A kind of aerosol fire extinguishing device and assembly method

A fire extinguishing device and aerosol technology, applied in fire rescue and other directions, can solve the problems of poor seismic performance, failure, and inability to ensure consistency, and achieve the effect of improving sealing and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

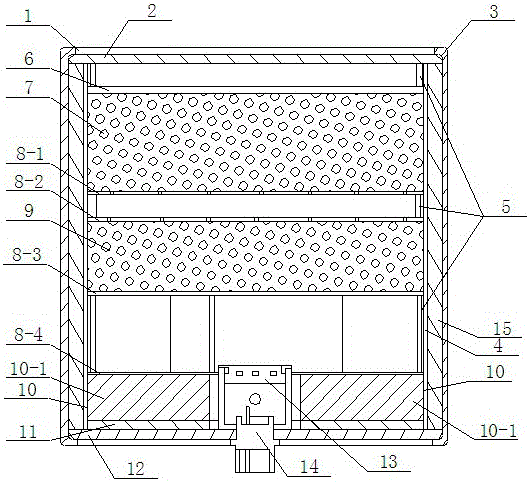

[0009] see figure 1 , the specific embodiment adopts the following technical scheme: it includes the shell 1, the spout plate 2, the sealing plate 3, the inner cylinder 4, the spacer ring 5, the orifice plate 6, the coolant 7, the first net plate 8-1, the second net Plate 8-2, third net plate 8-3, fourth net plate 8-4, flame suppressant 9, fire extinguishing agent 10, bottom heat insulation layer 11, bottom plate 12, starting charge pack 13, connector 14, shell insulation The heat layer 15; the spout plate 2 is bonded to the flange at the upper end of the casing 1 through a high-temperature sealant; the bottom plate 12 is bonded to the flange at the lower end of the casing 1 through a high-temperature sealant; the inside of the spout plate 2 is provided with a sealing film 3, The inner cylinder 4 is arranged on the inner side of the shell 1, the shell insulation plate 15 is arranged between the shell 1 and the inner cylinder 4, the orifice plate 6 is arranged on the upper side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com