Exchangeable blade type center cutter for shield machine

A center knife and shield machine technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of diffuse wear of the center knife arm, increase construction cost, non-replaceable blades, etc., to improve wear resistance, Avoid the waste of resources, the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The principle structure and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

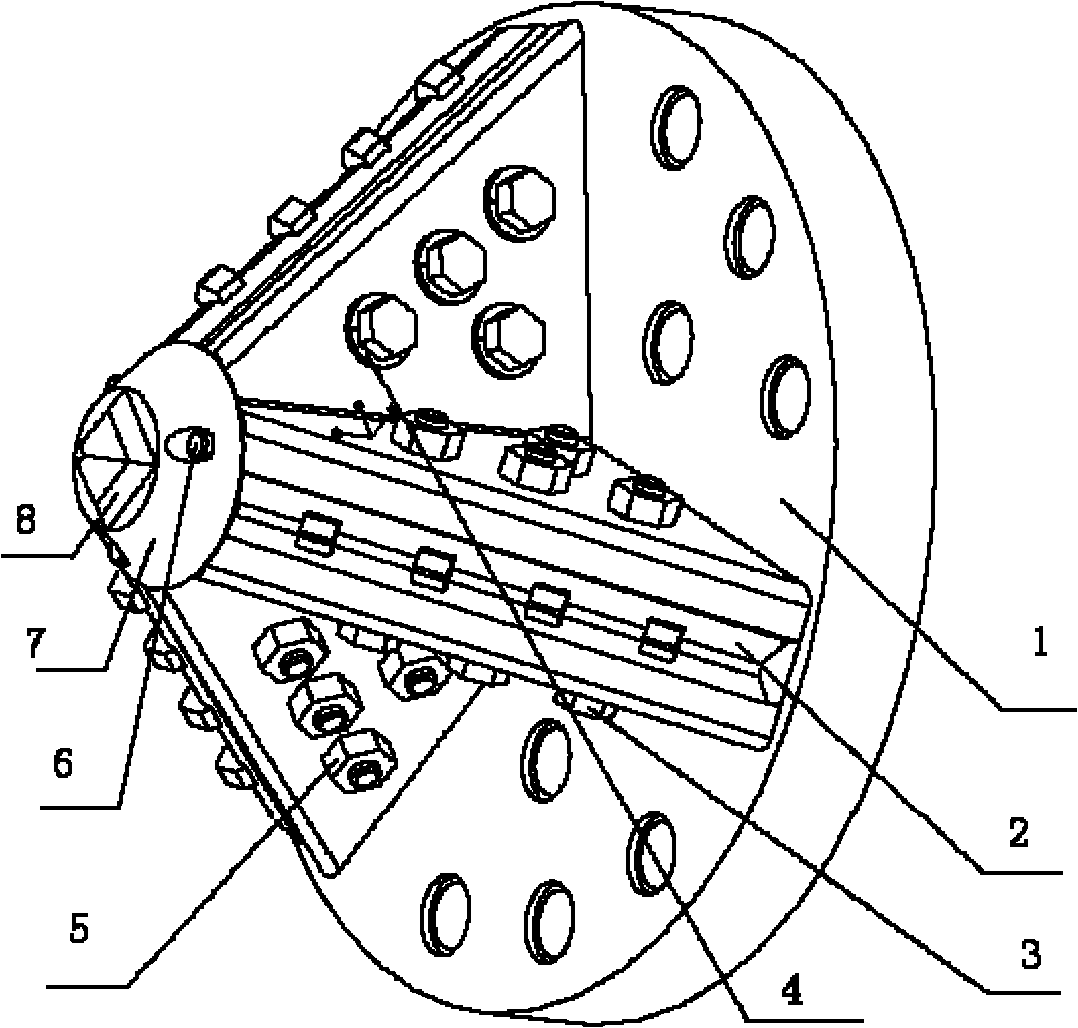

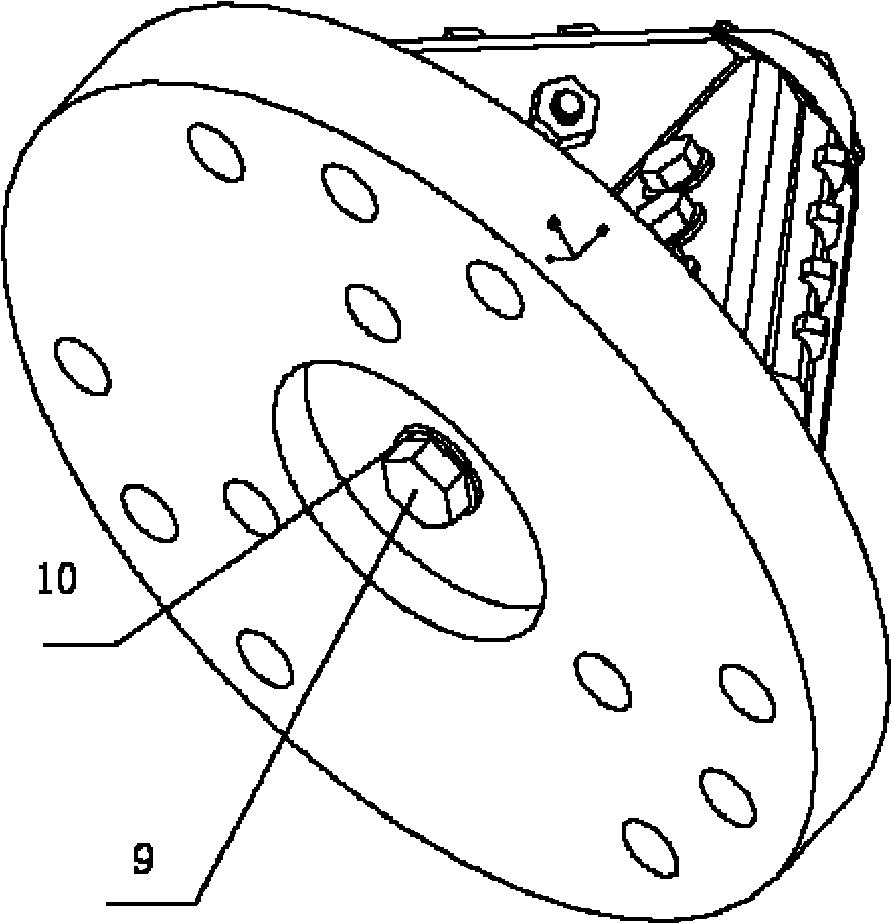

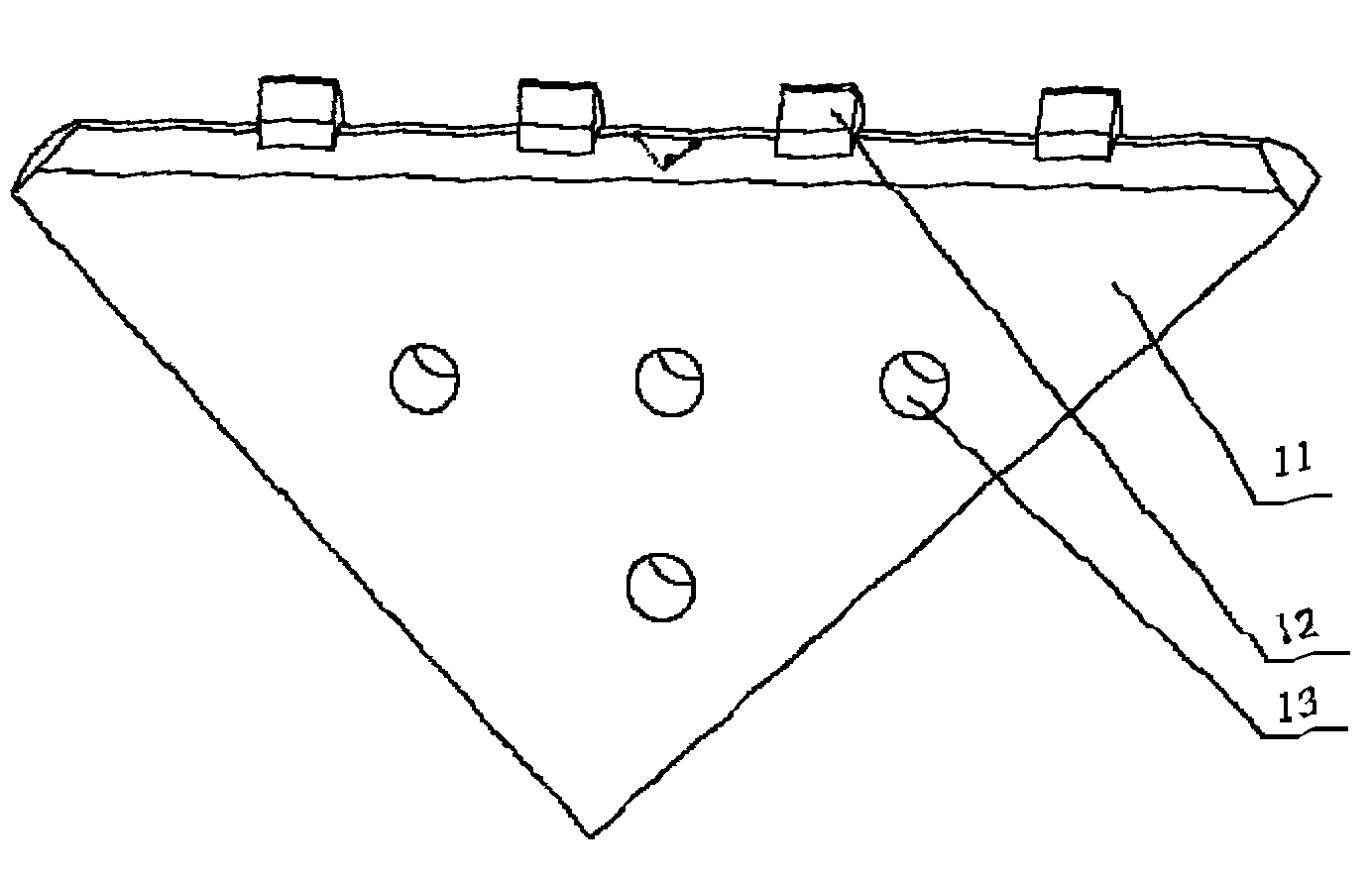

[0014] The present invention provides a replaceable blade-type central knife mainly consisting of a blade seat 1, a blade (including side blades 2 and a central knife block 8) and a cemented carbide block (a side blade cemented carbide block 12 and a central knife block cemented carbide block) 14) consists of three parts. The hard alloy block is connected to the blade by special welding to form a non-detachable weld, which has high impact resistance, wear resistance and vibration resistance. On the one hand, a number of positioning holes 13 are processed on the side blade 11, and the side blade is positioned on the corresponding knife of the blade seat through bolt connection (as shown in the accompanying drawings, the bolt 3, the gasket 4, the nut 5 and the bolt connection hole 21) On frame 18, form knife arm. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com