Spring nut with good anti-loosening performance

A spring nut, anti-loosening technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of poor anti-loosening performance, troublesome installation, easy damage to washers, etc., and achieve the effect of enhancing anti-vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

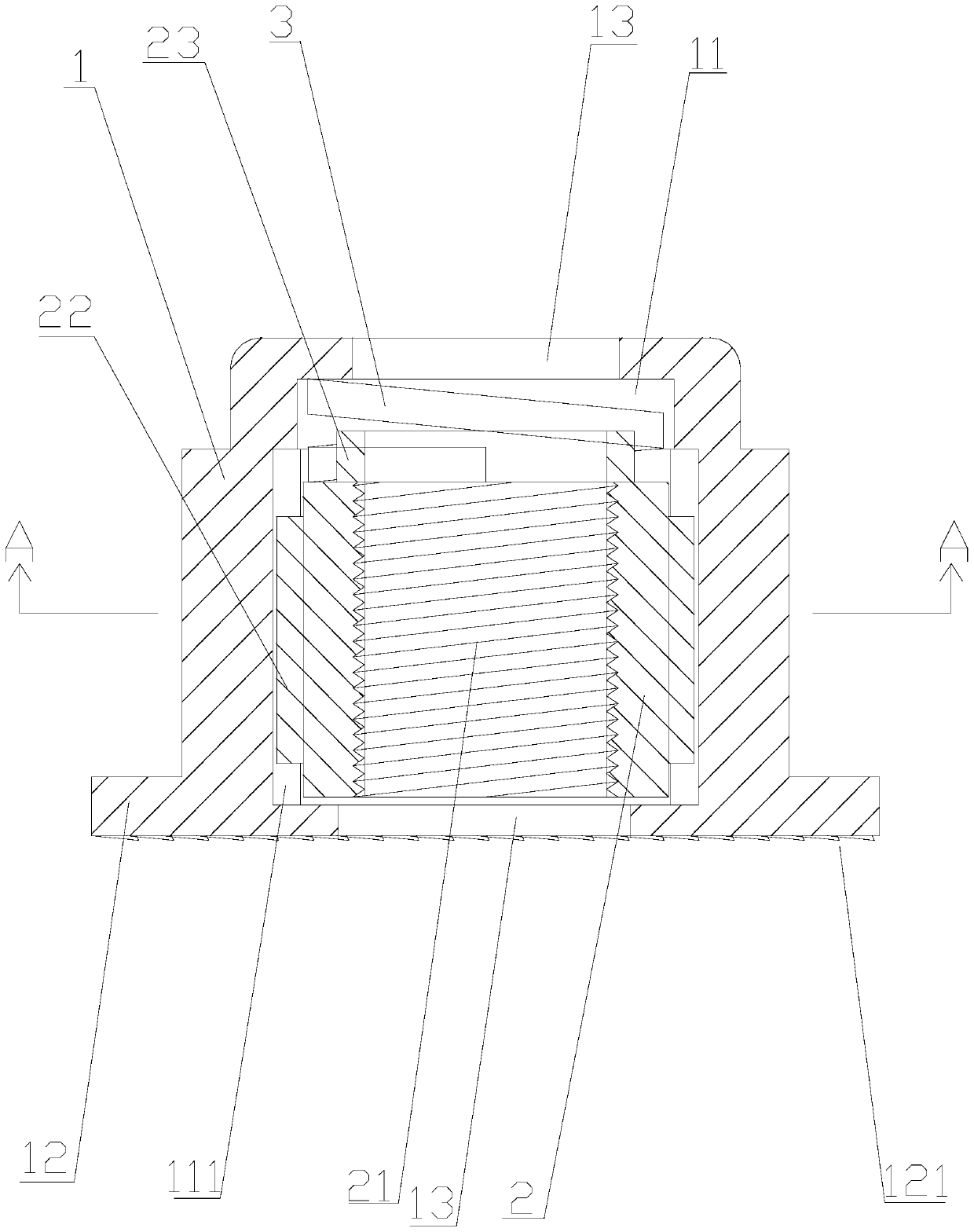

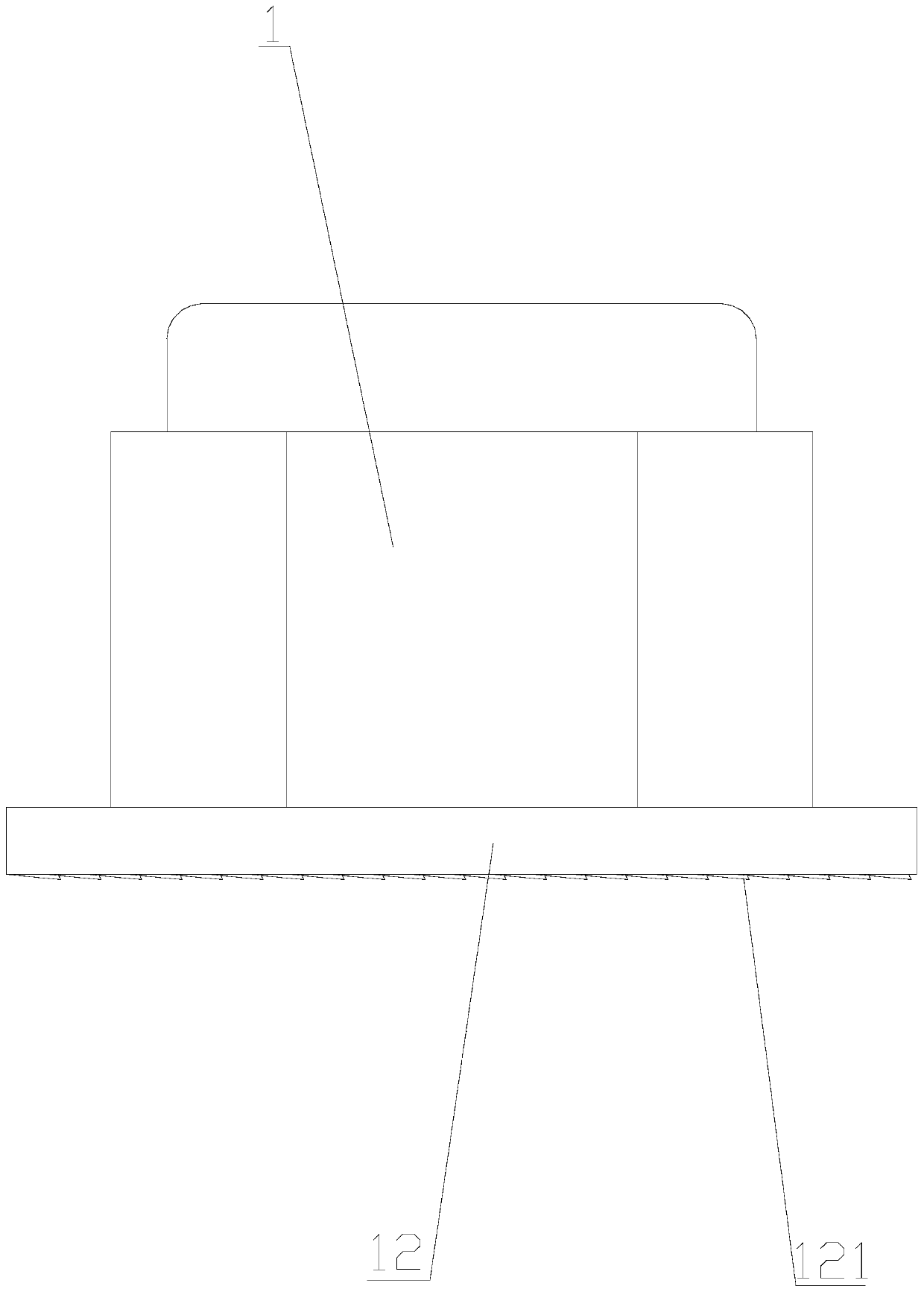

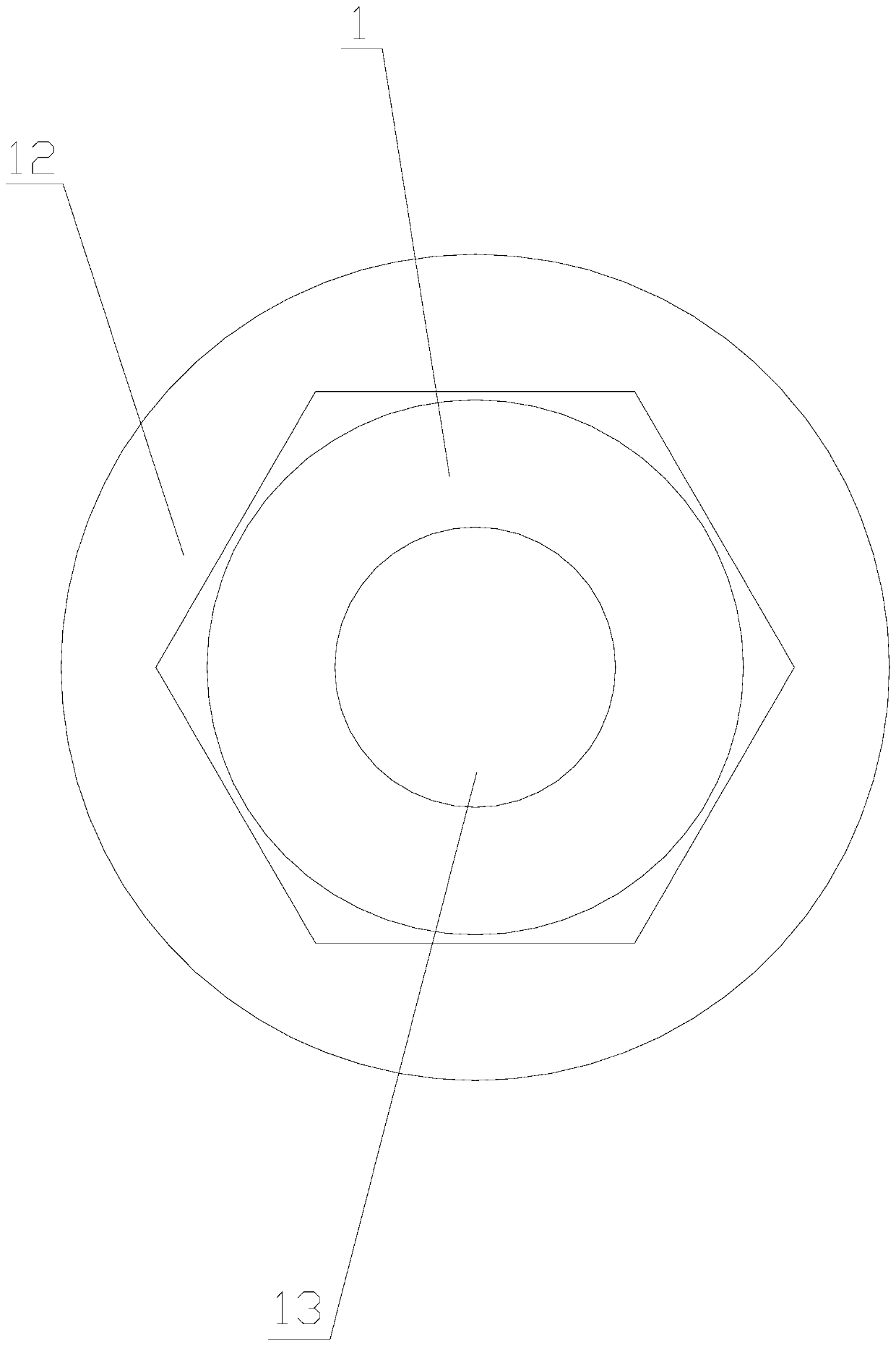

[0023] refer to figure 1 , figure 2 , image 3 and Figure 4 , a spring nut with good anti-loosening performance according to the present invention includes a nut body 1, an inner nut 2, and a spring washer 3. The nut body 1 is provided with an inner nut installation cavity 11 that can cooperate with the inner nut 2. The inner nut 2 is vertically arranged in the inner nut installation cavity 11 and is slidably connected up and down with the inner nut installation cavity 11. The center of the inner nut 2 is vertically provided with a threaded through hole 21, and the upper end of the inner nut 2 is A spring washer 3 is provided, and the upper end of the spring washer 3 cooperates with the upper end top wall of the inner nut installation chamber 11, and the inner nut 2 is supported downward by the inner nut 2 when the spring washer 3 is in a free state, and the inner nut 2 The side wall of the outer ring is vertically provided with several limit baffles 22, and the inner nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com