Hydrogen-oxygen generator for automobile or ship

A generator and marine technology, applied in engine components, combustion engines, machines/engines, etc., can solve the problems of air intake pipe tempering, engine cylinder pulling, difficult vehicle and ship implementation, etc., to improve octane number, improve corrosion resistance, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

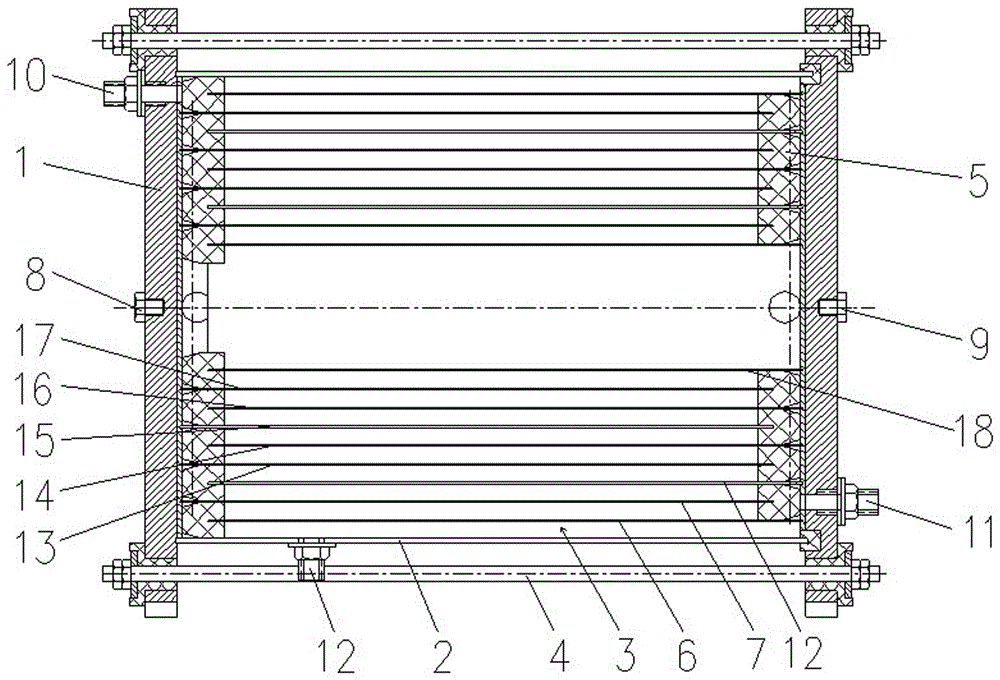

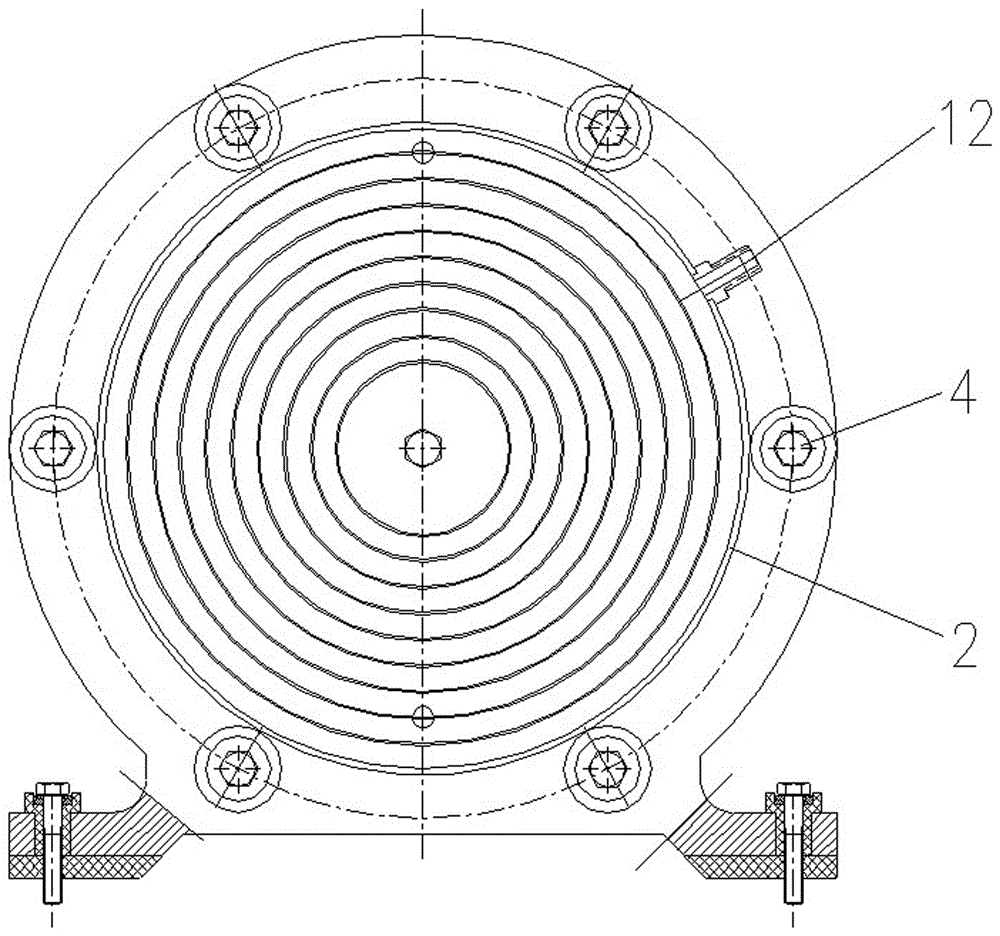

[0021] A hydrogen-oxygen generator for vehicles or ships, comprising two end-face plates 1, an outer wall 2 and an inner cavity multi-layered cylindrical plate 3, the two end-face plates 1 are arranged in parallel, the outer wall 2 and the inner cavity multi-layered cylindrical plate The plates 3 are arranged perpendicularly to the end face plates 1 respectively, the outer wall 2 is set outside the inner cavity multi-layer cylindrical plate 3, and the two end face plates 1 are arranged at both ends of the outer wall 2 and the inner cavity multi-layer cylindrical plate 3, Tighten and fix by multiple fastening bolts 4;

[0022] The multi-layer cylindrical pole plates 3 in the inner cavity are clamped and fixed by a plurality of positioning blocks 5, and a plurality of positioning blocks 5 are arranged on the set position of the left end surface of the first layer of cylindrical pole plates 6, and the second layer of cylindrical pole plates 6 A plurality of positioning blocks 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com