Middle-sized bulk container

A medium bulk container and frame technology, which is applied in the field of packaging containers, can solve the problems of complicated manufacturing procedures, falling off welding points, and easily damaged round tubes, etc., and achieves the effect of improving the anti-bump performance, saving production costs and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

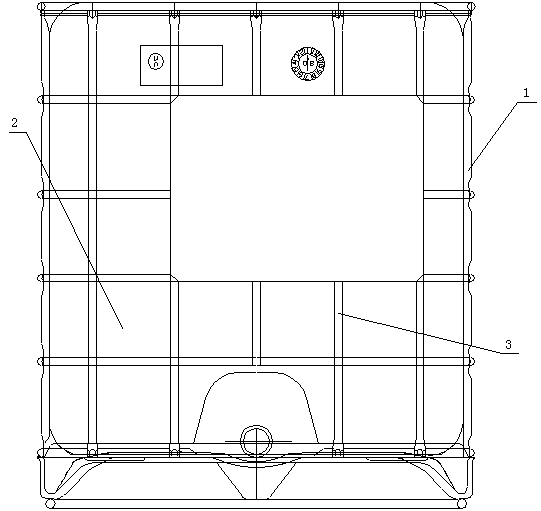

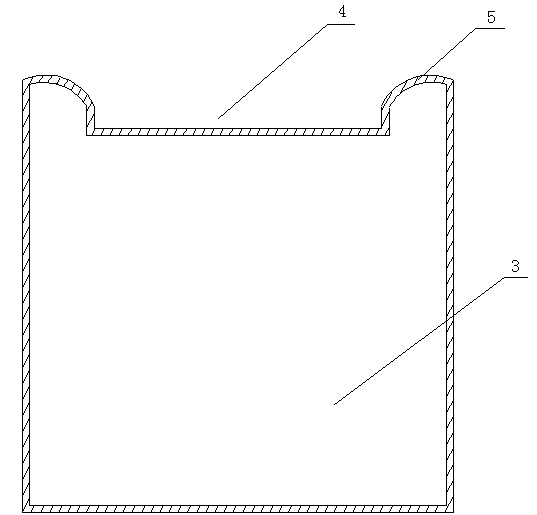

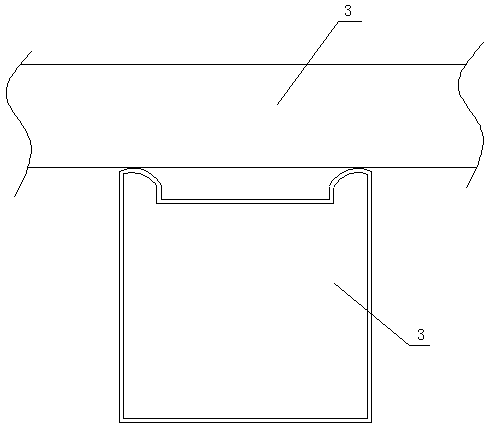

[0013] Such as Figure 1 to Figure 3 , the present invention relates to an intermediate bulk container, comprising a frame 1 and an inner barrel 2, the inner barrel 2 is placed in the frame 1, the frame 1 is welded by several horizontally and vertically arranged square tubes 3, the square tubes 3 A groove 4 is provided in the middle of the top surface of the groove 4, and the two sides of the groove 4 are raised to form a welding surface 5, and the welding surface 5 is used for welding the square tubes arranged horizontally and vertically.

[0014] The frame of this medium-sized bulk container is composed of several square tubes. The top surface of the square tubes is provided with a welding surface, which can easily weld the horizontally and vertically arranged square tubes together, eliminating the need to squeeze the welding points to form local depressions. Not only the process is simple, but also the production cost is saved. Moreover, the tensile, anti-drop, and anti-tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com