A Composite Oil Phase Used to Prepare Bulk Emulsion Explosives with Upward Hole Charges

A technology for compounding oil phase and emulsion explosives, which is applied in explosives, non-explosive/non-thermal agent components, offensive equipment, etc., can solve the problem of short storage period of bulk emulsion explosives, the phenomenon of upward hole charging dropping, and poor anti-turbulence ability. and other problems, to achieve the effect of excellent anti-turbulence performance, suitable fluidity, and high working ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The following raw materials were weighed in parts by mass: No. 5 white oil: 36 parts, KN4010: 30 parts, polymer ester emulsifier: 30 parts, polyisobutylene: 2 parts, stearic acid: 2 parts. Prepared in the following manner:

[0051] First, heat No. 5 white oil, KN4010, and high-molecular ester emulsifier in a separate melting tank to 60-70°C, then pump them into the reaction kettle sequentially through the oil pump and electronic scale according to the proportioning requirements, stir, After heating up to 80°C, add the measured polyisobutene and stearic acid, and continue to stir for about 30 minutes. After the polyisobutene and stearic acid are fully melted, the finished product is obtained after filtration.

Embodiment 2

[0053] No. 10 white oil: 38 parts, KN4006: 27 parts, polymer ester emulsifier: 28 parts, S-80: 2.5 parts, polyisobutylene: 2.5 parts, palmitic acid: 2 parts. Prepared in the following manner:

[0054] First, heat No. 10 white oil, KN4006, polymer ester emulsifier, and S-80 in a separate melting tank to 60-70°C, and then pump them into the reaction kettle sequentially through the oil pump and electronic scale according to the ratio requirements Inside, after stirring and raising the temperature to 85°C, add the measured polyisobutene and palmitic acid, and continue to stir for about 30 minutes. After the polyisobutene and palmitic acid are fully melted, the finished product is obtained after filtration.

Embodiment 3

[0056] No. 15 white oil: 37.5 parts, KN4006: 20 parts, KN4010: 10 parts, polymer ester emulsifier: 28 parts, polyisobutylene: 2.5 parts, stearamide: 2 parts. Prepared in the following manner:

[0057] First, heat No. 15 white oil, KN4006, KN4010, and high molecular weight ester emulsifier in a separate melting tank to 60-70°C, then pump them into the reaction kettle sequentially through the oil pump and electronic scale according to the ratio requirements. After stirring and raising the temperature to 90°C, add the measured polyisobutene and stearamide, and continue stirring for about 30 minutes. After the polyisobutene and stearamide are fully melted, the finished product is obtained after filtration.

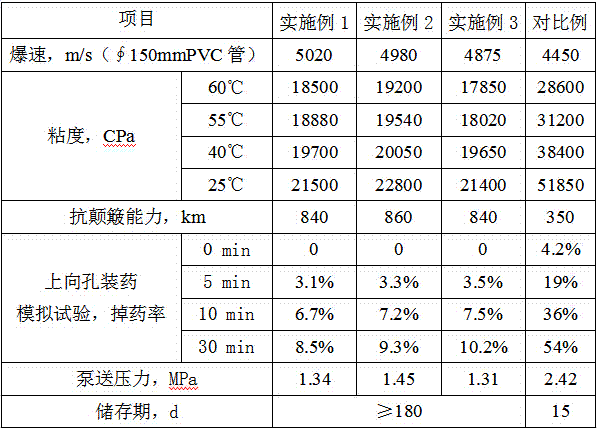

[0058] The water-resistant composite oil phase of the above three groups of embodiments is used as a raw material to prepare bulk emulsion explosives according to the formula of bulk emulsion explosives, according to ammonium nitrate: water: composite oil phase = 75.8: 18: 6.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com