OLED flexible laminating device and laminating process thereof

A flexible bonding and bonding technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of reducing bonding air bubbles, FILM diaphragm position offset, and easy occurrence of air bubbles, etc., to prevent Effect of detachment, reduction of bonding air bubbles, and improvement of bonding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing:

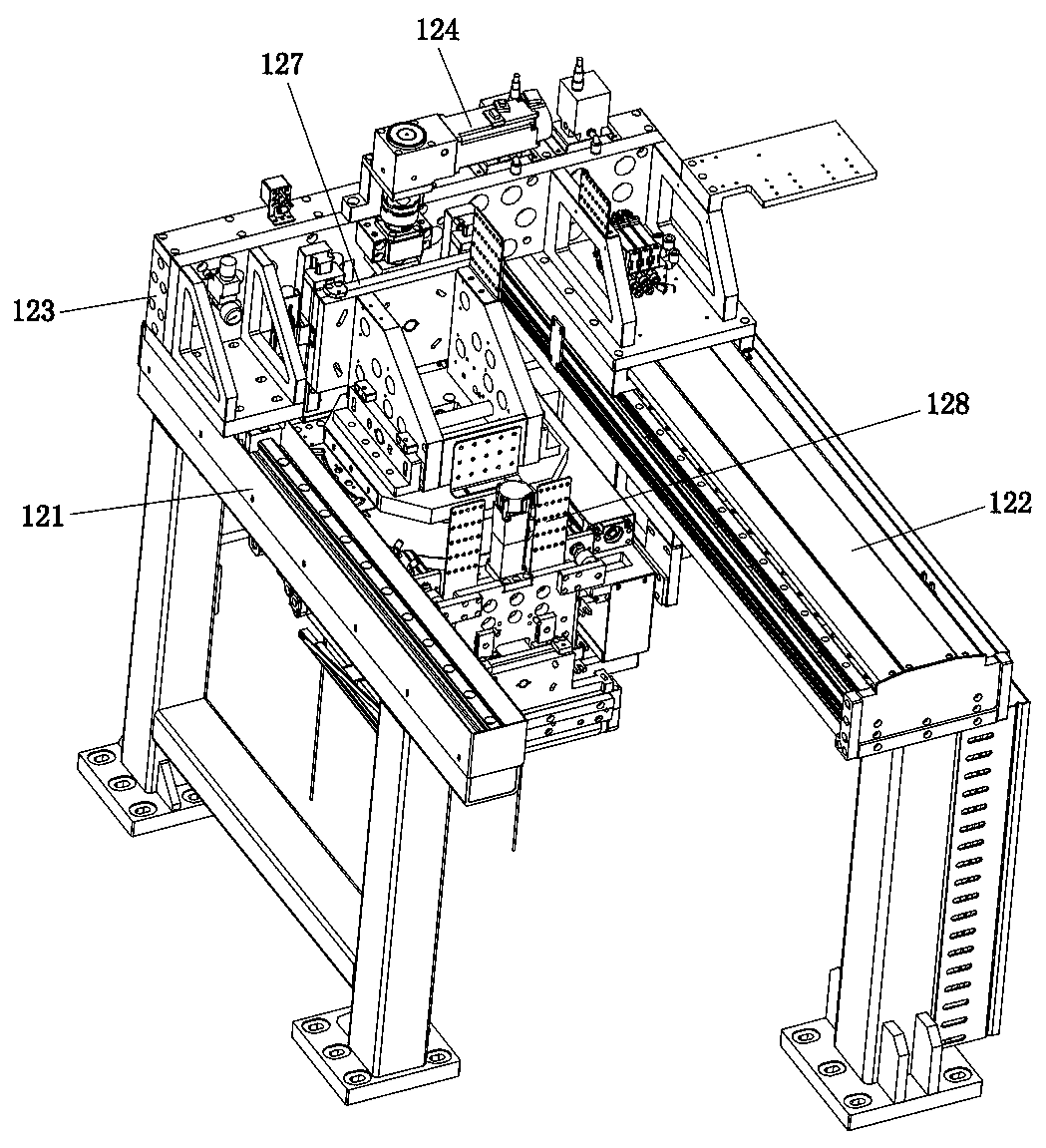

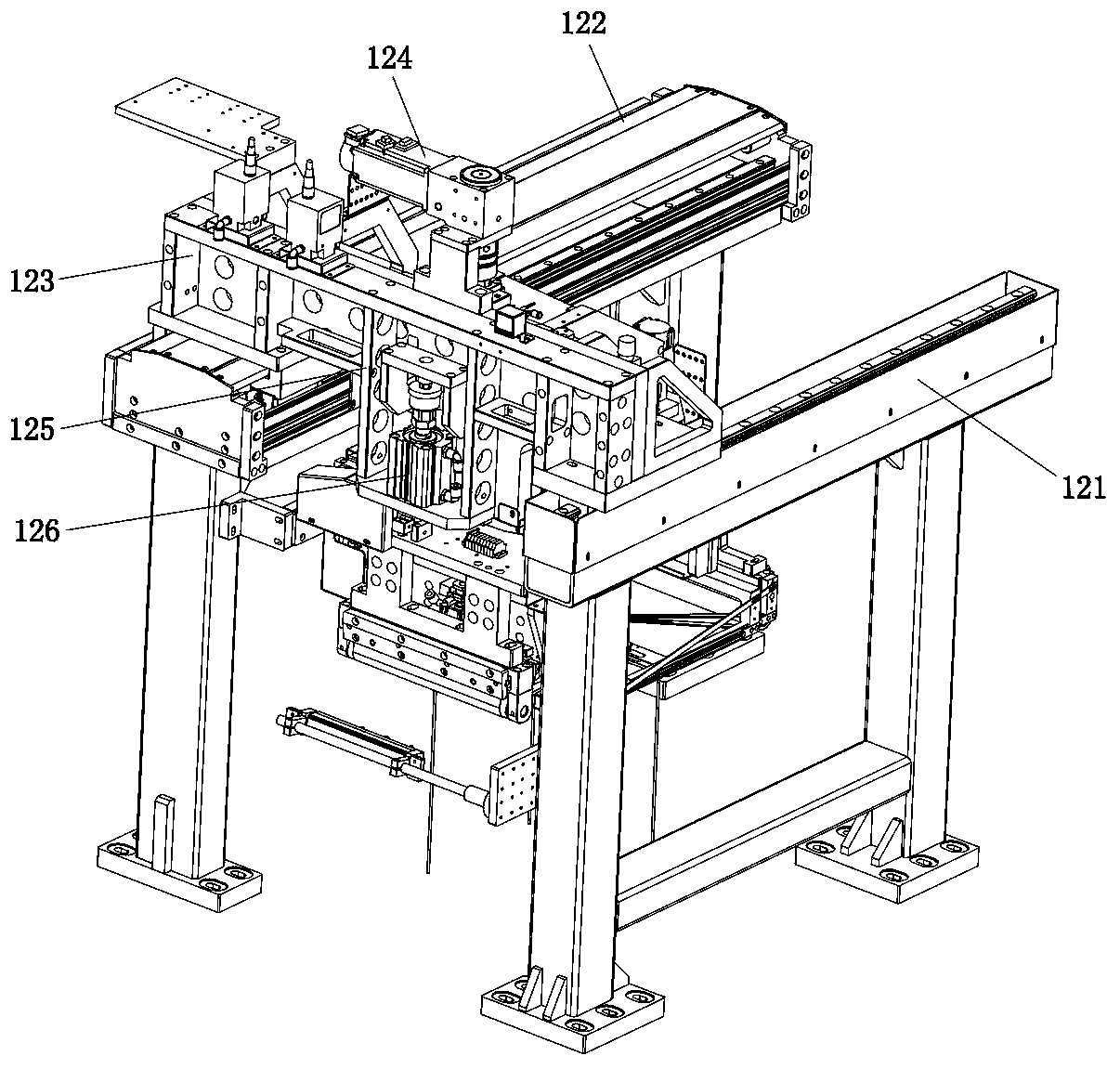

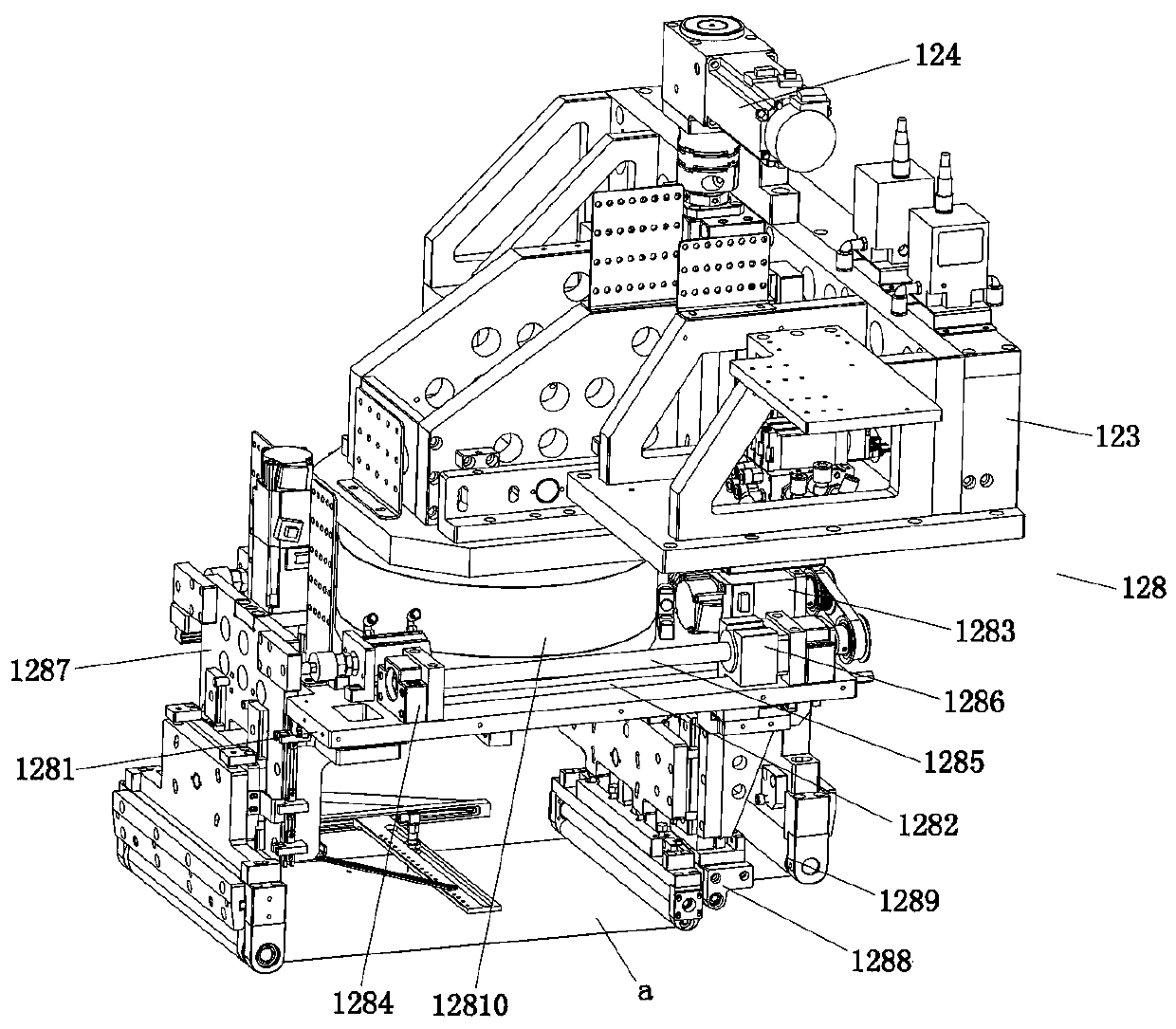

[0035] Such as Figure 1 to Figure 10 As shown, the technical scheme adopted by the present invention is as follows: a kind of OLED flexible laminating device is arranged in the soft-to-soft laminating machine, and moves the FILM diaphragm to the soft-to-soft lamination by adhering the FILM diaphragm after tearing the film. Take pictures at the CCD mechanism of the machine, and after correcting the FILM diaphragm, make the FILM diaphragm and OLED diaphragm continuously complete the bonding; including the bonding bracket 121, the bonding linear module 122, the bonding linear slide 123, the bonding Fit lifting motor 124, fit mounting seat 125, fit weight-reducing cylinder 126, fit lifting seat 127 and fit head 128, wherein, above-mentioned fit bracket 121 is arranged on the rear end of frame, fit bracket 121 includes parallel There are two frames arranged at intervals, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com