Vehicle instrument panel and manufacturing method thereof

A technology for automobile instrument panels and manufacturing methods, which is applied in the direction of instrument panels, vehicle parts, upper structure sub-assemblies, etc., and can solve the problems of low use strength, easy loosening of the air duct, and unstable connection between the main body of the instrument panel and the air duct of the instrument panel and other problems, to achieve the effects of high use intensity, stable air duct connection, improved anti-turbulence and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

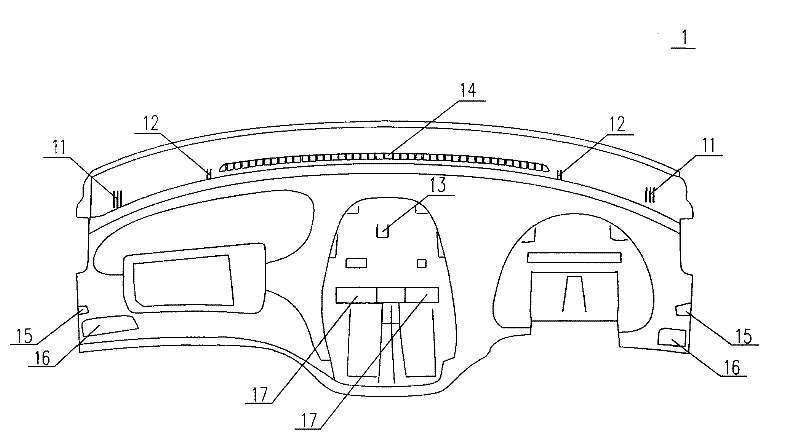

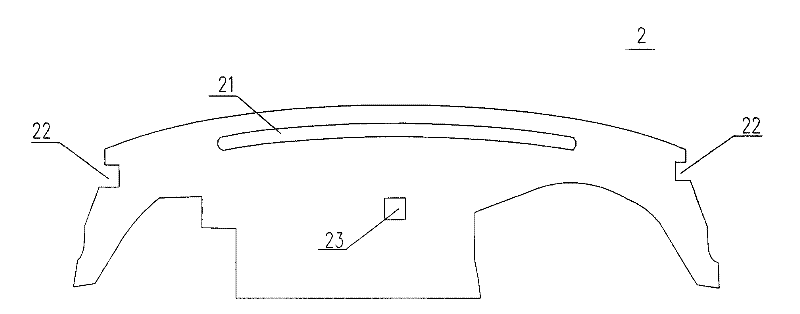

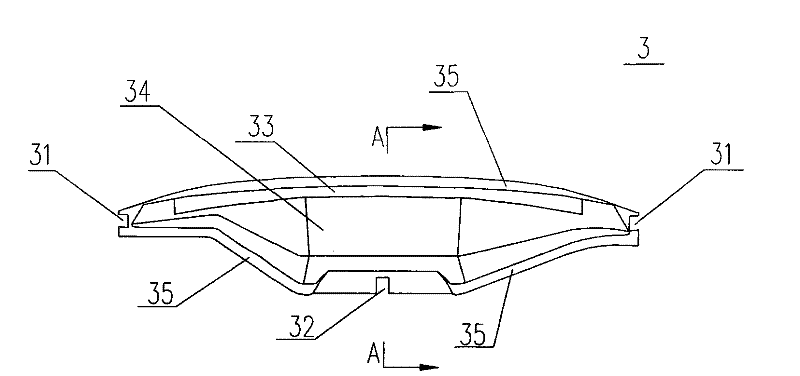

[0075] refer to Figure 9 and Figure 10 , the automobile instrument panel 100 of the present invention mainly includes an instrument panel body 1 , a heat insulating sponge 2 , an air duct distribution plate 3 and an air duct plate 4 . Among them, the instrument panel body 1 , the air duct distribution plate 3 and the air duct plate 4 are all made of plastic through injection molding process. The heat insulation sponge 2 and the air duct distribution plate 3 are arranged between the instrument panel body 1 and the air duct plate 4. Of course, the automobile instrument panel also includes panels, decorative panels, instrument covers, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com