Vertical PECVD compound PVD vacuum coating system

A vacuum coating, vertical technology, applied in the direction of vacuum evaporation coating, overlay coating, sputter coating, etc., can solve the problems of poor film uniformity and low ionization rate, and achieve low production cost and prevent ionization Pollution, the effect of ensuring film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

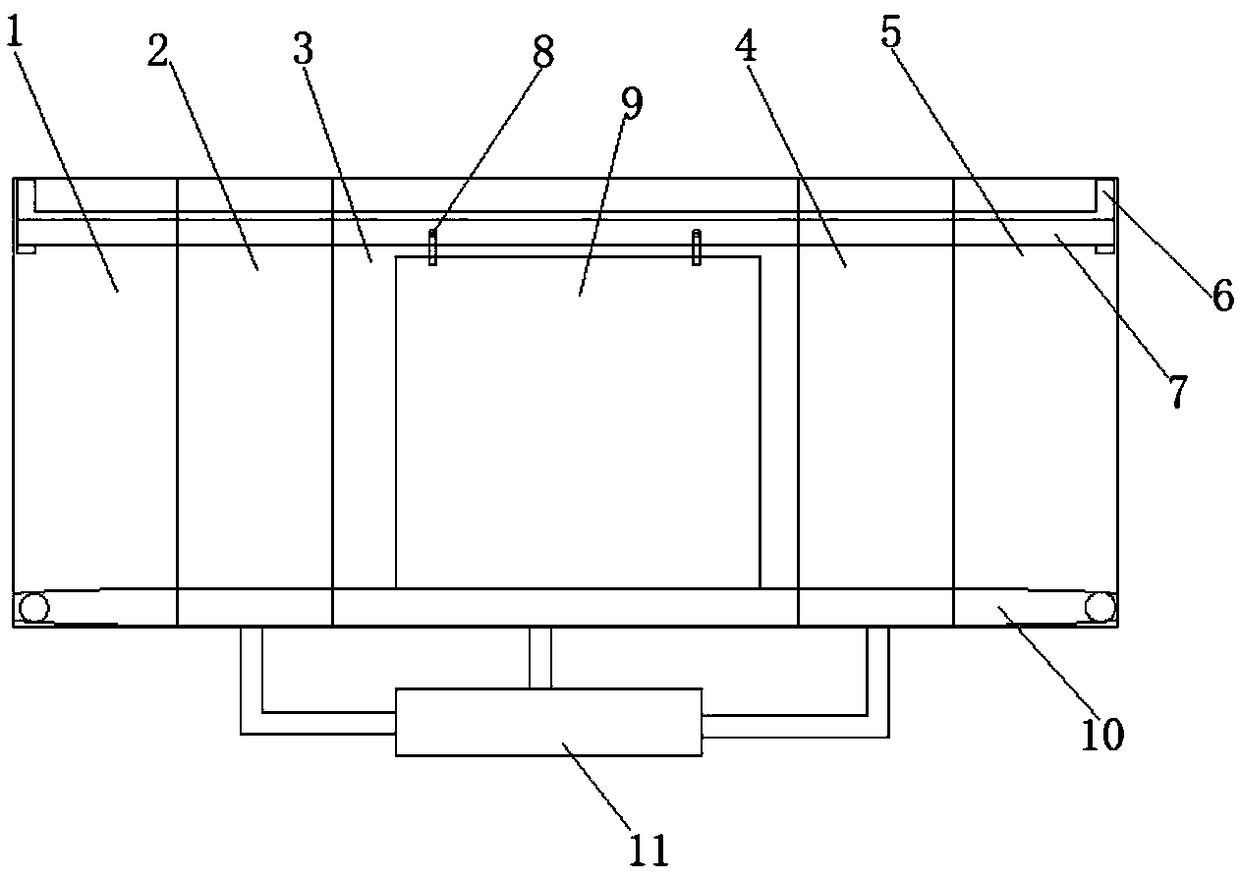

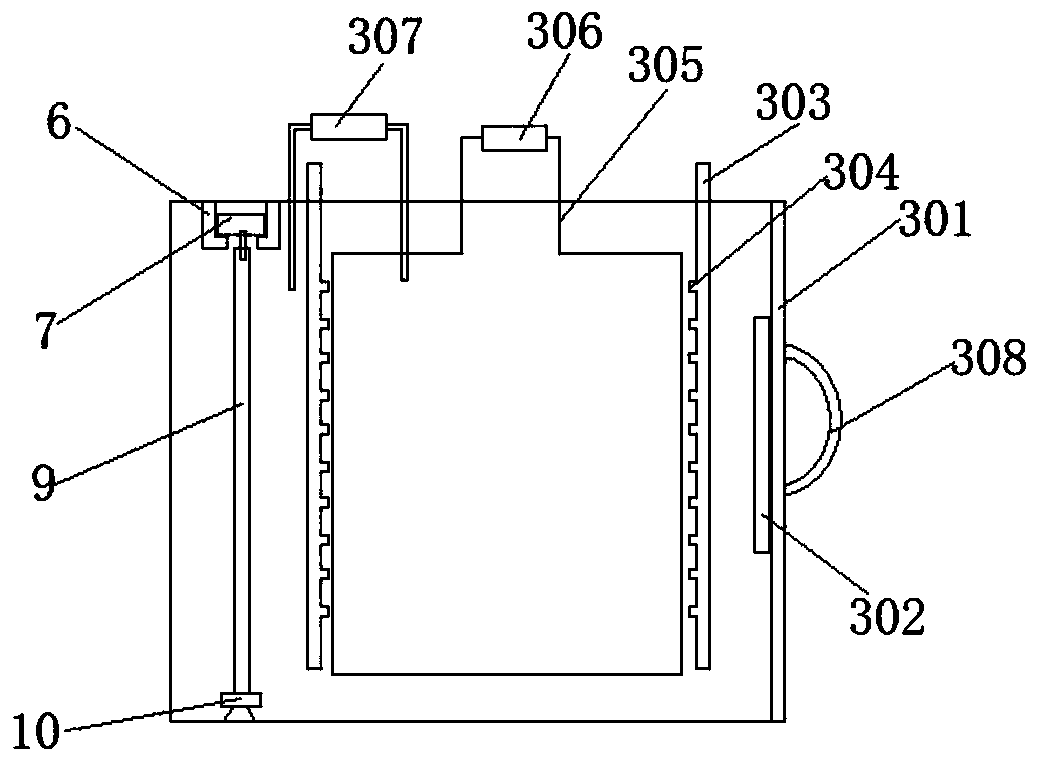

[0022] The present invention is a vertical PECVD composite PVD vacuum coating system, the structure is as follows Figure 1~Figure 3 As shown, it includes a feed chamber 1, a preheating chamber 2, a coating chamber 3, a buffer chamber 4, and a discharge chamber 5 that are closely connected in sequence. The feed chamber 1 and the discharge chamber 5 are in the atmosphere, and the preheating chamber 2, Both the coating chamber 3 and the buffer chamber 4 are connected with a vacuum pumping system 11, and the top of the coating chamber 3 is welded with a rail 6, and a substrate frame 7 is nested in the rail 6, and a substrate 9 is hung on the substrate frame 7 through a hook 8. The bottom of the substrate 9 is located on the conveyor belt 10, and the conveyor belt 10 is connected to the bottom of the coating chamber 3 through driving rollers.

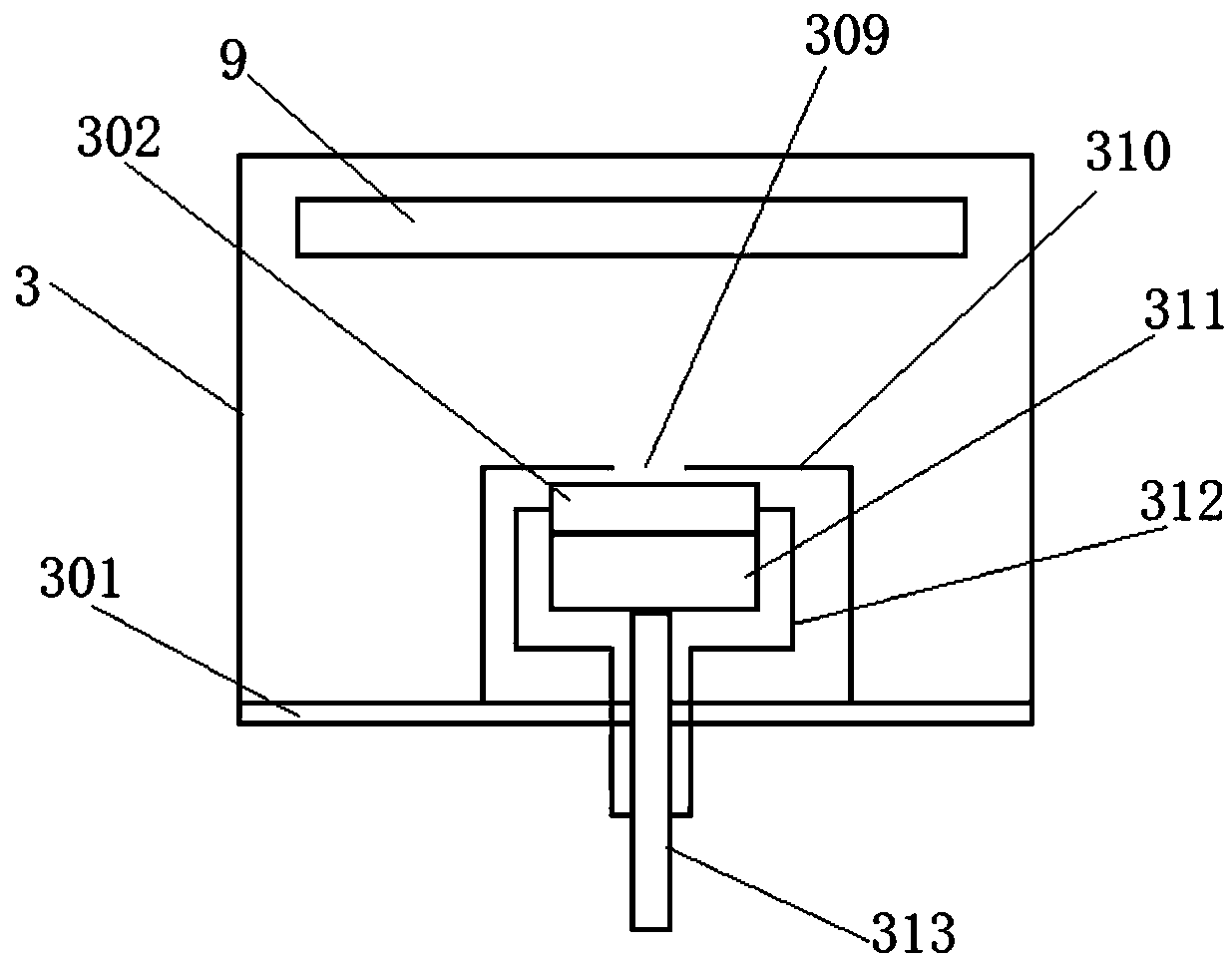

[0023] The coating chamber 3 is provided with a PVD magnetron sputtering device, a gas release device and a PECVD device, the PVD magnetro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com