Wireless charging accessory film coating equipment

A technology of wireless charging and film sticking equipment, which is applied in the direction of external support, transportation packaging, packaging, etc., can solve problems that affect product application and development, affect product quality and yield, and reduce product competitiveness, so as to save manpower and time, improve High product yield and high precision of film attachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

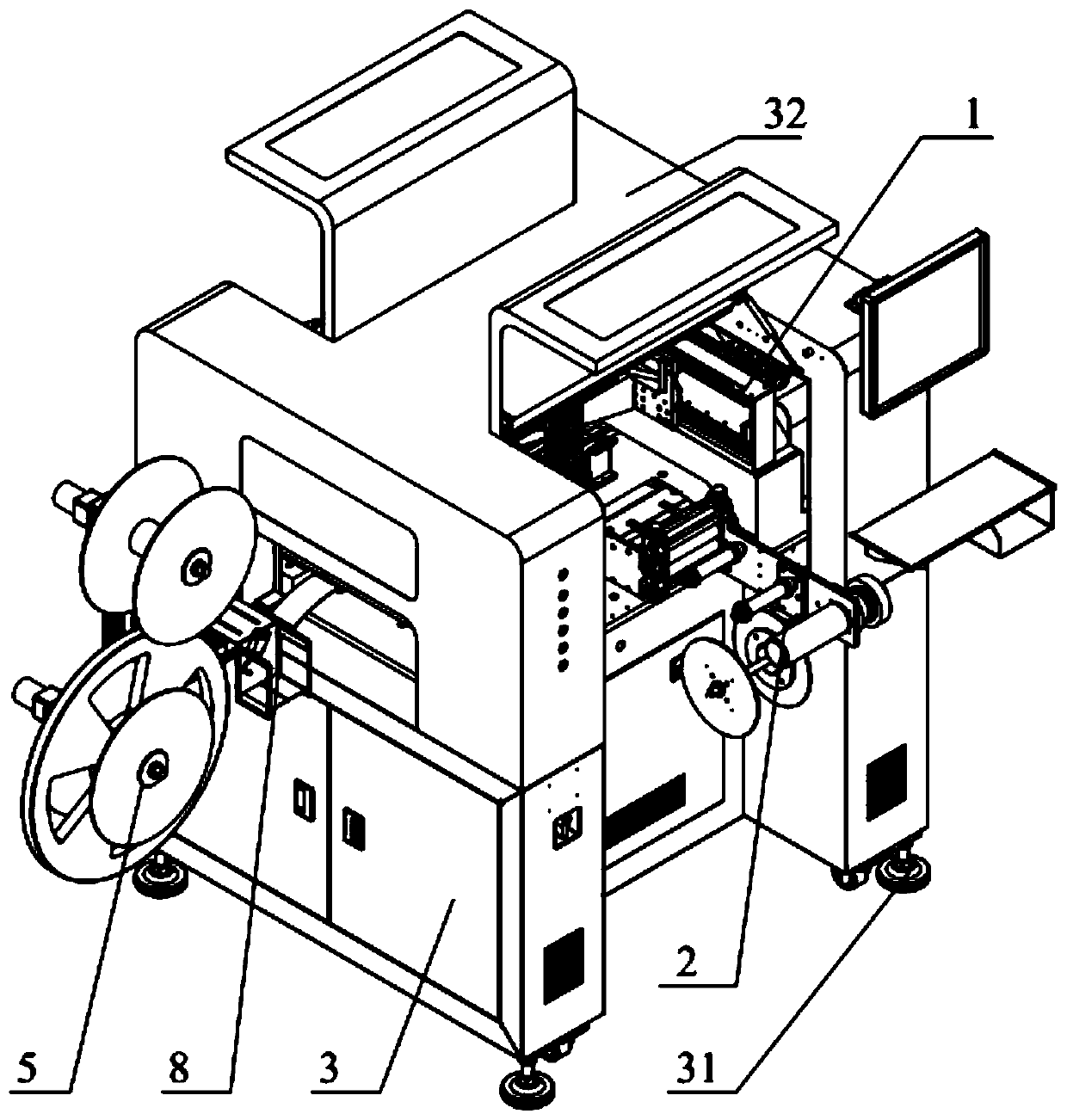

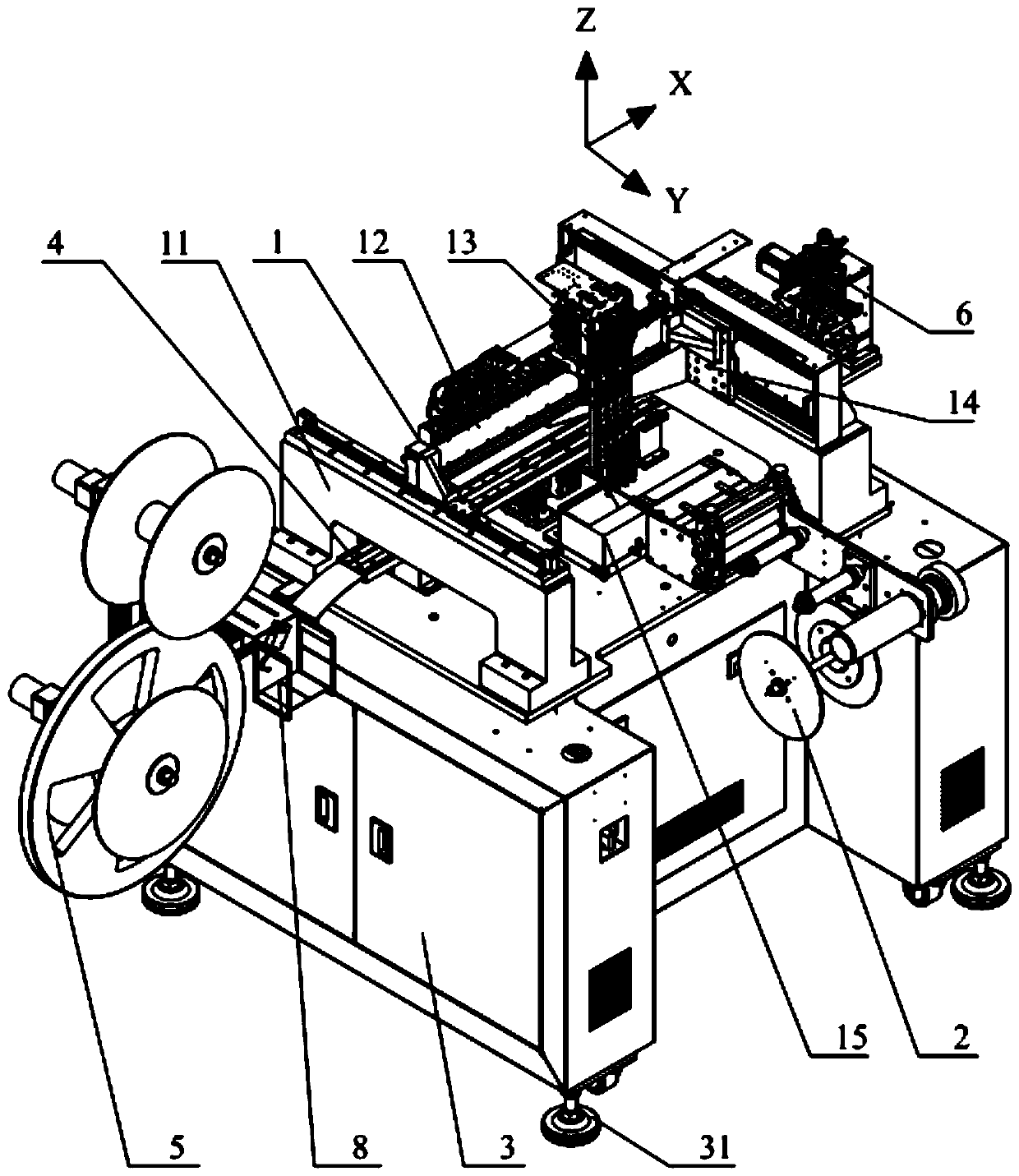

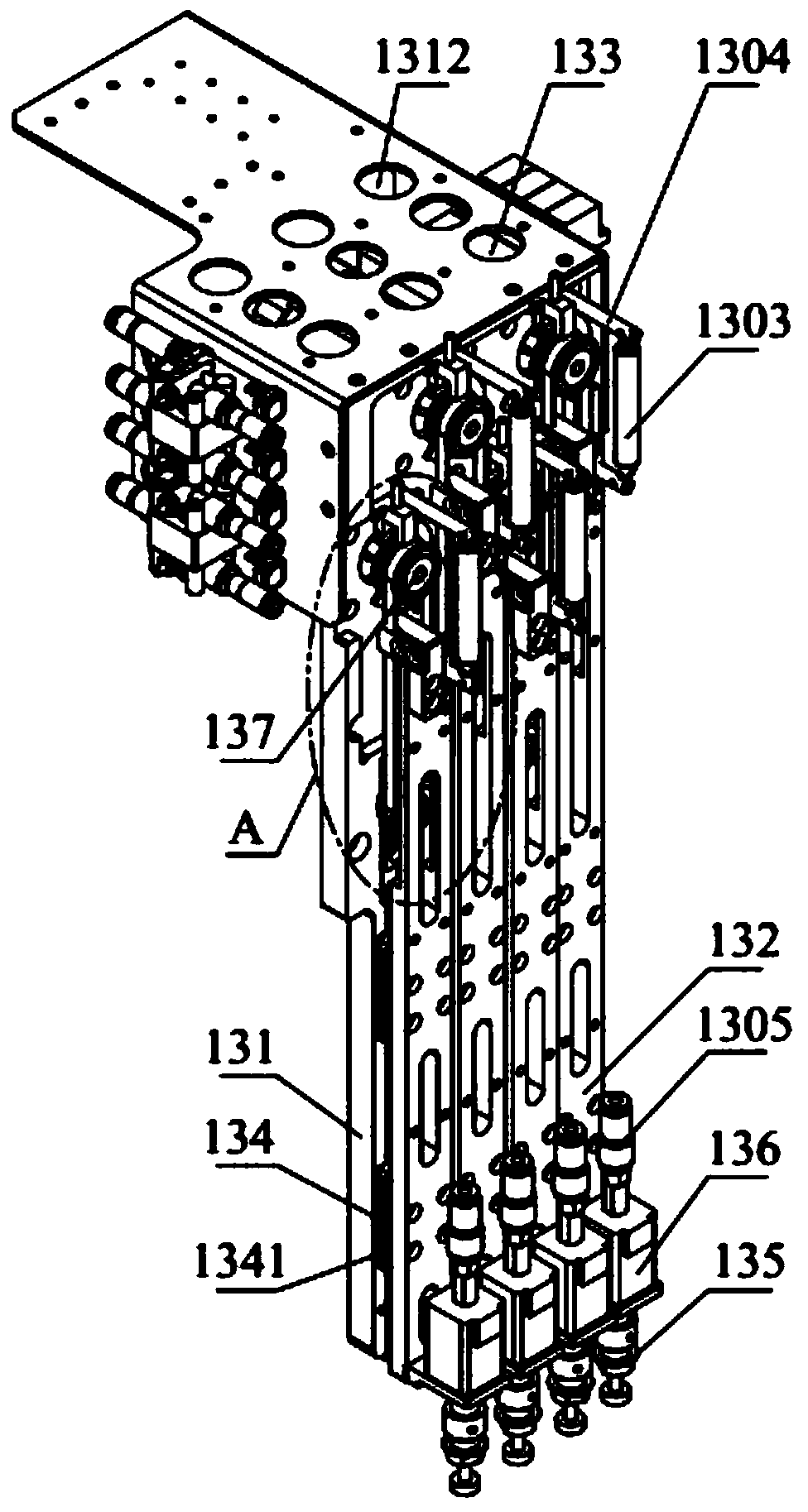

[0045] Such as Figure 1-21 As shown, a film sticking device for wireless charging accessories includes a frame 3, on which a material suction transfer device 1, a material stripping device 2, a stage assembly 4, a first discharging mechanism 5, a material pulling mechanism 6 and In addition to the air bubble assembly 7, the first discharge mechanism 5, the stage assembly 4 and the material pulling mechanism 6 are arranged in sequence, and the material suction transfer device 1 includes a material suction assembly 13, a first linear mold that drives the material suction assembly 13 to move in the X direction Group 12, the second linear module 14 that drives the first linear module 12 to move along the Y direction, and the detection component 15 that cooperates with the suction component 13, the suction component 13 and the air removal component 7 are located on the stage component 4 Above, the first tape with the wireless charging accessories attached to it output by the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com