Water resistant whiting emulsion pressure sensitive adhesive synthesis method

A hydraulic and emulsifier technology, applied in the direction of adhesive types, ester copolymer adhesives, etc., can solve the problems of energy consumption, cumbersome operation steps, and increase the manufacturing cost of pressure-sensitive emulsifiers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

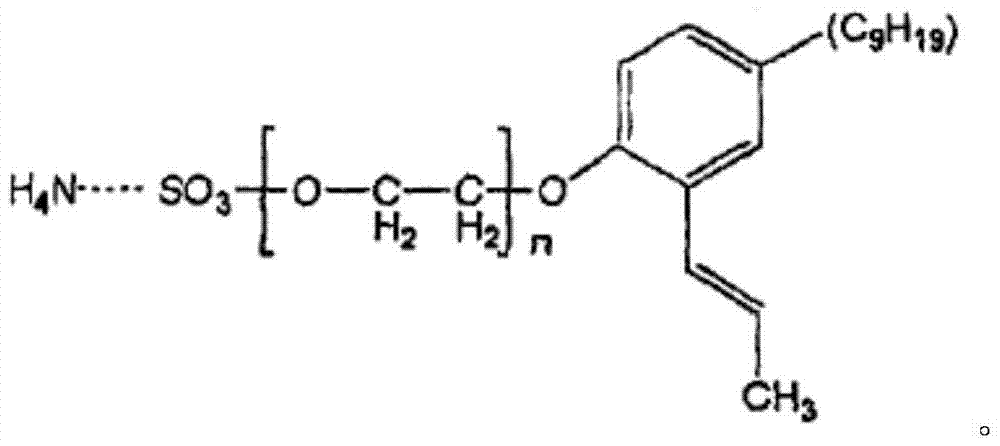

Method used

Image

Examples

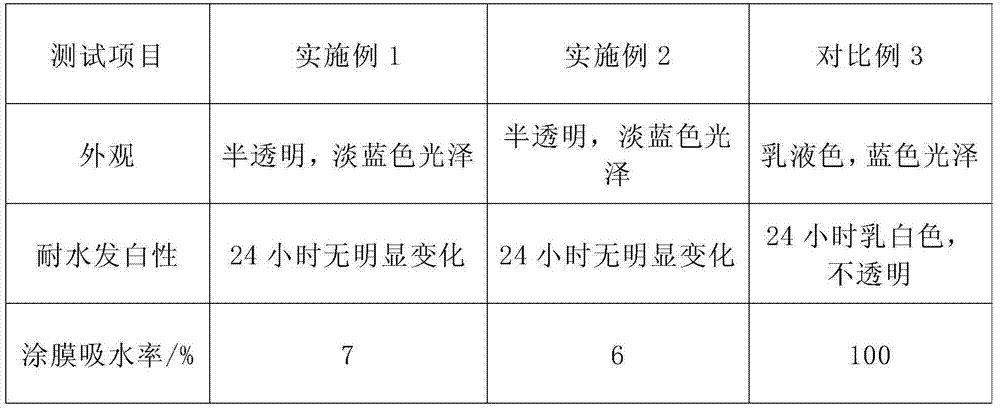

Embodiment 1

[0068] Add 2 parts of emulsifier DNS-86, 1 part of methacrylic acid, 30 parts of butyl acrylate, 1 part of methyl methacrylate, 10 parts of 2-ethylhexyl acrylate, and 2 parts of hydroxyethyl acrylate into the mixing tank Stir evenly in medium to prepare a mixed solution of emulsifier and monomer, set aside.

[0069] Add 50 parts of deionized water into the reaction kettle, raise the temperature, and control the temperature at 78-82°C. Add 0.1 part of potassium persulfate, stir for 5 minutes, and directly add the mixed solution containing emulsifier prepared above dropwise for 2 to 5 hours. After adding the mixed solution for 30 minutes, add 0.1 part of potassium persulfate dropwise to trigger The solution was added dropwise for 3 hours, the reaction temperature was controlled at 80-85°C, and the temperature was kept for 0.5 hours.

[0070] After the heat preservation is over, lower the temperature to 60°C and add tert-butyl hydroperoxide and sodium methyl sulfoxylate aqueous ...

Embodiment 2

[0072] Add 2 parts of emulsifier KD SN-10, 1 part of acrylic acid, 20 parts of 2-ethylhexyl acrylate, 1 part of styrene, 20 parts of butyl acrylate, and 2 parts of hydroxyethyl acrylate into the pre-emulsification tank and stir for a while Evenly to prepare the mixed solution of emulsifier and monomer, set aside.

[0073] Add 50 parts of deionized water into the reaction kettle, raise the temperature, and control the temperature at 78-82°C. Add 0.1 part of potassium persulfate, stir for 5 minutes, drop the above mixed solution containing emulsifier directly, dropwise for 2 to 5 hours, after dropping the monomer mixed solution for 30 minutes, add 0.1 part of potassium persulfate initiator dropwise Solution, the time of dropping is 3 hours, the reaction temperature is controlled at 80-85°C, and the temperature is kept for 0.5 hours.

[0074] After the heat preservation is over, lower the temperature to 60°C and add tert-butyl hydroperoxide and sodium methyl sulfoxylate aqueous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com