Polyethylene greenhouse film resin composition and preparation method thereof

A technology of resin composition and polyethylene, which is applied in the field of micro-crosslinked modified polyethylene shed film resin composition and its preparation, can solve the problem of low physical and mechanical strength of shed film, uneven quality of shed film, and transverse tearing Low strength and other problems, to achieve significant resin reinforcement, solve accumulation or swing, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

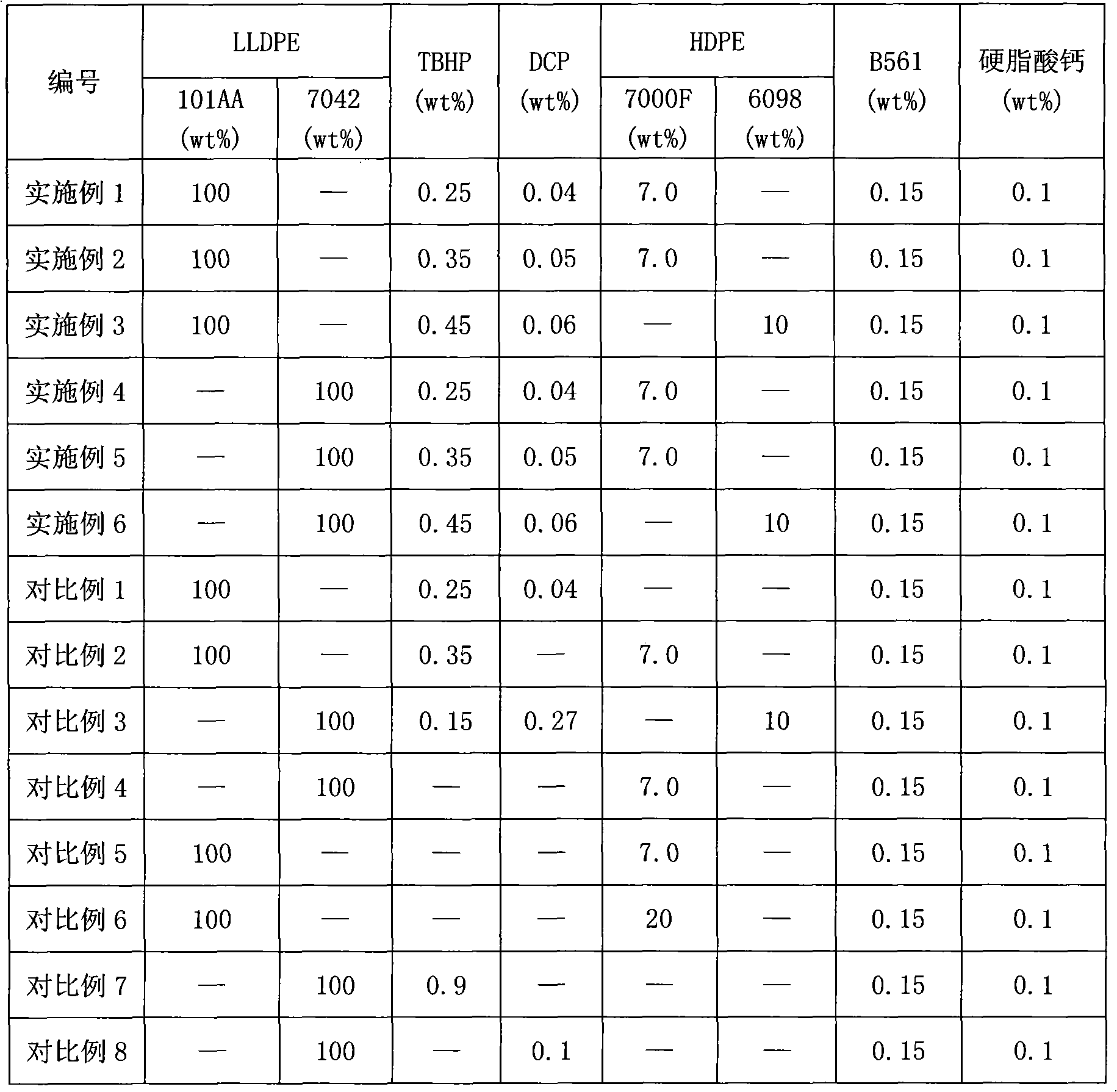

Examples

Embodiment Construction

[0021] 1. Raw materials

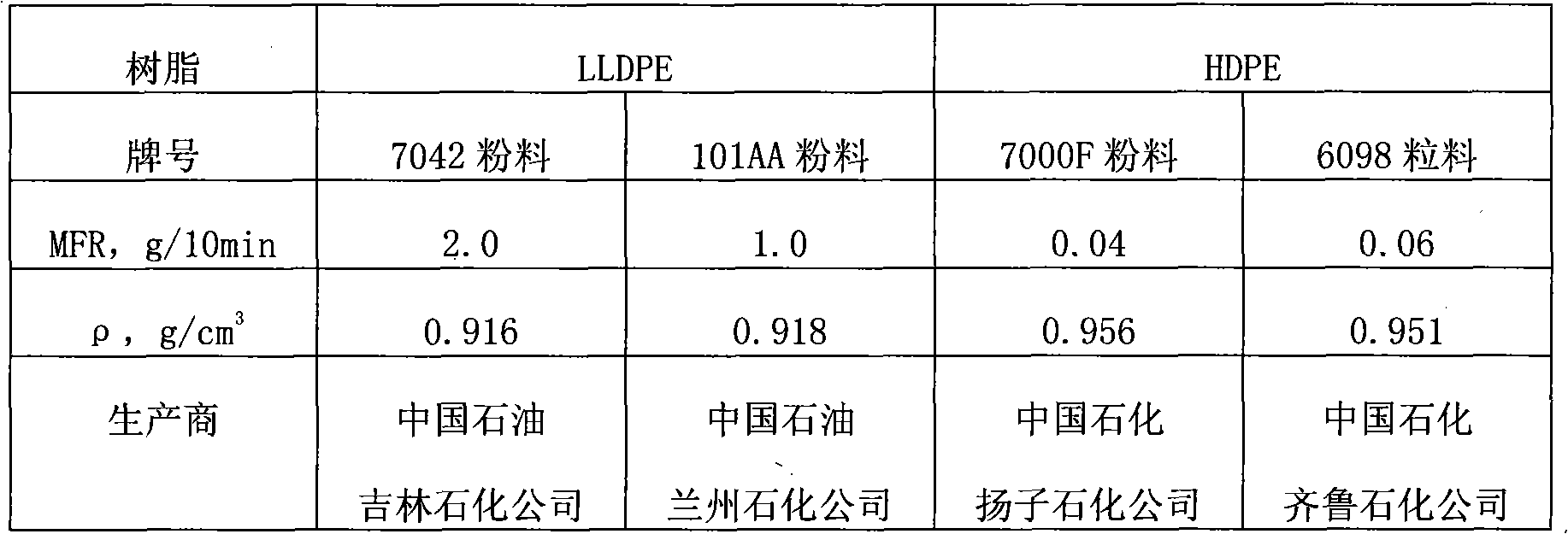

[0022] 1) Resin

[0023]

[0024] 2) peroxide

[0025] The half-life of tert-butyl hydroperoxide T=264℃ / 1min, Lanzhou Auxiliary Factory

[0026] Dicumyl peroxide half-life T=170℃ / 1min, Lanzhou Auxiliary Factory

[0027] 3) Auxiliary

[0028] Antioxidant B561 Ciba, Switzerland

[0029] Calcium Stearate Chongqing Changjiang Chemical Factory

[0030] 2. Performance test standard

[0031] Melt flow rate MFR (g / 10min) GB / T3682-2000

[0032] Density (g / cm 3 )GB / T1033-1986

[0033] Film tensile strength GB / T1040-1992

[0034] Film elongation at break GB / T1040-1992

[0035] Film tear strength GB / T16578

[0036] 3. Equipment and instruments

[0037] Ф34 twin-screw extruder length / diameter=34 / 1 German Lestreiz company

[0038] Piston type metering pump range: 0 ~ 100 liters / hour American Passfield Company

[0039] 10L High Speed Mixer Fuxin Plastic Machinery Factory

[0040] Ф120 three-layer composite blown film machine Dalian Rubber & Pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com