end of the pintle, the syringe needle horizontally penetrates through the outer tube, and the outer tube sleeves a left part of the syringe needle.

Owner:周小辉

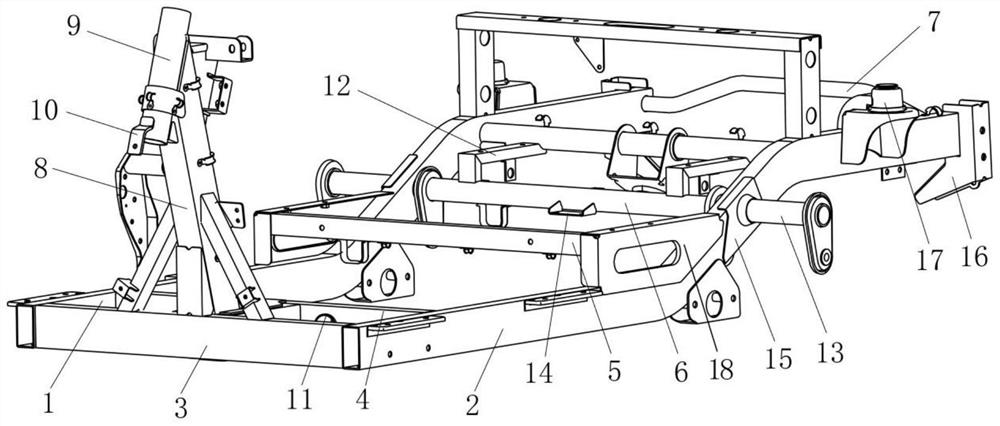

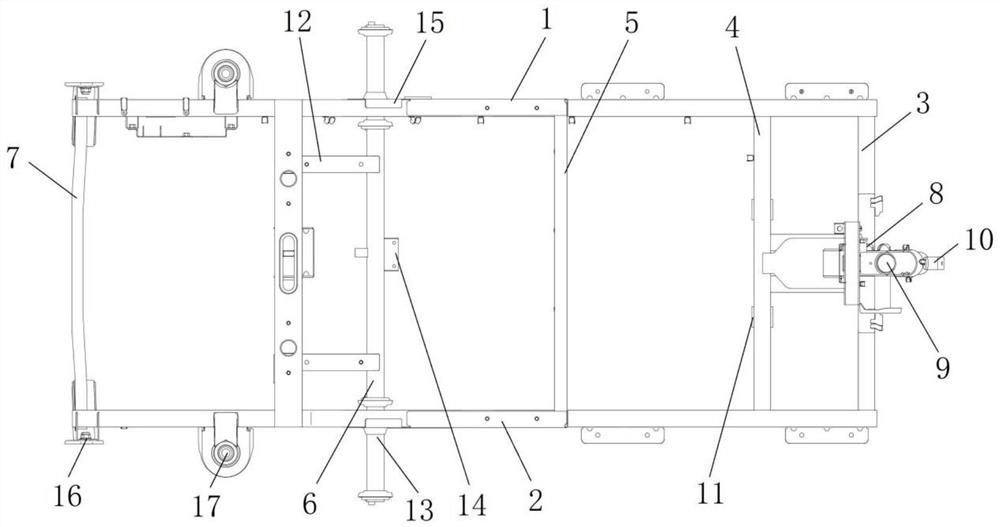

Chassis structure assembly and vehicle

The invention discloses a chassis structure assembly and a vehicle. The chassis structure assembly comprises a first longitudinal beam, a second longitudinal beam, a first cross beam, a second cross beam, a third cross beam, a fourth cross beam and a fifth cross beam, wherein the first longitudinal beam and the second longitudinal beam are arranged in parallel, and the first cross beam, the secondcross beam, the third cross beam, the fourth cross beam and the fifth cross beam are sequentially welded between the first longitudinal beam and the second longitudinal beam. The first beam is arranged at the front end of the first longitudinal beam, and the fifth beam is arranged at the tail end of the first longitudinal beam. According to the chassis structure assembly, the first cross beam, the second cross beam and the third cross beam are sequentially welded to the bent structures of the first longitudinal beam and the second longitudinal beam, the overall structure of the frame chassisis formed by embedding different assemblies, and the states of the bent structures of the first longitudinal beam and the second longitudinal beam obtained when the whole vehicle runs are consistent with the states of the bent structures obtained when whole vehicle suddenly passes through the convex blocks or the concave pits when running on the road surface, so that the impact resistance and thebumping resistance of the whole vehicle are greatly improved.

Owner:CHONGQING ZONGSHEN INNOVATION TECH RES INST CO LTD

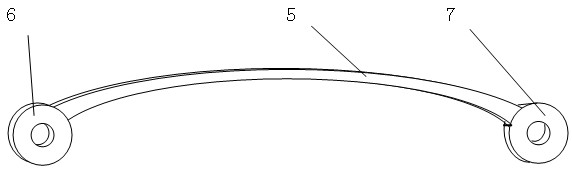

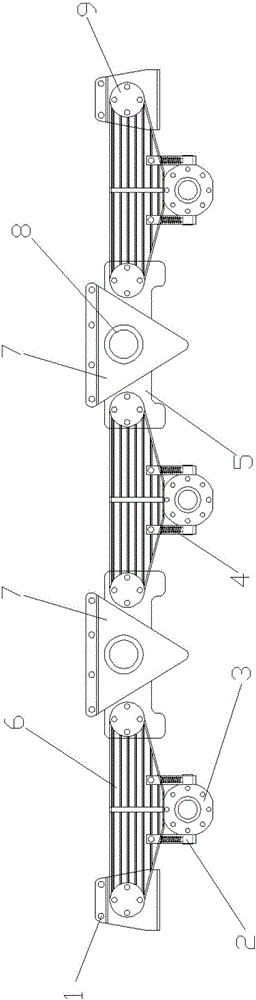

Three-line six-axis suspension fork for vehicle machines

PendingCN106608153ASuspension stabilizationStable structureResilient suspensionsVehicle springsSheet steelAgricultural engineering

The invention discloses a three-line six-axis suspension fork for vehicle machines. The three-line six-axis suspension fork comprises mounting holes, wheel shaft brackets, steel plate springs and supporting frames, wherein the twelve mounting holes in all are formed in the supporting frames; a fixing shaft of each of the steel plate springs penetrates through one end of the corresponding steel plate spring to be embedded in the corresponding supporting frame, and penetrates through the other end of the corresponding steel plate spring to be embedded in a corresponding connecting axle; each of the wheel shaft brackets is fixedly connected with the corresponding steel plate spring; a wheel shaft assembly is connected with each wheel shaft bracket; a spring is mounted in each wheel shaft bracket; and each of the connecting axles is embedded in the corresponding supporting frame and is connected to the corresponding supporting frame through a corresponding connecting shaft. According to the three-line six-axis suspension fork for the vehicle machines disclosed by the invention, the middle two supporting frames adopt a triangular structure, and the triangular structures are stable and firm, so that the suspension fork can be more stable; and rotatable shafts are separately mounted at joints between each of the wheel shaft assemblies and the corresponding wheel shaft bracket, so that wheel shafts can swing from left to right, and a vehicle can be more smooth when travelling on an uneven road surface.

Owner:GUIZHOU UNIV

Trim loading method and device for passenger aircraft

ActiveCN113492982BSmall center of gravity deviationSmall center of gravity deviation from optimal positionFreight handlingGround installationsData packPassenger transport

The present invention mainly relates to a trim loading method of a passenger aircraft, comprising the following steps: obtaining model data, the model data including the original center of gravity envelope, passenger cabin layout, and cargo hold layout; within the scope of the original center of gravity envelope, preset standards Center of gravity data; determine the number of passengers and the quantity of cargo, based on the cabin layout and cargo cabin layout, with the goal of minimizing the deviation of the center of gravity, establish an integer programming model for aircraft loading, pre-allocate the positions of passengers and cargo, and use heuristic intelligent algorithms, Iteratively optimize the model to determine the target loading scheme. Based on the trim loading method proposed by the present invention, positive effects such as loading visualization, one-key optimization, and analysis of center of gravity deviation of loading can be realized.

Owner:CIVIL AVIATION UNIV OF CHINA

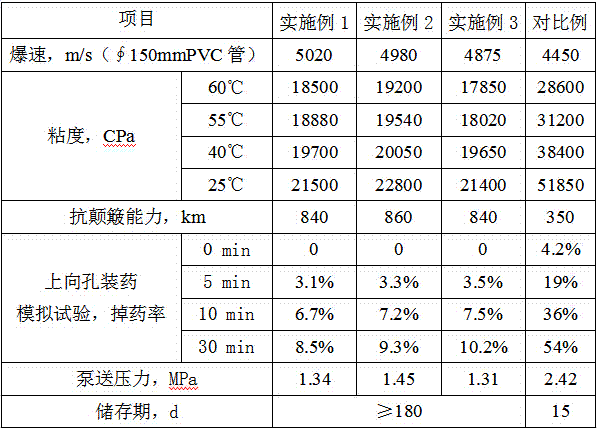

A Composite Oil Phase Used to Prepare Bulk Emulsion Explosives with Upward Hole Charges

ActiveCN105272784BEliminate potential safety hazardsImprove working abilityNon-explosive/non-thermic compositionsFiltrationEmulsion explosive

The invention discloses a composite oil phase for preparing bulk emulsified explosives with upward hole charges. The composite oil phase consists of white oil, naphthenic oil, polymer ester emulsifier, crosslinking agent, S-80 , anti-turbulence agent, and prepared by the following method: first heat white oil, naphthenic oil, polymer ester emulsifier, and S-80 in separate melting tanks to 60-70°C, and then mix according to the ratio requirements The oil pump is measured by the electronic scale and then pumped into the reaction kettle one by one. After stirring and heating up to 80-90°C, add the measured cross-linking agent and anti-turbulence agent, and continue stirring for about 30 minutes until the cross-linking agent and anti-turbulence agent are fully After melting, the finished product is obtained after filtering. The bulk emulsion explosive produced by the composite oil phase of the present invention has the remarkable characteristics of good explosive performance, high working capacity, long storage period, anti-turbulence, long-distance transportation, small colloidal viscosity gradient coefficient, and easy pumping at room temperature. When used in underground mines to charge holes, the rate of drug return is extremely low. It can replace imported products to produce high-quality bulk emulsion explosives, and has good economic benefits.

Owner:LIUYANG JINKE NEW MATERIAL CO LTD

Hydrofoil craft having hydroplane function

InactiveCN101249873BReduce consumptionEnhanced bump resistanceHydrodynamic/hydrostatic featuresGravity centerRudder

The invention discloses a hydrofoil ship with a displacement boat function, which comprises a main hull, a propulsion device and a stern rudder, wherein a deep-wetted hydrofoil and a movable sliding hydrofoil which can achieve lift adjustment are arranged at the bottom of the main hull, the deep-wetted hydrofoil is arranged at the rear portion of the gravity of the main hull while the movable sliding hydrofoil is arranged on the head portion of the main hull, and the distance between the deep-wetted hydrofoil and the main hull is longer than that between the movable sliding hydrofoil and the main hull. The hydrofoil ship has the advantages of fast route speed, sound dynamic stability, high safety, energy-saving and low production cost.

Owner:周洪斌

A chassis structure assembly and vehicle

The invention discloses a chassis structure assembly and a vehicle, comprising a first longitudinal beam, a second longitudinal beam, a first transverse beam, a second transverse beam, a third transverse beam, a fourth transverse beam and a fifth transverse beam, the first longitudinal beam and the second transverse beam The longitudinal beams are arranged in parallel, the first transverse beam, the second transverse beam, the third transverse beam, the fourth transverse beam and the fifth transverse beam are sequentially welded between the first longitudinal beam and the second longitudinal beam, and the first transverse beam is arranged at the front end of the first longitudinal beam, The fifth beam is placed at the end of the first longitudinal beam. In the chassis structure assembly disclosed in the present application, the first beam, the second beam, and the third beam are welded to the bending structures of the first longitudinal beam and the second longitudinal beam in sequence, and the overall structure of the frame chassis is assembled by different components. Embedded, the bending structure of the first longitudinal beam and the second longitudinal beam is consistent with the state that the whole vehicle suddenly passes through bumps or pits when the vehicle is running on the road, which greatly improves the impact resistance of the vehicle. and anti-bump performance.

Owner:CHONGQING ZONGSHEN INNOVATION TECH RES INST CO LTD

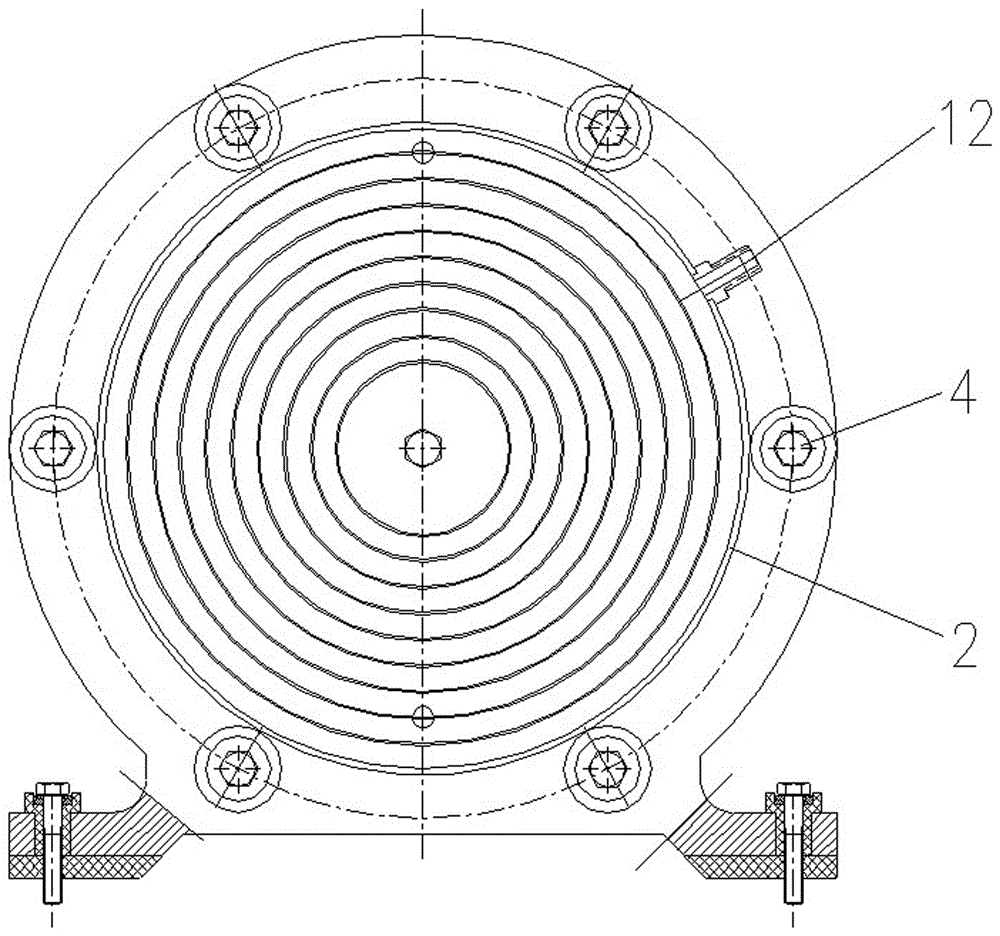

Hydraulic oil cylinder gland opening and closing device with reinforcing structure for automobile

ActiveCN111963513AImprove anti-turbulence abilityImprove securityFluid-pressure actuatorsPhysicsDriving safety

The invention relates to the technical field of hydraulic oil cylinders, in particular to a hydraulic oil cylinder gland opening and closing device with a reinforcing structure for an automobile. Thedevice comprises a cylinder body and a gland arranged on the top of the cylinder body, an outer side sealing plate is arranged on the periphery of the top of the cylinder body, a plurality of bolt insertion holes are annularly formed in the periphery of the top of the gland, bolts are inserted into the bolt insertion holes, the bolts are in threaded connection with the outer side sealing plate forfixing the gland and the cylinder body, and a reinforcing device is arranged on the periphery of the outside of the cylinder body. Through the arranged reinforcing device, the clamping fit of a limiting plate and a clamping block and threaded connection between the bolts and the outer side sealing plate, double fixation of the gland and the cylinder body is realized, so that the reinforcing effect is achieved, the anti-bumping capability of bolt connection is improved, and the driving safety is further improved.

Owner:CHANGDE JIAHONG MACHINERY

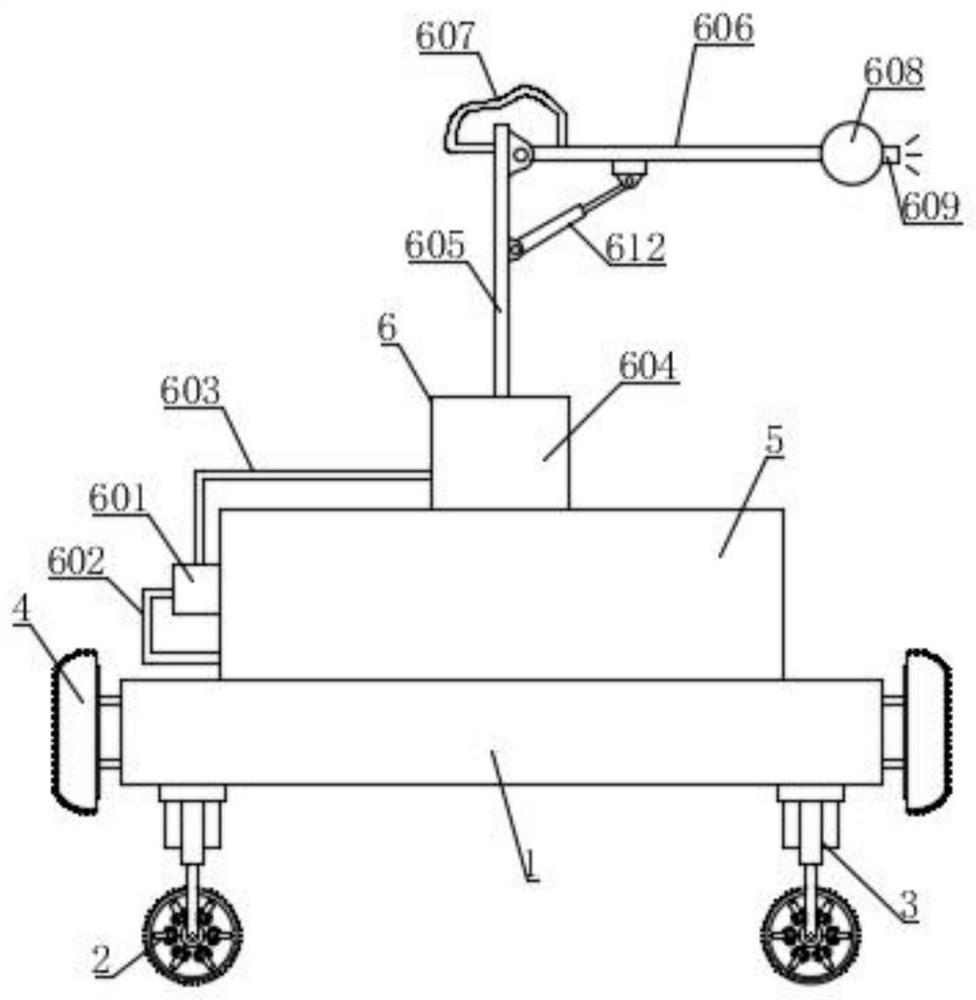

Orchard pesticide spraying robot with anti-bumping moving mechanism

InactiveCN113498765ARealize the spraying operationEasy to useTyre tread bands/patternsResilient suspensionsAgricultural scienceAgricultural engineering

The invention belongs to the technical field of pesticide spraying robots. The problems that an existing orchard pesticide spraying robot does not have an anti-bumping function, the movement process is not stable enough, internal parts of the pesticide spraying robot are prone to loosening and damage due to bumping and shaking, and the overall protection performance of the pesticide spraying robot is poor are solved. The invention discloses an orchard pesticide spraying robot with an anti-bumping moving mechanism. The orchard pesticide spraying robot with the anti-bumping moving mechanism comprises a bearing seat and a pesticide conveying and spraying assembly, a pesticide storage box is installed on the bearing seat, the pesticide conveying and spraying assembly is arranged on the pesticide storage box, the bottom of the bearing seat is provided with a anti-bumping moving mechanism, and the anti-bumping moving mechanism is connected with the bearing seat through a buffering assembly; according to the orchard pesticide spraying robot, by arranging an anti-collision assembly, the orchard pesticide spraying robot is prevented from being damaged by impact force generated by direct collision, by arranging the anti-bumping moving mechanism and the buffering assembly, damage to the orchard pesticide spraying robot due to bumping and shaking is relieved, and the overall protection performance of the pesticide spraying robot is remarkably improved.

Owner:泗县汉和智能装备科技有限公司

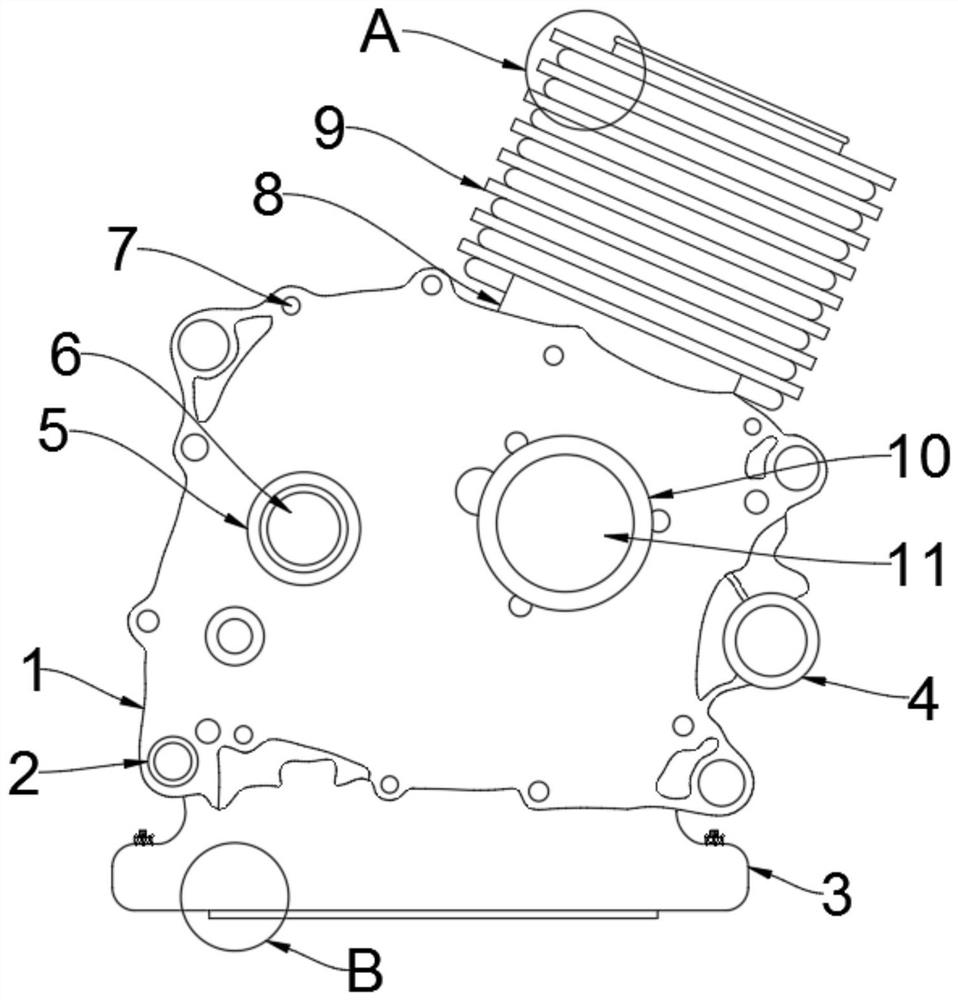

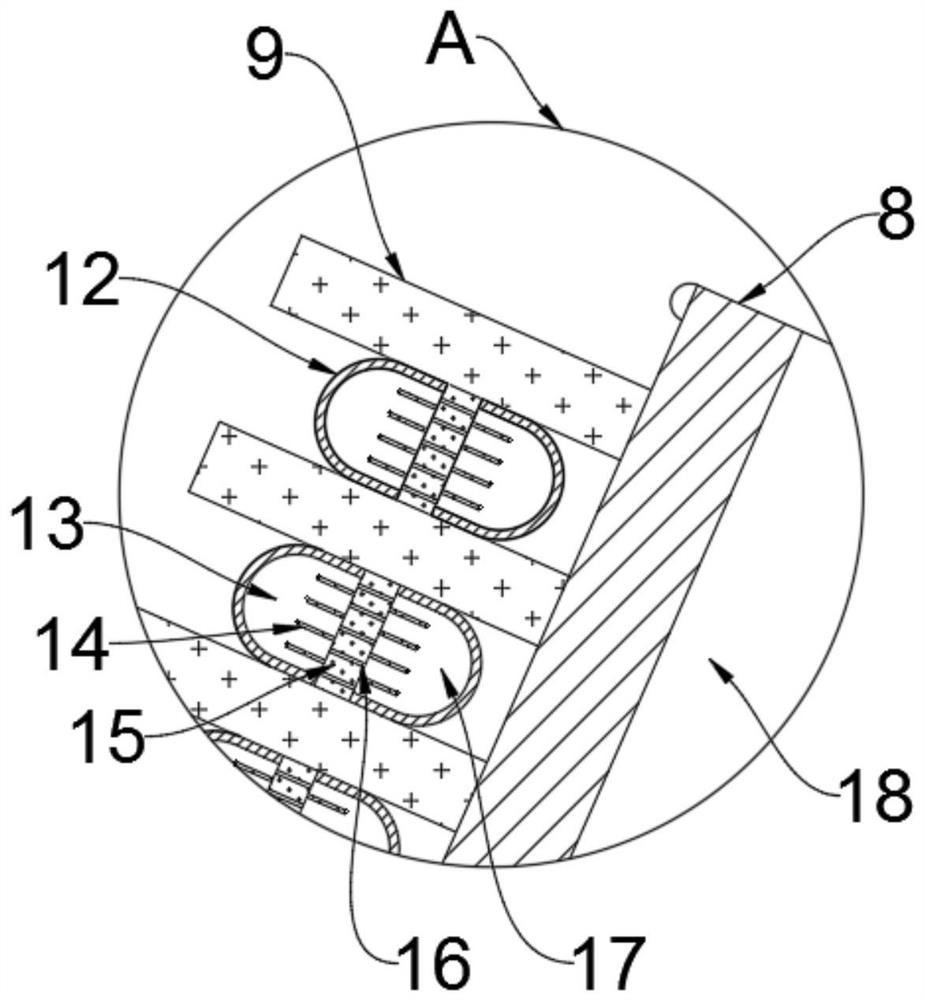

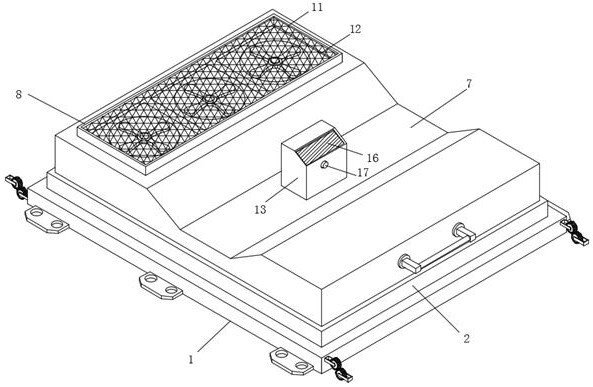

Engine case capable of rapidly dissipating heat

PendingCN112682210AImprove thermal conductivityReduce the temperatureLiquid coolingCasingsWater flowEngineering

The invention discloses an engine case capable of rapidly dissipating heat, relates to the technical field of engine cases, and aims to solve the problems that when an engine case in the prior art operates, due to continuous movement of an inner piston, the temperature of the case is increased quickly, quick aging of devices in the engine case is accelerated, and the service life of the engine case is affected. A piston hole is formed in a piston rod pipe, die-casting aluminum cooling fins are installed on the outer side of the piston rod pipe, the piston rod pipe is fixedly connected with the die-casting aluminum cooling fins through bolts, cooling pipelines are arranged below the die-casting aluminum cooling fins, and the die-casting aluminum cooling fins are connected with the cooling pipelines in a spot welding mode. Die-casting aluminum heat conduction plates are installed in the cooling pipelines, penetrate through the cooling pipelines and are fixedly connected with the die-casting aluminum cooling fins, cooling fins are installed on the two sides of the die-casting aluminum heat conduction plates, the die-casting aluminum heat conduction plates are connected with the cooling fins in a spot welding mode, and water flow through holes are formed in the die-casting aluminum heat conduction plates.

Owner:NINGBO ZHOUCHI VEHICLE IND

Shockproof anti-jolt chassis of passenger car

InactiveCN102139614BImprove anti-vibrationEnhanced bump resistanceInterconnection systemsSimple componentWheel and axle

Owner:SHANGHAI INST OF TECH

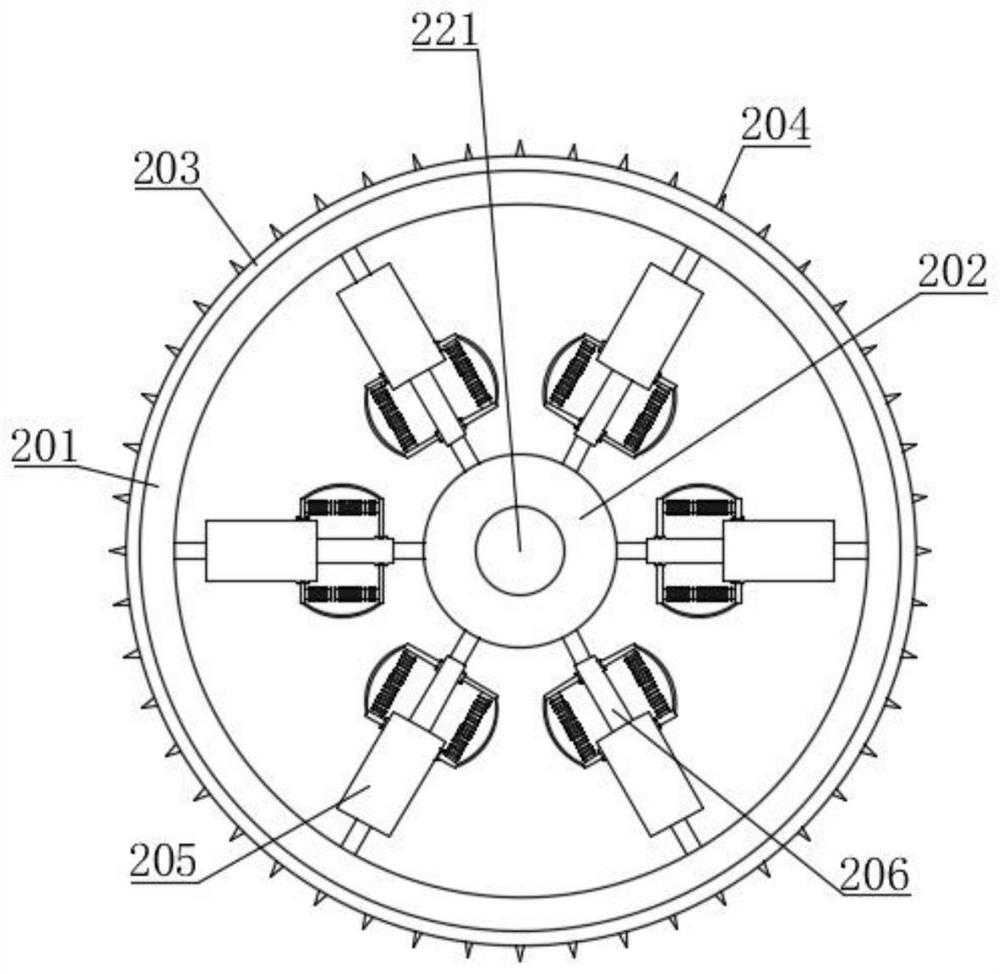

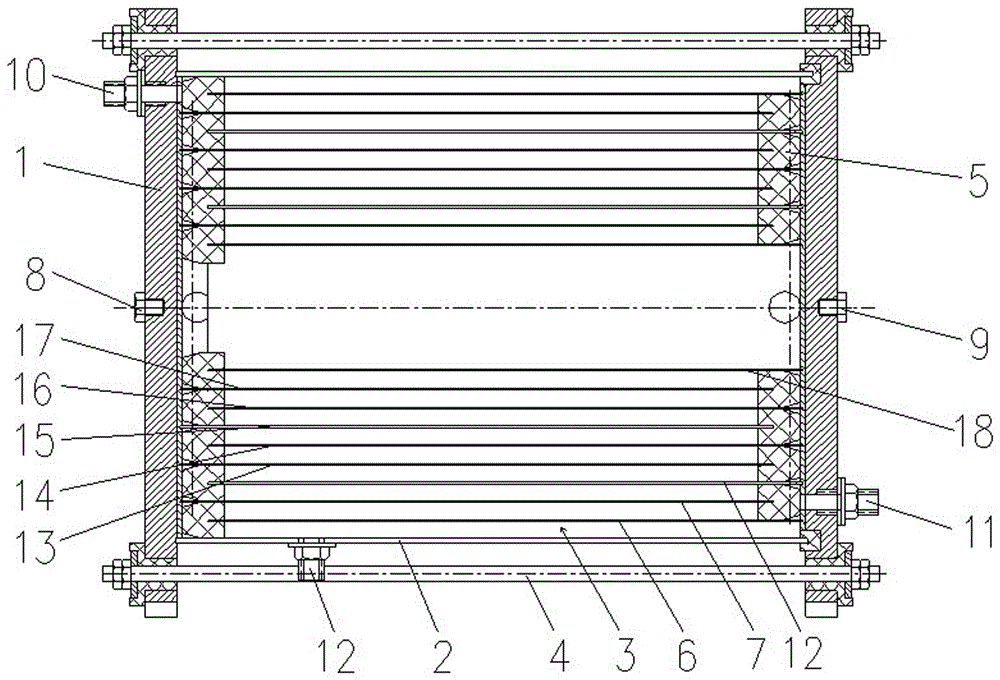

Hydrogen-oxygen generator for automobile or ship

InactiveCN105781806AOccurrence area is largeIncrease productionCellsInternal combustion piston enginesHydrogenEngineering

A hydrogen-oxygen generator for an automobile or a ship comprises two end face pole plates, an outer wall and a plurality of layers of inner cavity cylindrical pole plates. The two end face pole plates are arranged in parallel and arranged at the two ends of the outer wall and at the two ends of each layer of inner cavity cylindrical pole plate and screwed and fixed through a plurality of fastening bolts. The multiple layers of inner cavity cylindrical pole plates are clamped and fixed through a plurality of positioning blocks. Positioning blocks are arranged at the left end of the first layer of cylindrical pole plate, positioning blocks are arranged at the right end of the second layer of cylindrical pole plate, and in the similar way, the rear ends of the positioning blocks abut against the inner walls of the two end face pole plates. A positive pole is arranged at the center position of one end face pole plate, and a negative pole is arranged at the center position of the other end face pole plate. Each of the two end face pole plates is provided with a water inlet and an air outlet, and a dirt outlet is formed in the outer wall. According to the hydrogen-oxygen generator, the reaction efficiency, the anti-vibration performance and the anti-jolting performance are effectively improved.

Owner:李兵

Anti-bump car seat

ActiveCN109895662BPlay the role of anti-seismic and anti-turbulenceStrong anti-seismic and anti-turbulence abilityMovable seatsSeat suspension devicesCar seatAir pump

The invention discloses an anti-turbulence car seat, which can solve the problem that although the existing car seat is also equipped with an anti-turbulence shock-absorbing structure, the problem of insufficient ride comfort due to insufficient anti-turbulence ability exists, and the existing The car seat does not have the ability to independently select and adjust the anti-turbulence ability of the car seat according to different road sections, and can only perform anti-seismic and anti-turbulence according to the setting function of the shock-absorbing structure, so there is a defect of insufficient adaptability. It includes a chair body and a base located at the bottom of the base. Left and right base supports are respectively installed on the bottoms of the two ends of the base. Both ends of the base are provided with side supports connected to the bottom of the chair body. The bottom of the support is welded with a connecting seat; the structure of the left base and the right base is the same, and an air pump is installed at one end of the top of the left base and the right base, and the other end of the top of the left base and the right base is Each is equipped with a fixed seat.

Owner:湖南长丰汽车沙发有限责任公司

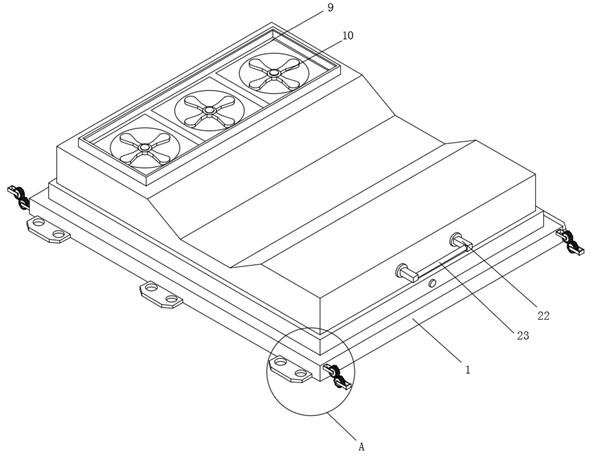

Vehicle-mounted battery for new energy electric vehicle

InactiveCN112172502ATo achieve the purpose of heat dissipationExtended service lifeElectric propulsion mountingPropulsion by batteries/cellsElectrical batteryIn vehicle

The invention discloses a vehicle-mounted battery for a new energy electric vehicle in the field of new energy vehicles; the vehicle-mounted battery comprises a fixed frame and a heat dissipation control system, a battery fixing box is fixedly connected to the interior of the fixed frame, and two partition plates are fixedly connected to the inner wall of the battery fixing box; the two partitionplates divide the interior of the battery fixing box into three battery containing cavities, protection pads are arranged in the battery containing cavities, and vehicle-mounted batteries are arrangedon the upper surfaces of the protection pads. The temperature measuring instrument transmits information to a wireless signal transmitter, then the wireless signal receiver transmits signals to a central processing unit in a control host, the central processing unit transmits the signals to a cooling fan, and the cooling fan is started to circulate air inside and outside the battery fixing box; and circulation of hot air in the battery fixing box is promoted, so that the purpose of dissipating heat of the vehicle-mounted battery is achieved, the service life of the vehicle-mounted battery isprolonged, and the situation that the service life of the vehicle-mounted battery is shortened due to over-high temperature is prevented.

Owner:景宁唯雅玩具设计工作室

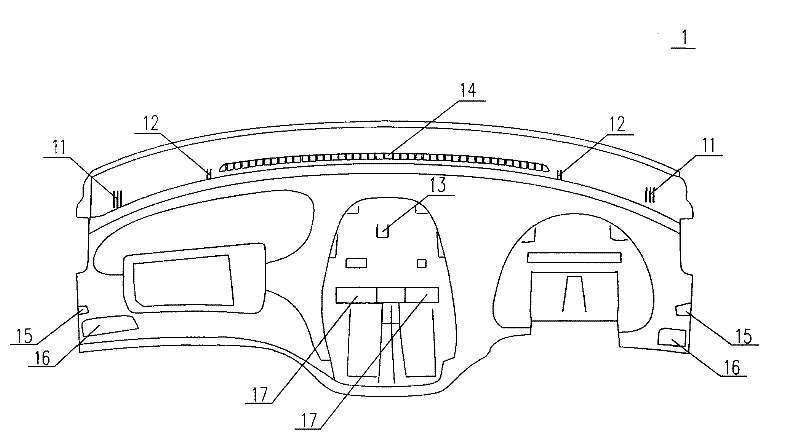

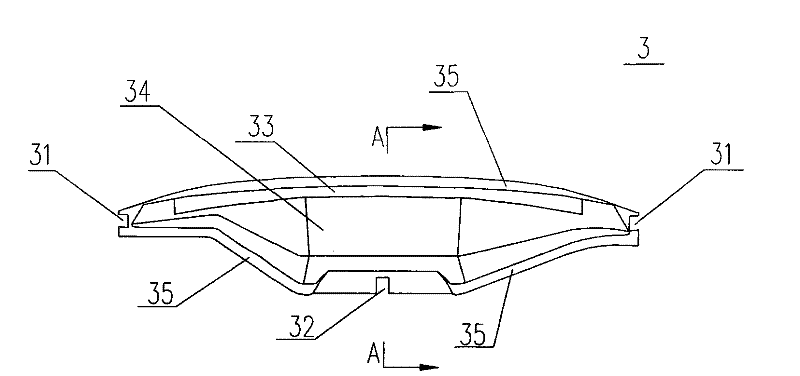

Vehicle instrument panel and manufacturing method thereof

ActiveCN101659216BHigh strengthEnhanced bump resistanceAir-treating devicesVehicle heating/cooling devicesDashboardEngineering

The invention relates to a vehicle instrument panel and a manufacturing method thereof, wherein the vehicle instrument panel comprises an instrument panel body extending along a width direction of the vehicle and an air duct plate arranged on the instrument panel body, wherein the air duct plate is formed with a plurality of ventilation openings and airflow channels corresponding to the pluralityof ventilation openings; an air duct distributing plate is installed between the instrument panel body and the air duct plate; an inner surface of the instrument panel body is provided with a first welding part and a second welding part; the air duct distributing plate is welded on the first welding part; and the air duct plate is welded on the second welding part. The instrument panel body is welded with the air duct distributing plate and the air duct plate by means of welding; and the welded instrument panel body is formed into a box structure in whole, thereby largely improving the whole strength of the instrument panel and largely improving the bumpiness resistance and service life of the instrument panel.

Owner:BEIQI FOTON MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com