A processing method for fully laminating liquid crystal displays

A liquid crystal display and processing method technology, applied in chemical instruments and methods, instruments, lamination devices, etc., can solve problems such as insufficient softness, low yield of finished products, and many bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

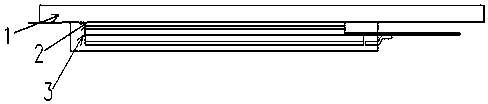

[0015] The present invention is achieved in this way, a method for processing a fully laminated liquid crystal display. For the TFTLCM in the full lamination module, OCA optical glue 2 is first attached to the surface of the upper polarizer, pre-baked, and after degassing under pressure, the CTP1 and TFTLCM3 are pre-laminated in alignment with a jig, and then Laminating machine is used for lamination operation, and after degassing by heating and pressure in degassing furnace, it becomes a finished product.

[0016] Specifically, TFT LCM3 first sticks OCA2 glue on the surface of the upper polarizer.

[0017] Specifically, after the TFT LCM3 is bonded to the OCA2, the defoaming operation is performed under high temperature and high pressure.

[0018] Specifically, after the TF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com