Modular adsorption bed structure

An adsorption bed and modular technology, applied in the direction of absorbent/adsorbent, adsorption machine, refrigeration and liquefaction, etc., can solve the problems of limited engine exhaust waste heat recovery, inapplicability, and bulky, etc., to increase strength and resistance The effects of bumpiness, realization of modularization, and improvement of system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

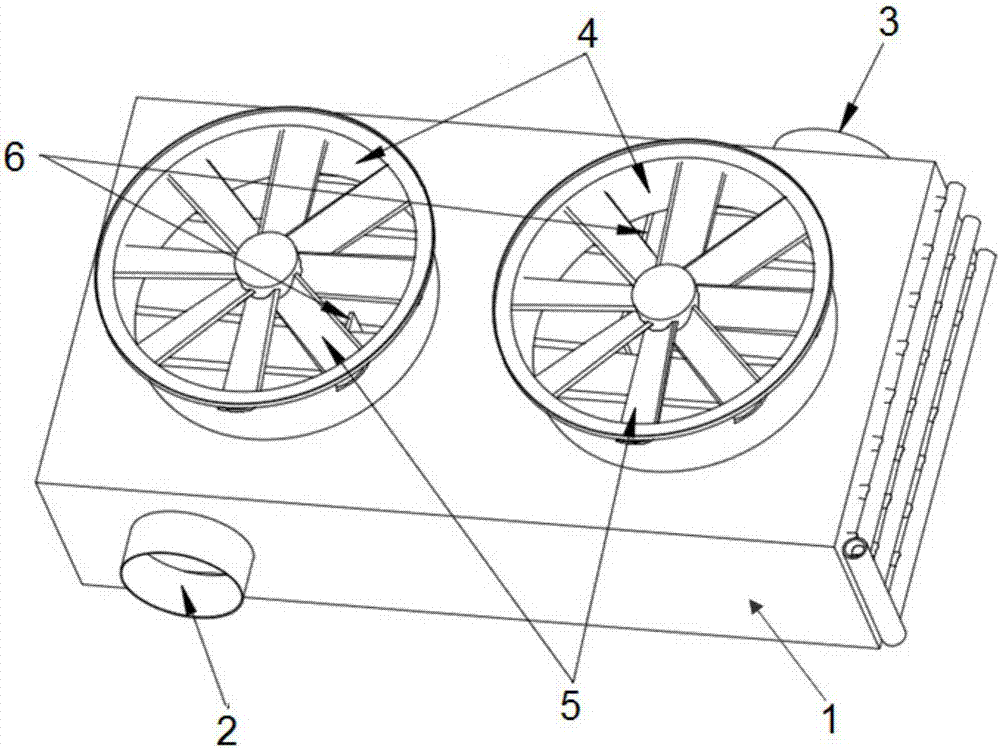

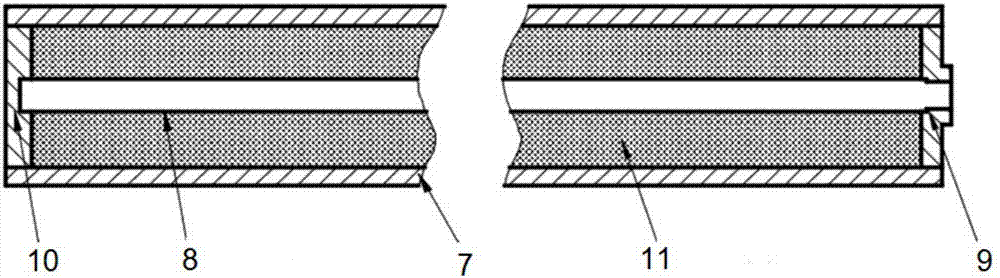

[0015] Examples of the present invention are Figure 1 to Figure 3 As shown, the present invention includes an adsorption bed shell 1, several unit pipes, a flue gas inlet 2, a flue gas outlet 3, a cooling air inlet 4, a cooling fan 5, a baffle plate 6, and a gate valve. 7. Inner metal mesh pipe 8 with spring, open front end cover 9, sealed rear end cover 10 and multi-salt composite adsorbent 11 filled in between, the flue gas inlet 2 and flue gas outlet 3 are arranged on the side wall of the adsorption bed shell 1 Above, the cooling air inlet 4 and the cooling fan 5 are arranged on the upper wall of the adsorption bed shell 1 .

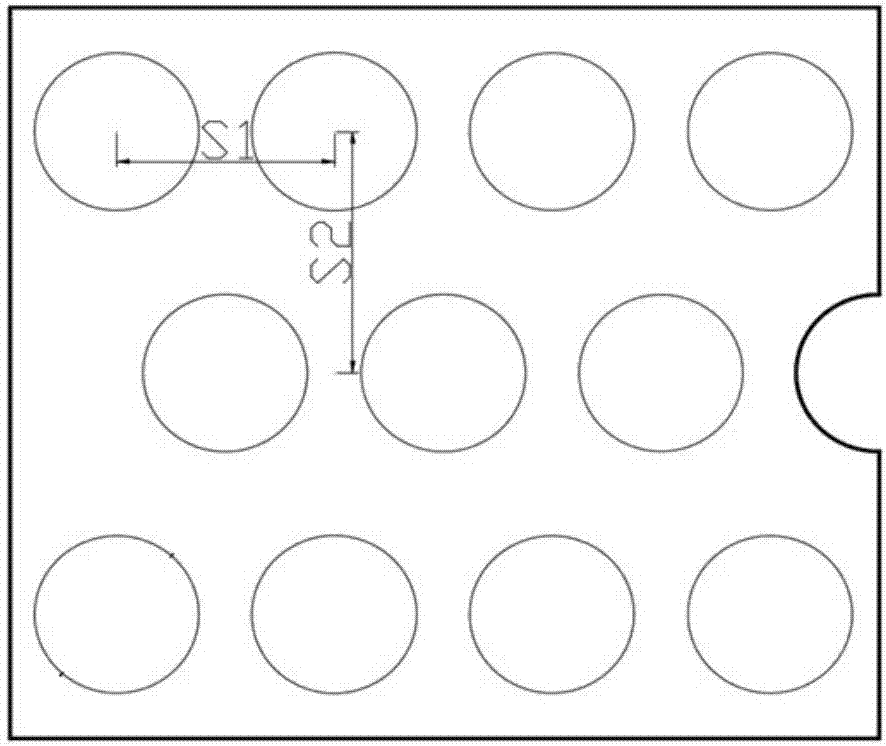

[0016] The shell 1 of the adsorption bed is provided with the inlet and outlet of the external heat source and cold source. The unit tubes are arranged inside the shell of the adsorption bed in a fork row, and the flow direction of the external medium is perpendicular to the unit tubes. The metal mesh tube 8, the open front end cover 9, the sealed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com