Manufacturing method for prestressed chilled cast iron roll

A technology of chilled cast iron and a production method, which is applied in the field of prestressed chilled cast iron roll production, can solve the problems of high material cost and manufacturing cost, uneven plasticizing sheet production, poor effect, etc., to achieve sheet quality assurance, eliminate Risk of roll breakage, effect of improving chilled cast iron roll structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

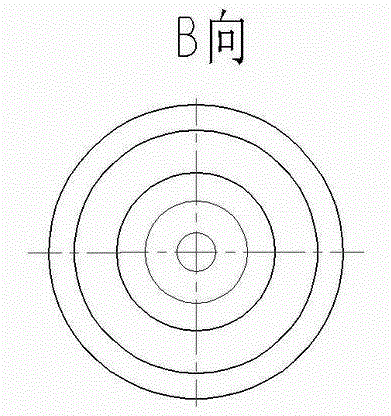

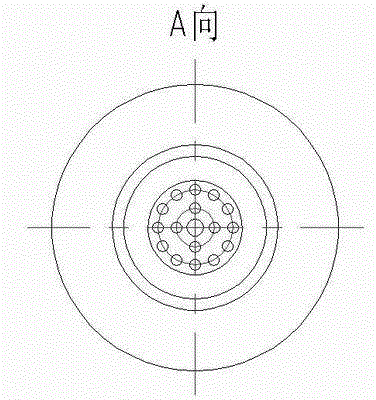

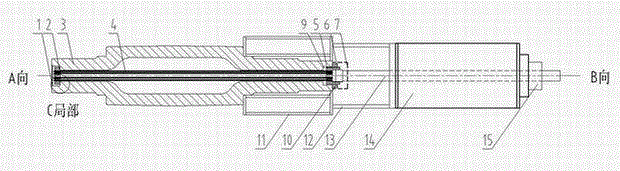

[0025] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a prestressed chilled cast iron roll manufacturing method, the manufacturing method includes making a prestressed heading anchor bundle assembly, using a through-type jack assembly to tension the prestressed heading anchor bundle assembly, thereby cooling Workflow for prestressing hard cast iron rolls.

[0026] The prestressed heading anchor bundle assembly includes the prestressed high-strength steel wire bundle 4 passing through the inner hole of the chilled cast iron roll 3, and the two ends respectively passing through the fixed end heading anchor plate 2 and the tensioning end heading anchor 10 corresponding The hole is upset with a special tool, so as to reliably ensure that the prestressed high-strength steel wire bundle 4 is anchored on the anchor plate 2 at the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com