Robot automatic spray system used for quick drying mould coating

An automatic spraying and quick-drying paint technology, applied in the field of robots, can solve the problems of the thickness, uniformity and consistency of the isolation film cannot be guaranteed, the spraying distance and spraying time cannot be guaranteed, etc., to achieve a high degree of automation and flexible movement. , the effect of improving flexibility and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

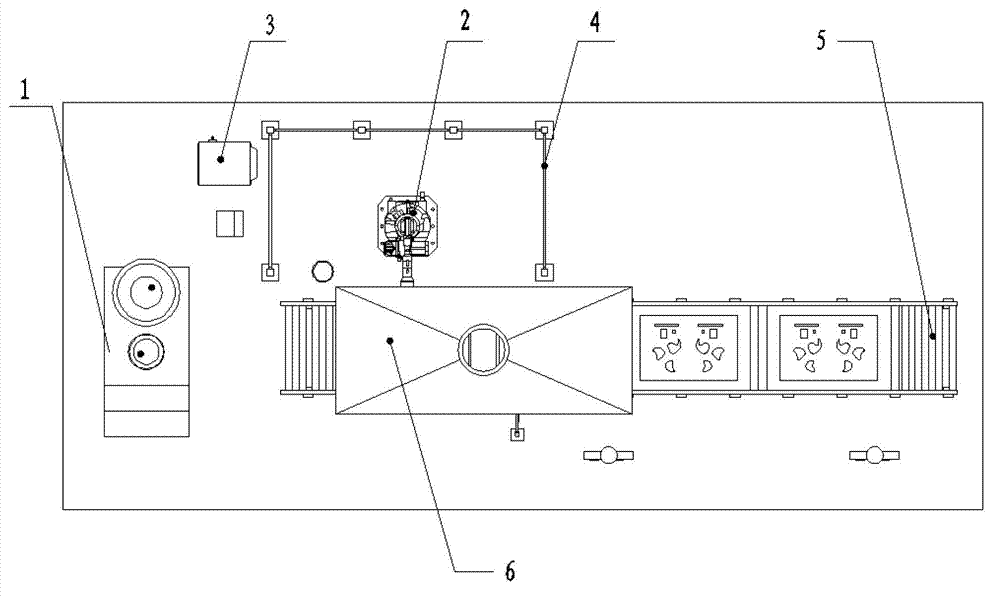

[0030] Please refer to figure 1 , the present invention provides a robot 2 automatic spraying system 1 for mold quick-drying paint, which includes a robot 2, a robot control cabinet 3, a mold conveying roller table 5, an exhaust hood 6 and an automatic spraying system 1.

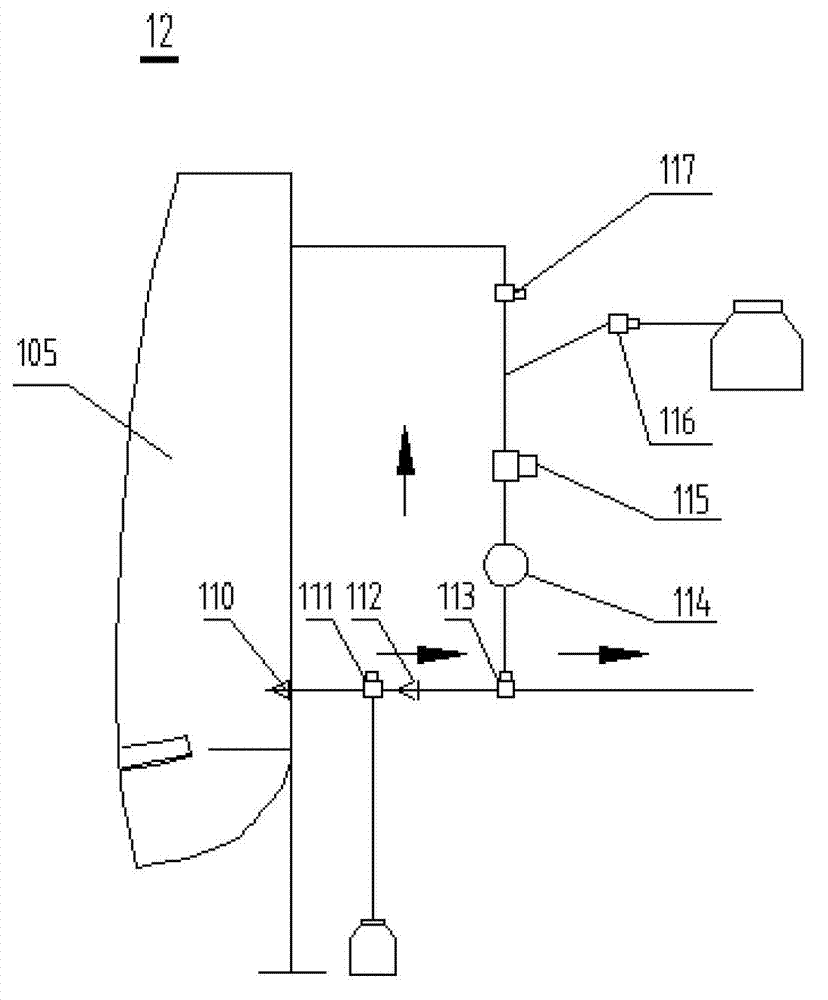

[0031] Please refer to figure 1 , the robot 2 is arranged on the side of the mold conveying roller table 5 , and a safety fence 4 is provided on the outer periphery of the robot 2 . The robot 2 receives the command from the robot control cabinet 3 to start the automatic spraying system 1 to work. The automatic spraying system 1 includes a paint stirring module 11 , a circulating filter module 12 , a spraying module 13 and a cleaning module 14 .

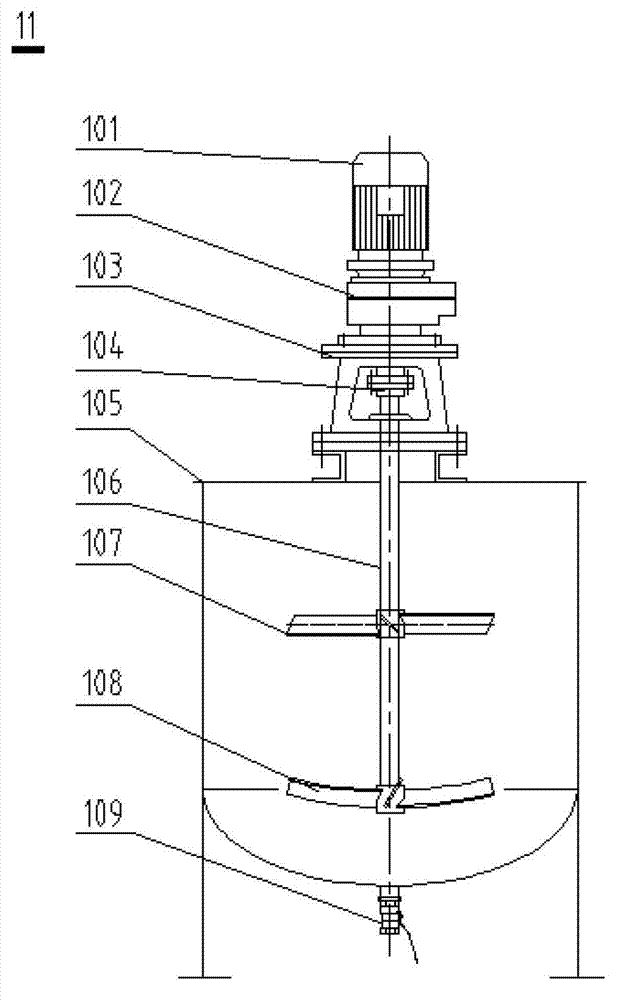

[0032] Please refer to figure 2 , the paint stirring module 11 includes a frequency conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com